Kevin Johnson and crank scrapers.

#76

Rennlist Member

Good summary of the topic. I think you are right on the money. Thats the main reason that I have not done too many, or ANY of the mods suggested. Sure its nice to have cooler oil, as 260F in extreme cases is pushing it, but 240F with a cooler might only help things last a little longer. dry sump, accusump might help with oil pressure fluctuation, but i havent seen any, especially since I run the engine in its sweet spot of up to only 6600rpm. pretty low rpms when thinking of what all those general mods are supposed to cure. I figure, if im running DOTs, never pulling more than 1.5Gs, not running the engine higher than 6600rpm, and always see 5 bar pressure while using Amsoil, i dont thnk things are too bad. you would think i would see some type of poor wear patterns and certainly wouldnt be able to race as I have over 7 full redline beating racing seasons. However, I do think that when you start running the engines over 400rwhp, rpms in the 7000rpm range, and full slicks, its probably good to have many of the features of the options discussed here. I would bet many of the failures are linked to detonation, or driving style, maybe even warm up rituals. Certainly , Boosted engines even at 5psi, run the risk of detonation. I would love to get that diagnostic port set up to see if I have any knocking with the new engine. Pulling apart the old engine didnt show any abnormal wear, even with the oil sent out to the oil analysers several times, which came back perfect. One thing i do know is that i have good oil pressure up to 6600rpm, and in any left or right 1.5g sweeper (ie a turn longer than 5-10 seconds), with Amsoil and the stock set up. My new engine has the chevy drilled crank and the, hopefully, harder chevy rod bearings. Like you say, the drilling is key as you start increases the forces that the oil is trying to protect from.

I know there are other oils out there that work, Redlne, Motul, etc, but its nice to see Amsoil increasing their zinc content for their racing oil as that just steps up their level of protection. What has impressed me is the lack of the loss of oil pressure , even on those 100F race days, where the oil is 260f during a race, and I still see the oil pressure gauge pegged at 5 bar! . With the other oils ive tried, the oil pressure has fallen on its face and that cant be good.

. With the other oils ive tried, the oil pressure has fallen on its face and that cant be good.

mk

I know there are other oils out there that work, Redlne, Motul, etc, but its nice to see Amsoil increasing their zinc content for their racing oil as that just steps up their level of protection. What has impressed me is the lack of the loss of oil pressure , even on those 100F race days, where the oil is 260f during a race, and I still see the oil pressure gauge pegged at 5 bar!

. With the other oils ive tried, the oil pressure has fallen on its face and that cant be good.

. With the other oils ive tried, the oil pressure has fallen on its face and that cant be good.mk

I doubt that many people, with a good grasp of the "big picture", are going to debate that the 928 engine has "oiling issues" that get worse under severe use conditions. There are 3 or 4 entirely separate things that occur, under different conditions, that make the "oiling issue" appear. The resulting damage all looks the same and is always manifested in the same area, within the engine (#2 and #6 rods bearings). That is what is so frustating about the problem. You can cure one of the issues and still have the engine go "boom". A dry sump system or the "perfect" windage tray system isn't going to save every engine from damage....they just help. The engines still are going to suffer from "uber" soft rod bearings (in the stock rod engines), oil supply to the rods (crankshaft design problem), and oil quality issues (foaming, poor additive packages, and viscosity issues).

Certainly, the "perfect" oil might help cover up some of these issues...which is what Mark Kibort thinks his Amsoil does so well. There are other proven oils that work very well (Torco is one). If you compare the different "designer" oils that seem to help protect these engines from damage, they all seem to have many things in common.....good base stocks and high quantities of Zinc and Phosphorus. However, it is important to remember that the "oiling issues" are still there and will still cause failures. Doing one thing will not solve the problems. What is required is a good overview of the issues and a plan to eliminate as many of the individual problems as possible.

Certainly, the "perfect" oil might help cover up some of these issues...which is what Mark Kibort thinks his Amsoil does so well. There are other proven oils that work very well (Torco is one). If you compare the different "designer" oils that seem to help protect these engines from damage, they all seem to have many things in common.....good base stocks and high quantities of Zinc and Phosphorus. However, it is important to remember that the "oiling issues" are still there and will still cause failures. Doing one thing will not solve the problems. What is required is a good overview of the issues and a plan to eliminate as many of the individual problems as possible.

#77

How much (maybe a WAG at a percentage of the problem) is the oil supply to the rods issue? Of the 3 or 4 main issues?

