Please help me get this clutch working properly!!

#151

Rennlist Member

#153

Rennlist Member

Yep, and that is why I posted the new pictures. the gap on the INT plate in my car now, has the same gap as the '79 pressure plate and has the same gap as Scots as well as the "like new" one (that did look like new by the way) . They all measure 1.4mm gap.

This picture is the installed picture angle. Its a little decieving, and is why i took all the new pictures from the side and at other angles that show the different angles of the arms. by showing the new pictures, you can see that the wider gap, is kind of an optical allusion due to the camera angle. now, there could be a little surface damge due to my wrenching on the H adjsters before I developed the right technique to move them open or close. but most of what you see is just abnormalities in the stamping/casting. there is no wear on them as well. and why would there be? the only contact the top portion you see on the H adjusters is from when it stops the "finger pressure flat spring pressure" int plate from going rear ward when the clucth is engaged. Its not even a "tap" as far as its movement rear ward. its a touch. very light touch. It cant wear out anything. adjusted properly or not, this portion can not wear. (measureably). If it can, please tell me how it is possible.

Again if my adjusters were "worn" then why do they measure the same exact dimensions at the '79 which also shows NO wear at all based on the clear contact patch? If it was worn, the gap would be larger than 1.4mm. Lets say it was 1.5mm. that is not enough to change the fact that proper adjustment happens at very close to 1mm gap at the H adjusters.

If you want me to show a picture of the feeler gauge in this H adjusters' gap, I will do again and post.

This picture is the installed picture angle. Its a little decieving, and is why i took all the new pictures from the side and at other angles that show the different angles of the arms. by showing the new pictures, you can see that the wider gap, is kind of an optical allusion due to the camera angle. now, there could be a little surface damge due to my wrenching on the H adjsters before I developed the right technique to move them open or close. but most of what you see is just abnormalities in the stamping/casting. there is no wear on them as well. and why would there be? the only contact the top portion you see on the H adjusters is from when it stops the "finger pressure flat spring pressure" int plate from going rear ward when the clucth is engaged. Its not even a "tap" as far as its movement rear ward. its a touch. very light touch. It cant wear out anything. adjusted properly or not, this portion can not wear. (measureably). If it can, please tell me how it is possible.

Again if my adjusters were "worn" then why do they measure the same exact dimensions at the '79 which also shows NO wear at all based on the clear contact patch? If it was worn, the gap would be larger than 1.4mm. Lets say it was 1.5mm. that is not enough to change the fact that proper adjustment happens at very close to 1mm gap at the H adjusters.

If you want me to show a picture of the feeler gauge in this H adjusters' gap, I will do again and post.

Mark, that is another interesting single data point.

However, you have completely ignored my questions about the earlier picture that you yourself posted(unless I missed something). Where did this picture come from? What is the max gap on this fork? How do you reconcile these obvious signs of wear with your theory that they never ever wear at all? If you want to completely ignore a piece of data that does not agree with your theory, fine -- let's call it like it is. But if you want to contend that the forks never ever wear then we need an explanation for this picture(below) or you should probably qualify with "the forks that I choose to pay attention to do not show signs of wear"...

However, you have completely ignored my questions about the earlier picture that you yourself posted(unless I missed something). Where did this picture come from? What is the max gap on this fork? How do you reconcile these obvious signs of wear with your theory that they never ever wear at all? If you want to completely ignore a piece of data that does not agree with your theory, fine -- let's call it like it is. But if you want to contend that the forks never ever wear then we need an explanation for this picture(below) or you should probably qualify with "the forks that I choose to pay attention to do not show signs of wear"...

#155

Rennlist Member

Mark, you're dodging the question again and/or ignoring evidence. I'm talking about the pic in post #150. You have certainly NOT shown a second angle on that particular fork.

You have shown no evidence of any optical illusion, other than the optical illusions you create when you show pics of different forks. Please address the questions, to wit: Where did this picture come from? What is the max gap on this fork? How do you reconcile these obvious signs of wear with your theory that they never ever wear at all? And one more: Is that pic (in post #150) an early or late plate, and what is the max gap?

