My porsche 944 S2 16 valve turbo project

#212

Instructor

Thread Starter

Hi Chris, Yes it was CNC Machined, from a single piece of Forged Chrome Molly Steel. Its looking good with the AP clutch fitted. We have got to make some small alterations to the bell housing but should be worth it for the driveability. The centre push slave cylinder is going to be tight but we are getting there. Should be dummy built in the next few days, I'll let you know how it goes.

#213

Instructor

Thread Starter

#214

Drifting

#215

Drifting

Hi Chris, Yes it was CNC Machined, from a single piece of Forged Chrome Molly Steel. Its looking good with the AP clutch fitted. We have got to make some small alterations to the bell housing but should be worth it for the driveability. The centre push slave cylinder is going to be tight but we are getting there. Should be dummy built in the next few days, I'll let you know how it goes.

.

.

#217

Instructor

Thread Starter

#218

Instructor

Thread Starter

#219

Drifting

#220

Nordschleife Master

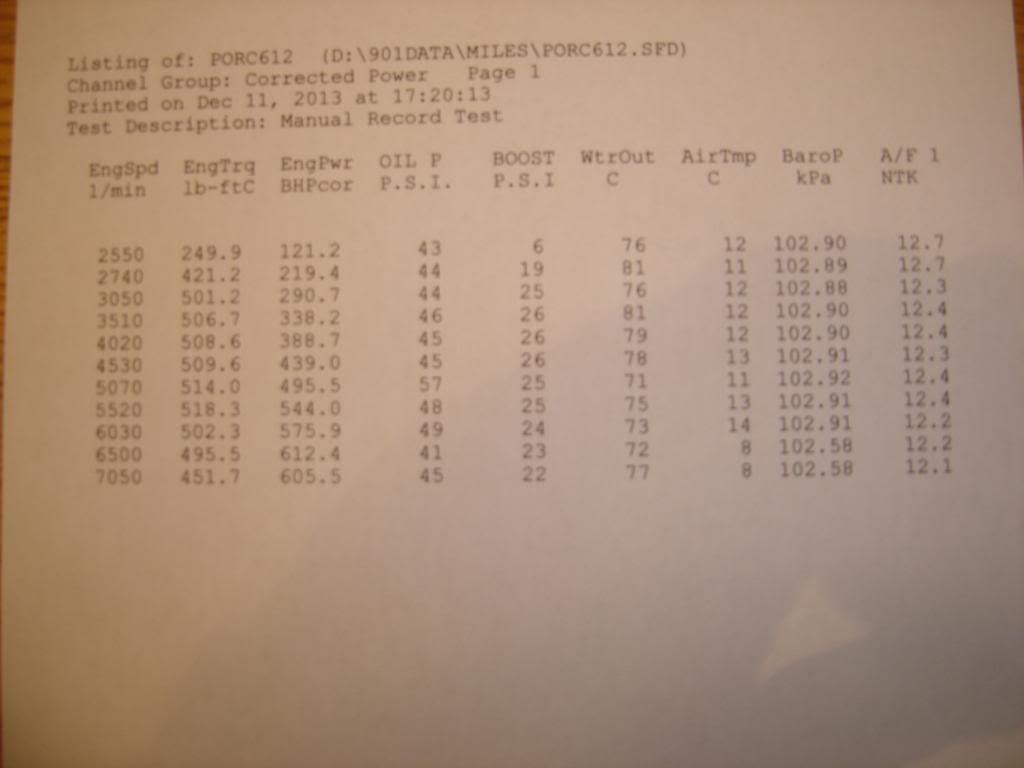

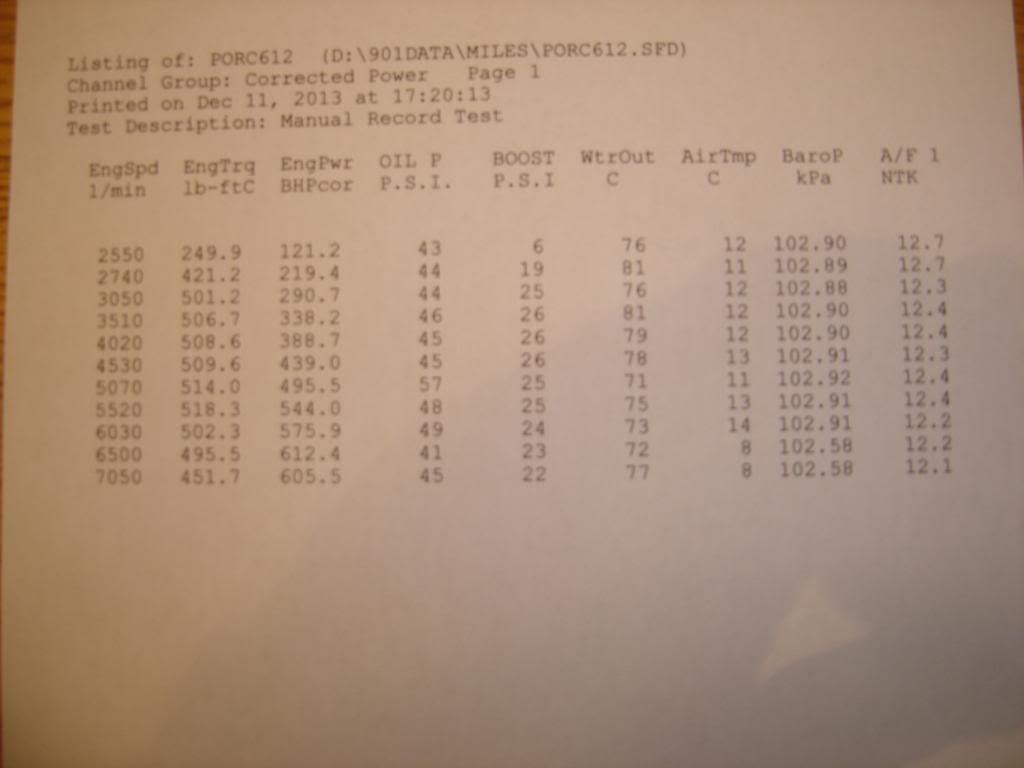

Right guys, I have finally finished the revised engine build. Has you know I had a little trouble with number one big end bearing, maybe it from revving it to 8000 rpm, oil temp to high or possibly to tight a tolerance. Anyway I had to decide what I was trying to achieve, the car is mainly going to be used on the road with standard gearbox etc. so I did not really need 700 plus horsepower and huge torque. So having read various threads and comments I decide to go a different route. I have turned the engine back to three litre, I've taken the compression ratio up to nine to one and have mapped the engine using the Garrett stage five turbo(T350 exhaust wheel, 61 inducer and .82 exhaust housing). This setup as worked really well I think, especially for road use. It should come on boost well and have loads of usable torque. Below is a dyno sheet and plot for your inspection. The last two recorded pulls have different temp and bara readings because the wastegate pipe broke and we finished it the following night.

Here's a question: How did you get the naturally aspirated torque curve to be that flat? The motor seems to be making between 12 and 13 ft-lbs per psi of absolute pressure in the entire 2500-7000 rev range. Without a turbo, that would be something like 175-195 ft-lbs for the entire 2500-7000 rpm range. That's remarkable. In my turbo project (it's 928 S4), when I want the torque curve to be flat, I need to vary the boost all over the place to compensate for the variation in the naturally aspirated torque curve.

#221

Rennlist Member

Congratulations for a fantastic road motor you've built here.

Here's a question: How did you get the naturally aspirated torque curve to be that flat? The motor seems to be making between 12 and 13 ft-lbs per psi of absolute pressure in the entire 2500-7000 rev range. Without a turbo, that would be something like 175-195 ft-lbs for the entire 2500-7000 rpm range. That's remarkable. In my turbo project (it's 928 S4), when I want the torque curve to be flat, I need to vary the boost all over the place to compensate for the variation in the naturally aspirated torque curve.