#80

Rennlist

Basic Site Sponsor

Basic Site Sponsor

I've read the calculations for centrifical force vs oil pressure and have seen that on paper, the oil should be able to get back to the center of the crankshaft and thus to the rod journal. Calculations and reality sometimes don't work together. I do know that until Porsche Racing changed the design of the 944 crankshafts used in the 944 GTRs, they had a hell of a time running the engines at 7,000rpm's. The later "sprint" engines, after the oiling problems had been solved, ran hard to 7800rpms. All of the 944 GTR engines were dry sumped...from the very beginning (I own engine 001, with the mechanical injections system) and they still spewed hot oily parts everywhere...until they made some changes.

__________________

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

#81

Road Warrior

Rennlist Member

Rennlist Member

think we've already solved the bottom end issues. stroker bottom ends can be bomb proof. HP cranks/lighter rods/pistons/oiling, nikasil, special rings/pins, etc, etc... top ends seem to hold up fine.

IMO, the intake is the biggest NA HP blocker at this point. I'd like to see someone come up w/a nice clean OEM looking PVC or carbon fiber intake that bolts on in an hour been a few interesting/successful prototypes - prof. ott/devek and phil threshie come to mind... then we'd be very scary step children.

been a few interesting/successful prototypes - prof. ott/devek and phil threshie come to mind... then we'd be very scary step children.

IMO, the intake is the biggest NA HP blocker at this point. I'd like to see someone come up w/a nice clean OEM looking PVC or carbon fiber intake that bolts on in an hour

been a few interesting/successful prototypes - prof. ott/devek and phil threshie come to mind... then we'd be very scary step children.

been a few interesting/successful prototypes - prof. ott/devek and phil threshie come to mind... then we'd be very scary step children.

#82

Rennlist

Basic Site Sponsor

Basic Site Sponsor

You must have wheeled right by the new intake system sitting in the shop.....I'll show you when your car is "whole" again.

#83

Rennlist Member

One guy here in germany has looked at the oilissue at rod 2 and 6.he pull the bottom of the engine away and put a plexyglaswindow on the bottom of the engine.Than he make flowbenches with oil.The oil donīt like the way to rod 2/6.After deepening the oilcanal bevore the crossing to 2/6 the supply was much better.

The oil must be 10W40 or higher.0 W or 5 W 40*50*60 are to thin for this engines.One guy here in Germany has a long talk with a guy from Castrol racing.

He suggest using an oil for dieselengines(15 W40 super high performance) is a good idea because the zinccontent is much higher and the oil is very pressurestable.

The downside is zinc isnīt good for catīs.

The oil must be 10W40 or higher.0 W or 5 W 40*50*60 are to thin for this engines.One guy here in Germany has a long talk with a guy from Castrol racing.

He suggest using an oil for dieselengines(15 W40 super high performance) is a good idea because the zinccontent is much higher and the oil is very pressurestable.

The downside is zinc isnīt good for catīs.

#84

Addict

Rennlist Member

Rennlist Member

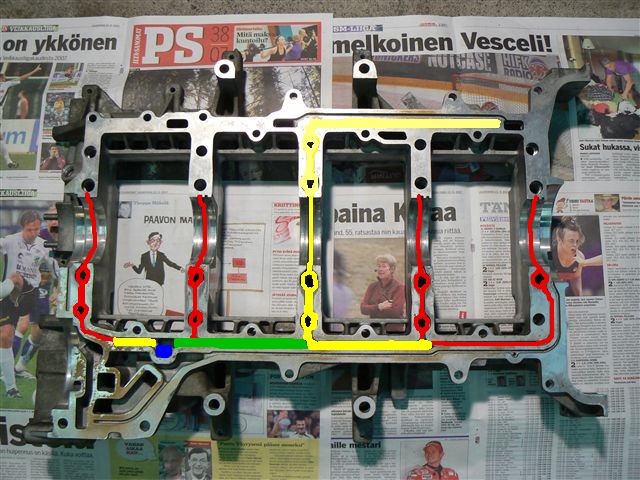

One guy here in germany has looked at the oilissue at rod 2 and 6.he pull the bottom of the engine away and put a plexyglaswindow on the bottom of the engine.Than he make flowbenches with oil.The oil donīt like the way to rod 2/6.After deepening the oilcanal bevore the crossing to 2/6 the supply was much better.

https://rennlist.com/forums/928-foru...-thoughts.html

Thread can be little hard to read as all posts made by Kevin Johnson are gone.

My message #168 goes into details of lower block oil channels. I think what you are saying is that german guys plexi trial shows that front end of green area needs to be deeper from blue feed from oil filter to red 2/6 rod channel. Correct?