Regarding this new set of pics, the forks you show do not show significant wear -- yet they have worn enough to remove the stamping marks that surely were there when it was manufactured. They have a perfectly flat landing surface and they do not start out that way. Pics of a single not-very-worn plate do not prove that they do not wear, and I would think that the existence of a plate that is obviously worn would be of particular interest for you to go back and double-check -- so why do you keep avoiding it?

You have shown no evidence of any optical illusion, other than the optical illusions you create when you show pics of different forks. Please address the questions, to wit: Where did this picture come from? What is the max gap on this fork? How do you reconcile these obvious signs of wear with your theory that they never ever wear at all? And one more: Is that pic (in post #150) an early or late plate, and what is the max gap?

Regarding this new set of pics, the forks you show do not show significant wear -- yet they have worn enough to remove the stamping marks that surely were there when it was manufactured. They have a perfectly flat landing surface and they do not start out that way. Pics of a single not-very-worn plate do not prove that they do not wear, and I would think that the existence of a plate that is obviously worn would be of particular interest for you to go back and double-check -- so why do you keep avoiding it?

#156

Rennlist Member

Dave, It is you that is not reading the posts. I'll say it again. The pic is from the Holbert machine. The INT plate has gone through 150,000miles and 8 full seasons of racing. It came off my, at the time, 90,000mile '84. It was the original INT plate. I cant show a second angle on the Forks, because there is no way to get another angle unless the clutch is pulled off the car!

Anyway, YOU are avoiding the question. How is there supposed to be ANY wear on the forks. I assume by now you understand how they work and operate. what is the ONLY force that is applied to them? what is the value of that force. When is it applied? All questions that point to a situation where very little wear, if any can occur. PLUS, even if there was .1 to .2mm of wear, it wouldnt change the fact that the gap needs to be around 1mm to release from the flwheel and not contact the pressure plate on clutch engagemnent.

why dont you show a pic of the new plate. Why are you avoiding this OBVIOUS requirement to the discussion? You can see from the plate that has been "stored in salt water" has no visable wear. you say that the original stamping marks have been worn away, but I dont know what those are. You created drawings showing the .2mm of wear and how geometrically it is removed by wear. BUT, Ive shown how the H or Fork arms are not worn and they still have that downward angle showing no wear and the pics from the side or below the side can create an optical illusion. now the wear you think you see on the "demo" plate , over 30 years old, is worth noting? If there was any wear on that part, we are talking something measured in microns.

So, how much do you think they can wear??? why is it, on this Fork set up on the '79 plate, does the gap show a normal 1.4mm. why is it that the one on my car is 1.4mm as well (the one in post 152). I asked if you wanted some pics of that measurement, for which Ill crawl under the car and measure and shot some pictures for you I guess.

Now, Im curious as to seeing the 1.1mm new pressure plate gap. If it exists, it is not the same as all the others Ive run into that do not show any signs of wear at the H or Fork adjusters. the '79, my 84 on the holbert car, Scots old , scots new, all measured 1.4mm.

Anyway, YOU are avoiding the question. How is there supposed to be ANY wear on the forks. I assume by now you understand how they work and operate. what is the ONLY force that is applied to them? what is the value of that force. When is it applied? All questions that point to a situation where very little wear, if any can occur. PLUS, even if there was .1 to .2mm of wear, it wouldnt change the fact that the gap needs to be around 1mm to release from the flwheel and not contact the pressure plate on clutch engagemnent.

why dont you show a pic of the new plate. Why are you avoiding this OBVIOUS requirement to the discussion? You can see from the plate that has been "stored in salt water" has no visable wear. you say that the original stamping marks have been worn away, but I dont know what those are. You created drawings showing the .2mm of wear and how geometrically it is removed by wear. BUT, Ive shown how the H or Fork arms are not worn and they still have that downward angle showing no wear and the pics from the side or below the side can create an optical illusion. now the wear you think you see on the "demo" plate , over 30 years old, is worth noting? If there was any wear on that part, we are talking something measured in microns.

So, how much do you think they can wear??? why is it, on this Fork set up on the '79 plate, does the gap show a normal 1.4mm. why is it that the one on my car is 1.4mm as well (the one in post 152). I asked if you wanted some pics of that measurement, for which Ill crawl under the car and measure and shot some pictures for you I guess.

