My IMS Solution DIY installation thread...

#91

Drifting

Jake,

Please ignore the negative types. Neither you nor anyone else will ever please them.They are sick people.

The vast majority of Rennlisters support you, are grateful for your generosity in sharing knowledge and enjoy your posts. Don't let the very few nasty people spoil it for the rest of us, please.

M96 dyno/torture test videos - great !! Who else would post such apocalyptic stuff on this engine?

Please ignore the negative types. Neither you nor anyone else will ever please them.They are sick people.

The vast majority of Rennlisters support you, are grateful for your generosity in sharing knowledge and enjoy your posts. Don't let the very few nasty people spoil it for the rest of us, please.

M96 dyno/torture test videos - great !! Who else would post such apocalyptic stuff on this engine?

#93

#94

Race Car

Yes but it's kinda of like reading test results on a new product. If it's a company that you know is full of crap, you just completely discount the information and probably don't make it past the first sentence. If it's coming from Driven or LN, there is a chance you might read the whole thing twice. Same thing with RL. Just consider the source and filter appropriately. And have faith that the rest of us will do the same.

#95

Rennlist Member

Thread Starter

It's been a long time since the last update because I pulled the front differential to replace the output shaft seals. So, now that I'm done with that I am back at finishing up this piece of the project. All that remains is to put the transmission back into the car. That is what I spent 6-7 hours working on yesterday and it has been a giant pain in the ***. Getting it back under the car was the reverse of removing - we had to turn it on its side and slide it on some tripled up cardboard. Once underneath, we turned it back up and worked it onto the transmission jack. This was done by lifting the small end up onto the jack, then using some wooden blocks and a breaker bar as a level to left the bell housing end and sliding the jack towards the center.

Once on the jack, very very carefully raise it up. I started out with the top mounting bracket resting on the top of the transmission since I wasn't able to remove that completely out of the way when I initially dropped it. This adds some complexity and you have to be very careful not to pinch/crush some of the black tubes running around in the transmission tunnel.

Eventually it is high enough to clear the rear cross member and at that point you can slide it towards the rear of the car - this should make things easier with the bracket mentioned above. I was able to get the input shaft into the clutch without much trouble at all - just working it back and forth a bit while turning the output on the end of the transmission and then it locked together and slid in. GREAT! Until it was about 1/2" or so from the crank case. Then, it stopped - thud. I spent the next 5-6 hours trying to get it to go together. It was perfectly aligned from what I could tell - I was able to easily put bolts in and get them started just by finger turning them. But it would not budge forward. I'm convinced it was the input shaft hitting the pilot bearing and not going through it.

Eventually I pulled the transmission away, lowered it and re-checked the clutch alignment. It was perfect - tool goes in and out with no resistance at all. However, I've read other people having issues with these plastic alignment tools - apparently they may not be precise enough (it is sure starting to seem that way).

So at the moment, I'm back in the position I was in earlier. Transmission is aligned, shaft is through the clutch spline and I'm bumped up against the pilot bearing.

My plan for today, now that I'm rested, is to first try to get it in normally, then attempt to put pressure on the release fork via the slave cylinder hole while I'm trying to push the transmission. I suspect the solution will be to get the transmission out of the way, loosen the pressure plate, and do some very precise aligning.

To be honest, this has me a bit perplexed - I've used plastic clutch alignment tools on a few other occasions and I've never had this trouble. Any advice or ideas would be greatly appreciated! As a last resort, I found a metal tool online that someone from the forum recommended. I can order that, but unfortunately it won't be here until next week.

Cheers

Charlie

Once on the jack, very very carefully raise it up. I started out with the top mounting bracket resting on the top of the transmission since I wasn't able to remove that completely out of the way when I initially dropped it. This adds some complexity and you have to be very careful not to pinch/crush some of the black tubes running around in the transmission tunnel.