> Blue = 15mm wide round feed pipe from oil filter = 177mm^2

> Green = 8.5mm wide x 16mm deep = 136mm^2

> Yellow = 8.5mm wide x 10mm deep = 85mm^2

> Light yellow = 7.5mm wide x 11 deep = 83mm^2

> Red = 5mm wide x 5 mm deep = 25mm^2

>

> Yellow means both short straight thing from blue feed to #1 main bearing

> and from green to end of #3 main bearing and towards #4 and #5. Light

> yellow is from #3 main to input to upper half of block for right head.

>

> Left head takes its oil from green area IIRR or maybe more likely from

> forward yellow. Anyone remember exact position for it? How close it is to red

> input of #2 main?

>

> 4x25mm^2 + 85mm^2 = 185mm^2. Should total area for 5 main bearings

> be larger or smaller than feed from filter? Does it make any difference in to

> this relationship that feed is round while channels are rectangle? Obviously

> feed to left head needs to be added also. So total area for all channels is

> significantly larger than feed.

>

> Should light yellow feed to head be smaller or larger in size when using

> stroker crank where #3 is feeding two rods too?

>

> Could and should feeds to both head be made slightly smaller or larger in

> order to leave more oil for main and rod bearings?

Does german fix include deepening green area between blue and 2/6 red areas to lets say 8.5mm wide x 17.5mm deep = 149mm^2?

As a summary. I think these are oiling issues in 928 engine:

1. Shallow sump

- Crank is too close to oil surface

- Oil pickup is easily exposed to air

2. Oil distribution in lower block

- Channel diameters can be wrong which results uneven distribution of oil, especially into 2/6 rods

3. Oil return from heads

- Return holes drain directly to rotating assembly

- Crank windage keeps oil up in passenger side head

4. Crank oil holes

- Drilled wrong for high rpm use

5. Conrod bearings

- Too soft material

6. Oil pressure relief valve

- Using stock parts without checking actual pressure they produce can result too low release threshold

7. Oil type

- Cams need zinc to protect their lobes (I think). Modern oils have less and less zinc. Oils meant for diesel engine have more and should be used instead.

- These engines are not designed to run on 0Wxx or 5Wxx oils

Anything else? As if above isn't enough.

#86

Race Car

Often people ask the list what type of oil to use, and it's a common recommendation to use 0W-40 that Porsche recommends for all their cars. Unless you live close to the north pole, don't do it in a 928, please!

Dan

'91 928GT S/C 475hp/460lb.ft

475hp/460lb.ft

Dan

'91 928GT S/C

475hp/460lb.ft

475hp/460lb.ft

#87

Owns the Streets

Needs Camber

Lifetime Rennlist

Member

Needs Camber

Lifetime Rennlist

Member

Put more oil in to keep oil pickup submerged. Crank whips oil into nice chocolate latte froth.

Little less oil than normal to keep crank from Slap-Chopping the oil, engine gets starved of oil.

Just can't win. Sigh.

Little less oil than normal to keep crank from Slap-Chopping the oil, engine gets starved of oil.

Just can't win. Sigh.

#88

Road Warrior

Rennlist Member

Rennlist Member

there has been a cure for a long time - custom cranks/bearings/rods and a dry sump... iirc, mark A has been running that setup for years w/no issues except broken trannys from time to time

#89

Rennlist Member

Or no fix, just amsoil which now has zinc. Ive been racing this way with the lower hp S4 motor for 7 full racing seasons. thats over 105 race days.

I think andersons fixes are then end all catch all, expecially if you are breaking into the 400rwhp range and are twisting the engine up to 7000rpm while racing on real slicks!

mk

I think andersons fixes are then end all catch all, expecially if you are breaking into the 400rwhp range and are twisting the engine up to 7000rpm while racing on real slicks!

mk

#90

Rennlist

Basic Site Sponsor

Basic Site Sponsor

Erkka:

Nice overview. That pretty much covers the subject.

Note that oil type is only one thing on the list. Mark Kibort also has it figured out: Use one of the "designer" oils, keep the cornering loads low, and don't rev the engine very high. He's got a properly drilled crank and better rod bearings. If he stays away from Thunderhill, as much as possible, he'll do fine.

Nice overview. That pretty much covers the subject.

Note that oil type is only one thing on the list. Mark Kibort also has it figured out: Use one of the "designer" oils, keep the cornering loads low, and don't rev the engine very high. He's got a properly drilled crank and better rod bearings. If he stays away from Thunderhill, as much as possible, he'll do fine.