Repairing my PDK Gearbox Experience & Guide

#46

Three Wheelin'

Not to hijack the thread here but it would be really nice to clarify exactly what needs to be done after removing the black caps on the driveshaft and mainshaft (Damien's step 6) as there's confusion here and it's probably different between the PDK variants. I'd like to included this info in the PDK repair sticky thread. I've summarized what I think it is below but corrections are requested.

Top cap (when viewed as installed, see Damien's first picture) at the end of the driveshaft - I believe this is the same on all PDK variants and is just one big bolt that holds the bearing to the shaft end. Can anyone fill in the size of this and what tools are required beyond a socket (if any)?

Bottom cap at the end of the mainshaft - This applies to 987/981's and 997/991's with 2WD only. I think there is a bearing lock nut here that screws onto the threaded shaft and holds the bearing in place on the shaft. The correct tool for this is something like a KM socket with multiple tangs or a hook spanner (though it can probably also be removed with makeshift tools). There is also a snap ring (circlip) inside the shaft but it's not clear to me if that actually needs to be removed.

No bottom cap but the mainshaft protruding from the case - This applies to 997/991's with AWD. There's a coupling flange on the shaft end outside the PDK case that needs to be removed. It's held in place with a big nut that screws on the threaded shaft. Once the nut is removed the flange can be slid off the splined mainshaft. There's a replaceable seal here available from Porsche as PN 9G1-321-807-00. Anyone know the nut size and if anything else needs to be removed?

Top cap (when viewed as installed, see Damien's first picture) at the end of the driveshaft - I believe this is the same on all PDK variants and is just one big bolt that holds the bearing to the shaft end. Can anyone fill in the size of this and what tools are required beyond a socket (if any)?

Bottom cap at the end of the mainshaft - This applies to 987/981's and 997/991's with 2WD only. I think there is a bearing lock nut here that screws onto the threaded shaft and holds the bearing in place on the shaft. The correct tool for this is something like a KM socket with multiple tangs or a hook spanner (though it can probably also be removed with makeshift tools). There is also a snap ring (circlip) inside the shaft but it's not clear to me if that actually needs to be removed.

No bottom cap but the mainshaft protruding from the case - This applies to 997/991's with AWD. There's a coupling flange on the shaft end outside the PDK case that needs to be removed. It's held in place with a big nut that screws on the threaded shaft. Once the nut is removed the flange can be slid off the splined mainshaft. There's a replaceable seal here available from Porsche as PN 9G1-321-807-00. Anyone know the nut size and if anything else needs to be removed?

Last edited by PV997; 07-17-2021 at 02:25 PM. Reason: added new info

The following users liked this post:

Presto (01-06-2023)

#47

On my 991.1 c2s there was no nuts to loosen, only 2 retaining clips.

I have worked on 997.2 4s and it had the nut that needed to be removed for the FWD, but it was a standard socket so I didn’t pay too much attention to it.

I have worked on 997.2 4s and it had the nut that needed to be removed for the FWD, but it was a standard socket so I didn’t pay too much attention to it.

Last edited by amet; 07-18-2021 at 10:03 AM.

#49

Three Wheelin'

I have only ever worked on my 997 AWD so I'm shooting in the dark here. The PDK sticky I wrote was aimed at 997's but there's interest regarding the 987, 981, and 991 so I'm trying to sort out the differences.

#50

Three Wheelin'

One thing I just realized is that the 997/991 and 987/981 PDK transmissions are mirror images of each other. If you are looking at the 997/991 from the engine coupling end, the pinion shaft and parking pawl are on the right hand side, and the shift forks are on the left hand side. On the 987/981 this is reversed when looking from the engine end.

Since the 987/981 has the PDK rotated 180 deg compared to the 997/991, this puts the pinion shaft/parking pawl on the passenger side (LHD) on all models. Weird that I never noticed that before. So the 911 2WD PDK and Cayman/Boxster PDK are definitely different in at least one major way.