Eventually it is high enough to clear the rear cross member and at that point you can slide it towards the rear of the car - this should make things easier with the bracket mentioned above. I was able to get the input shaft into the clutch without much trouble at all - just working it back and forth a bit while turning the output on the end of the transmission and then it locked together and slid in. GREAT! Until it was about 1/2" or so from the crank case. Then, it stopped - thud. I spent the next 5-6 hours trying to get it to go together. It was perfectly aligned from what I could tell - I was able to easily put bolts in and get them started just by finger turning them. But it would not budge forward. I'm convinced it was the input shaft hitting the pilot bearing and not going through it.

Eventually I pulled the transmission away, lowered it and re-checked the clutch alignment. It was perfect - tool goes in and out with no resistance at all. However, I've read other people having issues with these plastic alignment tools - apparently they may not be precise enough (it is sure starting to seem that way).

So at the moment, I'm back in the position I was in earlier. Transmission is aligned, shaft is through the clutch spline and I'm bumped up against the pilot bearing.

My plan for today, now that I'm rested, is to first try to get it in normally, then attempt to put pressure on the release fork via the slave cylinder hole while I'm trying to push the transmission. I suspect the solution will be to get the transmission out of the way, loosen the pressure plate, and do some very precise aligning.

To be honest, this has me a bit perplexed - I've used plastic clutch alignment tools on a few other occasions and I've never had this trouble. Any advice or ideas would be greatly appreciated! As a last resort, I found a metal tool online that someone from the forum recommended. I can order that, but unfortunately it won't be here until next week.

Cheers

Charlie

#96

Shameful Thread Killer

Rennlist Member

Rennlist Member

I've not done a 996 clutch, so that's my disclaimer but I have done a lot of other cars, including a number of Porsches.

The usual culprit with the clutch alignment tool is gravity droops the friction plate in the PP. So it's typical that the friction plate splines line up, and then the pilot shaft will strike the pilot bearing low. I confirmed this on a 914 using the plastic alignment tool when a buddy got frustrated and just banged it in. We pulled the trans and the pilot bearing and it was bent up on the bottom. Which confirms the issue with gravity on the friction plate.

Ever since then, as I set up the pressure plate bolts with the friction plate I try to do it with the shaft vertical, and the tool inserted. This take gravity out of the mix. The other options is to release the pressure on the PP bolts, put the tool in, and gently lift the friction plate so the alignment tool is just a skosh tipped up to compensate for gravity.

When installing, the shaft gets to the pilot bearing. At that point, you would wiggle the nose(front) of the trans mostly up and down to get it to insert while backing the trans out and in a bit. Mostly up and down will do it, not side to side.

That's the best I can offer, but again I've never done a 996.

The usual culprit with the clutch alignment tool is gravity droops the friction plate in the PP. So it's typical that the friction plate splines line up, and then the pilot shaft will strike the pilot bearing low. I confirmed this on a 914 using the plastic alignment tool when a buddy got frustrated and just banged it in. We pulled the trans and the pilot bearing and it was bent up on the bottom. Which confirms the issue with gravity on the friction plate.

Ever since then, as I set up the pressure plate bolts with the friction plate I try to do it with the shaft vertical, and the tool inserted. This take gravity out of the mix. The other options is to release the pressure on the PP bolts, put the tool in, and gently lift the friction plate so the alignment tool is just a skosh tipped up to compensate for gravity.

When installing, the shaft gets to the pilot bearing. At that point, you would wiggle the nose(front) of the trans mostly up and down to get it to insert while backing the trans out and in a bit. Mostly up and down will do it, not side to side.

That's the best I can offer, but again I've never done a 996.

#97

Rennlist Member

Thread Starter

I've not done a 996 clutch, so that's my disclaimer but I have done a lot of other cars, including a number of Porsches.

The usual culprit with the clutch alignment tool is gravity droops the friction plate in the PP. So it's typical that the friction plate splines line up, and then the pilot shaft will strike the pilot bearing low. I confirmed this on a 914 using the plastic alignment tool when a buddy got frustrated and just banged it in. We pulled the trans and the pilot bearing and it was bent up on the bottom. Which confirms the issue with gravity on the friction plate.

