Need HELP :-(

#16

Technical Guru

Rennlist Member

Rennlist Member

Originally Posted by delanobe

The shaft is fixed as it should be (I hope). How much work is it to put the pulley back were it belongs??

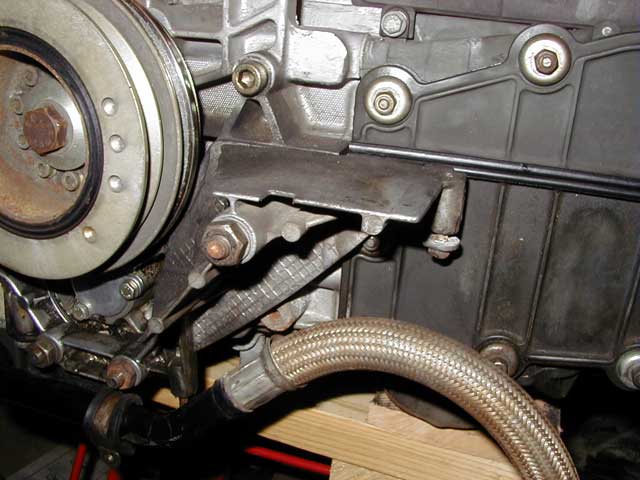

These are from a 964 (the pulley is slightly different) but will give you an idea of how little space there is to work.

#17

Three Wheelin'

Thread Starter

There is a good chance that the "krukas" crank shaft pulley is broken

The engine must come out and be dissambled completly (45 Hours work??? Is this possible?)

A new crankshaft costs 2800$

What to do????

The engine must come out and be dissambled completly (45 Hours work??? Is this possible?)

A new crankshaft costs 2800$

What to do????

#18

Advanced

Join Date: May 2002

Location: Stockholm, Sweden

Posts: 53

Likes: 0

Received 0 Likes

on

0 Posts

Uh, isn't the crank shaft pulley just mounted to the crankshaft, hence what we look on here is a lower-the-engine then remount pulley? Again, I'm confused as to what could make the pulley loosen up like that.

#19

Three Wheelin'

Thread Starter

The mechanic said that there is a little pin on the end of the crank shaft (were the pulley is attached), if that's broken I'm in big trouble (complete engine rebuild????)

#20

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Its very unlikely that you hurt the crankshaft and I highly doubt if a rebuld is needed.

The crank pulley uses the pin for proper alignment. This pin is permantely attached to the crank pully and is inserted into a alignment hole on the end of the crankshaft. The alignment is needed to properly indicated TDC for timing. It sounds like the main bolt on the crank has loosened and needs to be tightened up. Maybe the alignment pin sheared in the process. I have torqued the crank pulley while the engine is in the car during my DIY Engine rebuild when I had to time the cams while the engine is in the car...its doable but a fair amount of work. However its work that would have to happen regardless if the engine was in or out of the car so I would opt to do it in the car. You have to jack up the car and get the rear end nice and high and support it via jackstands.

Going from memory you then have to support the engine with a jack, remove the rear motor mount nuts and lower the engine up to 5"...just check all the hoses/cables up top to make sure you are not pulling anything loose (be carefully of the PS pump feed hose...that seems to crimp first).. remove the mufflers and cat. Take off the A/C pump and belt. The cat is likely to give you trouble since its ofter rusted in "real-good". Once the cat is out you can remove the lower air heat tube which is a cast aluminum tube that runs across the rear of the car. Then loosen the sheet metal around the sides of the engine and start to take off the rear engine mount bar. The engine mount bar is bolted directly to the rear of the engine. Once that is off you should be able to have clear access to the crank pully. If its loose, take off the main bolt (in the center) and remove the pully. Inspect the pin, if its sheared I bet you have replace the pulley. Once you have that fixed, put the pulley back onto the crank, put the bolt on and torque it up to 125ftlbs. This is the tricky part ; I don't like spending money on overpriced factory tools so I would just have an assistant use the brakes and have the car in gear, and if you have a decent clutch you should be able to torque the crankshaft pulley down fine with the driveline holding the crank still. The put all the parts back together and away you go.