Since the 987/981 has the PDK rotated 180 deg compared to the 997/991, this puts the pinion shaft/parking pawl on the passenger side (LHD) on all models. Weird that I never noticed that before. So the 911 2WD PDK and Cayman/Boxster PDK are definitely different in at least one major way.

Last edited by PV997; 07-18-2021 at 12:50 PM.

#51

5th Gear

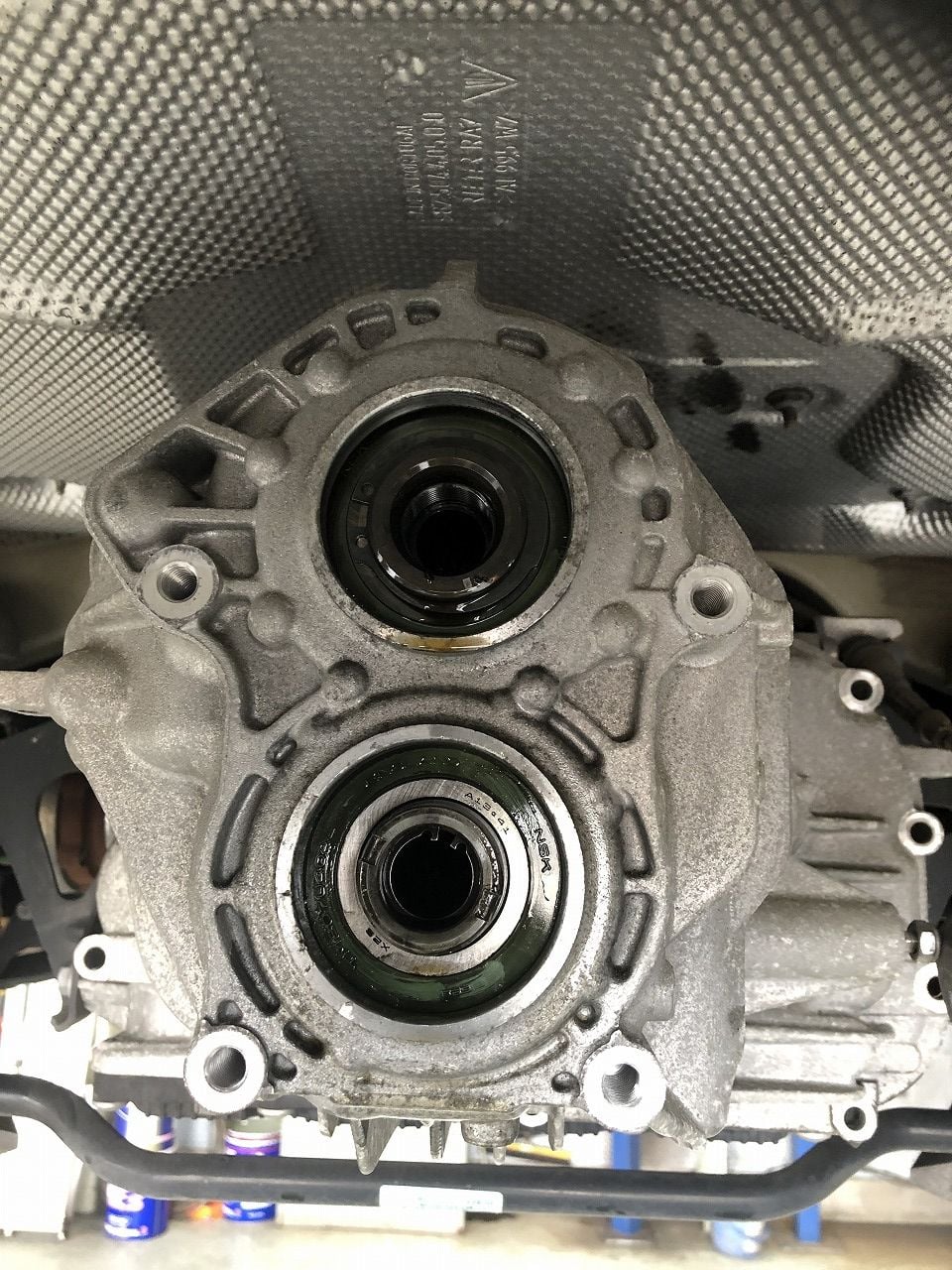

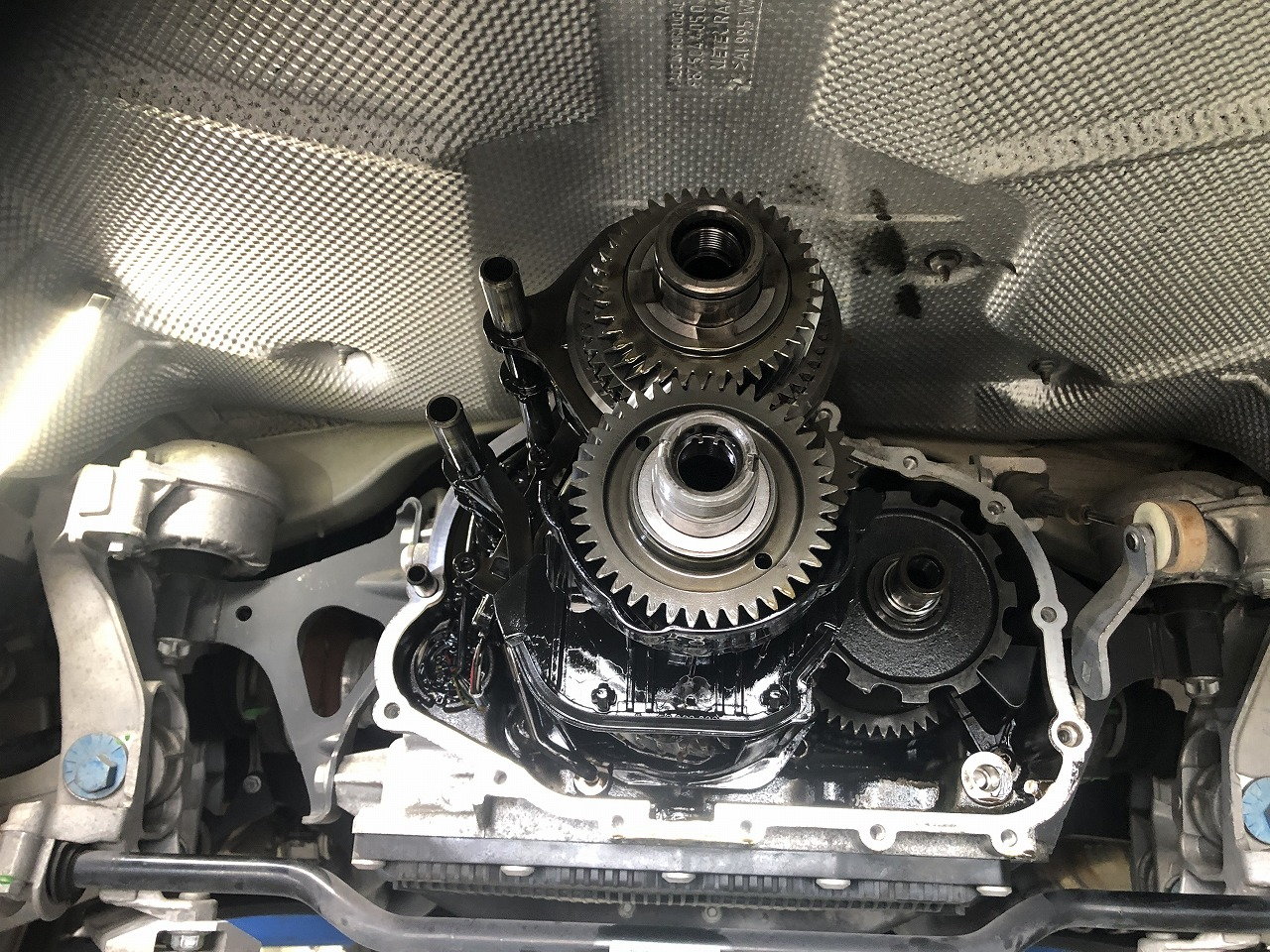

here are two pictures… the end of gearbox where the rods are. Also, the nuts and snap ring removed.

End of gearbox with the two rods

Snap ring and nuts removed from rods

perpendicular bolt had also been removed

Last edited by jbolduc27; 07-19-2021 at 05:15 PM. Reason: One more picture

The following users liked this post:

cbracerx (06-02-2024)

#52

use rubber mallet or a regular hammer with a wood on top of the rods… and give it a good smack, chances are that rods are stuck in the bearings.

apart from perimeter bolts and reverse gear bolt, nothing else is holding the housing in place.

just my $0.02, not responsible if your dog dies or the PDK doesn’t work after

#53

Three Wheelin'

Sometimes bearings are so frozen into place by age they have to "pop" before they'll start to move. I was rebuilding an alternator about a month ago and the bearing literally made a snap noise then started to move freely. I was replacing the bearing anyways so I didn't mind if I damaged it but I had to tighten the puller much more than I would have expected to get it started.

