View Poll Results: For only a head gasket replacement only on a 16v and no other service work, would you

Voters: 59. You may not vote on this poll

Blown/Damaged Head Gasket?

#586

RL Community Team

Rennlist Member

Rennlist Member

Thread Starter

I reinstalled the OEM dipstick to see if the oil I'm seeing is blowing out of that dipstick extension junction.

Also, I've been wondering why my timing changes from time to time when I check it. I decided to test the vacuum advance and retard functions of the distributor with the engine running and think that has been part of my issue.

If I understand the goal correctly, it's to have the timing advanced when the engine is not under load or boost and then pull timing to prevent knock under load and boost. Creating vsccum on the top port of my distributor adds advance and creating vacuum on the underside port retards the timing. Putti positive pressure (blowing into the hose) on either port does not seem to have much effect. I also am not detecting much if any vacuum from the hose connected to the port next to the idle speed screw.

I then figured that coming from the port on the front of the spider body, my boost / vac gauge shows vacuum at idle and under light load but then boost from the supercharger under more throttle, so I'm trying to figure out how I would ever get vacuum onto the retard port when the car is in boost to retard the timing and why I can't just T off that same hose that goes to the boost gauge to run a line from there to the advance port on the distributor. Doing this, at idle and under light load vacuum in that line will advance the timing and when the car goes into boost, positive pressure into the advance port of the distributor removes the vacuum and retards the timing. I drove it with this setup capping off the previous advance and retard connections at the throttle body and it seems to run very well, better than before. On the retard port of the distributor I just installed a small air filter so the distributor can't suck in debris through that port if it somehow ends up in a vacuum condition, but I don't see how that can occur as creating vacuum on the advance vacuum port did not seem to do the same on the retard port.

Question - can improper timing cause only certain cylinders to misfire and not all of them, and could this explain why different cylinders on the 5-8 sides seem to be fouling plugs, or would they all foul about the same if there was a mistiming issue?

Any issue with running the advance / retard this way from that spider body port with my supercharger setup.

Also, I've been wondering why my timing changes from time to time when I check it. I decided to test the vacuum advance and retard functions of the distributor with the engine running and think that has been part of my issue.

If I understand the goal correctly, it's to have the timing advanced when the engine is not under load or boost and then pull timing to prevent knock under load and boost. Creating vsccum on the top port of my distributor adds advance and creating vacuum on the underside port retards the timing. Putti positive pressure (blowing into the hose) on either port does not seem to have much effect. I also am not detecting much if any vacuum from the hose connected to the port next to the idle speed screw.

I then figured that coming from the port on the front of the spider body, my boost / vac gauge shows vacuum at idle and under light load but then boost from the supercharger under more throttle, so I'm trying to figure out how I would ever get vacuum onto the retard port when the car is in boost to retard the timing and why I can't just T off that same hose that goes to the boost gauge to run a line from there to the advance port on the distributor. Doing this, at idle and under light load vacuum in that line will advance the timing and when the car goes into boost, positive pressure into the advance port of the distributor removes the vacuum and retards the timing. I drove it with this setup capping off the previous advance and retard connections at the throttle body and it seems to run very well, better than before. On the retard port of the distributor I just installed a small air filter so the distributor can't suck in debris through that port if it somehow ends up in a vacuum condition, but I don't see how that can occur as creating vacuum on the advance vacuum port did not seem to do the same on the retard port.

Question - can improper timing cause only certain cylinders to misfire and not all of them, and could this explain why different cylinders on the 5-8 sides seem to be fouling plugs, or would they all foul about the same if there was a mistiming issue?

Any issue with running the advance / retard this way from that spider body port with my supercharger setup.

#587

Three Wheelin'

indeed strange fouling of different plugs ….ignition or K jet ????

i would remove that vac advance/retard on the distributor….. i think this is all emission stuff.... not needed on a supercharged engine.

I did it on my rally car engine but had to fix the base plate , as this one comes "loose" when the vac pod is removed.

Improper timing will be the same for all cilinders.... cannot imagine that would be different for a few.....

Indeed lean, under boost i would like to see 11.5..max 12.5 … not 13.