Here is what it looked like when I did it...of course I went further since I needed to get to the cams...you can see the crankshaft pulley free and clear on the left hand corner. You can also see how far you can drop the engine with no problems. Be carefull though, check for binding above and below...

Yes, its a pain in the *** to do but its not difficult and I have done it so you have my sympathy! You might have to wrestle with some rusty bolts/nuts but that's about it. Its cramped so you should be able to do it in a day. The chances that the crank is broken is very close to zero.

I do not know what caused the crankshaft bolt to loosen but its best to "dig" into the problem first and post pictures of the condition of the pulley, pin and bolt. That would give us more to discuss! You can always but a few drops of locktight when you reassemble for that peace of mind.

Best of luck and please post if you have problems/questions, we are all here to help.

Cheers,

Mike

The crank pulley uses the pin for proper alignment. This pin is permantely attached to the crank pully and is inserted into a alignment hole on the end of the crankshaft. The alignment is needed to properly indicated TDC for timing. It sounds like the main bolt on the crank has loosened and needs to be tightened up. Maybe the alignment pin sheared in the process. I have torqued the crank pulley while the engine is in the car during my DIY Engine rebuild when I had to time the cams while the engine is in the car...its doable but a fair amount of work. However its work that would have to happen regardless if the engine was in or out of the car so I would opt to do it in the car. You have to jack up the car and get the rear end nice and high and support it via jackstands.

Going from memory you then have to support the engine with a jack, remove the rear motor mount nuts and lower the engine up to 5"...just check all the hoses/cables up top to make sure you are not pulling anything loose (be carefully of the PS pump feed hose...that seems to crimp first).. remove the mufflers and cat. Take off the A/C pump and belt. The cat is likely to give you trouble since its ofter rusted in "real-good". Once the cat is out you can remove the lower air heat tube which is a cast aluminum tube that runs across the rear of the car. Then loosen the sheet metal around the sides of the engine and start to take off the rear engine mount bar. The engine mount bar is bolted directly to the rear of the engine. Once that is off you should be able to have clear access to the crank pully. If its loose, take off the main bolt (in the center) and remove the pully. Inspect the pin, if its sheared I bet you have replace the pulley. Once you have that fixed, put the pulley back onto the crank, put the bolt on and torque it up to 125ftlbs. This is the tricky part ; I don't like spending money on overpriced factory tools so I would just have an assistant use the brakes and have the car in gear, and if you have a decent clutch you should be able to torque the crankshaft pulley down fine with the driveline holding the crank still. The put all the parts back together and away you go.

Here is what it looked like when I did it...of course I went further since I needed to get to the cams...you can see the crankshaft pulley free and clear on the left hand corner. You can also see how far you can drop the engine with no problems. Be carefull though, check for binding above and below...

Yes, its a pain in the *** to do but its not difficult and I have done it so you have my sympathy! You might have to wrestle with some rusty bolts/nuts but that's about it. Its cramped so you should be able to do it in a day. The chances that the crank is broken is very close to zero.

I do not know what caused the crankshaft bolt to loosen but its best to "dig" into the problem first and post pictures of the condition of the pulley, pin and bolt. That would give us more to discuss! You can always but a few drops of locktight when you reassemble for that peace of mind.

Best of luck and please post if you have problems/questions, we are all here to help.

Cheers,

Mike

#21

Addict

Rennlist Member

Rennlist Member

Join Date: Aug 2001

Location: Tucson AZ

Posts: 246

Likes: 0

Received 0 Likes

on

0 Posts

Mike is correct... it's a monumental PITA but totally possible to tighten the pulley bolt in the car. I just went thru a similar adventure re-timing the cams in the car (with help from Mike, thanks my friend!) and it just takes time and patience. I found it was possible to loosen and tighten the crank pulley bolt while holding the pulley with a strap wrench (much lower cost than the P-tool), and there was room in there without lowering the engine (although the motor mount must come out anyhow to get to the pulley. I also removed the air pipe and cat as one big assembly... it's heavier that way, but saves messing with many hard to reach fasteners. Feel free to PM if you need help... like Mike said we are here!

