Please help me get this clutch working properly!!

#46

Nordschleife Master

Originally Posted by GlenL

Assuming what works for you on this will work for others is a huge mistake. The factory ditched the design because it couldn't be serviced. There's a hint that it takes something more than any one written procedure to adjust the intermediate plate successfully.

I'm standing on the above statement. Insisting that 1mm works, or 0.75mm, or spacing the discs or, yes, cranking them back will absolutely work is FALSE.

Ya gotta try a few things and see what works. I do believe that getting the hydraulics right is critical. Plus having a good ball stud bushing. The arm has got to yank the pressure plate back strongly. Getting all the air out is tricky. (The tricks are listed elsewhere.)

Here's my best tip:

Don't take the car off the stands until it goes into first and reverse without grinding.

#47

Rennlist Member

Bob, We're getting along fine.

Glen, That's a great tip. One thing I would add, give it up to a second or two of clutch-in before trying reverse, especially on early cars with no reverse synchro.

Mark, to your credit you are absolutely right that in adjusting the clutch we must take care that BOTH the front and rear discs release, and you would be correct if you said that pushing the forks all the way back MAY not work in all cases. Note that I use the term "Fork" from the WSM -- AKA "H" adjusters. But you have said at various times that it DOESN'T work, it CAN'T work, it NEVER works. When people say it did work for them you brush it off as an anomaly. I encourage you to examine the question, "WHY does it work for some and not for others?".

To highlight where you and I disagree on that point, Here is what I tell people about pushing the forks all the way to the rear:

"It SHOULD work with NEW PARTS, but probably won't if your forks are worn because in that case the 'all the way back' approach may cause your rear disk to drag."

I will be referencing these images later in the post:

To answer your question about technical mistakes and confusing points, there are two more glaring inaccuracies just in your last post:

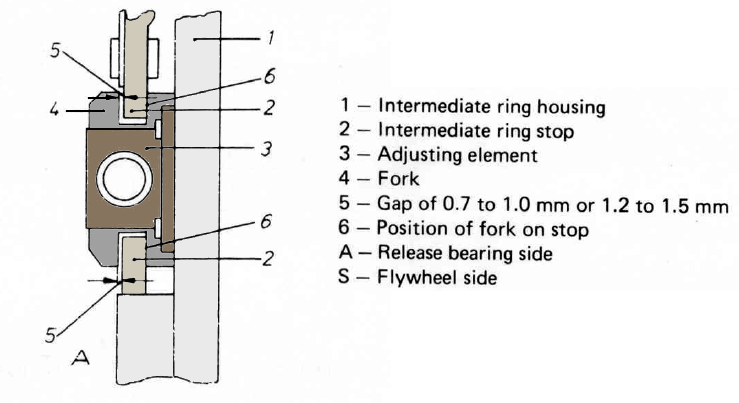

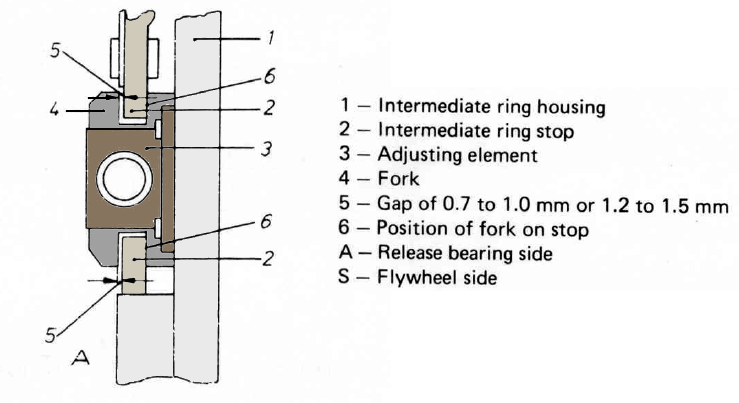

1. The forks wear in TWO ways, one relates to their holding power, one relates to how much movement they permit the IP before the "holding power" becomes a factor The latter case is the one you seem to be overlooking; referencing the line drawing above I am talking about wear primarily at point (5) but also at point (6). Remember, with the clutch disengaged you have the IP supported ONLY by the three spring strips and the contact when gap (5) closes. This contact is relatively light but the IP is balanced imperfectly(as is the whole clutch pack) so it must vibrate, and this vibration is what causes the wear at the contact area. The wear at point 6 occurs only when the clutch is engaged, and while it is a minuscule amount of wear it is present(look at your parts).

2. You state that the design intent was not to have the forks move forward as the clutch wears; this contradicts the WSM, Greg Brown and other expert's statements, and my own analysis. Note in the above pic, point (6) is "position of fork on stop". Now, if it is true as stated in the WSM text adjacent to the above line drawing that "[The gap] alone will guarantee proper function of the clutch and stop brackets", let's leave aside the couple of interpretations we've heard of what exactly that is supposed to mean and instead focus on the question, "Well then, what is the purpose of stop 6, and why did they take pains to point it out twice?" A careful analysis of the part will show that that end of the "H" has nothing whatsoever to do with clutch release. It can't. So why is it there? why point it out? Well, the folks who engineered this car rarely included features on parts that had no purpose. So let's think about how the system would behave without it. Let's say you start with a 1mm gap, all new parts. Somewhere down the road, due to the wear on the disk, the flywheel and the IP, the IP now sits 1mm further forward with the clutch engaged(measured from some datum not subject to wear, perhaps the rivet head on the spring). Now the gap (5) at the fork is 2mm. Presumably the rear disk, the PP, and the back surface of the IP have also worn in this time so it should still release OK, but it will feel sloppy; you now have to move the pedal twice as far before the rear disk disengages. So they added a feature to the part, the stop at (6) so that as the front disk wears the fork is pushed forward so the 1mm gap at (5) is maintained and the feel of the clutch is more consistent throughout its life.

3. The "Devek method" is not "Pull the forks all the way back".

Earlier in the thread, you indicated the ball cup was not worth checking. What an individual will check during diagnosis varies, but I think you underestimate the importance of this part, especially considering how easy it is to check and/or replace.

Regarding inaccuracies and confusion in the other thread that you linked, here goes. This is not exhaustive due to time constraints on my end.

Note that on an almost brand new IP(The PO put 50 miles on it while struggling with clutch release, it didn't fix his problem, so he sold it to me) there is about a 1.2mm gap, with the fork against stop (6). New parts may vary due to casting and stamping differences, but I'm going to go out on a limb here and say there's no frickin' way a new one has a 2mm gap.

Normally I don't pick through people's posts like this, I just remember seeing the errors and seeing how you appeared to ignore when people pointed them out, so I stayed out of it. When I did go back and pick through I had no trouble finding them.

The reason I decided to speak up here is because I see you making absolute black-and white "statements of fact" that are either not factual, not always factual because of MY differences, or not always factual because of differences in wear.

Anyway... onward.

Other thread

Post #24 At this point you had it right, the fork can move forward as the front disk wears... I don't know what changed your mind.

Post #26 3-4mm - this is WORN - pic shows wear(As i read further I realized that this was in reference to the slot and pin on the fork, not the gap, even though in this post you specifically reference a 3-4mm gap. Nevertheless it's confusing).