Now, Im curious as to seeing the 1.1mm new pressure plate gap. If it exists, it is not the same as all the others Ive run into that do not show any signs of wear at the H or Fork adjusters. the '79, my 84 on the holbert car, Scots old , scots new, all measured 1.4mm.

Mark, you're dodging the question again and/or ignoring evidence. I'm talking about the pic in post #150. You have certainly NOT shown a second angle on that particular fork.

You have shown no evidence of any optical illusion, other than the optical illusions you create when you show pics of different forks. Please address the questions, to wit: Where did this picture come from? What is the max gap on this fork? How do you reconcile these obvious signs of wear with your theory that they never ever wear at all? And one more: Is that pic (in post #150) an early or late plate, and what is the max gap?

Regarding this new set of pics, the forks you show do not show significant wear -- yet they have worn enough to remove the stamping marks that surely were there when it was manufactured. They have a perfectly flat landing surface and they do not start out that way. Pics of a single not-very-worn plate do not prove that they do not wear, and I would think that the existence of a plate that is obviously worn would be of particular interest for you to go back and double-check -- so why do you keep avoiding it?

You have shown no evidence of any optical illusion, other than the optical illusions you create when you show pics of different forks. Please address the questions, to wit: Where did this picture come from? What is the max gap on this fork? How do you reconcile these obvious signs of wear with your theory that they never ever wear at all? And one more: Is that pic (in post #150) an early or late plate, and what is the max gap?

Regarding this new set of pics, the forks you show do not show significant wear -- yet they have worn enough to remove the stamping marks that surely were there when it was manufactured. They have a perfectly flat landing surface and they do not start out that way. Pics of a single not-very-worn plate do not prove that they do not wear, and I would think that the existence of a plate that is obviously worn would be of particular interest for you to go back and double-check -- so why do you keep avoiding it?

#157

Rennlist Member

Dave, It is you that is not reading the posts. I'll say it again. The pic is from the Holbert machine. The INT plate has gone through 150,000miles and 8 full seasons of racing. It came off my, at the time, 90,000mile '84. It was the original INT plate. I cant show a second angle on the Forks, because there is no way to get another angle unless the clutch is pulled off the car!

Anyway, YOU are avoiding the question. How is there supposed to be ANY wear on the forks. I assume by now you understand how they work and operate. what is the ONLY force that is applied to them? what is the value of that force. When is it applied? All questions that point to a situation where very little wear, if any can occur. PLUS, even if there was .1 to .2mm of wear, it wouldnt change the fact that the gap needs to be around 1mm to release from the flwheel and not contact the pressure plate on clutch engagemnent.