About two weeks ago amet posted pictures of the bearings in this thread and it looks like they are available if they do get damaged.

Can you tell if the bearing has moved on the shaft at all or is it frozen?

Last edited by PV997; 07-20-2021 at 11:20 AM.

#55

Three Wheelin'

As long as we are throwing out ideas, how about using an impact driver on the puller? If the bearing is frozen on the shaft you need a sharp force to break it free, seems like an impact driver could do the trick.

Standard caveat in that it's an expensive transmission and any of these ideas could do real damage if applied recklessly.

Edit: After thinking about this more, here's what I'd try: Measure the distance from the bearing inner race to the end of the shaft using calipers or a precision scale. . Tighten the puller so it's snug and ensure the puller is positioned so it cannot damage the end of the shaft. Hit the puller a few times with an impact driver on a low setting. Stop and remeasure the distance and see if the bearing moved at all. If yes, switch over and do the same for the other bearing. If no, try it at a higher setting or a longer duration on the impact driver.

This assumes the bearing is frozen to the shaft and there isn't a simple explanation like a missed case screw of course. Good luck.

Standard caveat in that it's an expensive transmission and any of these ideas could do real damage if applied recklessly.

Edit: After thinking about this more, here's what I'd try: Measure the distance from the bearing inner race to the end of the shaft using calipers or a precision scale. . Tighten the puller so it's snug and ensure the puller is positioned so it cannot damage the end of the shaft. Hit the puller a few times with an impact driver on a low setting. Stop and remeasure the distance and see if the bearing moved at all. If yes, switch over and do the same for the other bearing. If no, try it at a higher setting or a longer duration on the impact driver.

This assumes the bearing is frozen to the shaft and there isn't a simple explanation like a missed case screw of course. Good luck.

Last edited by PV997; 07-19-2021 at 09:56 PM.

#56

Hello Damien ,

Thanks for the write up.

I had the infamous P1731 fault code .

i replaced the distance sensor on my 997.2 with the T-Desgn one.

The gear box does not work and throws fault code P1764.

- will this go away with calibration ?

- will the calibration actually start if the gear oil temp sensor is below 60degrees Celsius ?

What is your experience after switching the sensor ?

Thanks in advance !

Heiko

Thanks for the write up.

I had the infamous P1731 fault code .

i replaced the distance sensor on my 997.2 with the T-Desgn one.