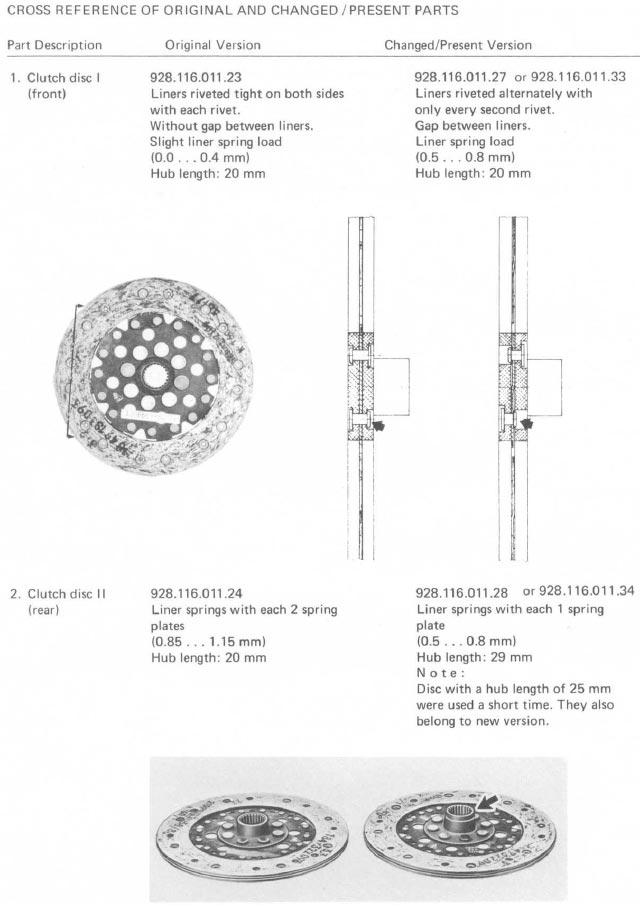

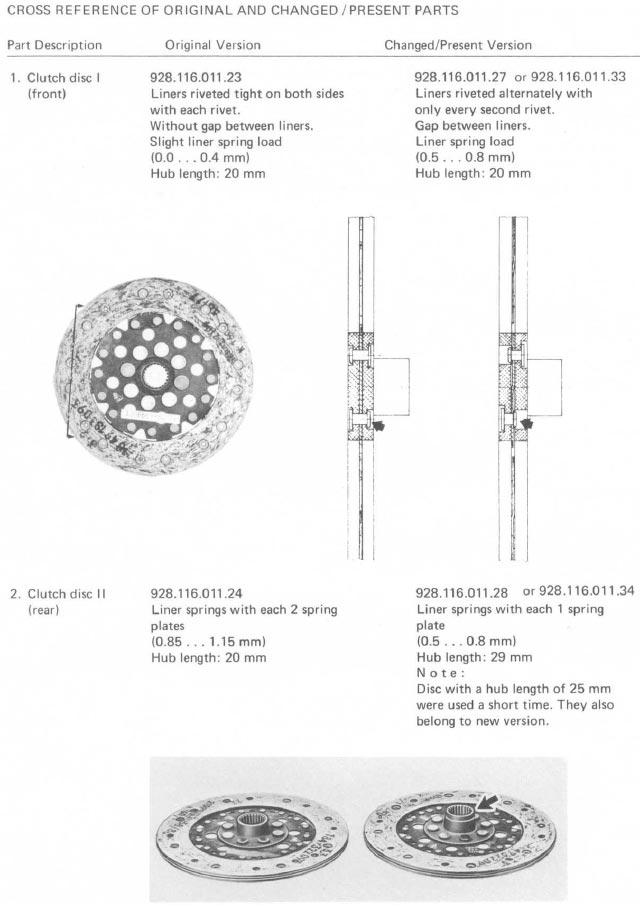

Post #38 "It only moves back with the force of the springs of the intermediate plate," No, look at the WSM description of the clutch plates posted above. The very early cars like mine have a very light "spring load", 0-0.4mm; later cars have more "spring load", 0.5-0.8mm. So the front friction disk itself helps push the intermediate plate away from the flywheel. Note that this may be up to .8mm, so if someone has this disk variant and it is at the upper spec for "spring load", then your recommendation of setting the gap to 0.7mm-1mm could result in a range of outcomes, from "it won't disengage" to "it only disengages by 0.2mm". Since this is a technical innacuracy that could cause someone problems, I thought it worth pointing out.

Post #55 "The reason for the adjustement, is that you would need to colapse the forks to the flywheel if the discs were worn badly, as the gap would grow out of spec. until it hit the bottom of the adjuster and then would not be able to apply pressure on the flywheel." I discussed this above. This is one of the reasons why Greg suggested a bit of lube on the forks, because the PP NEEDS to be able to overcome this friction.

Post #63 "all you need is .5 to 1mm and it will release itself" Due to the springs in the front disk, you need more. Do you have the correct front disk in your setup?

Post#64 Now you say 2mm gap -- this is still worn.

Post #64 "you only need less than 1mm for the intermedaite plate to release from the flywheel" Springs in front disk...

Post #64 "the intermediate plate FLOATs in the fork window. that window, doesnt wear or move, UNLESS it is too far rearward," No, it wears both in the engaged and disengaged position(usually)

Post #84 "Tell me if im reading it correctly. when the intermediate plate is pressing on the flywheel and front disc, and the adjustment is correct (less than 1mm gap on the forks) the spring pressure is the only thing that will retract the int. plate from the flywheel and disc. if there was no spring pressure, than it would continue to drag a bit." No, springs in clutch disk.

Post #90 "there is nothing to force the adjusters forward when the clutch is released (let out)." The "H" is forced forward when gap #6 is zero and the PP/IP continue to move forward.

Greg in post #119: "The forks wear"

Post #121 - You refute this by again pointing to the dimensions of yor worn pieces

Post #124 Greg patiently explains how the forks wear.

Post #127 Again you go back to your worn adjusters to try to guess about the design intent.

Post #136 you find that the actual gap at the "H" is 1.5mm. This still indicates wear.

Post #141 You gloss over a different gap measurement as a MY difference, again ignoring that these parts wear.

------------------------------------------

Let's not turn this into another argument thread. If you disagree about the technical points, then disagree and let's move on. I know that we both like to make accurate information available. I don't think that you want to disseminate wrong information but I think you get excited at having found something that works and make simplistic statements that don't take into account the many unknown variables. You know my history. You can look at my build and identify anything that might have been overlooked. Flybry is new here, we don't know if his clutch is a month old or 25 years old. It's probably a mix.

It seems that a good way to cover the contingencies would be to say, "move the forks all the way back and if the gap is more than ~1-1.2mm then close it down to that dimension. If at that dimension the front disk cannot be wiggled with a thin screwdriver with the clutch disengaged, open the gap .2mm and try again, repeat until you can wiggle the front disk but the gap should not be more than 1.5mm".

Glen, That's a great tip. One thing I would add, give it up to a second or two of clutch-in before trying reverse, especially on early cars with no reverse synchro.

Mark, to your credit you are absolutely right that in adjusting the clutch we must take care that BOTH the front and rear discs release, and you would be correct if you said that pushing the forks all the way back MAY not work in all cases. Note that I use the term "Fork" from the WSM -- AKA "H" adjusters. But you have said at various times that it DOESN'T work, it CAN'T work, it NEVER works. When people say it did work for them you brush it off as an anomaly. I encourage you to examine the question, "WHY does it work for some and not for others?".

To highlight where you and I disagree on that point, Here is what I tell people about pushing the forks all the way to the rear:

"It SHOULD work with NEW PARTS, but probably won't if your forks are worn because in that case the 'all the way back' approach may cause your rear disk to drag."

I will be referencing these images later in the post:

To answer your question about technical mistakes and confusing points, there are two more glaring inaccuracies just in your last post:

1. The forks wear in TWO ways, one relates to their holding power, one relates to how much movement they permit the IP before the "holding power" becomes a factor The latter case is the one you seem to be overlooking; referencing the line drawing above I am talking about wear primarily at point (5) but also at point (6). Remember, with the clutch disengaged you have the IP supported ONLY by the three spring strips and the contact when gap (5) closes. This contact is relatively light but the IP is balanced imperfectly(as is the whole clutch pack) so it must vibrate, and this vibration is what causes the wear at the contact area. The wear at point 6 occurs only when the clutch is engaged, and while it is a minuscule amount of wear it is present(look at your parts).

2. You state that the design intent was not to have the forks move forward as the clutch wears; this contradicts the WSM, Greg Brown and other expert's statements, and my own analysis. Note in the above pic, point (6) is "position of fork on stop". Now, if it is true as stated in the WSM text adjacent to the above line drawing that "[The gap] alone will guarantee proper function of the clutch and stop brackets", let's leave aside the couple of interpretations we've heard of what exactly that is supposed to mean and instead focus on the question, "Well then, what is the purpose of stop 6, and why did they take pains to point it out twice?" A careful analysis of the part will show that that end of the "H" has nothing whatsoever to do with clutch release. It can't. So why is it there? why point it out? Well, the folks who engineered this car rarely included features on parts that had no purpose. So let's think about how the system would behave without it. Let's say you start with a 1mm gap, all new parts. Somewhere down the road, due to the wear on the disk, the flywheel and the IP, the IP now sits 1mm further forward with the clutch engaged(measured from some datum not subject to wear, perhaps the rivet head on the spring). Now the gap (5) at the fork is 2mm. Presumably the rear disk, the PP, and the back surface of the IP have also worn in this time so it should still release OK, but it will feel sloppy; you now have to move the pedal twice as far before the rear disk disengages. So they added a feature to the part, the stop at (6) so that as the front disk wears the fork is pushed forward so the 1mm gap at (5) is maintained and the feel of the clutch is more consistent throughout its life.

3. The "Devek method" is not "Pull the forks all the way back".

Earlier in the thread, you indicated the ball cup was not worth checking. What an individual will check during diagnosis varies, but I think you underestimate the importance of this part, especially considering how easy it is to check and/or replace.

Regarding inaccuracies and confusion in the other thread that you linked, here goes. This is not exhaustive due to time constraints on my end.

Note that on an almost brand new IP(The PO put 50 miles on it while struggling with clutch release, it didn't fix his problem, so he sold it to me) there is about a 1.2mm gap, with the fork against stop (6). New parts may vary due to casting and stamping differences, but I'm going to go out on a limb here and say there's no frickin' way a new one has a 2mm gap.

