View Poll Results: Who's interested in 3D printed door pocket reinforcements?

Yes

69

95.83%

No

3

4.17%

Voters: 72. You may not vote on this poll

Next 3D printing project.....Door Pocket reinforcements.

#61

Advanced

I have access to a 3D printer and can print solid ABS* (100% infill). If you send me an STL file of the reinforcements, I could print them for less than $40 a pair, maybe much less if I can tune in reliable print settings. A large, thick, flat ABS surface has a tendency to curl even on a heated print bed.

Davis

Note ABS melts between 200 and 230 Celsius, so there might not be a huge safety margin for a dark car interior on a hot, bright summer day.

Davis

Note ABS melts between 200 and 230 Celsius, so there might not be a huge safety margin for a dark car interior on a hot, bright summer day.

#62

Rennlist Member

Thread Starter

I have access to a 3D printer and can print solid ABS* (100% infill). If you send me an STL file of the reinforcements, I could print them for less than $40 a pair, maybe much less if I can tune in reliable print settings. A large, thick, flat ABS surface has a tendency to curl even on a heated print bed.

Davis

Note ABS melts between 200 and 230 Celsius, so there might not be a huge safety margin for a dark car interior on a hot, bright summer day.

Davis

Note ABS melts between 200 and 230 Celsius, so there might not be a huge safety margin for a dark car interior on a hot, bright summer day.

That's fine, I have a company that has done printing for me in the past that I will use again to manufacture these.

G

#65

Rennlist Member

I may put this one up on Shapeways depending on what their finish looks like. The heat cycling properties are good enough by a long shot. That way anybody who wants to order a set can just do it through there.

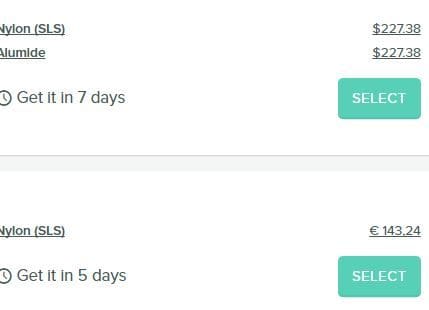

Nylon prints are prohibitively expensive. Holy cow, the cost is 3 to 5 times the cost for nylon prints!

G

Nylon prints are prohibitively expensive. Holy cow, the cost is 3 to 5 times the cost for nylon prints!

G

Nylon is nice because its a bit more flexible than PLA without sacrificing infill. Which makes it a bit more shatter resistant. For example, if someone decides to really torque a screw head into the print, nylon might absorb that force more than PLA, but really it doesnt matter I'm guessing.

Keep up the good work. 3D printing is great.

#66

Rennlist Member

#67

Advanced

I figured somebody would comment on my concern for the ABS melting point. I should have added that the usable temperature (i.e. before it starts to soften) would be much lower. By Google research, I found:

"ABS maximum temperature is 80░C (176░F) and melt at 105░C (221░F)"

http://bricks.stackexchange.com/ques...icks-withstand

I know, from work-related measurements, that the temperature in the headliner of one model of black car, parked in Arizona on on a clear summer day will exceed 165░F, so the temperature margin would be less than 11░F for that car.

I think your idea is great and there seems to be a lot of interest. I'm just suggesting that if there is a reasonable cost option for a plastic/nylon with a higher temperature tolerance, it would be worthwhile to consider.

Davis

"ABS maximum temperature is 80░C (176░F) and melt at 105░C (221░F)"

http://bricks.stackexchange.com/ques...icks-withstand

I know, from work-related measurements, that the temperature in the headliner of one model of black car, parked in Arizona on on a clear summer day will exceed 165░F, so the temperature margin would be less than 11░F for that car.

I think your idea is great and there seems to be a lot of interest. I'm just suggesting that if there is a reasonable cost option for a plastic/nylon with a higher temperature tolerance, it would be worthwhile to consider.

Davis

#68

Rennlist Member

Thread Starter

It's pretty hot here during summer so if a closed door pocket gets anywhere near that temperature, I'd be very surprised. That being said, I'll be sure to test the piece before it goes out. If people think the safety margin is worth tripling the production cost(not the cost per set), I can look into nylon prints.

#70

Rennlist Member

Thread Starter

Shapeways seem to use an sls nylon which is available in black, though they don't offer the polished option on it that was available on all the other colors. The problem is that the texture is a little grainy. Maybe as it's in the door pockets it wouldn't make a difference.

G

G

#71

Advanced

Here is some more, hopefully helpful information:

When the ambient temperature is 120░F, the temperature inside of a closed car can reach 167░F in an hour:

http://www.tempsensornews.com/biomed...erature-table/

Wikipedia also states the maximum working temperature of ABS is about 80░C (176░F) :

https://en.wikipedia.org/wiki/Acrylo...adiene_styrene

I don't know where you send your parts to be 3D printed, but 3Dhubs seems to offer competitive pricing:

https://www.3dhubs.com/

When the ambient temperature is 120░F, the temperature inside of a closed car can reach 167░F in an hour:

http://www.tempsensornews.com/biomed...erature-table/

Wikipedia also states the maximum working temperature of ABS is about 80░C (176░F) :

https://en.wikipedia.org/wiki/Acrylo...adiene_styrene

I don't know where you send your parts to be 3D printed, but 3Dhubs seems to offer competitive pricing:

https://www.3dhubs.com/

It's pretty hot here during summer so if a closed door pocket gets anywhere near that temperature, I'd be very surprised. That being said, I'll be sure to test the piece before it goes out. If people think the safety margin is worth tripling the production cost(not the cost per set), I can look into nylon prints.

#72

Rennlist Member

Thread Starter

You are also mistaking the cost of pure production for the cost of my time and effort, shipping and handling, costs associated with producing these which include software, test prints etc.

Also, 3D Hubs becomes prohibitively expensive as soon as you get away from PLA and ABS.

#73

Advanced

I see from the following article that other rennlisters have reinforced their door pockets with solid ABS:

https://rennlist.com/forums/993-foru...forcement.html

Some noted that maybe the original part is made out of ABS as well, but given that the part failed, that's not necessarily an endorsement.

The article is over 2 years old and no one has complained of failures, so for most people using an appropriately-thick, solid ABS part is probably ok.

Davis

https://rennlist.com/forums/993-foru...forcement.html

Some noted that maybe the original part is made out of ABS as well, but given that the part failed, that's not necessarily an endorsement.

The article is over 2 years old and no one has complained of failures, so for most people using an appropriately-thick, solid ABS part is probably ok.

Davis

#74

Rennlist Member

Thread Starter

Just to be Devil's Advocate, my car is 20 years old so 2 years is just 10% of the cars life. In a further 10+ years it may become an issue again. I think that I will print some of these and offer them to people but also put them on Shapeways to be printed in black sls nylon if that is what is desired.

G

G