Engine building tips?

#1

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Thread Starter

OK, you all have seen the thread about Dennis Kao's motor that we are rebuilding. if not, look here.

After two quick engine failures apparently involving 2/6 rod bearings (at least we have confirmed that on the second motor) despite Accusump, Dennis was ready to throw in the towel and just drive his spec Miata. Well, Jim Morton and I have goaded him into not giving up and the motor is apart. We are replacing the short block, but will be going through the whole motor and lubrication system, of course.

We are going to Chevy-drill the replacement crank. It will be cleaned, magnafluxed and polished. We are going to use rod bearings carefully mic'd for tolerance. Jim has a lot of experience with this and has some other plans as well, but I would like to hear suggestions from the group as to what you would do to make the engine more reliable. We are using stock pistons, rods, crank and block from a very low mile S4 motor we just located if that deal goes through.

At this point we will be staying with the Accusump, although we need to carefully evaluate it and make sure it is working correctly. Dry sump is a neat idea but probably not going to happen. Ishihara-Johnson scraper and windage is also a neat idea, but doesn't appear to do anything for 2/6. Louie's breather ideas and oil control ideas are also neat.

What else would you guys do internally? Have at it!

After two quick engine failures apparently involving 2/6 rod bearings (at least we have confirmed that on the second motor) despite Accusump, Dennis was ready to throw in the towel and just drive his spec Miata. Well, Jim Morton and I have goaded him into not giving up and the motor is apart. We are replacing the short block, but will be going through the whole motor and lubrication system, of course.

We are going to Chevy-drill the replacement crank. It will be cleaned, magnafluxed and polished. We are going to use rod bearings carefully mic'd for tolerance. Jim has a lot of experience with this and has some other plans as well, but I would like to hear suggestions from the group as to what you would do to make the engine more reliable. We are using stock pistons, rods, crank and block from a very low mile S4 motor we just located if that deal goes through.

At this point we will be staying with the Accusump, although we need to carefully evaluate it and make sure it is working correctly. Dry sump is a neat idea but probably not going to happen. Ishihara-Johnson scraper and windage is also a neat idea, but doesn't appear to do anything for 2/6. Louie's breather ideas and oil control ideas are also neat.

What else would you guys do internally? Have at it!

#2

Rennlist Member

Make sure the rod bearings clear the radius on the crank(chamfer if necessary), use plastigage, New oil thermostat, complete disassembly and thorough flush of all internal/external oil components. Pressurize the oil system(incl. accusump) by spinning the OP with a drill or similar before attempting to crank it. Do this with the valve covers off so you can verify cam & tensioner oiling. This will give you a chance to validate the accusump setup too, before running it.

Also, don't drive it to the track & flog it right away. Put 1,000-1,500 miles on it before abusing.

Also, don't drive it to the track & flog it right away. Put 1,000-1,500 miles on it before abusing.

#3

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Thread Starter

Yes, we are certainly going completely through the lubrication system, as you mention. I think we have the basic bearing fitting down w/o plastigage. Any mods to the bearings (oil groove)?

#4

Rennlist Member

Our accusump kit as installed by the previous owner, kept Dennis' engine safe for many years of use. I would check the wiring carefully and look for intermittent failure modes, including when all the track "stuff" in inserted and removed form the back. Most importantly, check the function of the accusump before and during every event, just like you check oil level.

The engines that have properly routed accusumps do not fail unless they are not electrically functioning or if manual, not turned on. As a fool proof solution, we will no longer configure these kits with electric valves as the wiring and reliance on user checking pre-event can be avoided by removing the valve completely.

The engines that have properly routed accusumps do not fail unless they are not electrically functioning or if manual, not turned on. As a fool proof solution, we will no longer configure these kits with electric valves as the wiring and reliance on user checking pre-event can be avoided by removing the valve completely.

#5

Rennlist Member

Originally Posted by Bill Ball

Yes, we are certainly going completely through the lubrication system, as you mention. I think we have the basic bearing fitting down w/o plastigage. Any mods to the bearings (oil groove)?

Originally Posted by marc@DEVEK

The engines that have properly routed accusumps do not fail unless they are not electrically functioning or if manual, not turned on.

#6

Three Wheelin'

Originally Posted by Bill Ball

Any mods to the bearings (oil groove)?

BTW, that SAE paper is 2000-01-1341. I'd be glad to discuss it with you or you can download it from SAE pretty cheaply.