Normally I don't pick through people's posts like this, I just remember seeing the errors and seeing how you appeared to ignore when people pointed them out, so I stayed out of it. When I did go back and pick through I had no trouble finding them.

The reason I decided to speak up here is because I see you making absolute black-and white "statements of fact" that are either not factual, not always factual because of MY differences, or not always factual because of differences in wear.

Anyway... onward.

Other thread

Post #24 At this point you had it right, the fork can move forward as the front disk wears... I don't know what changed your mind.

Post #26 3-4mm - this is WORN - pic shows wear(As i read further I realized that this was in reference to the slot and pin on the fork, not the gap, even though in this post you specifically reference a 3-4mm gap. Nevertheless it's confusing).

Post #38 "It only moves back with the force of the springs of the intermediate plate," No, look at the WSM description of the clutch plates posted above. The very early cars like mine have a very light "spring load", 0-0.4mm; later cars have more "spring load", 0.5-0.8mm. So the front friction disk itself helps push the intermediate plate away from the flywheel. Note that this may be up to .8mm, so if someone has this disk variant and it is at the upper spec for "spring load", then your recommendation of setting the gap to 0.7mm-1mm could result in a range of outcomes, from "it won't disengage" to "it only disengages by 0.2mm". Since this is a technical innacuracy that could cause someone problems, I thought it worth pointing out.

Post #55 "The reason for the adjustement, is that you would need to colapse the forks to the flywheel if the discs were worn badly, as the gap would grow out of spec. until it hit the bottom of the adjuster and then would not be able to apply pressure on the flywheel." I discussed this above. This is one of the reasons why Greg suggested a bit of lube on the forks, because the PP NEEDS to be able to overcome this friction.

Post #63 "all you need is .5 to 1mm and it will release itself" Due to the springs in the front disk, you need more. Do you have the correct front disk in your setup?

Post#64 Now you say 2mm gap -- this is still worn.

Post #64 "you only need less than 1mm for the intermedaite plate to release from the flywheel" Springs in front disk...

Post #64 "the intermediate plate FLOATs in the fork window. that window, doesnt wear or move, UNLESS it is too far rearward," No, it wears both in the engaged and disengaged position(usually)

Post #84 "Tell me if im reading it correctly. when the intermediate plate is pressing on the flywheel and front disc, and the adjustment is correct (less than 1mm gap on the forks) the spring pressure is the only thing that will retract the int. plate from the flywheel and disc. if there was no spring pressure, than it would continue to drag a bit." No, springs in clutch disk.

Post #90 "there is nothing to force the adjusters forward when the clutch is released (let out)." The "H" is forced forward when gap #6 is zero and the PP/IP continue to move forward.

Greg in post #119: "The forks wear"

Post #121 - You refute this by again pointing to the dimensions of yor worn pieces

Post #124 Greg patiently explains how the forks wear.

Post #127 Again you go back to your worn adjusters to try to guess about the design intent.

Post #136 you find that the actual gap at the "H" is 1.5mm. This still indicates wear.

Post #141 You gloss over a different gap measurement as a MY difference, again ignoring that these parts wear.

------------------------------------------

Let's not turn this into another argument thread. If you disagree about the technical points, then disagree and let's move on. I know that we both like to make accurate information available. I don't think that you want to disseminate wrong information but I think you get excited at having found something that works and make simplistic statements that don't take into account the many unknown variables. You know my history. You can look at my build and identify anything that might have been overlooked. Flybry is new here, we don't know if his clutch is a month old or 25 years old. It's probably a mix.

It seems that a good way to cover the contingencies would be to say, "move the forks all the way back and if the gap is more than ~1-1.2mm then close it down to that dimension. If at that dimension the front disk cannot be wiggled with a thin screwdriver with the clutch disengaged, open the gap .2mm and try again, repeat until you can wiggle the front disk but the gap should not be more than 1.5mm".

#48

Rennlist Member

I think there is a lot of misconceptions listed below in your post.

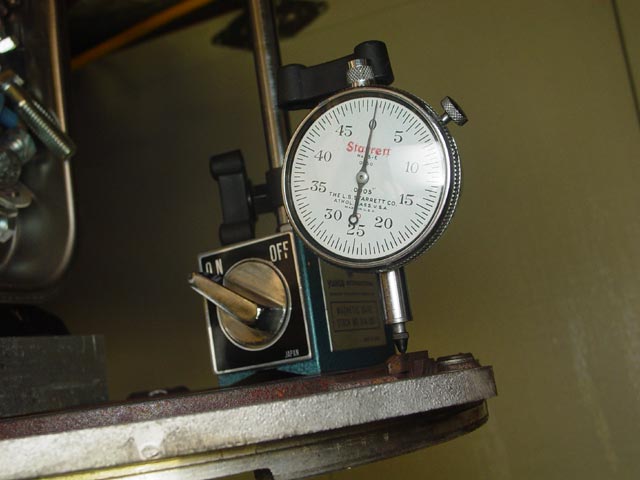

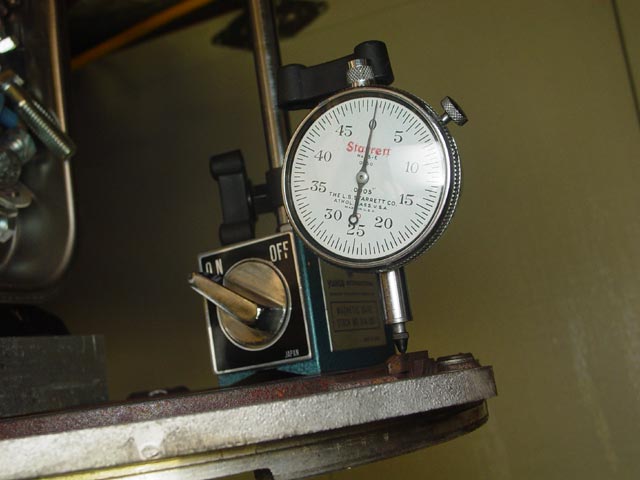

1. the forks (ex calling them "H"s) do not wear. I have provided a picture of a 79 IP. you can see, those tabs on the sides dont wear. I didnt have a good measurement before, as it looked like 2-4 mm, when actuality, the max gap is 1.5mm the setting is near .75mm. thats all you need to have the intermediate plate in the proper "neutral" position. Now, all IPs Ive worked and seen all have this full range for the fork adjusters. below is a picture of what a 1mm gap looks like . That is a feeler gauge set at 1mm

2. The you are missing the purpose around the H (forks). It limits the rear ward movement of the intermediate plate as to not touch the pressure plate disc but also allow for the release of the Intermediate plate off the flyweel disc. It doesnt matter if there is a spring loaded front disc or not, the main movment of the disc is due to the flat springs.

By the way, you must of missed the part where even Greg Brown had an "Ah ha" moment after my trials and tribulations making the INt. Plate work.

Lubing the adjusters, is NOT a good thing. he now agrees

they dont wear or are subjected to any real forces during their action. However a big torquey motor can start twisting the intermediate plate , rotating it and tweeking on the "H" fork adjusters. as the forkes get old their holding ability is compromised.

3. What I meant with the adjustment ability of the Forks front ward as the clutch disc wears, is an adjustment that would be done manually or by the pressure of the pressure plate. as the front disc wears , the gap of the forks would increase until they bottom out. This would allow a larger gap to be used.

Keep in mind the H adjusters is really seting a neutral point for the floating disc .

4. Yes, if the "All the way back" technique works, it only means that the pull back lever mechanism is allowing the front disc to be released. there is a chance that it wont work. There is also a chance that you could lessen pressure on the front disc, as when the disc wears, the pressure plate cant always move the H forks forward, so you could have less friction and clutch slip

5. the .75 -1mm gap will work almost always. and why wouldnt it? all the entire mechanism is really doing is just pulling back the intermediate plate from the flywheel, but not too far as it could remain in contact with the pressure plate (as limited by the Forks)

6. the intermediate plate when the clutch is engaged, is only resting with flat spring pressure on the edges of the H forks. when engaged, it is floating and NOTHING is touching the forks.

7. Yes the clutch disc has springs, but if it is fully expanded by a fraction of a mm, then there is no real force on it. Yes I have the right discs and the front one has the sligth spring action. about 1mm gap alows for full release any more becomes diffucult to shift. any less and the same thing happens. that is probably why there is a range of .5 to 1mm and up to 1.5mm.

again, Ive adjusted a few of these now. they all said that my bigger torque engine would murder the Forks, but 12 races later, the clutch is working well. occasionally i need to adust, as the Forks are old and move too easily. street driving is no problem. racing tends to tweak the intermediate plate. pressing the H adjusters rear ward. Its never undriveable, but I like it to be perfect around the street . racing has never been a problem as the force even a little dragging causes, doesnt effect smooth shifts (as you can hear from my race videos)

in a nut shell, if you have shift problems and you pull off the bell housing, just move the adjuster forward slightly and close the gap. go down to 1mm and futher if needed. as Glen says, keep the car on the jack stands.