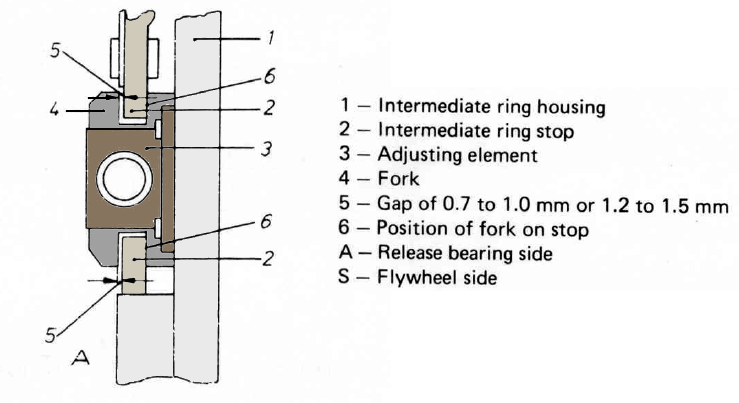

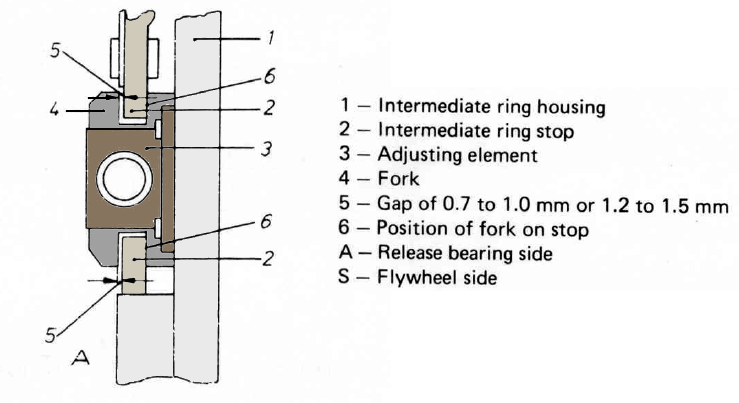

1. The forks wear in TWO ways, one relates to their holding power, one relates to how much movement they permit the IP before the "holding power" becomes a factor The latter case is the one you seem to be overlooking; referencing the line drawing above I am talking about wear primarily at point (5) but also at point (6). Remember, with the clutch disengaged you have the IP supported ONLY by the three spring strips and the contact when gap (5) closes. This contact is relatively light but the IP is balanced imperfectly(as is the whole clutch pack) so it must vibrate, and this vibration is what causes the wear at the contact area. The wear at point 6 occurs only when the clutch is engaged, and while it is a minuscule amount of wear it is present(look at your parts).

why dont you show a pic of the new plate. Why are you avoiding this OBVIOUS requirement to the discussion? You can see from the plate that has been "stored in salt water" has no visable wear. you say that the original stamping marks have been worn away, but I dont know what those are.

Regarding the stamping marks, they are the rough edges, especially on the insides of the forks, where the metal was torn in the process of stamping the fork using a die. I have attached one of your photos from post #147 where I have highlighted the still-visible stamping marks(I forget the exact technical term ATM), which are notably absent from the surface where the fork contacts the IP. That contact point is never that flat on a new fork and only looks like your pic if it has worn some.

Also I have posted your "worn" pic yet again. Can you honestly look at both pics and say that you do not see any signs of wear on the second pic?

You created drawings showing the .2mm of wear and how geometrically it is removed by wear. BUT, Ive shown how the H or Fork arms are not worn and they still have that downward angle showing no wear and the pics from the side or below the side can create an optical illusion. now the wear you think you see on the "demo" plate , over 30 years old, is worth noting? If there was any wear on that part, we are talking something measured in microns.

If the contact area has doubled as the picture that you posted seems to show, then IMHO the wear will be measurable in microns -- at least 500 microns. Most would say .5mm in that case.

If the contact area has doubled as the picture that you posted seems to show, then IMHO the wear will be measurable in microns -- at least 500 microns. Most would say .5mm in that case.I must admit that I find it mildly entertaining that you, the only one who seems to believe that the forks never ever wear more than a few microns, have posted a pic of the most worn fork I have ever seen -- yet you still deny that they wear.

So, how much do you think they can wear??? why is it, on this Fork set up on the '79 plate, does the gap show a normal 1.4mm. why is it that the one on my car is 1.4mm as well (the one in post 152). I asked if you wanted some pics of that measurement, for which Ill crawl under the car and measure and shot some pictures for you I guess.

Now, Im curious as to seeing the 1.1mm new pressure plate gap. If it exists, it is not the same as all the others Ive run into that do not show any signs of wear at the H or Fork adjusters. the '79, my 84 on the holbert car, Scots old , scots new, all measured 1.4mm.

Now, Im curious as to seeing the 1.1mm new pressure plate gap. If it exists, it is not the same as all the others Ive run into that do not show any signs of wear at the H or Fork adjusters. the '79, my 84 on the holbert car, Scots old , scots new, all measured 1.4mm.

#158

Rennlist Member

Dave,

I read what you said. I dont agree with your theory on wear. If you truely understand how the IP works, you might rethink parts of your wear theory below. the IP plate will have a gap on the rear and on the front when the clutch is disengaged. there is nothing touching, or rubbing, even with vibration, due to the space at the front and rear of the Fork adjusters. when the clutch is engaged, you know that the only force is the finger pressure spring force holding the INT Plate from traveling further rear ward. If at near max rear adjustement, this force is less than 0 as seen by my pics where the adjusters are moved all the way rear ward. (1mm gap with no preload tension on springs) This means when the adjusters are moved forward 1mm, there would be 0 pressure and a progressive pressure as the adjusters are moved forward. If what you are saying is that when the clutch is released that the INT plate is sandwitched between the two discs but still able to move rearward to hit the adjuster, would be a stretch. Where I think contact is made, is when the clutch is engaged and some really high reving and accelerations are made on the engine, where the interia of the INT plate, only supported at this time by the flat springs will allow the plate to move rear ward based on how it is suspended by the flat springs and the forces on accel of the int plate with the clutch in. (think about this for a second before you go on or respond). At that point, the flexing INT within the flat springs can move and press on the rear ward part of the H Fork adjusters. force to move them is relatively light, so I dont see that being a measureable wear force or result.