Here's a question: How did you get the naturally aspirated torque curve to be that flat? The motor seems to be making between 12 and 13 ft-lbs per psi of absolute pressure in the entire 2500-7000 rev range. Without a turbo, that would be something like 175-195 ft-lbs for the entire 2500-7000 rpm range. That's remarkable. In my turbo project (it's 928 S4), when I want the torque curve to be flat, I need to vary the boost all over the place to compensate for the variation in the naturally aspirated torque curve.

#222

Nordschleife Master

Congratulations for a fantastic road motor you've built here.

Here's a question: How did you get the naturally aspirated torque curve to be that flat? The motor seems to be making between 12 and 13 ft-lbs per psi of absolute pressure in the entire 2500-7000 rev range. Without a turbo, that would be something like 175-195 ft-lbs for the entire 2500-7000 rpm range. That's remarkable. In my turbo project (it's 928 S4), when I want the torque curve to be flat, I need to vary the boost all over the place to compensate for the variation in the naturally aspirated torque curve.

Here's a question: How did you get the naturally aspirated torque curve to be that flat? The motor seems to be making between 12 and 13 ft-lbs per psi of absolute pressure in the entire 2500-7000 rev range. Without a turbo, that would be something like 175-195 ft-lbs for the entire 2500-7000 rpm range. That's remarkable. In my turbo project (it's 928 S4), when I want the torque curve to be flat, I need to vary the boost all over the place to compensate for the variation in the naturally aspirated torque curve.

rpm, TT3 torque, TT3 boost psi, Torque per abs psi, TT3 torque rescaled to ambient, Stock 16v 3L torque

2550 250 6 12.1 178 195

2740 421 19 12.5 184 197

3050 501 25 12.6 186 200

3510 507 26 12.5 183 206

4020 509 26 12.5 184 207

4530 510 26 12.5 184 206

5070 514 25 12.9 190 205

5520 518 25 13.0 192 198

6030 502 24 13.0 191 182

6500 495 23 13.1 193 160

7050 451 22 12.3 181 130

How was this done? Is it that the intake manifold was designed to do that with the shorter runners? Or is the intake manifold tuned to give the two Helmholtz peaks at 3000 and 6500 rpm and then the camshaft fills in the hole in between? Would like to know, just to learn.

#224

#225

Nordschleife Master

Right now they are stock S4 cams timed as they came from the factory. They fall on their faces after 5000 or so rpm so a lot of what I am compensating for at high rpms is the small cams. I get that. I know that I can "rotate" the torque curve a bit with bigger cams.

Still, even with the variable geometry (stock) intake manifold I will not be anywhere as flat as TurboTim's torque curve. That torque curve is the flattest I've ever seen from 2500-7000 rpm.

Still, even with the variable geometry (stock) intake manifold I will not be anywhere as flat as TurboTim's torque curve. That torque curve is the flattest I've ever seen from 2500-7000 rpm.