Onward!

1. the forks (ex calling them "H"s) do not wear. I have provided a picture of a 79 IP. you can see, those tabs on the sides dont wear. I didnt have a good measurement before, as it looked like 2-4 mm, when actuality, the max gap is 1.5mm the setting is near .75mm. thats all you need to have the intermediate plate in the proper "neutral" position. Now, all IPs Ive worked and seen all have this full range for the fork adjusters. below is a picture of what a 1mm gap looks like . That is a feeler gauge set at 1mm

2. The you are missing the purpose around the H (forks). It limits the rear ward movement of the intermediate plate as to not touch the pressure plate disc but also allow for the release of the Intermediate plate off the flyweel disc. It doesnt matter if there is a spring loaded front disc or not, the main movment of the disc is due to the flat springs.

By the way, you must of missed the part where even Greg Brown had an "Ah ha" moment after my trials and tribulations making the INt. Plate work.

Lubing the adjusters, is NOT a good thing. he now agrees

they dont wear or are subjected to any real forces during their action. However a big torquey motor can start twisting the intermediate plate , rotating it and tweeking on the "H" fork adjusters. as the forkes get old their holding ability is compromised.

3. What I meant with the adjustment ability of the Forks front ward as the clutch disc wears, is an adjustment that would be done manually or by the pressure of the pressure plate. as the front disc wears , the gap of the forks would increase until they bottom out. This would allow a larger gap to be used.

Keep in mind the H adjusters is really seting a neutral point for the floating disc .

4. Yes, if the "All the way back" technique works, it only means that the pull back lever mechanism is allowing the front disc to be released. there is a chance that it wont work. There is also a chance that you could lessen pressure on the front disc, as when the disc wears, the pressure plate cant always move the H forks forward, so you could have less friction and clutch slip

5. the .75 -1mm gap will work almost always. and why wouldnt it? all the entire mechanism is really doing is just pulling back the intermediate plate from the flywheel, but not too far as it could remain in contact with the pressure plate (as limited by the Forks)

6. the intermediate plate when the clutch is engaged, is only resting with flat spring pressure on the edges of the H forks. when engaged, it is floating and NOTHING is touching the forks.

7. Yes the clutch disc has springs, but if it is fully expanded by a fraction of a mm, then there is no real force on it. Yes I have the right discs and the front one has the sligth spring action. about 1mm gap alows for full release any more becomes diffucult to shift. any less and the same thing happens. that is probably why there is a range of .5 to 1mm and up to 1.5mm.

again, Ive adjusted a few of these now. they all said that my bigger torque engine would murder the Forks, but 12 races later, the clutch is working well. occasionally i need to adust, as the Forks are old and move too easily. street driving is no problem. racing tends to tweak the intermediate plate. pressing the H adjusters rear ward. Its never undriveable, but I like it to be perfect around the street . racing has never been a problem as the force even a little dragging causes, doesnt effect smooth shifts (as you can hear from my race videos)

in a nut shell, if you have shift problems and you pull off the bell housing, just move the adjuster forward slightly and close the gap. go down to 1mm and futher if needed. as Glen says, keep the car on the jack stands.

Onward!

Bob, We're getting along fine.

To highlight where you and I disagree on that point, Here is what I tell people about pushing the forks all the way to the rear:

"It SHOULD work with NEW PARTS, but probably won't if your forks are worn because in that case the 'all the way back' approach may cause your rear disk to drag."

To answer your question about technical mistakes and confusing points, there are two more glaring inaccuracies just in your last post:

1. The forks wear in TWO ways, one relates to their holding power, one relates to how much movement they permit the IP before the "holding power" becomes a factor The latter case is the one you seem to be overlooking; referencing the line drawing above I am talking about wear primarily at point (5) but also at point (6). Remember, with the clutch disengaged you have the IP supported ONLY by the three spring strips and the contact when gap (5) closes. This contact is relatively light but the IP is balanced imperfectly(as is the whole clutch pack) so it must vibrate, and this vibration is what causes the wear at the contact area. The wear at point 6 occurs only when the clutch is engaged, and while it is a minuscule amount of wear it is present(look at your parts).

2. You state that the design intent was not to have the forks move forward as the clutch wears; this contradicts the WSM, Greg Brown and other expert's statements, and my own analysis. Note in the above pic, point (6) is "position of fork on stop". Now, if it is true as stated in the WSM text adjacent to the above line drawing that "[The gap] alone will guarantee proper function of the clutch and stop brackets", let's leave aside the couple of interpretations we've heard of what exactly that is supposed to mean and instead focus on the question, "Well then, what is the purpose of stop 6, and why did they take pains to point it out twice?" A careful analysis of the part will show that that end of the "H" has nothing whatsoever to do with clutch release. It can't. So why is it there? why point it out? Well, the folks who engineered this car rarely included features on parts that had no purpose. So let's think about how the system would behave without it. Let's say you start with a 1mm gap, all new parts. Somewhere down the road, due to the wear on the disk, the flywheel and the IP, the IP now sits 1mm further forward with the clutch engaged(measured from some datum not subject to wear, perhaps the rivet head on the spring). Now the gap (5) at the fork is 2mm. Presumably the rear disk, the PP, and the back surface of the IP have also worn in this time so it should still release OK, but it will feel sloppy; you now have to move the pedal twice as far before the rear disk disengages. So they added a feature to the part, the stop at (6) so that as the front disk wears the fork is pushed forward so the 1mm gap at (5) is maintained and the feel of the clutch is more consistent throughout its life.

3. The "Devek method" is not "Pull the forks all the way back".

Earlier in the thread, you indicated the ball cup was not worth checking. What an individual will check during diagnosis varies, but I think you underestimate the importance of this part, especially considering how easy it is to check and/or replace.

Regarding inaccuracies and confusion in the other thread that you linked, here goes. This is not exhaustive due to time constraints on my end.

Note that on an almost brand new IP(The PO put 50 miles on it while struggling with clutch release, it didn't fix his problem, so he sold it to me) there is about a 1.2mm gap, with the fork against stop (6). New parts may vary due to casting and stamping differences, but I'm going to go out on a limb here and say there's no frickin' way a new one has a 2mm gap.

Normally I don't pick through people's posts like this, I just remember seeing the errors and seeing how you appeared to ignore when people pointed them out, so I stayed out of it. When I did go back and pick through I had no trouble finding them.

The reason I decided to speak up here is because I see you making absolute black-and white "statements of fact" that are either not factual, not always factual because of MY differences, or not always factual because of differences in wear.

Anyway... onward.

Other thread

Post #24 At this point you had it right, the fork can move forward as the front disk wears... I don't know what changed your mind.

Post #26 3-4mm - this is WORN - pic shows wear(As i read further I realized that this was in reference to the slot and pin on the fork, not the gap, even though in this post you specifically reference a 3-4mm gap. Nevertheless it's confusing).

Post #38 "It only moves back with the force of the springs of the intermediate plate," No, look at the WSM description of the clutch plates posted above. The very early cars like mine have a very light "spring load", 0-0.4mm; later cars have more "spring load", 0.5-0.8mm. So the front friction disk itself helps push the intermediate plate away from the flywheel. Note that this may be up to .8mm, so if someone has this disk variant and it is at the upper spec for "spring load", then your recommendation of setting the gap to 0.7mm-1mm could result in a range of outcomes, from "it won't disengage" to "it only disengages by 0.2mm". Since this is a technical innacuracy that could cause someone problems, I thought it worth pointing out.

Post #55 "The reason for the adjustement, is that you would need to colapse the forks to the flywheel if the discs were worn badly, as the gap would grow out of spec. until it hit the bottom of the adjuster and then would not be able to apply pressure on the flywheel." I discussed this above. This is one of the reasons why Greg suggested a bit of lube on the forks, because the PP NEEDS to be able to overcome this friction.

Post #63 "all you need is .5 to 1mm and it will release itself" Due to the springs in the front disk, you need more. Do you have the correct front disk in your setup?

Post#64 Now you say 2mm gap -- this is still worn.

Post #64 "you only need less than 1mm for the intermedaite plate to release from the flywheel" Springs in front disk...

Post #64 "the intermediate plate FLOATs in the fork window. that window, doesnt wear or move, UNLESS it is too far rearward," No, it wears both in the engaged and disengaged position(usually)

Post #84 "Tell me if im reading it correctly. when the intermediate plate is pressing on the flywheel and front disc, and the adjustment is correct (less than 1mm gap on the forks) the spring pressure is the only thing that will retract the int. plate from the flywheel and disc. if there was no spring pressure, than it would continue to drag a bit." No, springs in clutch disk.

Post #90 "there is nothing to force the adjusters forward when the clutch is released (let out)." The "H" is forced forward when gap #6 is zero and the PP/IP continue to move forward.