My adjusters have been through a lot of screw driver pry's during the discovery of the way to adjust them best. the illusion is still present, as the max gap that I was able to measure was 1.5mm. In NO WAY is it 2mm, as your theory would suggest. Remember when I was eyeballing the gap when I first saw it and estimated it to be 4mm?? well, I corrected my estimate later with the accurate measurement and ending adjustment of 1mm. that value was 1.5mm. +/-. 1mm. Also, the reason I posted the picture at near the same angle was to show how similar the max gap of the demo plate was, vs the installed plate. I will put a feeler gauge and do a max value again to show that the gap is no where NEAR 2mm, as your .5mm of wear estimation would indicate.

I read what you said. I dont agree with your theory on wear. If you truely understand how the IP works, you might rethink parts of your wear theory below. the IP plate will have a gap on the rear and on the front when the clutch is disengaged. there is nothing touching, or rubbing, even with vibration, due to the space at the front and rear of the Fork adjusters. when the clutch is engaged, you know that the only force is the finger pressure spring force holding the INT Plate from traveling further rear ward. If at near max rear adjustement, this force is less than 0 as seen by my pics where the adjusters are moved all the way rear ward. (1mm gap with no preload tension on springs) This means when the adjusters are moved forward 1mm, there would be 0 pressure and a progressive pressure as the adjusters are moved forward. If what you are saying is that when the clutch is released that the INT plate is sandwitched between the two discs but still able to move rearward to hit the adjuster, would be a stretch. Where I think contact is made, is when the clutch is engaged and some really high reving and accelerations are made on the engine, where the interia of the INT plate, only supported at this time by the flat springs will allow the plate to move rear ward based on how it is suspended by the flat springs and the forces on accel of the int plate with the clutch in. (think about this for a second before you go on or respond). At that point, the flexing INT within the flat springs can move and press on the rear ward part of the H Fork adjusters. force to move them is relatively light, so I dont see that being a measureable wear force or result.

My adjusters have been through a lot of screw driver pry's during the discovery of the way to adjust them best. the illusion is still present, as the max gap that I was able to measure was 1.5mm. In NO WAY is it 2mm, as your theory would suggest. Remember when I was eyeballing the gap when I first saw it and estimated it to be 4mm?? well, I corrected my estimate later with the accurate measurement and ending adjustment of 1mm. that value was 1.5mm. +/-. 1mm. Also, the reason I posted the picture at near the same angle was to show how similar the max gap of the demo plate was, vs the installed plate. I will put a feeler gauge and do a max value again to show that the gap is no where NEAR 2mm, as your .5mm of wear estimation would indicate.

I answered that question in post #47, and I have quoted that text again below. I guess reading really is overrated.

"Originally Posted by SharkSkin

1. The forks wear in TWO ways, one relates to their holding power, one relates to how much movement they permit the IP before the "holding power" becomes a factor The latter case is the one you seem to be overlooking; referencing the line drawing above I am talking about wear primarily at point (5) but also at point (6). Remember, with the clutch disengaged you have the IP supported ONLY by the three spring strips and the contact when gap (5) closes. This contact is relatively light but the IP is balanced imperfectly(as is the whole clutch pack) so it must vibrate, and this vibration is what causes the wear at the contact area. The wear at point 6 occurs only when the clutch is engaged, and while it is a minuscule amount of wear it is present(look at your parts).:"

.

"Originally Posted by SharkSkin

1. The forks wear in TWO ways, one relates to their holding power, one relates to how much movement they permit the IP before the "holding power" becomes a factor The latter case is the one you seem to be overlooking; referencing the line drawing above I am talking about wear primarily at point (5) but also at point (6). Remember, with the clutch disengaged you have the IP supported ONLY by the three spring strips and the contact when gap (5) closes. This contact is relatively light but the IP is balanced imperfectly(as is the whole clutch pack) so it must vibrate, and this vibration is what causes the wear at the contact area. The wear at point 6 occurs only when the clutch is engaged, and while it is a minuscule amount of wear it is present(look at your parts).:"

.

