Who has done the factory short block swap?

#1

Thereís lots of talk about the factory short block swap as an option for a blow engine. Iím curious to hear from owners who actually went this route. Are you happy with the results?

#2

Burning Brakes

I did it, happy with the results, and did all the work myself. I would do it again in a heartbeat if I found another roller near me in a similar condition. Note, I chose this option because my crank and at least one con rod was trashed, replacing these parts alone is expensive and the short block option came with many other new parts at a low price. Since this was my first Porsche and I had never driven it before I bought it, I was not in love with it (yet) so couldn’t justify an expensive FSI build, although I have no doubt this would have been a superior technical decision.

The car ran perfectly from the first start-up and has not had any CEL or other issues in the 4000 miles driven since. It is important to note the other parts I replaced at the same time, AOS, oil cooler, coils, plugs, oil filter conversion, scavenge pumps, etc, and the head work I outsourced. I would do it again in a heartbeat if I found another roller near me, although if my next one has a good crank, etc I would consider a rebuild with nickies, IMS Solution, overbore, etc., still doing the build myself.

Here’s the link to my thread on the build.

https://rennlist.com/forums/showthre...errerid=188196

The car ran perfectly from the first start-up and has not had any CEL or other issues in the 4000 miles driven since. It is important to note the other parts I replaced at the same time, AOS, oil cooler, coils, plugs, oil filter conversion, scavenge pumps, etc, and the head work I outsourced. I would do it again in a heartbeat if I found another roller near me, although if my next one has a good crank, etc I would consider a rebuild with nickies, IMS Solution, overbore, etc., still doing the build myself.

Here’s the link to my thread on the build.

https://rennlist.com/forums/showthre...errerid=188196

#3

@Coopduc Thanks for the info and for the riveting build thread. I read the whole thing - really nicely done thread and a beautiful result.

I wish I could do a project like this myself, but I don't have the space, time, or tools. So, I'll be sending this out to indy shop. Even with someone else doing the work, and getting the heads done, it ends up less expensive than most rebuild options, so I'm leaning towards this solution.

I didn't see in the thread which short block you ordered. Was it the standard 996-100-996TX or the X51 block 996-100-951TX? Someone on another thread linked a a new X51 short block for just $5,100, which seems like a great price vs. the regular short block for $6,900.

I wish I could do a project like this myself, but I don't have the space, time, or tools. So, I'll be sending this out to indy shop. Even with someone else doing the work, and getting the heads done, it ends up less expensive than most rebuild options, so I'm leaning towards this solution.

I didn't see in the thread which short block you ordered. Was it the standard 996-100-996TX or the X51 block 996-100-951TX? Someone on another thread linked a a new X51 short block for just $5,100, which seems like a great price vs. the regular short block for $6,900.

#4

Rennlist Member

@Coopduc Thanks for the info and for the riveting build thread. I read the whole thing - really nicely done thread and a beautiful result.

I wish I could do a project like this myself, but I don't have the space, time, or tools. So, I'll be sending this out to indy shop. Even with someone else doing the work, and getting the heads done, it ends up less expensive than most rebuild options, so I'm leaning towards this solution.

I didn't see in the thread which short block you ordered. Was it the standard 996-100-996TX or the X51 block 996-100-951TX? Someone on another thread linked a a new X51 short block for just $5,100, which seems like a great price vs. the regular short block for $6,900.

I wish I could do a project like this myself, but I don't have the space, time, or tools. So, I'll be sending this out to indy shop. Even with someone else doing the work, and getting the heads done, it ends up less expensive than most rebuild options, so I'm leaning towards this solution.

I didn't see in the thread which short block you ordered. Was it the standard 996-100-996TX or the X51 block 996-100-951TX? Someone on another thread linked a a new X51 short block for just $5,100, which seems like a great price vs. the regular short block for $6,900.