Good luck, Mark.

Good luck, Mark.

#22

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Originally Posted by MadMarkie

Mike is correct... it's a monumental PITA but totally possible to tighten the pulley bolt in the car. I just went thru a similar adventure re-timing the cams in the car (with help from Mike, thanks my friend!) and it just takes time and patience. I found it was possible to loosen and tighten the crank pulley bolt while holding the pulley with a strap wrench (much lower cost than the P-tool), and there was room in there without lowering the engine (although the motor mount must come out anyhow to get to the pulley. I also removed the air pipe and cat as one big assembly... it's heavier that way, but saves messing with many hard to reach fasteners. Feel free to PM if you need help... like Mike said we are here!

Good luck, Mark.

Good luck, Mark.

Not to hijack the thread but was there much difference on your car on the before/after timing? I am curious since we both advanced our cams from the stock setting. I have not noticed any difference in the limited time I have driven my car but I could not push the engine (yet).

You are right about taking off the whole assembly...that is easier than taking it apart in sections!

Cheers,

Mike

#23

Addict

Rennlist Member

Rennlist Member

Join Date: Aug 2001

Location: Tucson AZ

Posts: 246

Likes: 0

Received 0 Likes

on

0 Posts

Hi Mike,

I just finished up the suspension/steering upgrades last night... but ran out of time to put the trays back on, fill with oil and fire it up. Expect a full report once I do, but it might be hard to tell for sure since I also did a complete tune up, and there is no PS pump to steal precious power! Thanks again for the help, and stay tuned... I will post some butt dyno results soon.

Cheers, Mark.

I just finished up the suspension/steering upgrades last night... but ran out of time to put the trays back on, fill with oil and fire it up. Expect a full report once I do, but it might be hard to tell for sure since I also did a complete tune up, and there is no PS pump to steal precious power! Thanks again for the help, and stay tuned... I will post some butt dyno results soon.

Cheers, Mark.

#24

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Excellent...this stuff sure takes a lot of time, eh? My wife calls my garage "the cave", I guess where the cavemen go to hide! ;-)

Cheers,

Mike

Cheers,

Mike

#25

Technical Guru

Rennlist Member

Rennlist Member

Originally Posted by delanobe

The mechanic said that there is a little pin on the end of the crank shaft (were the pulley is attached).

#26

Seared

Rennlist Member

Rennlist Member

Very interesting thread. I look forward to seeing a pic or two of the crank end, pulley, and any stray shavings that may be a result of this change.

If I remember correctly, you were close to selling your 993 a few months ago?

Andreas

If I remember correctly, you were close to selling your 993 a few months ago?

Andreas

#27

Three Wheelin'

Thread Starter

Hi Andreas,

You remember correctly but I did a few ppi's on 993 Turbo's....

I felt in love again with my car because (I thought) it was in perfect condition !!

Mike,

Thank you for your respons, I'm having a little more hope that it "maybe" will turn out better.

Just another question: If that pin is sheared, can it be replaced and if the screw wire is damaged?

Thanks again guys!!!!

You remember correctly but I did a few ppi's on 993 Turbo's....

I felt in love again with my car because (I thought) it was in perfect condition !!

Mike,

Thank you for your respons, I'm having a little more hope that it "maybe" will turn out better.

Just another question: If that pin is sheared, can it be replaced and if the screw wire is damaged?

Thanks again guys!!!!

#30

Generally in these cases the bolt has just loosened up on the pulley. Now this can cause issues, but is easy to assess damage if any. A shop should be able to just put it on a lift and remove the exhaust and then the engine carrier supporting the engine with a screwjack. This will allow direct access to the pulley to see if it damaged the end of the crank. Most times the crank is OK but the pulley may need to be replaced. If you are lucky, you might be able to get away with just 3-4 hours worth of labor and you will be back on the road.... Good luck..