Refresh951's Hybrid Ultra Stroker Build

#646

Here's a link Paully. https://rennlist.com/forums/7514881-post208.html

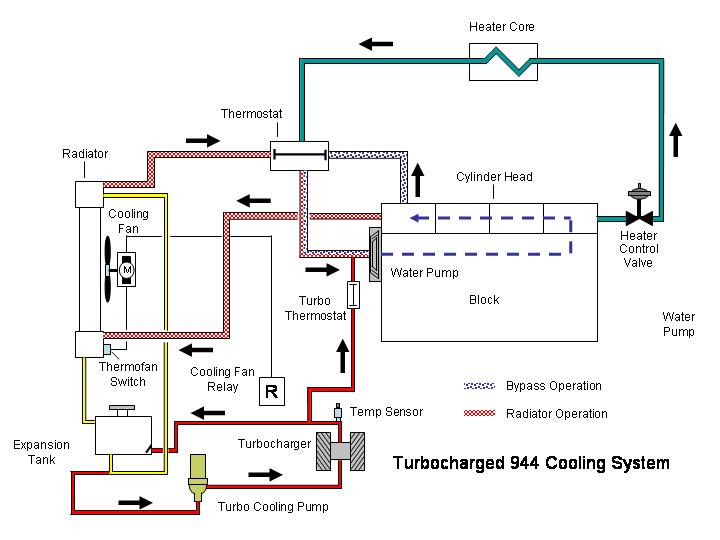

I still wonder on all this. Sid was using a secondary pump for the back of the block. Makes me think if this mightn't interrupt the flow somehow though?

I still wonder on all this. Sid was using a secondary pump for the back of the block. Makes me think if this mightn't interrupt the flow somehow though?

I would think it'll be ideal to use a pump and draw coolant out of there to keep a constant flow?

#647

Addict

Rennlist Member

Rennlist

Small Business Partner

Rennlist Member

Rennlist

Small Business Partner

Joined: May 2006

Posts: 5,252

Likes: 6

From: Denver

That's a good question. I don't think it is, but then I also haven't tried adjusting the column headings either.

Might be interesting to see if you can (or a possible feature/enhancement request for Rogue if you can't...) for those who have no intention of running 28psi, get a little more resolution into tuning for lower boost levels.

Might be interesting to see if you can (or a possible feature/enhancement request for Rogue if you can't...) for those who have no intention of running 28psi, get a little more resolution into tuning for lower boost levels.

Here's a link Paully. https://rennlist.com/forums/7514881-post208.html

I still wonder on all this. Sid was using a secondary pump for the back of the block. Makes me think if this mightn't interrupt the flow somehow though?

I still wonder on all this. Sid was using a secondary pump for the back of the block. Makes me think if this mightn't interrupt the flow somehow though?

#648

Yep that's what I was thinking but if Sid is pushing coolant in from another direction couldn't it disrupt the flow and possibly cause other issues elsewhere Josh? I'm pretty sure Sid has had no issues in this regard but I'm thinking of longer duration on the racetrack.

#650

Yep that's what I was thinking but if Sid is pushing coolant in from another direction couldn't it disrupt the flow and possibly cause other issues elsewhere Josh? I'm pretty sure Sid has had no issues in this regard but I'm thinking of longer duration on the racetrack.

I rather remove it like i said so the coolant can travel though the head quicker and being cooler, it'll absorbe more heat.

I think that makes sense

#651

That's a little more advance ramp up than I would run.. Even if it will run without knock it might not produce the most power with that much advance. But only one way to find out - dyno

Would be interesting to start out lower on the dyno and add more and more advance to see how the torque is affeced to determine best torque timing.

When it comes to studs, I run 9/16 ARP studs @ 175 Nm.

Would be interesting to start out lower on the dyno and add more and more advance to see how the torque is affeced to determine best torque timing.

When it comes to studs, I run 9/16 ARP studs @ 175 Nm.

#653

#654

#655

That's a little more advance ramp up than I would run.. Even if it will run without knock it might not produce the most power with that much advance. But only one way to find out - dyno

Would be interesting to start out lower on the dyno and add more and more advance to see how the torque is affeced to determine best torque timing.

When it comes to studs, I run 9/16 ARP studs @ 175 Nm.

Would be interesting to start out lower on the dyno and add more and more advance to see how the torque is affeced to determine best torque timing.

When it comes to studs, I run 9/16 ARP studs @ 175 Nm.