#6

Drifting

I'm not sure what an X51 short block would do for you. From what I've read, the X51 bits would be found outside the short block (except the baffled oil pan). See Loren's post here:

https://rennlist.com/forums/996-foru...1-package.html

https://rennlist.com/forums/996-foru...1-package.html

#7

My car has a replaced short block from Porsche by PO after his AOS failed. I have no idea how much he paid for it but it lists head job, rebuild with OEM short block. It has the 997 style IMS (non-serviceable). It has now 14k miles on it and I hope to have many more in its life.

Trending Topics

#8

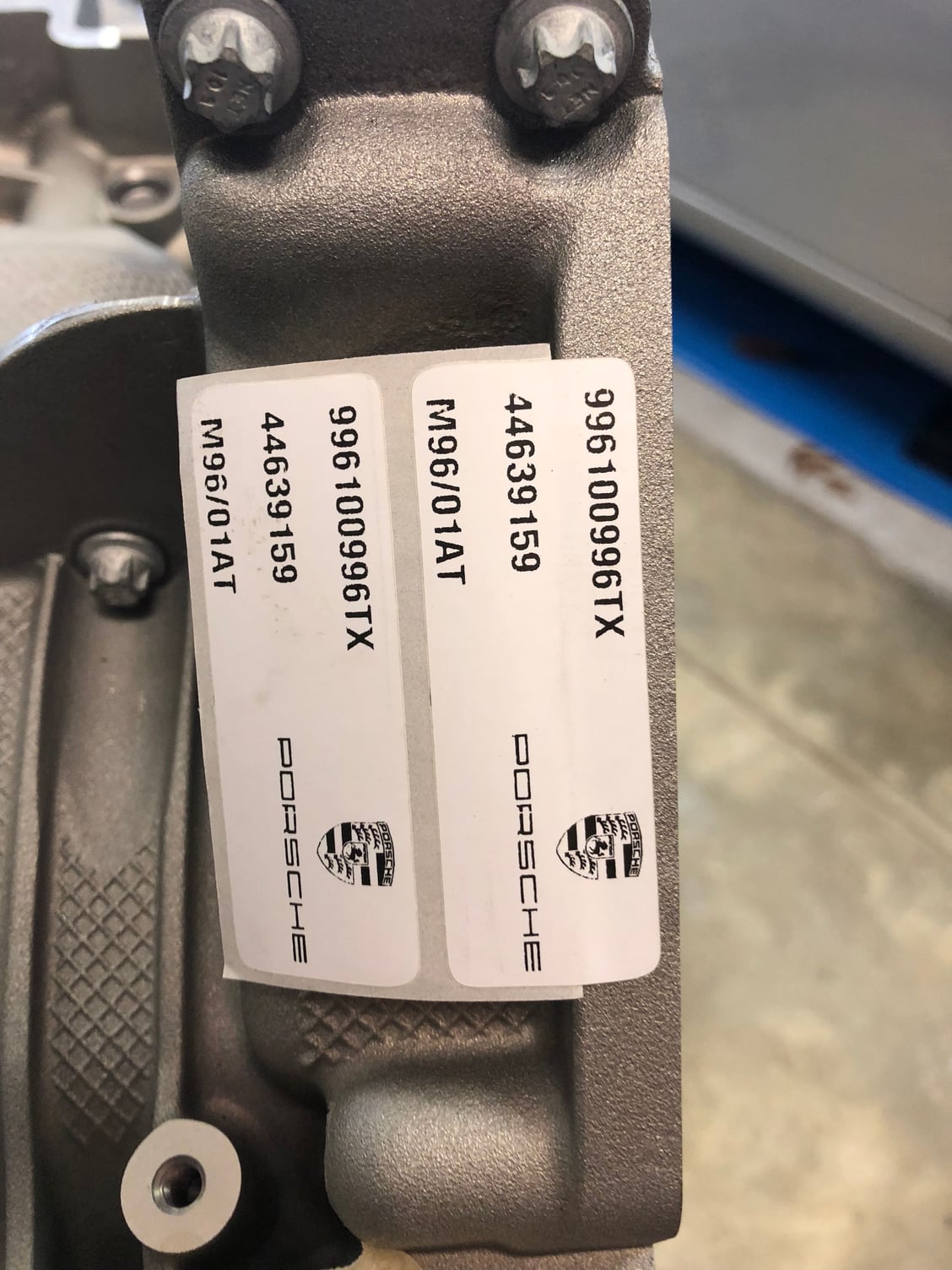

@808Bill Those are the part numbers for the 3.4. Coopduc and I both have 99s.