#159

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

This thread makes baby Jesus cry.

#160

Rennlist Member

Dave,

Here is your drawing referencing the gap 6 (front side gap) and gap 5 (rear ward, adjustable gap). see my inserts below: >>>>>>>>>>>>>>

Here is your drawing referencing the gap 6 (front side gap) and gap 5 (rear ward, adjustable gap). see my inserts below: >>>>>>>>>>>>>>

:

To answer your question about technical mistakes and confusing points, there are two more glaring inaccuracies just in your last post:

1. The forks wear in TWO ways, one relates to their holding power, one relates to how much movement they permit the IP before the "holding power" becomes a factor The latter case is the one you seem to be overlooking; referencing the line drawing above I am talking about wear primarily at point (5) but also at point (6). Remember, with the clutch disengaged you have the IP supported ONLY by the three spring strips and the contact when gap (5) closes.

>>>>>>>>>>>>>>>> When the gap 5 closes, the clutch is engaged and the INT plate moves rear ward based on the flat spring pressure. With the clutch disengaged, it means the INT plate is being sandwiched by the pressure plate pushing the rear disc on the INT plate onto the front disc to the flywheel. the Fork adjusters would then have a rear ward gap of near 1mm and .5mm on the front side. nothing on the Hs are touching or will touch.

This contact is relatively light but the IP is balanced imperfectly(as is the whole clutch pack) so it must vibrate, and this vibration is what causes the wear at the contact area. The wear at point 6 occurs only when the clutch is engaged, and while it is a minuscule amount of wear it is present(look at your parts).

>>>>>>>>>>no, you have it backward. You mean gap 5.

You make fun of me for not reading your post, yet you have things all mixed up!

".

To answer your question about technical mistakes and confusing points, there are two more glaring inaccuracies just in your last post:

1. The forks wear in TWO ways, one relates to their holding power, one relates to how much movement they permit the IP before the "holding power" becomes a factor The latter case is the one you seem to be overlooking; referencing the line drawing above I am talking about wear primarily at point (5) but also at point (6). Remember, with the clutch disengaged you have the IP supported ONLY by the three spring strips and the contact when gap (5) closes.

>>>>>>>>>>>>>>>> When the gap 5 closes, the clutch is engaged and the INT plate moves rear ward based on the flat spring pressure. With the clutch disengaged, it means the INT plate is being sandwiched by the pressure plate pushing the rear disc on the INT plate onto the front disc to the flywheel. the Fork adjusters would then have a rear ward gap of near 1mm and .5mm on the front side. nothing on the Hs are touching or will touch.

This contact is relatively light but the IP is balanced imperfectly(as is the whole clutch pack) so it must vibrate, and this vibration is what causes the wear at the contact area. The wear at point 6 occurs only when the clutch is engaged, and while it is a minuscule amount of wear it is present(look at your parts).

>>>>>>>>>>no, you have it backward. You mean gap 5.

You make fun of me for not reading your post, yet you have things all mixed up!

".

#161

Rennlist Member

Dave, I will measure my H adjusters soon. when i do, if they measure out to 1.5mm max, will you agree that there is no measureable wear? (or significant wear). Remember, you have estimated the wear to be the "most" you have ever seen" and you have adjusted how many different Int Plates?

Again, Ive measured and sucessfully adjusted 4 of them, and a few others on the list that used 1mm as a value to have a sucessful adjustement. now, you toss out that you measured your Int Plate H Forks and they only have a max gap of 1.1mm, yet I show a picture of one that shows little or no wear and measures 1.45mm. Where would all that wear go, if it cant be seen? The bottomline, as long as you adjust the gap to 1mm you will be in adjustement regardless, and that is the point of all this. Even if you have a new, narrow gap model like you seem to have , if you adjust it to 1mm, you are in good shape, even though you could go "all the way back" and have it in adjustment , assuming a max 1.1 gap available.