Cruising in "vac" ( no boost ) should be "14.7"

At idle it isn't important , but 16..17 is lean. ECU's hold it also on 14.7 ….. as on my 850i....

Yes, if you have a non firing cilinder , that one will pump a lot of unburnt O2 in the exhaust …. which the sensor reads as "lean" …. but in fact engine is running richer …. so your numbers will be better once all plugs fire.

i would remove that vac advance/retard on the distributor….. i think this is all emission stuff.... not needed on a supercharged engine.

I did it on my rally car engine but had to fix the base plate , as this one comes "loose" when the vac pod is removed.

Improper timing will be the same for all cilinders.... cannot imagine that would be different for a few.....

Indeed lean, under boost i would like to see 11.5..max 12.5 … not 13.

Cruising in "vac" ( no boost ) should be "14.7"

At idle it isn't important , but 16..17 is lean. ECU's hold it also on 14.7 ….. as on my 850i....

Yes, if you have a non firing cilinder , that one will pump a lot of unburnt O2 in the exhaust …. which the sensor reads as "lean" …. but in fact engine is running richer …. so your numbers will be better once all plugs fire.

#588

RL Community Team

Rennlist Member

Rennlist Member

Thread Starter

indeed strange fouling of different plugs ….ignition or K jet ????

i would remove that vac advance/retard on the distributor….. i think this is all emission stuff.... not needed on a supercharged engine.

I did it on my rally car engine but had to fix the base plate , as this one comes "loose" when the vac pod is removed.

Improper timing will be the same for all cilinders.... cannot imagine that would be different for a few.....

Indeed lean, under boost i would like to see 11.5..max 12.5 … not 13.

Cruising in "vac" ( no boost ) should be "14.7"

At idle it isn't important , but 16..17 is lean. ECU's hold it also on 14.7 ….. as on my 850i....

Yes, if you have a non firing cilinder , that one will pump a lot of unburnt O2 in the exhaust …. which the sensor reads as "lean" …. but in fact engine is running richer …. so your numbers will be better once all plugs fire.

i would remove that vac advance/retard on the distributor….. i think this is all emission stuff.... not needed on a supercharged engine.

I did it on my rally car engine but had to fix the base plate , as this one comes "loose" when the vac pod is removed.

Improper timing will be the same for all cilinders.... cannot imagine that would be different for a few.....

Indeed lean, under boost i would like to see 11.5..max 12.5 … not 13.

Cruising in "vac" ( no boost ) should be "14.7"

At idle it isn't important , but 16..17 is lean. ECU's hold it also on 14.7 ….. as on my 850i....

Yes, if you have a non firing cilinder , that one will pump a lot of unburnt O2 in the exhaust …. which the sensor reads as "lean" …. but in fact engine is running richer …. so your numbers will be better once all plugs fire.

Last drive had me at 12 on boost with the new advance/retard setup on the distributor. The purpose of that on the supercharged motor is to pull timing or retard it under boost to prevent detonation.

My old motor had the distributor with only the advance option.

#589

Three Wheelin'

sorry , i meant fouling comes from your either ignition parts or the K- jet

i should check it but i think there is only 1 diaphram in the vac pod…. so boost on the advance side is the same as vac on the retard. If both see the same ( vac or boost ) nothing happens , perhaps a little bit , the working pressure surface will be greater on the advance side as the plunger passes the retard side fixed to the diaphram….

i should check it but i think there is only 1 diaphram in the vac pod…. so boost on the advance side is the same as vac on the retard. If both see the same ( vac or boost ) nothing happens , perhaps a little bit , the working pressure surface will be greater on the advance side as the plunger passes the retard side fixed to the diaphram….

#590

RL Community Team

Rennlist Member

Rennlist Member

Thread Starter

sorry , i meant fouling comes from your either ignition parts or the K- jet

i should check it but i think there is only 1 diaphram in the vac pod…. so boost on the advance side is the same as vac on the retard. If both see the same ( vac or boost ) nothing happens , perhaps a little bit , the working pressure surface will be greater on the advance side as the plunger passes the retard side fixed to the diaphram….

i should check it but i think there is only 1 diaphram in the vac pod…. so boost on the advance side is the same as vac on the retard. If both see the same ( vac or boost ) nothing happens , perhaps a little bit , the working pressure surface will be greater on the advance side as the plunger passes the retard side fixed to the diaphram….