@Coopduc Thanks for the part number and photo! I'm thrilled to see a new water pump was included with standard short block.

@cds72911 My understanding is the earlier 3.4 motors had more differences in the lower block than the later X51 kits. That being said, the main benefit I'm looking for in this case it to save $1,000+, as I found the X51 short block on sale.

@Coopduc Thanks for the part number and photo! I'm thrilled to see a new water pump was included with standard short block.

@cds72911 My understanding is the earlier 3.4 motors had more differences in the lower block than the later X51 kits. That being said, the main benefit I'm looking for in this case it to save $1,000+, as I found the X51 short block on sale.

#9

I thought that the X51 block was the same than the regular one, being the differences on other parts, like oil pan, headers and so.

#10

Former Vendor

The main issues we see with these come from who is tasked with prepping the cylinder heads to be fitted onto the shortblock. The same goes for assembly.

The factory shortblock is OK if you have someone that’s extremely capable working with the cylinder heads, and if you are okay with accepting an engine that’s just like what you previously had from the cylinder decks inward.

The factory shortblock is OK if you have someone that’s extremely capable working with the cylinder heads, and if you are okay with accepting an engine that’s just like what you previously had from the cylinder decks inward.

#11

The main issues we see with these come from who is tasked with prepping the cylinder heads to be fitted onto the shortblock. The same goes for assembly.

The factory shortblock is OK if you have someone thatís extremely capable working with the cylinder heads, and if you are okay with accepting an engine thatís just like what you previously had from the cylinder decks inward.

The factory shortblock is OK if you have someone thatís extremely capable working with the cylinder heads, and if you are okay with accepting an engine thatís just like what you previously had from the cylinder decks inward.

#12

Former Vendor

@Flat6 Innovations What are some common errors made by less-capable engine builders when working on the heads in particular?

In most cases people simply do not understand the inherent issues with these engines, and they botch things that lead to other failures. Typical mistakes include reusing valve springs, trusting valve seats on the heads that are known to have low interference fit seats (but they donít know that, because they lack experience wit these heads) as well as improper decking procedures. From a performance perspective they make ports too damn big, kill velocity and they do it because they think bigger is better.

The #1 issue is making repairs to heads that are damaged from traumatic experiences on the prior engine, when those heads should be thrown away.

Typically the people buying these short blocks are on too tight of a budget, or too tight of a timeline. Calendars, clocks and shallow pockets waste money every time. They have to experience this to understand it, then they come crawling our way with a sob story. Iíve stopped even responding to those messages.

#13

Rennlist Member

You name it. We see hacks screwing things up more and more everyday. At times its because they let the customer dictate what they will have done, based on cost. That should never happen, the machinist is in charge, and if the customer wants something done half way, they should be turned away.

In most cases people simply do not understand the inherent issues with these engines, and they botch things that lead to other failures. Typical mistakes include reusing valve springs, trusting valve seats on the heads that are known to have low interference fit seats (but they don’t know that, because they lack experience wit these heads) as well as improper decking procedures. From a performance perspective they make ports too damn big, kill velocity and they do it because they think bigger is better.

The #1 issue is making repairs to heads that are damaged from traumatic experiences on the prior engine, when those heads should be thrown away.

Typically the people buying these short blocks are on too tight of a budget, or too tight of a timeline. Calendars, clocks and shallow pockets waste money every time. They have to experience this to understand it, then they come crawling our way with a sob story. I’ve stopped even responding to those messages.