Thanks Duke, I did end up backing off a bit. Thanks for the input!

#656

Interesting night at the dyno, not much went right. I had trouble controlling boost with my EBC. My theory is that my new exhaust significantly reduced back pressure and thus substantially changed the settings in my Greddy EBC and I had trouble on the dyno getting it dialed in. The dyno was really busy with a long line behind me and so I had no time to figure it out. The first run I was expecting 16 psi and saw it shoot to 21 psi so I let off the throttle and then decided to finish the run. This run was at 21 psi with me pulling off the throttle in the middle of the run! The results are show below:

I adjusted the EBC and made a second run and psi shot right back to 21 psi so I let off and pulled the plug on the night. I think I am done with this EBC. Getting it set right is difficult and dialing it in on the street with this much power is difficult. MBC goes back on this week.

However I was encouraged that I am going to make my goals outlined in the original post. Glad I listened to advice and backed off timing at peak torque. (thanks Thom and Duke) Tonight's runs alone with the 3/4 bottom end runs I made a couple weeks ago lead me to believe I am close. In the next week or two I will return to the dyno to see if I can put it all together.

(thanks Thom and Duke) Tonight's runs alone with the 3/4 bottom end runs I made a couple weeks ago lead me to believe I am close. In the next week or two I will return to the dyno to see if I can put it all together.

Also, great hanging out with Josh B and ilikemy944 (Brad) tonight

http://www.youtube.com/watch?v=FVMhN...ature=youtu.be

I adjusted the EBC and made a second run and psi shot right back to 21 psi so I let off and pulled the plug on the night. I think I am done with this EBC. Getting it set right is difficult and dialing it in on the street with this much power is difficult. MBC goes back on this week.

However I was encouraged that I am going to make my goals outlined in the original post. Glad I listened to advice and backed off timing at peak torque.

(thanks Thom and Duke) Tonight's runs alone with the 3/4 bottom end runs I made a couple weeks ago lead me to believe I am close. In the next week or two I will return to the dyno to see if I can put it all together.

(thanks Thom and Duke) Tonight's runs alone with the 3/4 bottom end runs I made a couple weeks ago lead me to believe I am close. In the next week or two I will return to the dyno to see if I can put it all together.

Also, great hanging out with Josh B and ilikemy944 (Brad) tonight

http://www.youtube.com/watch?v=FVMhN...ature=youtu.be

Last edited by refresh951; 06-20-2013 at 11:53 PM.

#657

heck yeah!!! Just throw a black **** on there with some heavy springs in the WG and be done with it.

Looks like you are on your way. You should spend the $$ and just book a couple hrs to get it all dialed in.

Nice TQ!!!!

Looks like you are on your way. You should spend the $$ and just book a couple hrs to get it all dialed in.

Nice TQ!!!!

#658

Things are looking pretty good. This motor is going to have a pretty special power band for a big power motor and does it ever have torque! Thanks for all your input. Good to see you around here

Here is the timing I went with for tonight. In the end I went fairly conservative and I am glad I did considering the problems I had controlling boost.

#660

Nice!

You'll need time to adjust your EBC. The only reason i'd go EBC is having 2 or more boost modes. High and low. or in my case, 6.. ~12psi, ~15psi, ~16psi, ~16.8psi ~17.3psi ~18psi (pretty much the last 5 are because of weather. If it's very cold, it'll boost higher so if i want 18 psi i'll need to go to the 16.8 or 17.3 psi group. Because mine is closed loop. Open loop you can set a target boost pressure and it'll hit that 99% of the time.

What i did was set it to a very low boost level and make sure it's a flat curve, you can adjust the sensitivity until it's flat. then you bump it up to increase the boost & if that's flat also, just bump it up untill you've got your target boost pressure.

You'll need time to adjust your EBC. The only reason i'd go EBC is having 2 or more boost modes. High and low. or in my case, 6.. ~12psi, ~15psi, ~16psi, ~16.8psi ~17.3psi ~18psi (pretty much the last 5 are because of weather. If it's very cold, it'll boost higher so if i want 18 psi i'll need to go to the 16.8 or 17.3 psi group. Because mine is closed loop. Open loop you can set a target boost pressure and it'll hit that 99% of the time.

What i did was set it to a very low boost level and make sure it's a flat curve, you can adjust the sensitivity until it's flat. then you bump it up to increase the boost & if that's flat also, just bump it up untill you've got your target boost pressure.