Greg in post #119: "The forks wear"

Post #121 - You refute this by again pointing to the dimensions of yor worn pieces

Post #124 Greg patiently explains how the forks wear.

Post #127 Again you go back to your worn adjusters to try to guess about the design intent.

Post #136 you find that the actual gap at the "H" is 1.5mm. This still indicates wear.

Post #141 You gloss over a different gap measurement as a MY difference, again ignoring that these parts wear.

------------------------------------------

Let's not turn this into another argument thread. If you disagree about the technical points, then disagree and let's move on. I know that we both like to make accurate information available. I don't think that you want to disseminate wrong information but I think you get excited at having found something that works and make simplistic statements that don't take into account the many unknown variables. You know my history. You can look at my build and identify anything that might have been overlooked. Flybry is new here, we don't know if his clutch is a month old or 25 years old. It's probably a mix.

It seems that a good way to cover the contingencies would be to say, "move the forks all the way back and if the gap is more than ~1-1.2mm then close it down to that dimension. If at that dimension the front disk cannot be wiggled with a thin screwdriver with the clutch disengaged, open the gap .2mm and try again, repeat until you can wiggle the front disk but the gap should not be more than 1.5mm".

To highlight where you and I disagree on that point, Here is what I tell people about pushing the forks all the way to the rear:

"It SHOULD work with NEW PARTS, but probably won't if your forks are worn because in that case the 'all the way back' approach may cause your rear disk to drag."

To answer your question about technical mistakes and confusing points, there are two more glaring inaccuracies just in your last post:

1. The forks wear in TWO ways, one relates to their holding power, one relates to how much movement they permit the IP before the "holding power" becomes a factor The latter case is the one you seem to be overlooking; referencing the line drawing above I am talking about wear primarily at point (5) but also at point (6). Remember, with the clutch disengaged you have the IP supported ONLY by the three spring strips and the contact when gap (5) closes. This contact is relatively light but the IP is balanced imperfectly(as is the whole clutch pack) so it must vibrate, and this vibration is what causes the wear at the contact area. The wear at point 6 occurs only when the clutch is engaged, and while it is a minuscule amount of wear it is present(look at your parts).

2. You state that the design intent was not to have the forks move forward as the clutch wears; this contradicts the WSM, Greg Brown and other expert's statements, and my own analysis. Note in the above pic, point (6) is "position of fork on stop". Now, if it is true as stated in the WSM text adjacent to the above line drawing that "[The gap] alone will guarantee proper function of the clutch and stop brackets", let's leave aside the couple of interpretations we've heard of what exactly that is supposed to mean and instead focus on the question, "Well then, what is the purpose of stop 6, and why did they take pains to point it out twice?" A careful analysis of the part will show that that end of the "H" has nothing whatsoever to do with clutch release. It can't. So why is it there? why point it out? Well, the folks who engineered this car rarely included features on parts that had no purpose. So let's think about how the system would behave without it. Let's say you start with a 1mm gap, all new parts. Somewhere down the road, due to the wear on the disk, the flywheel and the IP, the IP now sits 1mm further forward with the clutch engaged(measured from some datum not subject to wear, perhaps the rivet head on the spring). Now the gap (5) at the fork is 2mm. Presumably the rear disk, the PP, and the back surface of the IP have also worn in this time so it should still release OK, but it will feel sloppy; you now have to move the pedal twice as far before the rear disk disengages. So they added a feature to the part, the stop at (6) so that as the front disk wears the fork is pushed forward so the 1mm gap at (5) is maintained and the feel of the clutch is more consistent throughout its life.

3. The "Devek method" is not "Pull the forks all the way back".

Earlier in the thread, you indicated the ball cup was not worth checking. What an individual will check during diagnosis varies, but I think you underestimate the importance of this part, especially considering how easy it is to check and/or replace.

Regarding inaccuracies and confusion in the other thread that you linked, here goes. This is not exhaustive due to time constraints on my end.

Note that on an almost brand new IP(The PO put 50 miles on it while struggling with clutch release, it didn't fix his problem, so he sold it to me) there is about a 1.2mm gap, with the fork against stop (6). New parts may vary due to casting and stamping differences, but I'm going to go out on a limb here and say there's no frickin' way a new one has a 2mm gap.

Normally I don't pick through people's posts like this, I just remember seeing the errors and seeing how you appeared to ignore when people pointed them out, so I stayed out of it. When I did go back and pick through I had no trouble finding them.

The reason I decided to speak up here is because I see you making absolute black-and white "statements of fact" that are either not factual, not always factual because of MY differences, or not always factual because of differences in wear.

Anyway... onward.

Other thread

Post #24 At this point you had it right, the fork can move forward as the front disk wears... I don't know what changed your mind.

Post #26 3-4mm - this is WORN - pic shows wear(As i read further I realized that this was in reference to the slot and pin on the fork, not the gap, even though in this post you specifically reference a 3-4mm gap. Nevertheless it's confusing).

Post #38 "It only moves back with the force of the springs of the intermediate plate," No, look at the WSM description of the clutch plates posted above. The very early cars like mine have a very light "spring load", 0-0.4mm; later cars have more "spring load", 0.5-0.8mm. So the front friction disk itself helps push the intermediate plate away from the flywheel. Note that this may be up to .8mm, so if someone has this disk variant and it is at the upper spec for "spring load", then your recommendation of setting the gap to 0.7mm-1mm could result in a range of outcomes, from "it won't disengage" to "it only disengages by 0.2mm". Since this is a technical innacuracy that could cause someone problems, I thought it worth pointing out.

Post #55 "The reason for the adjustement, is that you would need to colapse the forks to the flywheel if the discs were worn badly, as the gap would grow out of spec. until it hit the bottom of the adjuster and then would not be able to apply pressure on the flywheel." I discussed this above. This is one of the reasons why Greg suggested a bit of lube on the forks, because the PP NEEDS to be able to overcome this friction.

Post #63 "all you need is .5 to 1mm and it will release itself" Due to the springs in the front disk, you need more. Do you have the correct front disk in your setup?

Post#64 Now you say 2mm gap -- this is still worn.

Post #64 "you only need less than 1mm for the intermedaite plate to release from the flywheel" Springs in front disk...

Post #64 "the intermediate plate FLOATs in the fork window. that window, doesnt wear or move, UNLESS it is too far rearward," No, it wears both in the engaged and disengaged position(usually)

Post #84 "Tell me if im reading it correctly. when the intermediate plate is pressing on the flywheel and front disc, and the adjustment is correct (less than 1mm gap on the forks) the spring pressure is the only thing that will retract the int. plate from the flywheel and disc. if there was no spring pressure, than it would continue to drag a bit." No, springs in clutch disk.

Post #90 "there is nothing to force the adjusters forward when the clutch is released (let out)." The "H" is forced forward when gap #6 is zero and the PP/IP continue to move forward.

Greg in post #119: "The forks wear"

Post #121 - You refute this by again pointing to the dimensions of yor worn pieces

Post #124 Greg patiently explains how the forks wear.

Post #127 Again you go back to your worn adjusters to try to guess about the design intent.

Post #136 you find that the actual gap at the "H" is 1.5mm. This still indicates wear.

Post #141 You gloss over a different gap measurement as a MY difference, again ignoring that these parts wear.

------------------------------------------

Let's not turn this into another argument thread. If you disagree about the technical points, then disagree and let's move on. I know that we both like to make accurate information available. I don't think that you want to disseminate wrong information but I think you get excited at having found something that works and make simplistic statements that don't take into account the many unknown variables. You know my history. You can look at my build and identify anything that might have been overlooked. Flybry is new here, we don't know if his clutch is a month old or 25 years old. It's probably a mix.

It seems that a good way to cover the contingencies would be to say, "move the forks all the way back and if the gap is more than ~1-1.2mm then close it down to that dimension. If at that dimension the front disk cannot be wiggled with a thin screwdriver with the clutch disengaged, open the gap .2mm and try again, repeat until you can wiggle the front disk but the gap should not be more than 1.5mm".

#49

Rennlist Member

1. the forks (ex calling them "H"s) do not wear. I have provided a picture of a 79 IP. you can see, those tabs on the sides dont wear. I didnt have a good measurement before, as it looked like 2-4 mm, when actuality, the max gap is 1.5mm the setting is near .75mm. thats all you need to have the intermediate plate in the proper "neutral" position. Now, all IPs Ive worked and seen all have this full range for the fork adjusters. below is a picture of what a 1mm gap looks like . That is a feeler gauge set at 1mm

2. The you are missing the purpose around the H (forks). It limits the rear ward movement of the intermediate plate as to not touch the pressure plate disc but also allow for the release of the Intermediate plate off the flyweel disc. It doesnt matter if there is a spring loaded front disc or not, the main movment of the disc is due to the flat springs.

Me: The sky is Blue

Mark: You seem to have missed the point that the sky is blue.

Me:

Boggles the mind.