#591

RL Community Team

Rennlist Member

Rennlist Member

Thread Starter

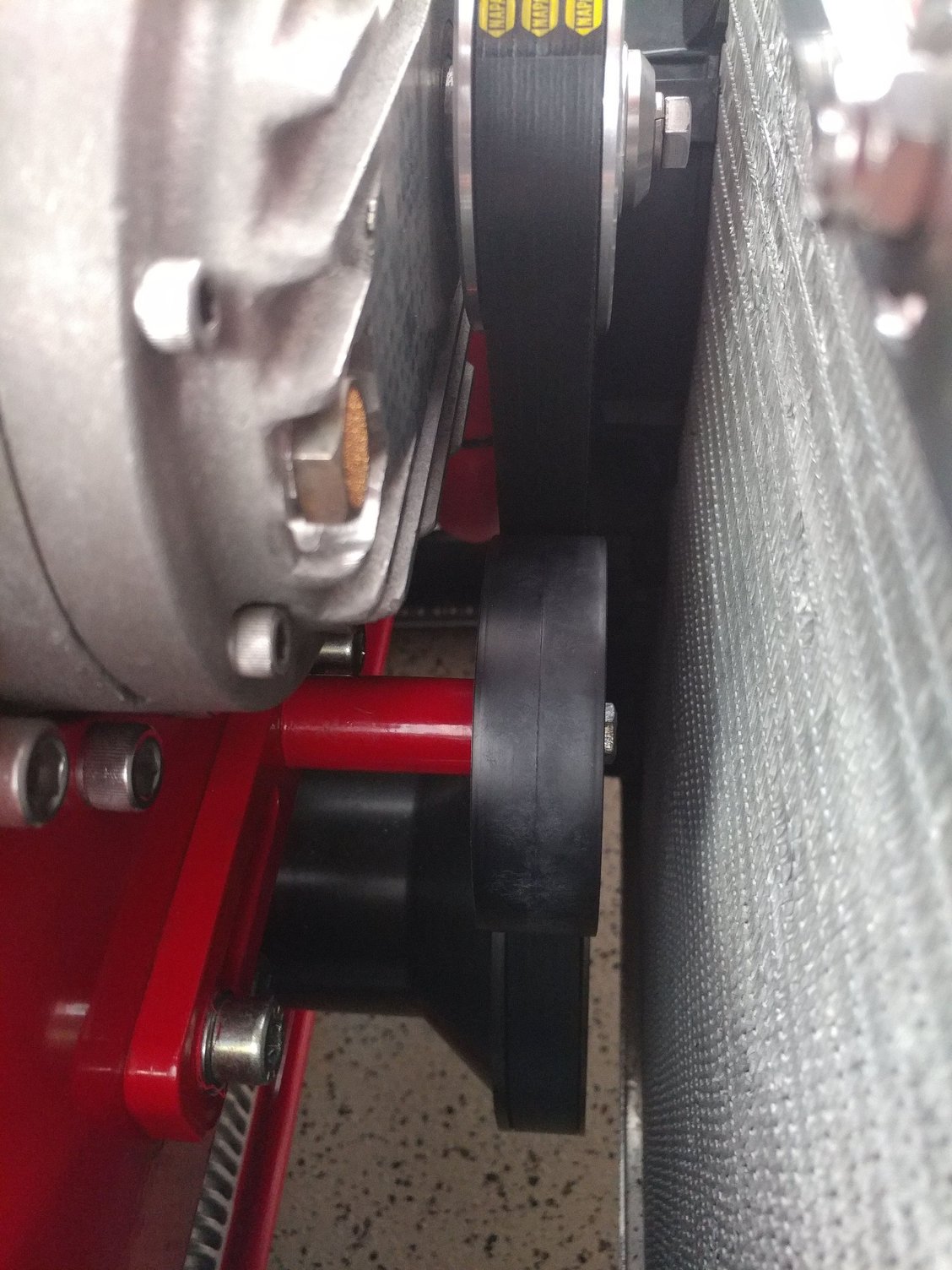

A Napa 38007 pulley has the same 17 mm ID but instead of an 86.79 mm diameter on the belt running surface, has a 90.71 mm running surface diameter, so 3.92 mm running surface diameter difference, or almost 2 mm more encroachment into the belt path with the tensioner fastened in the same position. The only other difference is that the original pulley has belt guiding sides whereas the new one does not but the running surface width of both pulleys is 1" wide and the belt is 0.8" wide so enough margin for error IMO. Since the SC belt is micro v-rib design and both the crank pulley and the supercharger pulley are grooved, the guide sides on the pulley aren't really needed as long as the geometry of the tensioner mount with respect to the supercharger and crank pulley are designed properly and the belt runs true, which it does. Looking at my old pulley which has probably 20,000 miles on it, there is virtually no edge wear on the guide rails so I'm not concerned about using a pulley with out them.

I was able to pull the belt tension further without the fasteners or tensioner assembly bottoming out, so the belt is now slightly tighter than it was previously and I have the Sure-Grip pulley installed. We'll see how it goes with the boost now.