#7

Three Wheelin'

Join Date: Dec 2003

Location: Vancouver, Canada

Posts: 1,729

Likes: 0

Received 0 Likes

on

0 Posts

Bill,

This could be a very useful thread. I think all the engine building threads I have seen have related to strokers, FI and high horsepower apps. Between alusil, nicasil, pistons, crank mods, head gaskets, I'm pretty overwhelmed and confused. How about for guys like me that have an older, high mileage engine that may have a couple weak cylinders, that would just like to do a good, reliable,refresh. What can/should/needs to be done, keeping it simple and budget? What's the minimum machining and can be done by local shops? Keep parts as stock as possible, but maybe some that aren't that have really proven superior to stock/for $$ spent? Don't know if thats where you were going with this. If not, my apologies for the hijack (attempt).

Glenn

This could be a very useful thread. I think all the engine building threads I have seen have related to strokers, FI and high horsepower apps. Between alusil, nicasil, pistons, crank mods, head gaskets, I'm pretty overwhelmed and confused. How about for guys like me that have an older, high mileage engine that may have a couple weak cylinders, that would just like to do a good, reliable,refresh. What can/should/needs to be done, keeping it simple and budget? What's the minimum machining and can be done by local shops? Keep parts as stock as possible, but maybe some that aren't that have really proven superior to stock/for $$ spent? Don't know if thats where you were going with this. If not, my apologies for the hijack (attempt).

Glenn

Trending Topics

#8

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

The engines that have properly routed accusumps do not fail unless they are not electrically functioning or if manual, not turned on. As a fool proof solution,

#9

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Bill,

Drilled like a Chevy, 360 groove the thrust bearing, accusump, good oil. Shift at 6K when possible and change the rod bearings once a season!.

This kept my hybrid alive and well for a few years.

Drilled like a Chevy, 360 groove the thrust bearing, accusump, good oil. Shift at 6K when possible and change the rod bearings once a season!.

This kept my hybrid alive and well for a few years.