By the way, you must of missed the part where even Greg Brown had an "Ah ha" moment after my trials and tribulations making the INt. Plate work.

Lubing the adjusters, is NOT a good thing. he now agrees

they dont wear or are subjected to any real forces during their action. However a big torquey motor can start twisting the intermediate plate , rotating it and tweeking on the "H" fork adjusters. as the forkes get old their holding ability is compromised.

Lubing the adjusters, is NOT a good thing. he now agrees

they dont wear or are subjected to any real forces during their action. However a big torquey motor can start twisting the intermediate plate , rotating it and tweeking on the "H" fork adjusters. as the forkes get old their holding ability is compromised.

3. What I meant with the adjustment ability of the Forks front ward as the clutch disc wears, is an adjustment that would be done manually or by the pressure of the pressure plate. as the front disc wears , the gap of the forks would increase until they bottom out. This would allow a larger gap to be used.

Keep in mind the H adjusters is really seting a neutral point for the floating disc .

Keep in mind the H adjusters is really seting a neutral point for the floating disc .

4. Yes, if the "All the way back" technique works, it only means that the pull back lever mechanism is allowing the front disc to be released. there is a chance that it wont work. There is also a chance that you could lessen pressure on the front disc, as when the disc wears, the pressure plate cant always move the H forks forward, so you could have less friction and clutch slip

7. Yes the clutch disc has springs, but if it is fully expanded by a fraction of a mm, then there is no real force on it. Yes I have the right discs and the front one has the sligth spring action. about 1mm gap alows for full release any more becomes diffucult to shift. any less and the same thing happens. that is probably why there is a range of .5 to 1mm and up to 1.5mm.

again, Ive adjusted a few of these now. they all said that my bigger torque engine would murder the Forks, but 12 races later, the clutch is working well. occasionally i need to adust, as the Forks are old and move too easily. street driving is no problem. racing tends to tweak the intermediate plate. pressing the H adjusters rear ward. Its never undriveable, but I like it to be perfect around the street . racing has never been a problem as the force even a little dragging causes, doesnt effect smooth shifts (as you can hear from my race videos)

Have you checked your own misconceptions? I have not seen you address your previous factual errors other than to repeat them, otherwise you ignore them; are we tabling that part of the discussion?

#50

Rennlist Member

Dave,

No , the H's dont wear. that picture is 1.4mm. It looks greater than it is due to the angle. But, I measured it with a feeler gauge.

Now, here are some factoids:

max gap can be 1.5m . at this point the rear H arms are resting on the back side of the INT PLATE.

If you max out the gap. (pushing them all the way back) depending on how far you can pull them, you will reduce the flat spring pressure. In fact, if you pull them back too much, you might effect how fast the INT plate can retract. the first .2mm from the disc itself, but the springs can be completely neturalized.

The range of adjustability of the H's is 4mm. when the top are flush to the int plate, compared to if they are pulled all the way back and hit the mechancal limit of the front H arms (forks) on the Int Plate.

Now, it is true there is a window of operation, but just blindly pulling them back is not the correct way to do it. in fact, it could cause other issues as the clutch disc wears, and also could create a slower release of the flywheel in a speed shift scenareo.

The only think that you are latching on to is the fact that I did mention that the gap originally was "4mm". It looked like it compared to where it should have been and where it ended up after it was adjusted correctly. However, I already said that that was a guess, not a measurement. the max window is 1.5mm. this is a mechanical limit and those ears on the Hs do not wear. You will not measure one more than 1.5mm. If you do, show us with a picture. If you cant, stop doubting what I have provided as it is sound advice, that will help others that are trying to fix their clutches.

Greg didnt post the Ah ha moment. He PM'ed me with it. Trust me, he is adjusting them a little differently now!

you also are confusing the "demo" Int plate from '79 where I did all my experimenting, and the one on the car which is in GREAT shape.

Also, you might want to explain to me what the H's and their arm limits are for. Im not talking past you on that, i might just missed your point.

To your last point. Yes, if you have a little very small gap. .5mm, it could be too close, but certainly 1mm will make the clutch work fine and release from the flywheel. It has to. It's how it is designed. Full press rearward adustment has a MUCH greater risk of an issue from not releasing from the pressure plate AND relieves effectiveness of the flat springs.

What I have found on more than a few cars now, is that with no gap or one less than .5mm, you keep pressure on the front disc and flywheel. too far, more than 1mm or so, and the pressure plate doesnt move back far enough to release contact from the INT plate and disc. more clutch slave cylinder movement and you might break it free.

I havent told anyone to avoid replaceing worn bushings on the ARM. what im saying, is if it is adjusted properly, the clutch will still work fine, albiet, you will narrow its operational window by having less total motion.Kind of like not being able to push the clutch all the way to the floor. (something like this as an effect)

mk

No , the H's dont wear. that picture is 1.4mm. It looks greater than it is due to the angle. But, I measured it with a feeler gauge.

Now, here are some factoids:

max gap can be 1.5m . at this point the rear H arms are resting on the back side of the INT PLATE.

If you max out the gap. (pushing them all the way back) depending on how far you can pull them, you will reduce the flat spring pressure. In fact, if you pull them back too much, you might effect how fast the INT plate can retract. the first .2mm from the disc itself, but the springs can be completely neturalized.

The range of adjustability of the H's is 4mm. when the top are flush to the int plate, compared to if they are pulled all the way back and hit the mechancal limit of the front H arms (forks) on the Int Plate.

Now, it is true there is a window of operation, but just blindly pulling them back is not the correct way to do it. in fact, it could cause other issues as the clutch disc wears, and also could create a slower release of the flywheel in a speed shift scenareo.

The only think that you are latching on to is the fact that I did mention that the gap originally was "4mm". It looked like it compared to where it should have been and where it ended up after it was adjusted correctly. However, I already said that that was a guess, not a measurement. the max window is 1.5mm. this is a mechanical limit and those ears on the Hs do not wear. You will not measure one more than 1.5mm. If you do, show us with a picture. If you cant, stop doubting what I have provided as it is sound advice, that will help others that are trying to fix their clutches.

Greg didnt post the Ah ha moment. He PM'ed me with it. Trust me, he is adjusting them a little differently now!

you also are confusing the "demo" Int plate from '79 where I did all my experimenting, and the one on the car which is in GREAT shape.

Also, you might want to explain to me what the H's and their arm limits are for. Im not talking past you on that, i might just missed your point.

To your last point. Yes, if you have a little very small gap. .5mm, it could be too close, but certainly 1mm will make the clutch work fine and release from the flywheel. It has to. It's how it is designed. Full press rearward adustment has a MUCH greater risk of an issue from not releasing from the pressure plate AND relieves effectiveness of the flat springs.

What I have found on more than a few cars now, is that with no gap or one less than .5mm, you keep pressure on the front disc and flywheel. too far, more than 1mm or so, and the pressure plate doesnt move back far enough to release contact from the INT plate and disc. more clutch slave cylinder movement and you might break it free.

I havent told anyone to avoid replaceing worn bushings on the ARM. what im saying, is if it is adjusted properly, the clutch will still work fine, albiet, you will narrow its operational window by having less total motion.Kind of like not being able to push the clutch all the way to the floor. (something like this as an effect)

mk

Last edited by mark kibort; 06-28-2009 at 02:54 AM.

#51

Rennlist Member

BTW if you are unfortunate enough to be using IE, that link I posted will not take you straight to the "Theory of operation" section of the page. You have to either click the "Theory of operation" link below the first graphic, or just scroll about 7/8 of the way down the page.

Below I show my measurement on my worn early plate. In this case the gap was 0.057"(indicator went more than one full revolution clockwise) which works out to about 1.45mm. So we are looking at a 0.25mm difference between a new part and an old one(both early plates). Whether or not it is significant in this case would be an entirely different discussion. The point is, yes they do wear. The next "QUOTE" block on this page is the new info that I have added to my website, same section that I linked way back in post #33. Even if you want to argue about the actual measured values, a casual inspection of the parts, if you're honest, will prove that the parts DO wear.

Originally Posted by My Website

After having a long discussion with Mark Kibort here about clutch adjustment, I am updating this page with some photos and discussion regarding the question of whether the forks(AKA "H" adjusters) wear or not. Most of his confusion about what the minimum allowable gap should be would have been cleared up had he read the above section, especially regarding the release sequence of events and the springs in the front disk. Because the front disk may expand up to 0.8mm, his recommendation to set the gap as small as 0.75mm would not allow the clutch to release in some cases.