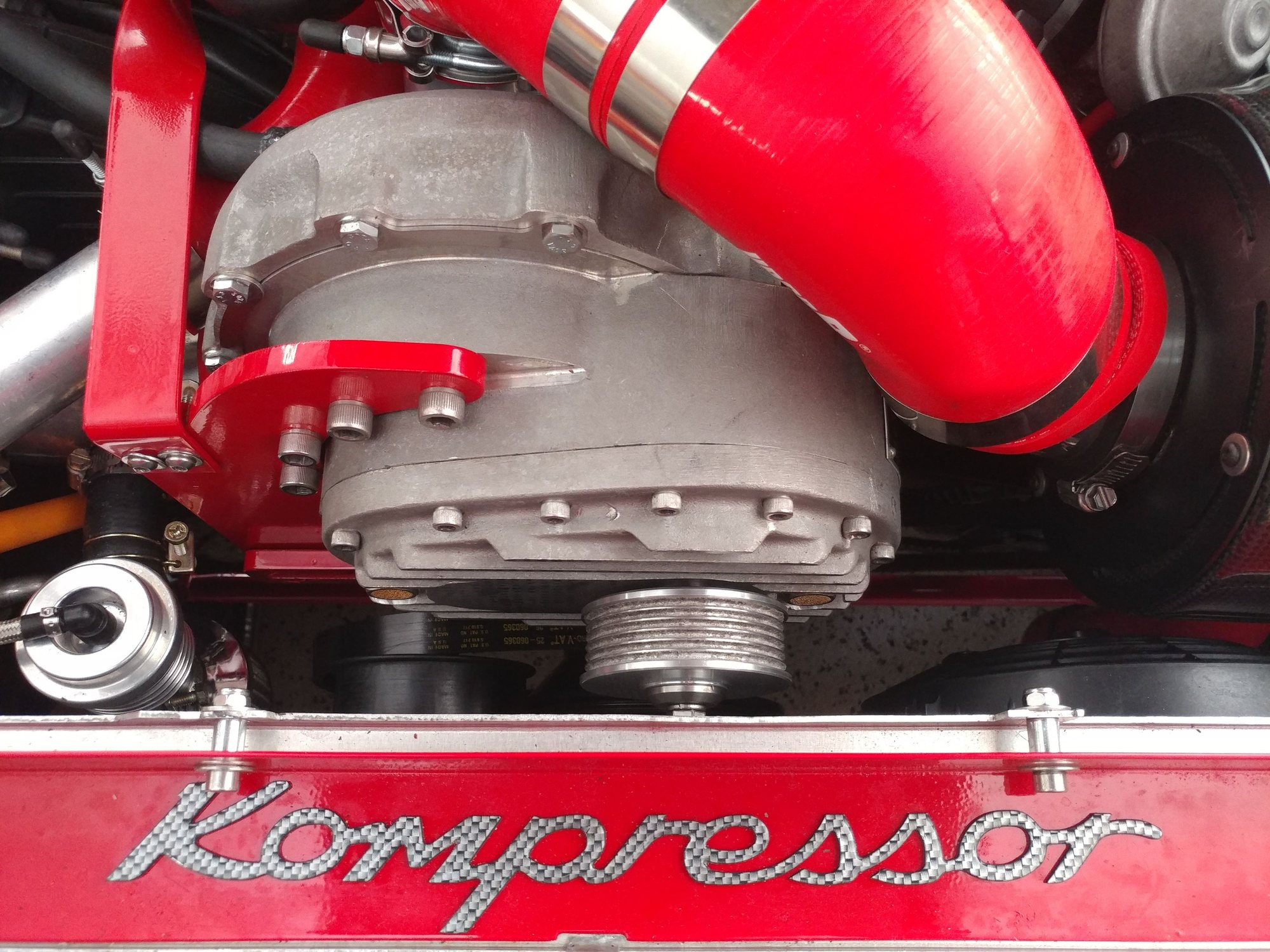

Sure-Grip Pulley Installed

Original SC Tensioner Pulley - note the marks on the tensioner mount from the fasteners are maxed out at the end of both adjustment slots

Running Surface Diameter of Original Pulley

Running Surface Diameter of New Pulley

Number off the new pulley bearing

New Pulley Mounted on Tensioner Assembly

Tensioner Assembly Reinstalled with New Pulley and Tensioned - note running position of SC belt on new pulley (photo is a little dark, but right in the center). Also note, the tensioner fastener position is still maxed out, but because of the larger diameter of the new pulley, the belt is now tighter and the surface area of SC pulley contact with the belt has also been increased ever so slightly

#593

Rennlist Member

I know I mentioned this earlier, but I would approach this by simplifying by completely disabling the supercharger and get the engine running correctly/perfectly normally aspirated first.

Once the engine runs perfectly NA - all plugs look good, pulls hard, etc, then hook up the supercharger and start testing again.

This will help isolate one system from another, and narrow the number of variables to consider.

Once the engine runs perfectly NA - all plugs look good, pulls hard, etc, then hook up the supercharger and start testing again.

This will help isolate one system from another, and narrow the number of variables to consider.

#595

RL Community Team

Rennlist Member

Rennlist Member

Thread Starter

Drove the car to an appointment this morning - about 20 minutes each way - and did some experiments.

On the way there, I purposely stayed out of boost to see if the increased pressure from the supercharger might be causing oil to blow out the SOPG or from somewhere else. Arrived at the appt, looked underneath and no oil. This told me it was either the dipstick extension junction (which was replaced with an OEM dipstick last night) or a result of boost pressure.

