Holber race car gets a new engine. Progress Report

#76

Rennlist Member

Thread Starter

This entire season has seen shifts at redline, almost every shift and thats over the past 8 races! much of last year too.

I think a lot of the protection could have been amsoil. hard to say.

sure looked clean in there, I have to say!

Mk

I think a lot of the protection could have been amsoil. hard to say.

sure looked clean in there, I have to say!

Mk

#77

Rennlist Member

Thread Starter

#78

I was just going on what you posted a while back..talking about going into hard lefts and short shifting..can't remember when..but I think..that combined with no squirters (less aeration of the oil) and likely tighter hand built tolerances..is the main reason it's done so good.. How many miles are there on the Holbert motor..doesn't sound like it was run hard until you got it...

#79

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

#80

Rennlist Member

Thread Starter

I think i remember. Basically a style that doesnt have the engine at high rpms during the turns. better for the engine and better for exit power.

mk

mk

I was just going on what you posted a while back..talking about going into hard lefts and short shifting..can't remember when..but I think..that combined with no squirters (less aeration of the oil) and likely tighter hand built tolerances..is the main reason it's done so good.. How many miles are there on the Holbert motor..doesn't sound like it was run hard until you got it...

#81

So you have a choice - put the heads on the way they are with ALOT of copper spray, which may help in certain areas, or also use some permatex around the coolant and oil holes, and hope for the best, or find a 104mm fiber gasket (968) and use that.

A shop that "surfaces the heads and cleans up a few valves" in a day will not be a shop that tells you the truth about what is 50RA and what is not, nor, (and I may get bashed for this) would most even know the difference.

Thats neither here nor there. It seems Mark is now in a time scale where is either unwilling or unable to follow through with the surface prep on the head, the most important part of making the better gasketing that is the MLS work, so really, you should go back to the fiber gaskets.

#82

Man of many SIGs

Rennlist Member

Rennlist Member

http://www.schmitt-ind.com/pdf/Roughness.pdf

#83

Rennlist Member

Thread Starter

Brendan, I appricate the concern, and surely are taking the risks serously, but the shop is a good one and is no stranger to metal gaskets. the guy doing the work did nascar motors a long time ago, and is a artist. He only did the quick valve work, as he is quick, but certainly advised a full porting valve job.

the surface is 30RA, i saw the chart, compared to the surfact and it was much better than the 50RA on the chart (measuring card). certainly as good as the block is that came from Tim and Todd. the lines you see are there, but you cannot feel them.

mk

the surface is 30RA, i saw the chart, compared to the surfact and it was much better than the 50RA on the chart (measuring card). certainly as good as the block is that came from Tim and Todd. the lines you see are there, but you cannot feel them.

mk

I know the surface you are talking about Bill, and there is no way that this will work with Cometic gaskets or any other mls gasket for that matter.

So you have a choice - put the heads on the way they are with ALOT of copper spray, which may help in certain areas, or also use some permatex around the coolant and oil holes, and hope for the best, or find a 104mm fiber gasket (968) and use that.

A shop that "surfaces the heads and cleans up a few valves" in a day will not be a shop that tells you the truth about what is 50RA and what is not, nor, (and I may get bashed for this) would most even know the difference.

Thats neither here nor there. It seems Mark is now in a time scale where is either unwilling or unable to follow through with the surface prep on the head, the most important part of making the better gasketing that is the MLS work, so really, you should go back to the fiber gaskets.

So you have a choice - put the heads on the way they are with ALOT of copper spray, which may help in certain areas, or also use some permatex around the coolant and oil holes, and hope for the best, or find a 104mm fiber gasket (968) and use that.

A shop that "surfaces the heads and cleans up a few valves" in a day will not be a shop that tells you the truth about what is 50RA and what is not, nor, (and I may get bashed for this) would most even know the difference.

Thats neither here nor there. It seems Mark is now in a time scale where is either unwilling or unable to follow through with the surface prep on the head, the most important part of making the better gasketing that is the MLS work, so really, you should go back to the fiber gaskets.

#84

This has pics and explanations. if it looks like the block in the picture, the guys says thats 110ra.

http://www.hotrodders.com/forum/gask...ish-53907.html

There is a chance my head pics are of a better finish than 50RA, but Todd did them like that and he does them differently.

Use some copper spray. You can get this at NAPA....

http://www.hotrodders.com/forum/gask...ish-53907.html

There is a chance my head pics are of a better finish than 50RA, but Todd did them like that and he does them differently.

Use some copper spray. You can get this at NAPA....

#85

Mark,

I know your jammed for time but, This would be an excellent opportunity to

do a leak test. Seal up the water inlet/outlets and feed a garden hose to it,

Also, did you wait 24hrs between the torque sessions ?

I know your jammed for time but, This would be an excellent opportunity to

do a leak test. Seal up the water inlet/outlets and feed a garden hose to it,

Also, did you wait 24hrs between the torque sessions ?