, if you adjust it to 1mm, you are in good shape, even though you could go "all the way back" and have it in adjustment , assuming a max 1.1 gap available.

Ill get back to you with an exact measurement of the gap on the pictured H adjsusters, where you say there is a clear wear pattern of near "500 microns" or .5mm. If I dont measure 2mm, you are wrong.

Again, Ive measured and sucessfully adjusted 4 of them, and a few others on the list that used 1mm as a value to have a sucessful adjustement. now, you toss out that you measured your Int Plate H Forks and they only have a max gap of 1.1mm, yet I show a picture of one that shows little or no wear and measures 1.45mm. Where would all that wear go, if it cant be seen? The bottomline, as long as you adjust the gap to 1mm you will be in adjustement regardless, and that is the point of all this. Even if you have a new, narrow gap model like you seem to have

, if you adjust it to 1mm, you are in good shape, even though you could go "all the way back" and have it in adjustment , assuming a max 1.1 gap available.

, if you adjust it to 1mm, you are in good shape, even though you could go "all the way back" and have it in adjustment , assuming a max 1.1 gap available.

Ill get back to you with an exact measurement of the gap on the pictured H adjsusters, where you say there is a clear wear pattern of near "500 microns" or .5mm. If I dont measure 2mm, you are wrong.

#162

Archive Gatekeeper

Rennlist Member

Rennlist Member

Buying a Spec level 3+ clutch and bedding it in might be easier than waiting to see which one of you is 'right' about the adjustment of a DD clutch....

Seriously, there are a few gems in this thread that should be helpful in getting the DD clutch into the stroker. Now if I can just find them.

Seriously, there are a few gems in this thread that should be helpful in getting the DD clutch into the stroker. Now if I can just find them.

#163

Rennlist Member

Ill give you two "Gems" ive used in getting the DD into MY stroker. I've been racing it for over 20 race days too. Anyone else race a stroker with a DD successfully? Ok, the "Gems".

1. 1mm for adjustment at the Fork (H) adjuster

2. Get pressure plate sent off for higher clamping pressure by 928 Intl.

Go racing with no concerns, except if you have a weak INT plate, then you might need that hatch to adjust the H to 1mm every so often. (every other race weekend or never if you are only street racing-or driving)

If you have the magical 1.1mm max gap "new", Dave type INT Plate, you wont need to adjust it ever.

mk

1. 1mm for adjustment at the Fork (H) adjuster

2. Get pressure plate sent off for higher clamping pressure by 928 Intl.

Go racing with no concerns, except if you have a weak INT plate, then you might need that hatch to adjust the H to 1mm every so often. (every other race weekend or never if you are only street racing-or driving)

If you have the magical 1.1mm max gap "new", Dave type INT Plate, you wont need to adjust it ever.

mk

Buying a Spec level 3+ clutch and bedding it in might be easier than waiting to see which one of you is 'right' about the adjustment of a DD clutch....

Seriously, there are a few gems in this thread that should be helpful in getting the DD clutch into the stroker. Now if I can just find them.

Seriously, there are a few gems in this thread that should be helpful in getting the DD clutch into the stroker. Now if I can just find them.

#164

Rennlist Member

To answer your question about technical mistakes and confusing points, there are two more glaring inaccuracies just in your last post:

1. The forks wear in TWO ways, one relates to their holding power, one relates to how much movement they permit the IP before the "holding power" becomes a factor The latter case is the one you seem to be overlooking; referencing the line drawing above I am talking about wear primarily at point (5) but also at point (6). Remember, with the clutch disengaged you have the IP supported ONLY by the three spring strips and the contact when gap (5) closes.

>>>>>>>>>>>>>>>> When the gap 5 closes, the clutch is engaged and the INT plate moves rear ward based on the flat spring pressure. With the clutch disengaged, it means the INT plate is being sandwiched by the pressure plate pushing the rear disc on the INT plate onto the front disc to the flywheel. the Fork adjusters would then have a rear ward gap of near 1mm and .5mm on the front side. nothing on the Hs are touching or will touch.

This contact is relatively light but the IP is balanced imperfectly(as is the whole clutch pack) so it must vibrate, and this vibration is what causes the wear at the contact area. The wear at point 6 occurs only when the clutch is engaged, and while it is a minuscule amount of wear it is present(look at your parts).