#11

Addict

Rennlist Member

Rennlist Member

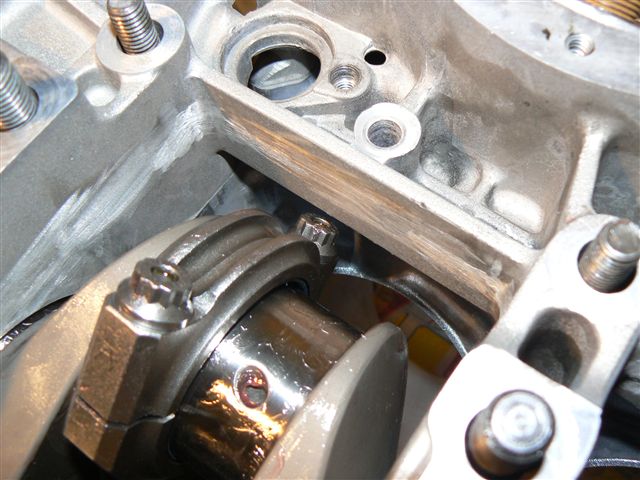

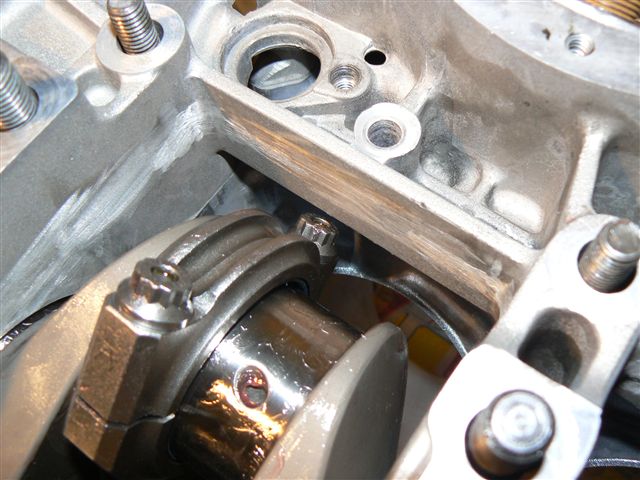

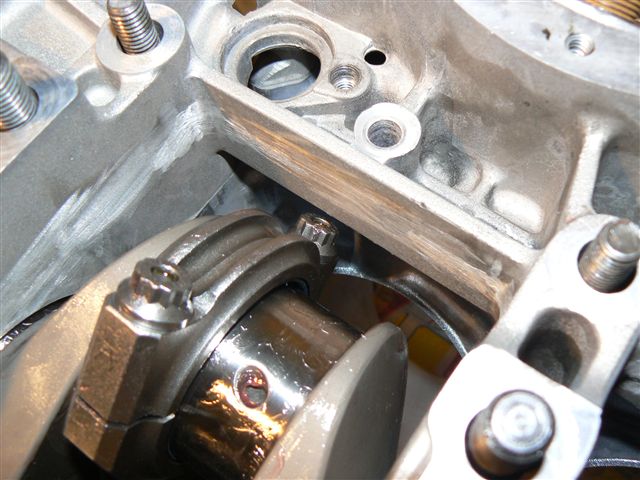

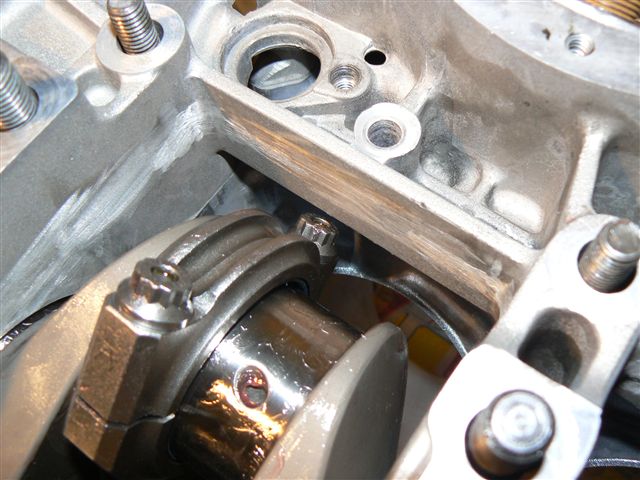

Clean up all excess material from block internals. It doesn't cost much to do. Below is sample of very quick job which could be done much better.

#12

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Thread Starter

Originally Posted by marc@DEVEK

Our accusump kit as installed by the previous owner, kept Dennis' engine safe for many years of use. I would check the wiring carefully and look for intermittent failure modes, including when all the track "stuff" in inserted and removed form the back. Most importantly, check the function of the accusump before and during every event, just like you check oil level.

The engines that have properly routed accusumps do not fail unless they are not electrically functioning or if manual, not turned on. As a fool proof solution, we will no longer configure these kits with electric valves as the wiring and reliance on user checking pre-event can be avoided by removing the valve completely.

The engines that have properly routed accusumps do not fail unless they are not electrically functioning or if manual, not turned on. As a fool proof solution, we will no longer configure these kits with electric valves as the wiring and reliance on user checking pre-event can be avoided by removing the valve completely.

#13

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Thread Starter

Originally Posted by marc@DEVEK

John, you are right, the only fool proof solution is dry sump!

#14

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Thread Starter

Originally Posted by sharkmeister85

Bill,

This could be a very useful thread. I think all the engine building threads I have seen have related to strokers, FI and high horsepower apps. Between alusil, nicasil, pistons, crank mods, head gaskets, I'm pretty overwhelmed and confused. How about for guys like me that have an older, high mileage engine that may have a couple weak cylinders, that would just like to do a good, reliable,refresh. What can/should/needs to be done, keeping it simple and budget? What's the minimum machining and can be done by local shops? Keep parts as stock as possible, but maybe some that aren't that have really proven superior to stock/for $$ spent? Don't know if thats where you were going with this. If not, my apologies for the hijack (attempt).

Glenn

This could be a very useful thread. I think all the engine building threads I have seen have related to strokers, FI and high horsepower apps. Between alusil, nicasil, pistons, crank mods, head gaskets, I'm pretty overwhelmed and confused. How about for guys like me that have an older, high mileage engine that may have a couple weak cylinders, that would just like to do a good, reliable,refresh. What can/should/needs to be done, keeping it simple and budget? What's the minimum machining and can be done by local shops? Keep parts as stock as possible, but maybe some that aren't that have really proven superior to stock/for $$ spent? Don't know if thats where you were going with this. If not, my apologies for the hijack (attempt).

Glenn

#15

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Thread Starter

Originally Posted by Vilhuer

Clean up all excess material from block internals. It doesn't cost much to do. Below is sample of very quick job which could be done much better.