VETTE TRANNY INSTALLED-SOME TESTING RESULTS AT POST 157

#108

Rennlist Member

Thread Starter

Porsche ends are not compatable with Vette ends. Different lobe design and they don't work with each other. My car will use Vette axles into Vette uprights that are modified to accept 5 x 130 lug spacing, since I already have several sets of 5 x 130 Forgelines for the car.

If we create a production kit, we will probably try work with Porsche axles and suspension. Still undecided and that design is taking a back seat to getting my car ready to go on track in about 18 days. Also, we hope to be be testing some new Delrin bushings for front lower control arms and a new upper control arm that is fully adjustable.

I'm starting to feel like a test pilot for experimental aircraft. I suspect the car will handle completely different than what I have been used to. Hopefully, I won't be gaining too much altitude.

If we create a production kit, we will probably try work with Porsche axles and suspension. Still undecided and that design is taking a back seat to getting my car ready to go on track in about 18 days. Also, we hope to be be testing some new Delrin bushings for front lower control arms and a new upper control arm that is fully adjustable.

I'm starting to feel like a test pilot for experimental aircraft. I suspect the car will handle completely different than what I have been used to. Hopefully, I won't be gaining too much altitude.

#109

Drifting

Hi Larry,

I don't quite understand when you say they aren't compatible with each other? U joints should be run in pairs, but CVs don't care what they are attached to since they are constant velocity by nature. What I meant was have a completely custom shaft that was splined differently on each end to deal with the different joints. Maybe I'm missing something.

I don't quite understand when you say they aren't compatible with each other? U joints should be run in pairs, but CVs don't care what they are attached to since they are constant velocity by nature. What I meant was have a completely custom shaft that was splined differently on each end to deal with the different joints. Maybe I'm missing something.

#110

Exactly. The early axle shafts are just rods with circlips holding the CVs on. You could use them and put different CVs on each side.

Or is the Vette axle set too short?

Or is the Vette axle set too short?

#111

Doesn't the 928 manual trans use 930 CV joints inner and outboard?

You can take a stock C5 axle and cut the outboard shaft area to length and respline it to the (presumeable 930) CV joint 28 count spline....

You can take a stock C5 axle and cut the outboard shaft area to length and respline it to the (presumeable 930) CV joint 28 count spline....

#113

That depends on the C5 inner CV spline size/count vs. the 928 CV spline count/size. The 930 CV's are also 28mm length spline interface. I'm watching this thread like a hawk because the Vette rearend to 948 swap is the last piece of the puzzle and the method would be the same.

#114

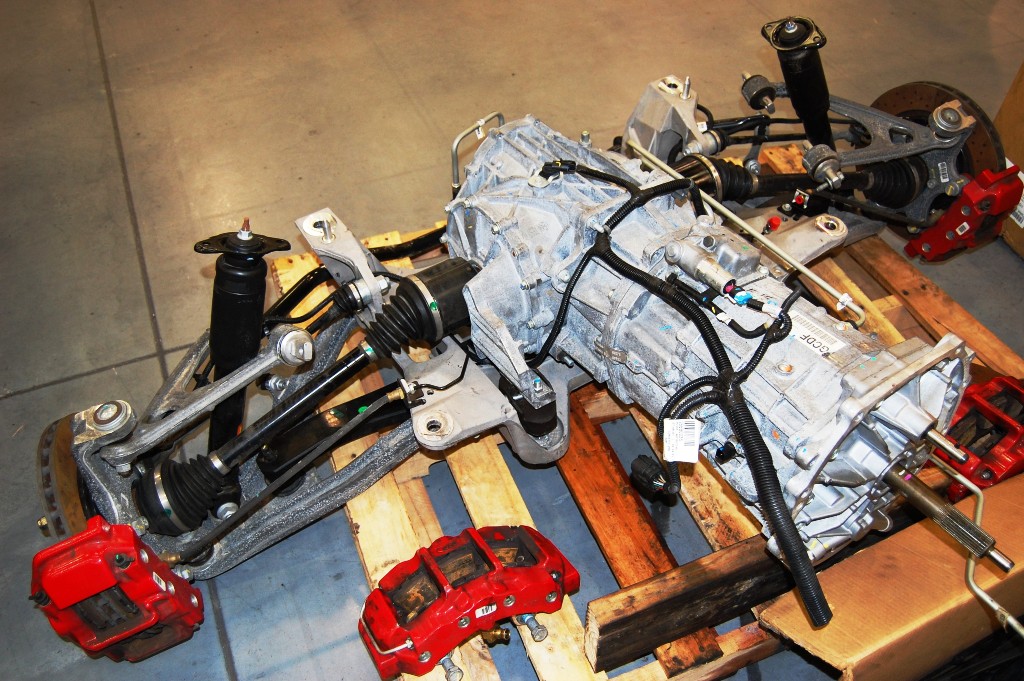

Here is the whole system. I don't see how using the upright on the 928 is a good idea. Using the trans and the half-shafts and positioning them correctly using either the TT from the vette or our TT IS a good idea.

#115

Rennlist Member

Thread Starter

Think of it as the Vette end beats 6 per second and the Porsche beats 5 per second (not that they beat anything per second, but just as an example of how things must time equally to be compatable). CVs aren't as simple as these posts suggest.

If you had each end of the CV joint mechanism functioning exactly the same as the other end, then you could try to adapt the splines of the Vette to the Porsche, and, in theory, it should work. The length won't be correct, so a custom CV is required. As the axles are made of hardened steel, machining them to new specs is not likely.

If you had each end of the CV joint mechanism functioning exactly the same as the other end, then you could try to adapt the splines of the Vette to the Porsche, and, in theory, it should work. The length won't be correct, so a custom CV is required. As the axles are made of hardened steel, machining them to new specs is not likely.

#116

Timing? I'm not getting that. You'll have to explain that a bit differently. The Vette trans is in the car, and that end is the way its shown. Its turning in the axle flange.

It has a universal joint so the axle itself can move with the unsprung part of the suspension and hub. The shaft comes out and attaches to the porsche hub. How it does that is up to the user. I am confused as to why it matters HOW it spins. Are you talking about CV bind?

I can see this being a bit more challenging if you want the 928 hub to be the late hub with ABS with the welded CV.

It has a universal joint so the axle itself can move with the unsprung part of the suspension and hub. The shaft comes out and attaches to the porsche hub. How it does that is up to the user. I am confused as to why it matters HOW it spins. Are you talking about CV bind?

I can see this being a bit more challenging if you want the 928 hub to be the late hub with ABS with the welded CV.

#117

I just built my own custom axles and yes the new 4340 chromoly steel axles are harder/stronger, but can be cut with Tungsten Carbide cutters....BTDT

My question is what is the spline specs for the inner C5/C6 CV joint?

Specifically the spline pattern size of the C5 CV joint races....

http://forums.corvetteforum.com/c5-t...int-101-a.html

My question is what is the spline specs for the inner C5/C6 CV joint?

Specifically the spline pattern size of the C5 CV joint races....

http://forums.corvetteforum.com/c5-t...int-101-a.html

Last edited by xschop; 04-25-2011 at 05:34 PM.

#118

Rennlist Member

Thread Starter

I'm going by what our CV guy is saying. Right or wrong, it has been confirmed by several others who know a lot more than I do about CV's. I'm pretty sure a couple of them are following this thread and may want to chime in on the issue.

#119

I'd sure like to learn.

#120

Phasing is true for Universal joints and there is a smaller maximum velocity angle allowed before quick failure. CV joints are a different story and have larger operating angles. The 930 CV joint is 25 degrees and can take alot of power and torque.