Ever since then, as I set up the pressure plate bolts with the friction plate I try to do it with the shaft vertical, and the tool inserted. This take gravity out of the mix. The other options is to release the pressure on the PP bolts, put the tool in, and gently lift the friction plate so the alignment tool is just a skosh tipped up to compensate for gravity.

When installing, the shaft gets to the pilot bearing. At that point, you would wiggle the nose(front) of the trans mostly up and down to get it to insert while backing the trans out and in a bit. Mostly up and down will do it, not side to side.

That's the best I can offer, but again I've never done a 996.

The usual culprit with the clutch alignment tool is gravity droops the friction plate in the PP. So it's typical that the friction plate splines line up, and then the pilot shaft will strike the pilot bearing low. I confirmed this on a 914 using the plastic alignment tool when a buddy got frustrated and just banged it in. We pulled the trans and the pilot bearing and it was bent up on the bottom. Which confirms the issue with gravity on the friction plate.

Ever since then, as I set up the pressure plate bolts with the friction plate I try to do it with the shaft vertical, and the tool inserted. This take gravity out of the mix. The other options is to release the pressure on the PP bolts, put the tool in, and gently lift the friction plate so the alignment tool is just a skosh tipped up to compensate for gravity.

When installing, the shaft gets to the pilot bearing. At that point, you would wiggle the nose(front) of the trans mostly up and down to get it to insert while backing the trans out and in a bit. Mostly up and down will do it, not side to side.

That's the best I can offer, but again I've never done a 996.

Thanks Doc. I think you're right. I've tried wiggling and lifting with no luck. I noticed when installing that the clutch sagged a bit due to gravity. I lifted it up slightly when tightening the bolts to try to counteract this but it seems it still isn't perfect.

I'm about to lower the transmission again to try to get enough room to visually see it while I'm aligning. If that doesn't work I'll be ordering a metal tool - I also found out there is a place 9 minutes from my house called Wright Motorsports, it looks like they build race cars so there is a chance I could get one from them.

Cheers

Charlie

#98

Just be really attentive that you are using the clutch tool and also your eyes looking straight at it to align it and not just by the feel of the clutch tool, if that makes any sense. Also make sure the transmission is lined up straight when you mate it. I know with it being relatively heavy can make this a difficult process to align.

If you feel like there is a lot of play at the end of your plastic clutch alignment tool, either get another one or wrap the end in a couple layers of tape. I've seen various tolerances on the many plastic clutch alignment tools I've worked with in the past.

Good luck.

#99

Former Vendor

We use an input shaft section chopped off a 996 transaxle for alignment of the clutch. The plastic units sometimes fit too loosely, causing misalignment issues like you are experiencing.

That said, this is where working on your back from a creeper under the car with a heavy transaxle being wrestled into place makes this a much less DIY job. The transaxle must be fitted at a precise angle to have the input shaft enter the pilot bearing. This is very difficult without a lift and a tranny jack that allows the unit to be supported and the angle changed easily.

It can be done, and I have laid on my back to install many trannys in the past. Its a job that sucks and with the weight of the 996 gearbox, coupled to it's length, its not easy at all.This one aspect is what would keep most DIY IMSR procedures from being straight forward.

Also, make sure you have the clutch disc in the proper direction, as that can be a big issue and make this even tougher, but its better to find that now than later.

That said, this is where working on your back from a creeper under the car with a heavy transaxle being wrestled into place makes this a much less DIY job. The transaxle must be fitted at a precise angle to have the input shaft enter the pilot bearing. This is very difficult without a lift and a tranny jack that allows the unit to be supported and the angle changed easily.

It can be done, and I have laid on my back to install many trannys in the past. Its a job that sucks and with the weight of the 996 gearbox, coupled to it's length, its not easy at all.This one aspect is what would keep most DIY IMSR procedures from being straight forward.

