View Poll Results: For only a head gasket replacement only on a 16v and no other service work, would you

Voters: 59. You may not vote on this poll

Blown/Damaged Head Gasket?

#317

Developer

Yes, you can sure tune it that way, many believe that is the best way. Don't think that its all in the 3mm mixture screw, it isn't. Check your ignition advance and idle air bleed screws as well.

Have a look at this description, its pretty good although its for a 911: http://forums.pelicanparts.com/porsc...-analyzer.html

Then there's the bible: http://www.type17.ch/downloads/Injec...p%20Manual.pdf

Have a look at this description, its pretty good although its for a 911: http://forums.pelicanparts.com/porsc...-analyzer.html

Then there's the bible: http://www.type17.ch/downloads/Injec...p%20Manual.pdf

#318

Rennlist Member

Totally normal. There seems to always be room for something you did not expect or something to be not quite right.

There is an orderly progression that will always find it, but I would start by:

-triple checking the timing. I think the dist can go in wrong such that it is 180 out.

-check the control pressures. Always a good idea. Fast and easy.

-mason jar test the injection system. Pull the injectors, cut 8 lengths of fuel line, slip one over each injector, and run to 8 mason jars. Jumper the fuel pump, and move the control plate around by hand while watching the fuel flow.

There is an orderly progression that will always find it, but I would start by:

-triple checking the timing. I think the dist can go in wrong such that it is 180 out.

-check the control pressures. Always a good idea. Fast and easy.

-mason jar test the injection system. Pull the injectors, cut 8 lengths of fuel line, slip one over each injector, and run to 8 mason jars. Jumper the fuel pump, and move the control plate around by hand while watching the fuel flow.

#319

Former Sponsor

It wouldn't be any "fun" if it just started up and ran perfectly.....what would you do with yourself?

#320

#321

RL Community Team

Rennlist Member

Rennlist Member

Thread Starter

#322

RL Community Team

Rennlist Member

Rennlist Member

Thread Starter

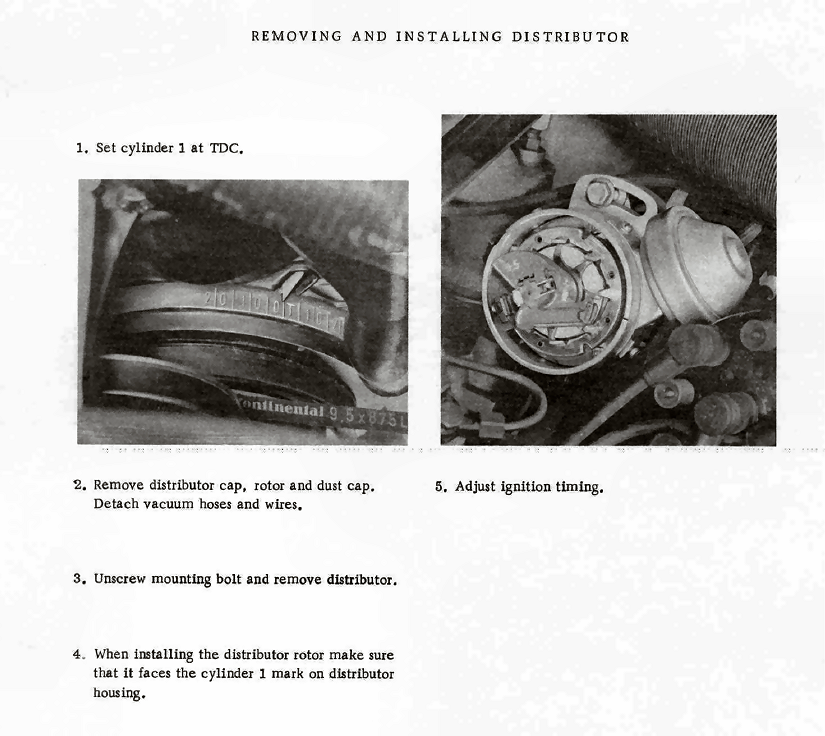

With the motor at TDC, should the rotor be on the scribe mark before installing, which actually makes it clocked past it when installed, or should it be set slightly before the scribe mark so that it's on the scribe mark once installed?