#86

Rennlist Member

Thread Starter

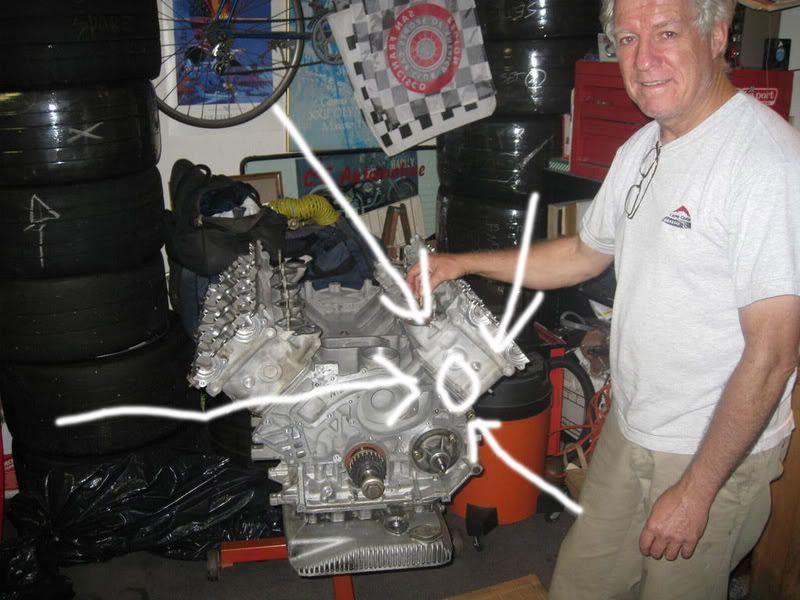

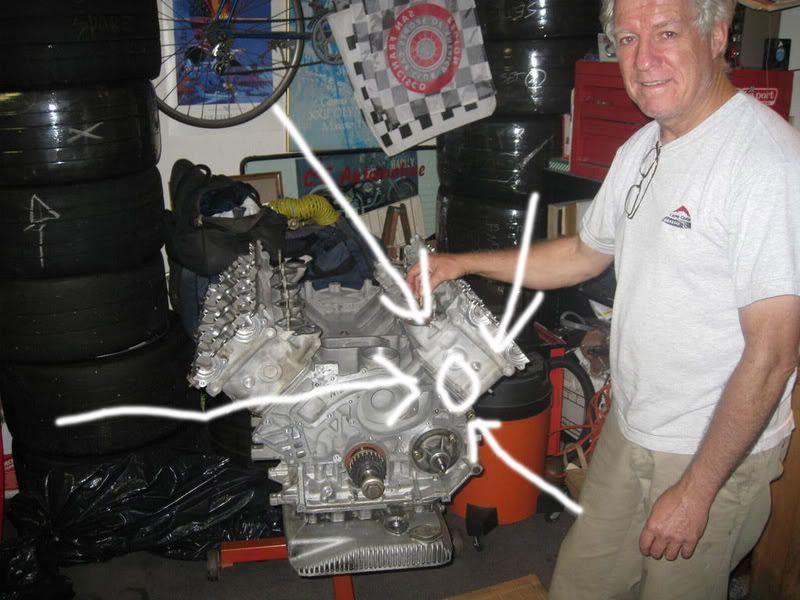

Here are some pics of the assembly and the heads as finished by Ellsworth.

you can see faint lines but they look more like stains, than lines. the surface matches the block as far as RA, maybe a tad better on the block.

anyone want to go through the calculations of the compression ratio?

30ccs for the pistons

37ccs for the heads

and .055 for the gasket, but thats uncompressed, so call it the standard 7ccs.

Mk

you can see faint lines but they look more like stains, than lines. the surface matches the block as far as RA, maybe a tad better on the block.

anyone want to go through the calculations of the compression ratio?

30ccs for the pistons

37ccs for the heads

and .055 for the gasket, but thats uncompressed, so call it the standard 7ccs.

Mk

#87

You will need at least some copper spray on each side of the head gasket.

#88

Rennlist Member

Thread Starter

I know you are not seeing these surfaces in person, but they are the same quality and RA. One from TODD and the other from Ellsworth. you can see the same kind of lines on todds surface that is supposed to be ready for the gasket. Todd said nothing of the spray and if the surface matches the correct value based on the manufacturer (cometic) what is the problem? its better than the 50RA recommended. when you compare the chart, to the surface, it is pretty obvious.

thoughts ? TIM, TODD????? thoughts ???

mk

thoughts ? TIM, TODD????? thoughts ???

mk

#89

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Also, Cometic says the MLS gaskets are coated with sealant and and they have a specfic recommendation not to use any additional sealant, saying they "must" be put on dry.

#90

So what you are saying is that you have already put the heads on, and you will not be removing them to complete the due diligence task of assuring sealing for the headgaskets.

DID YOU, before you torqued the head down, remove the rivet that keeps the head from going all the way down that I have highlighted in this pic? Or was it bent down to clear the head?

DID YOU, before you torqued the head down, remove the rivet that keeps the head from going all the way down that I have highlighted in this pic? Or was it bent down to clear the head?