In most cases people simply do not understand the inherent issues with these engines, and they botch things that lead to other failures. Typical mistakes include reusing valve springs, trusting valve seats on the heads that are known to have low interference fit seats (but they don’t know that, because they lack experience wit these heads) as well as improper decking procedures. From a performance perspective they make ports too damn big, kill velocity and they do it because they think bigger is better.

The #1 issue is making repairs to heads that are damaged from traumatic experiences on the prior engine, when those heads should be thrown away.

Typically the people buying these short blocks are on too tight of a budget, or too tight of a timeline. Calendars, clocks and shallow pockets waste money every time. They have to experience this to understand it, then they come crawling our way with a sob story. I’ve stopped even responding to those messages.

I concur with Jake 100%. We see shops or even at time, DIY guys, that will spend all the money on just Nickies alone, or a go the route of shortblock or longblock, and then cut corners and re-use components that should be replaced because they exhausted their budget.

While SSF was handling the RND program, changes had to be made to include things like a new AOS, oil cooler, vent tube, break-in oil, as well as to come up with very explicit guidelines for installation and break-in, as we found shops would reused items like used oil coolers and the AOS, among other components during a build, to keep the complete job price under a certain threashold to get the job.

It's kind of like walking into a dealership to buy a car and they whip out a four square and ask you how much you can afford to pay each month. They will sell you the cheapest car they have at the highest price to meet your monthly payment expectations.

Like with any rebuild or engine replacement, the final result is more than the sum of the parts inside the engine, but also the ancillaries as well as the competency of the shop carrying out the work.

#14

Former Vendor

Haste makes waste, as I learned early in life.

I concur with Jake 100%. We see shops or even at time, DIY guys, that will spend all the money on just Nickies alone, or a go the route of shortblock or longblock, and then cut corners and re-use components that should be replaced because they exhausted their budget.

While SSF was handling the RND program, changes had to be made to include things like a new AOS, oil cooler, vent tube, break-in oil, as well as to come up with very explicit guidelines for installation and break-in, as we found shops would reused items like used oil coolers and the AOS, among other components during a build, to keep the complete job price under a certain threashold to get the job.

It's kind of like walking into a dealership to buy a car and they whip out a four square and ask you how much you can afford to pay each month. They will sell you the cheapest car they have at the highest price to meet your monthly payment expectations.

Like with any rebuild or engine replacement, the final result is more than the sum of the parts inside the engine, but also the ancillaries as well as the competency of the shop carrying out the work.

I concur with Jake 100%. We see shops or even at time, DIY guys, that will spend all the money on just Nickies alone, or a go the route of shortblock or longblock, and then cut corners and re-use components that should be replaced because they exhausted their budget.

While SSF was handling the RND program, changes had to be made to include things like a new AOS, oil cooler, vent tube, break-in oil, as well as to come up with very explicit guidelines for installation and break-in, as we found shops would reused items like used oil coolers and the AOS, among other components during a build, to keep the complete job price under a certain threashold to get the job.

It's kind of like walking into a dealership to buy a car and they whip out a four square and ask you how much you can afford to pay each month. They will sell you the cheapest car they have at the highest price to meet your monthly payment expectations.

Like with any rebuild or engine replacement, the final result is more than the sum of the parts inside the engine, but also the ancillaries as well as the competency of the shop carrying out the work.

Thereís about 10,000 reasons why I wonít let anyone thats not under my roof install one of my engines. The shop isnít vested in the success of the project. its not their car, and not their engine. The way they look at it they are doing the slave labor, and ďmaking less money than everyone else didĒ.

They slap the engine in, pat the car on the ***, and donít give a damn what happens. If anything does happen the finger pointing starts and then they say ďWe did everything right, and followed the instructions verbatimĒ. Of course they did. Including the time that someone dropped an intake bolt down an intake port, and it destroyed a brand new RND engine. Yes, they did everything right.

Yeah, it sucks.