One point that seems especially difficult to get across is that the forks do in fact wear; Mark is as of this writing convinced that they do not. He has often mentioned that on his worn, spare plate from a '79 car, he sees a max gap(5 in line drawing above) of nearly 1.5mm, where I have observed the gap on a new plate to be more like 1.2mm. He has on occasion compared his to a later version of the plate, which starts off with a max gap(5) of about 1.5mm. I think that this apples and oranges comparison has misled Mark, since AFAIK he has never measured a new plate. The picture below, provided by Mark Kibort, illustrates that on his plate, there is a relatively large contact area where the fork contacts the intermediate plate when the clutch is released:

Here for comparison is a picture of the same feature on the intermediate plate that I pulled from my '78. Of particular interest here is the much smaller contact area. You can see that over much of the surface of the fork, there has been no contact with the intermediate plate. This is because on a new plate, a new fork starts off only making contact in a small area due to the relief angle that is formed as part of the fork. As the fork wears, the contact area increases as the fork wears and the contact area creeps up along this angled feature.

Here is an example of wear on the opposite side of the fork due to contact with the intermediate plate, which occurs as the front disk wears and the intermediate plate pushes the fork forward. The purpose of this feature, and the reason for pushing the fork forward as the front disk wears, is to keep the gap(5) from widening too much as the clutch wears. If this self-adjustment were not built-in, the clutch would begin to feel sloppy over time, as an increase in gap(5) will result in the rear disk disengaging later and later as the front disk wears. The wear is slight, but it is present. It is visible as a slightly discolored, smooth spot in the gap between the fork and the intermediate plate. I point this out because Mark made the statement that this side of the fork never wears.

Finally, here is my measurement of the gap on a slightly worn fork/intermediate plate. The mag base for the indicator was mounted to the steel friction plate, and the tip of the indicator was zeroed on the top of the fork.

Here I have deflected the intermediate plate until it contacted the fork, closing gap(5). Total movement was 0.057" or about 1.45mm. The new intermediate plate gap was measured ad 0.046" or about 1.168mm(call it 1.2mm) so here we have a difference of 0.2mm which is consistent with the observed wear.

In conclusion, it is clear that the forks do in fact wear over time, as the photographs above and my own measurements prove. If anyone would care to offer additional data to support either the assertion that they do wear or they do not wear I will gladly consider it and, if the measurement methods are valid and repeatable I will post the details here.

One point that seems especially difficult to get across is that the forks do in fact wear; Mark is as of this writing convinced that they do not. He has often mentioned that on his worn, spare plate from a '79 car, he sees a max gap(5 in line drawing above) of nearly 1.5mm, where I have observed the gap on a new plate to be more like 1.2mm. He has on occasion compared his to a later version of the plate, which starts off with a max gap(5) of about 1.5mm. I think that this apples and oranges comparison has misled Mark, since AFAIK he has never measured a new plate. The picture below, provided by Mark Kibort, illustrates that on his plate, there is a relatively large contact area where the fork contacts the intermediate plate when the clutch is released:

Here for comparison is a picture of the same feature on the intermediate plate that I pulled from my '78. Of particular interest here is the much smaller contact area. You can see that over much of the surface of the fork, there has been no contact with the intermediate plate. This is because on a new plate, a new fork starts off only making contact in a small area due to the relief angle that is formed as part of the fork. As the fork wears, the contact area increases as the fork wears and the contact area creeps up along this angled feature.

Here is an example of wear on the opposite side of the fork due to contact with the intermediate plate, which occurs as the front disk wears and the intermediate plate pushes the fork forward. The purpose of this feature, and the reason for pushing the fork forward as the front disk wears, is to keep the gap(5) from widening too much as the clutch wears. If this self-adjustment were not built-in, the clutch would begin to feel sloppy over time, as an increase in gap(5) will result in the rear disk disengaging later and later as the front disk wears. The wear is slight, but it is present. It is visible as a slightly discolored, smooth spot in the gap between the fork and the intermediate plate. I point this out because Mark made the statement that this side of the fork never wears.

Finally, here is my measurement of the gap on a slightly worn fork/intermediate plate. The mag base for the indicator was mounted to the steel friction plate, and the tip of the indicator was zeroed on the top of the fork.

Here I have deflected the intermediate plate until it contacted the fork, closing gap(5). Total movement was 0.057" or about 1.45mm. The new intermediate plate gap was measured ad 0.046" or about 1.168mm(call it 1.2mm) so here we have a difference of 0.2mm which is consistent with the observed wear.

In conclusion, it is clear that the forks do in fact wear over time, as the photographs above and my own measurements prove. If anyone would care to offer additional data to support either the assertion that they do wear or they do not wear I will gladly consider it and, if the measurement methods are valid and repeatable I will post the details here.

So, I ask you -- where is your proof that the forks do not wear? I have provided as much proof as I can without disassembling the clutch that is in the car or buying a new IP. You have shown nothing to indicate that you have ever seen a NEW IP.

Now, here are some factoids:

max gap can be 1.5m . at this point the rear H arms are resting on the back side of the INT PLATE.

If you max out the gap. (pushing them all the way back) depending on how far you can pull them, you will reduce the flat spring pressure. In fact, if you pull them back too much, you might effect how fast the INT plate can retract. the first .2mm from the disc itself, but the springs can be completely neturalized.

max gap can be 1.5m . at this point the rear H arms are resting on the back side of the INT PLATE.

If you max out the gap. (pushing them all the way back) depending on how far you can pull them, you will reduce the flat spring pressure. In fact, if you pull them back too much, you might effect how fast the INT plate can retract. the first .2mm from the disc itself, but the springs can be completely neturalized.

One, if the gap(5) is maxed then the "rear H arms" as you put it are resting on the FRONT of the IP, not the rear as you state. This point is not so much a technical issue but your statement would likely be confusing to anyone that might try to take you literally.

Second, your statement that the springs would be neutralized by too big of a gap is complete nonsense. If you were to cut the forks off entirely(infinite gap(5)) the springs would still cause the IP to retract when the clutch is disengaged. It would retract at the same rate over the first 1-2mm with or without the fork.

Originally Posted by mark kibort in the big thread referenced in post #17 above

This is with the clutch in the drive clamping position. notice how there is a pretty big gap from the "H" head and the intermediate ring. This space, right from the manual is supposed to be 1 to 1.5mm. this is more like 4mm. I think it was near 3mm when i started out, as it looked pretty rearward toward the pressure plate.

The only think that you are latching on to is the fact that I did mention that the gap originally was "4mm". It looked like it compared to where it should have been and where it ended up after it was adjusted correctly. However, I already said that that was a guess, not a measurement. the max window is 1.5mm. this is a mechanical limit and those ears on the Hs do not wear. You will not measure one more than 1.5mm. If you do, show us with a picture. If you cant, stop doubting what I have provided as it is sound advice, that will help others that are trying to fix their clutches.

To your last point. Yes, if you have a little very small gap. .5mm, it could be too close, but certainly 1mm will make the clutch work fine and release from the flywheel. It has to. It's how it is designed. Full press rearward adustment has a MUCH greater risk of an issue from not releasing from the pressure plate AND relieves effectiveness of the flat springs.

What I have found on more than a few cars now, is that with no gap or one less than .5mm, you keep pressure on the front disc and flywheel. too far, more than 1mm or so, and the pressure plate doesnt move back far enough to release contact from the INT plate and disc. more clutch slave cylinder movement and you might break it free.

If you take this understanding and re-read post #41 above, you will see that all I was doing was pointing out that as absolute statements, what you were saying was false. To take one example:

Originally Posted by mark kibort

You cant push the H adjusters all the way open and not have it drag on the pressure plate.

Originally Posted by mark kibort

Pushing the H adjusters all the way open may cause drag on the pressure plate.

Originally Posted by mark kibort

You cant push the H adjusters all the way open and not have it drag on the pressure plate, if the gap when pushed all the way back is much larger than 1.5mm.

I havent told anyone to avoid replaceing worn bushings on the ARM. what im saying, is if it is adjusted properly, the clutch will still work fine, albiet, you will narrow its operational window by having less total motion.Kind of like not being able to push the clutch all the way to the floor. (something like this as an effect)

#52

Nordschleife Master

Whew!

That's some very thorough analysis.

Can you summarize how to make these things work? My conclusion is:

"Get the hydraulics completely bled then fiddle with the adjusters until it works."

That's some very thorough analysis.

Can you summarize how to make these things work? My conclusion is:

"Get the hydraulics completely bled then fiddle with the adjusters until it works."

#53

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

I'm with Glen, you guys are taking something with the complexity of a big Lego set and turning it into brain surgery.

Granted I have a "cheater" bell housing cover and "all the way back" has not worked on any 928 I've tried it on (two of them with all new parts) but hey, WTF do I know.......?

Granted I have a "cheater" bell housing cover and "all the way back" has not worked on any 928 I've tried it on (two of them with all new parts) but hey, WTF do I know.......?

#55

Rennlist Member

"All the way back" is what worked for my recent clutch drop .... and it took the joy of dropping the lower cover & starter 3X to find that sweet spot before the clutch would release.

Part of what caught me out was that in moving the adjusters with a single screwdriver, I hadn't noticed that one adjuster was pivoting on its stud .... so when the gap was set on one side, the other side was closing . - which prevented release.