Also, make sure you have the clutch disc in the proper direction, as that can be a big issue and make this even tougher, but its better to find that now than later.

#100

Shameful Thread Killer

Rennlist Member

Rennlist Member

Another trick is to put some liquid white out on the nose of the trans shaft and give it another try. When you back it out, see where the white out has been rubbed off. It may give you some idea of which way to move the friction disk.

#101

Former Vendor

Some of the best alignment tools I have ever had I made from a wooden dowel, turned down to fit the pilot bearing and the ID of the clutch disc very tightly.

#103

Rennlist Member

Thread Starter

Alright - so the transmission is full seated and bolted to the transmission. It was a clutch alignment issue (crap plastic alignment tool). I ended up removing the transmission and climbing up between the two so that I could look directly into the clutch and see the pilot bearing. After loosening the pressure plate bolts enough to make minor adjustments I was able to use the alignment tool and get it as centered as possible by eye balling it. After that, re-torque the bolts and tried again. All in all it probably only took 20 minutes after that before it was fully seated. I wouldn't go so far as to say it slid in without effort, but compared to the effort we were putting behind it yesterday it was a breeze.

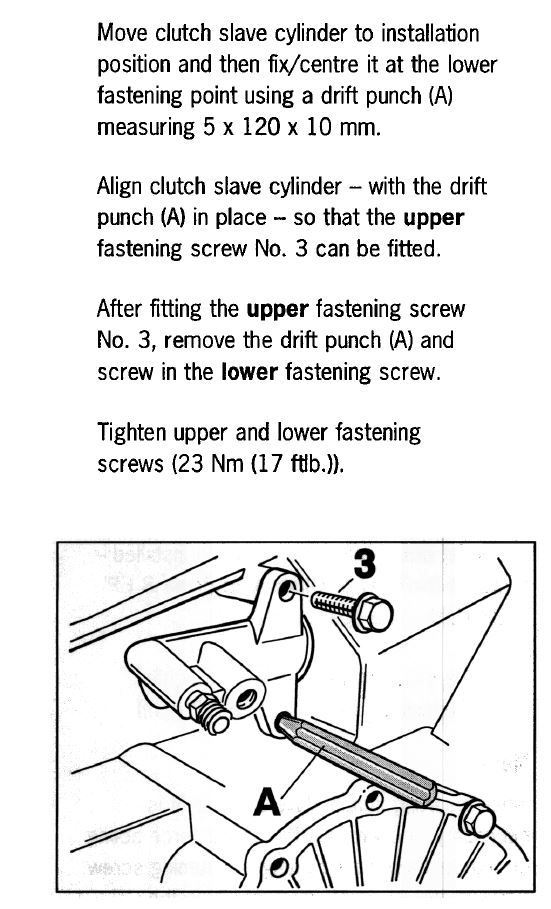

That being said, I'm now struggling with the slave cylinder. I am beginning to think the best approach is to pull the transmission away from the block, install slave cylinder, and then use the bolts to pull them back together? I've been trying to compress the rod back into the cylinder as I'm installing it and I am not sure its physically possible due to the angles + knowing I then have to get the bolt started. Any advise on this one?

Cheers

Charlie

That being said, I'm now struggling with the slave cylinder. I am beginning to think the best approach is to pull the transmission away from the block, install slave cylinder, and then use the bolts to pull them back together? I've been trying to compress the rod back into the cylinder as I'm installing it and I am not sure its physically possible due to the angles + knowing I then have to get the bolt started. Any advise on this one?

Cheers

Charlie

#105

Former Vendor

Often times when the slave cylinders are allowed to fully extend, with fluid in them, they can't have the rod re- inserted successfully. We open the bleeder valve and pull a vacuum on it before removing the slave. This will keep this from occurring so badly.

Your approach is about the only thing you can try now.

Your approach is about the only thing you can try now.