The gear box does not work and throws fault code P1764.

- will this go away with calibration ?

- will the calibration actually start if the gear oil temp sensor is below 60degrees Celsius ?

What is your experience after switching the sensor ?

Thanks in advance !

Heiko

Last edited by Pinkawa; 07-20-2021 at 11:24 AM.

#57

Three Wheelin'

Hello Damien ,

Thanks for the write up.

I had the infamous P1731 fault code .

i replaced the distance sensor on my 997.2 with the T-Desgn one.

The gear box does not work and throws fault code P1764.

- will this go away with calibration ?

- will the calibration actually start of the gear oil temp sensor is below 60degrees Celsius ?

what Are your experiences?

Thanks in advance !

Heiko

Thanks for the write up.

I had the infamous P1731 fault code .

i replaced the distance sensor on my 997.2 with the T-Desgn one.

The gear box does not work and throws fault code P1764.

- will this go away with calibration ?

- will the calibration actually start of the gear oil temp sensor is below 60degrees Celsius ?

what Are your experiences?

Thanks in advance !

Heiko

Did you use the proper clutch fluid fill procedure using a PIWIS after the work? Just speculating here but If there are air pockets in the hydraulic system I could see something like this happening. Regarding calibration, take a look at the first PDF file attached at the end of the post linked below as it has the procedure in it.

https://rennlist.com/forums/997-foru...ission-33.html

#58

Not Damien but a few comments. P1764 is a weird fault that means a specific gear cannot be engaged or disengaged. When you pulled the fault (if using a PIWIS or Durametric) you should have gotten some text that tells you which gear is having the problem. This should be helpful in troubleshooting. The good news is that the control unit (TCU) will only throw the P1764 code if the P1731, P1732, P1733, or P1734 codes are not present, so the the TCU thinks it's getting good data from the new distance sensor.

Did you use the proper clutch fluid fill procedure using a PIWIS after the work? Just speculating here but If there are air pockets in the hydraulic system I could see something like this happening. Regarding calibration, take a look at the first PDF file attached at the end of the post linked below as it has the procedure in it.

https://rennlist.com/forums/997-foru...ission-33.html

Did you use the proper clutch fluid fill procedure using a PIWIS after the work? Just speculating here but If there are air pockets in the hydraulic system I could see something like this happening. Regarding calibration, take a look at the first PDF file attached at the end of the post linked below as it has the procedure in it.

https://rennlist.com/forums/997-foru...ission-33.html

yes after moving the gear shift lever through all positions I get the following. Codes :

The 4th gear message popped up only once.

I used the Foxwell NT510 elite.

i also used the fill mode to properly fill the PDK clutch oil to the proper level .

TIA

#59

Three Wheelin'

I don't know how the TCU could also be having an issue too unless it's just a coincidental fault. The TCU does store adaptation values and it's possible that the values saved from when the distance sensor was failing are incompatible with the new part (the TCU senses this and throws a fault). If so, clearing the faults and running the calibration may correct this. Let us know how it goes.

Edit: Adding that if you have a PIWIS you can read the distance sensor outputs in real time and see if they make sense and properly correspond to the selected gear. Here's an example from my 997.2 when I started from a stop and manually shifted through all the gears.

Last edited by PV997; 07-20-2021 at 12:48 PM.

The following users liked this post:

J.Correa (08-01-2024)

#60

Rennlist Member

First Damien let me say you have very pretty hands. Second, thanks for the write-up. And thanks to all who have added color.

As jbolduc27 mentioned... the housing doesn't easily "slide off", even with a well-made double pulling tool our 991.1 let out a nice, loud "pop" when the bearings broke loose from the shafts.

As jbolduc27 mentioned... the housing doesn't easily "slide off", even with a well-made double pulling tool our 991.1 let out a nice, loud "pop" when the bearings broke loose from the shafts.

The following users liked this post:

J.Correa (08-01-2024)