. - which prevented release.

From now on, I will slip two screwdrivers in to assure that the adjuster slides straight back.

Bottom line, I support the earlier position that every clutch IP will have its sweet spot wrt the adjusters that allows a clean release - and symmetrical take up on engagement: leave it on the hoist until you find that spot. Once set, the dual plate unit is a supurbly smooth and effective clutch.

The inability of the average shop mechanic to do more than bolt in a new clutch and walk away to the cash register ( back in the mid '80's) is likely what killed use of the dual plate unit - not any inherent mechanical design weakness.

BTW, that lesson in adjustment for me was not due to replacing the clutch: it was a reinstall of the same due to a mouse nest that led to crap packed against the RMS ... that led to wicking of oil, etc, etc until a clutch slip started. All is well once the mouse house was evicted.

Part of what caught me out was that in moving the adjusters with a single screwdriver, I hadn't noticed that one adjuster was pivoting on its stud .... so when the gap was set on one side, the other side was closing

. - which prevented release.

. - which prevented release.From now on, I will slip two screwdrivers in to assure that the adjuster slides straight back.

Bottom line, I support the earlier position that every clutch IP will have its sweet spot wrt the adjusters that allows a clean release - and symmetrical take up on engagement: leave it on the hoist until you find that spot. Once set, the dual plate unit is a supurbly smooth and effective clutch.

The inability of the average shop mechanic to do more than bolt in a new clutch and walk away to the cash register ( back in the mid '80's) is likely what killed use of the dual plate unit - not any inherent mechanical design weakness.

BTW, that lesson in adjustment for me was not due to replacing the clutch: it was a reinstall of the same due to a mouse nest that led to crap packed against the RMS ... that led to wicking of oil, etc, etc until a clutch slip started. All is well once the mouse house was evicted.

#56

Three Wheelin'

Join Date: Dec 2005

Location: In the boatyard installing the mast and engine, we don't need a crane, we harness the mesquito's! Yeah!

Posts: 1,822

Likes: 0

Received 1 Like

on

1 Post

There is a reason I like this guy.... Short, and to the point....

I'm with Glen, you guys are taking something with the complexity of a big Lego set and turning it into brain surgery.

Granted I have a "cheater" bell housing cover and "all the way back" has not worked on any 928 I've tried it on (two of them with all new parts) but hey, WTF do I know.......?

Granted I have a "cheater" bell housing cover and "all the way back" has not worked on any 928 I've tried it on (two of them with all new parts) but hey, WTF do I know.......?

If I can finish reading all of this thread.... So now I know who not to ask.

#57

Rennlist Member

Wow, Dave, I just dont get how you cant see the obvious. The "H" adjusters (lets just call them H as that has been the theme on the thread for the "forks") do not wear. You have measured a new IP and an old IP and got a measurement difference of two parts 30 years age difference. That is just plain silly, dont you think?

No, the H adjusters do NOT wear. they dont contact front side of the INT plate either as that is the side where the disc is in contact with the flywheel. IF you push the adjusters all the way back, then yes, they MIGHT touch, but there is absolutely no force on them, thus no friction or wear. on the rear side if there is a large or small gap, the only time they touch is when you engage the clutch. and the presure they touch with is the force of the flat springs .(something you can overcome with finger pressure so it is a VERY light force. NOT in a million years can those two forces described here wear anything. I didnt do any super close picutures, but you can see casting reminance on the contact surface of that 30 year old intermediate plate in the pictures. (i.e. NO wear!)

Now, I dont now why you dont get the simplicity of the sytstem, but the bottom line is that you only want a small gap in the adjusters . Its in the 1mm range. too small an the front disc will not release from the flywheel. too far, and you release the flywheel fine, BUT are now endanger of making contact with the pressure plate and disc. This MIGHT not happen with the "all the way back technique " if you have a slave cylinder and lever arm that pulls back .25mm further. (possible, but not the way to do it or have it adjusted) NOW, the other main point is that if you push the adjuster all the way back YOU WILL neutralize the flat springs and that is what I was talking about. the flat springs can be neutralized if the H adjusters are back too far. the pressure plate will not have anything to move it back, excecpt for the slight movement of the uncoiling of the front disc and maybe vibration that would let it drift, but that is not good.

All you need to do to prove this is to push the adjusters back on the workbench and watch the flat springs just float the int plate within the H adjusters. this happens when the H adusters are pushed all the way back. at that point, there would be no flat spring pressure at all.

mk

No, the H adjusters do NOT wear. they dont contact front side of the INT plate either as that is the side where the disc is in contact with the flywheel. IF you push the adjusters all the way back, then yes, they MIGHT touch, but there is absolutely no force on them, thus no friction or wear. on the rear side if there is a large or small gap, the only time they touch is when you engage the clutch. and the presure they touch with is the force of the flat springs .(something you can overcome with finger pressure so it is a VERY light force. NOT in a million years can those two forces described here wear anything. I didnt do any super close picutures, but you can see casting reminance on the contact surface of that 30 year old intermediate plate in the pictures. (i.e. NO wear!)

Now, I dont now why you dont get the simplicity of the sytstem, but the bottom line is that you only want a small gap in the adjusters . Its in the 1mm range. too small an the front disc will not release from the flywheel. too far, and you release the flywheel fine, BUT are now endanger of making contact with the pressure plate and disc. This MIGHT not happen with the "all the way back technique " if you have a slave cylinder and lever arm that pulls back .25mm further. (possible, but not the way to do it or have it adjusted) NOW, the other main point is that if you push the adjuster all the way back YOU WILL neutralize the flat springs and that is what I was talking about. the flat springs can be neutralized if the H adjusters are back too far. the pressure plate will not have anything to move it back, excecpt for the slight movement of the uncoiling of the front disc and maybe vibration that would let it drift, but that is not good.

All you need to do to prove this is to push the adjusters back on the workbench and watch the flat springs just float the int plate within the H adjusters. this happens when the H adusters are pushed all the way back. at that point, there would be no flat spring pressure at all.

mk

First of all here is positive proof that you don't even bother to read what people say when you get in this mode. If you're not going to bother to read my side -- or if you can't retain the information long enough to consider it in your reply, or whatever the problem is, then I have little reason to repeat it. I have carefully read everything you have said in this thread and in the other thread that you have linked. If you want to debate, please grant me the same courtesy. The info was in the section of my clutch writeup that I linked, it was posted in this thread. Please read. If you can't be bothered to read someone's post then saying that the info in that post is wrong seems a bit silly, to put it kindly.

>>>>>>>Absolutely! I will read in detail and make comments.

BTW if you are unfortunate enough to be using IE, that link I posted will not take you straight to the "Theory of operation" section of the page. You have to either click the "Theory of operation" link below the first graphic, or just scroll about 7/8 of the way down the page.

The sky IS blue. No wait, what I meant to say is... Measuring a single worn part is not a conclusive indicator of wear or lack of wear. As much as you claim to work from empirical measurements, science and physics, it boggles the mind how you try to pass this off as conclusive. A brand-new plate(~50 miles of use, as stated above) has a ~1.2mm gap -- at least, the early plate does. I'm rounding up there -- I actually measured 0.046" which works out to 1.168mm. I stated this observation in post #41, the first sentence in the third paragraph that I typed. From the spec it would appear that the later plate has a 1.5mm max gap. Since you are getting your measurements from a '79 plate, I think it's safe to say that it started life with a ~1mm-1.2mm gap as my new early plate did.

>>>>>>>pure speculation since we dont have a "79" plate to look at. But knowing machined surfaces, you can see there is NO visible wear points, expecialy on the front portions of the "H" adusters. and why would there be? there is NO contact or pressure on the front side and only the pressure of the flat springs pressing on the intermediate plate against the rear of the H adjusters. the only wear might be if some monkey is using a screw driver to spread them apart.

the steel is soft and you can ding them up, but you are not going to make the clearances any greater.

Below I show my measurement on my worn early plate. In this case the gap was 0.057"(indicator went more than one full revolution clockwise) which works out to about 1.45mm. So we are looking at a 0.25mm difference between a new part and an old one(both early plates). Whether or not it is significant in this case would be an entirely different discussion. The point is, yes they do wear. The next "QUOTE" block on this page is the new info that I have added to my website, same section that I linked way back in post #33. Even if you want to argue about the actual measured values, a casual inspection of the parts, if you're honest, will prove that the parts DO wear.

>>>>>>>>>No, you only compared an old part to a new part. since the clearance total is not a controlled item in my opinion, that part could change over the years. It doesnt matter what the gap, as lond as the rear gap you adjust can be around 1mm.

The fact that you can look at the photograph that you posted(above, in the quote from my website and in post #49) and say the forks do not wear is truly mind-boggling. Giving you the benefit of the doubt, the only logical explanation is that you have never seen a truly "new" fork and therefore have no basis for comparison.