>>>>>>>>>>no, you have it backward. You mean gap 5.

You make fun of me for not reading your post, yet you have things all mixed up!

1. The forks wear in TWO ways, one relates to their holding power, one relates to how much movement they permit the IP before the "holding power" becomes a factor The latter case is the one you seem to be overlooking; referencing the line drawing above I am talking about wear primarily at point (5) but also at point (6). Remember, with the clutch disengaged you have the IP supported ONLY by the three spring strips and the contact when gap (5) closes.

>>>>>>>>>>>>>>>> When the gap 5 closes, the clutch is engaged and the INT plate moves rear ward based on the flat spring pressure. With the clutch disengaged, it means the INT plate is being sandwiched by the pressure plate pushing the rear disc on the INT plate onto the front disc to the flywheel. the Fork adjusters would then have a rear ward gap of near 1mm and .5mm on the front side. nothing on the Hs are touching or will touch.

This contact is relatively light but the IP is balanced imperfectly(as is the whole clutch pack) so it must vibrate, and this vibration is what causes the wear at the contact area. The wear at point 6 occurs only when the clutch is engaged, and while it is a minuscule amount of wear it is present(look at your parts).

>>>>>>>>>>no, you have it backward. You mean gap 5.

You make fun of me for not reading your post, yet you have things all mixed up!

With those statements you have gone way into this mode(and you're trying for the shoulders too):

With those statements you have gone way into this mode(and you're trying for the shoulders too):http://image indicating Mark doesn't get it

I give up. You can't be reasoned with. Black is White, White is black. War is Peace.

Last edited by SharkSkin; 07-06-2009 at 08:35 PM.

#165

Rennlist Member

Dave, I will measure my H adjusters soon. when i do, if they measure out to 1.5mm max, will you agree that there is no measureable wear? (or significant wear). Remember, you have estimated the wear to be the "most" you have ever seen" and you have adjusted how many different Int Plates?

Again, Ive measured and sucessfully adjusted 4 of them, and a few others on the list that used 1mm as a value to have a sucessful adjustement. now, you toss out that you measured your Int Plate H Forks and they only have a max gap of 1.1mm, yet I show a picture of one that shows little or no wear and measures 1.45mm. Where would all that wear go, if it cant be seen? The bottomline, as long as you adjust the gap to 1mm you will be in adjustement regardless, and that is the point of all this. Even if you have a new, narrow gap model like you seem to have  , if you adjust it to 1mm, you are in good shape, even though you could go "all the way back" and have it in adjustment , assuming a max 1.1 gap available.

, if you adjust it to 1mm, you are in good shape, even though you could go "all the way back" and have it in adjustment , assuming a max 1.1 gap available.

Ill get back to you with an exact measurement of the gap on the pictured H adjsusters, where you say there is a clear wear pattern of near "500 microns" or .5mm. If I dont measure 2mm, you are wrong.

, if you adjust it to 1mm, you are in good shape, even though you could go "all the way back" and have it in adjustment , assuming a max 1.1 gap available.

, if you adjust it to 1mm, you are in good shape, even though you could go "all the way back" and have it in adjustment , assuming a max 1.1 gap available.

Ill get back to you with an exact measurement of the gap on the pictured H adjsusters, where you say there is a clear wear pattern of near "500 microns" or .5mm. If I dont measure 2mm, you are wrong.

Again, without knowing the initial measurement you are not proving a damn thing by measuring worn parts. If that part started with a ~1.16mm gap and it's now 1.5mm, then I'm right, but there is no proof to be had either way, not without measuring new parts.

Maybe for some reason the damn things just stop wearing at 1.5mm, due to limits of slave cyl. travel, int. spring pressure, etc. If that were the case then your methodology would completely miss it.

At this point it's not only baby Jesus, but all men of science that are crying. Even my girlfriend, when asked, said that the one fork looked worn compared to the other. How is it that you can't see something that even a girl with no training can see?

Footnote: I thought you said that that int. plate(pics in post #147) had had the forks adjusted "all the way to the rear" for the whole time that you've had it, until you turned your gargantuan intellect on the problem. Have you overlooked the possibility that that fork is not worn, because it was adjusted in a way such that the forks never contacted the IP?