Also, where in the slot does the lock down bolt usually end up when the timing is correct. Mine was toward the front of the slot but not all the way before I removed it.

#323

Burning Brakes

How can the distributor go in 180 degrees out. It has the lock down tab that the bolt goes through. Don't you rotate it before installation so that once installed the rotor points the scribe mark on the top edge of the distributor housing? When you press it in, because of the angle of the gears it rotates clockwise as they mesh, which brings up a question.

With the motor at TDC, should the rotor be on the scribe mark before installing, which actually makes it clocked past it when installed, or should it be set slightly before the scribe mark so that it's on the scribe mark once installed?

Also, where in the slot does the lock down bolt usually end up when the timing is correct. Mine was toward the front of the slot but not all the way before I removed it.

With the motor at TDC, should the rotor be on the scribe mark before installing, which actually makes it clocked past it when installed, or should it be set slightly before the scribe mark so that it's on the scribe mark once installed?

Also, where in the slot does the lock down bolt usually end up when the timing is correct. Mine was toward the front of the slot but not all the way before I removed it.

#324

RL Community Team

Rennlist Member

Rennlist Member

Thread Starter

Might be a dumb question, but how many times does the distributor rotor rotate per revolution of the harmonic dampener? Is it a 1:1 relationship or could it be that I need to rotate the engine around one more time and then set the distributor position. Maybe this is what was meant by it being 180 degrees out.

#325

Rennlist Member

Hi Pete,

Remember that distributor has vacuum ports on both sides of the diaphragm. If only one is connected (I can see the advance hose), it will act unopposed. This may give a bad timing curve vs rpm. If your timing light says it's reasonable, then this is not the problem. Just saying.

Good luck,

Dave

Remember that distributor has vacuum ports on both sides of the diaphragm. If only one is connected (I can see the advance hose), it will act unopposed. This may give a bad timing curve vs rpm. If your timing light says it's reasonable, then this is not the problem. Just saying.

Good luck,

Dave

#327

RL Community Team

Rennlist Member

Rennlist Member

Thread Starter

#328

RL Community Team

Rennlist Member

Rennlist Member

Thread Starter

Hi Pete,

Remember that distributor has vacuum ports on both sides of the diaphragm. If only one is connected (I can see the advance hose), it will act unopposed. This may give a bad timing curve vs rpm. If your timing light says it's reasonable, then this is not the problem. Just saying.

Good luck,

Dave

Remember that distributor has vacuum ports on both sides of the diaphragm. If only one is connected (I can see the advance hose), it will act unopposed. This may give a bad timing curve vs rpm. If your timing light says it's reasonable, then this is not the problem. Just saying.

Good luck,

Dave

#330

Developer

It may look fantastic, but I can't get it running right. AFRs are jumping all over the place. Sometimes it goes totally lean and just dies. Other times it goes totally rich and then dies. Other times it seems like it's running out of fuel. I've tried timing numbers from 20-30 DBTDC. I rebaselined the mixture screw at 9.5 turns from fully CCW. I put the Harmonic Dampener at TDC and popped the distributor cap and it's pointing directly at #1, I and put in new spark plugs. I tried a fuel pump jumper and a different FPR and no joy, and this is all without ever leaving the garage, so don't even know what issues will show up under load and boost.

I didn't do any disassembly of the k-jet system - just moved it over from one car to the other, and realize this motor may have different fueling requirements, but I should have been in the ballpark.

It turns over much longer than the other engine used to before firing up and it doesn't run very smoothly once it does, then it fixes itself and the AFR becomes 12-13 and stays there a bit, then starts walking in one direction or the other until it dies.

I didn't do any disassembly of the k-jet system - just moved it over from one car to the other, and realize this motor may have different fueling requirements, but I should have been in the ballpark.

It turns over much longer than the other engine used to before firing up and it doesn't run very smoothly once it does, then it fixes itself and the AFR becomes 12-13 and stays there a bit, then starts walking in one direction or the other until it dies.

Hard to diagnose from here! You'll get it.