On the way back, I drove it normally, with some full throttle pulls holding it in boost. I never got that boost pressure release I was getting before and there was way less oil under the car when I threw it up on the lift when returning home, so the mass exodus of oil that would be dripping off the oil pan looks to have been from the dipstick extension. I've ordered a 90 degree silicone hose for my SC BOV so I can rotate it off to the side from where it sits now. That will give me space to get my hand in to the left of to to access the OEM dipstick.

There was still a little oil under there, but more on the A/C compressor bracket, the cross-member skid plate, and a few other places, and I don't know if that was residual that eventually dripped down or if I may have a small leak from the PS front cam seal. I'll keep an eye on it, but oil loss is now 1,000 less.

AFR #s, with the new advance/retard setup on the distributor, during light pedal driving, the AFR ranges from 13-14.5 depending on RPM, load, and pedal position. Under boost, it's at 12. Under vacuum like when coasting in gear it still goes full lean, but I'm happy with these #s for now.

Under boost, I feel like I've lost a little responsiveness from yesterdays earlier drives and think too much timing is being pulled when the vacuum advance line is seeing positive pressure. How much advance can I run when in a vacuum condition (idle, light throttle, etc) so that I can have a little more advance than I currently do under boost. I think from yesterdays testing I'm probably in the low 20s BTDC when under boost and around 30 when under vacuum. Can I move up to more advance under vacuum so I'm in the mid 20s under boost?

On the way there, I purposely stayed out of boost to see if the increased pressure from the supercharger might be causing oil to blow out the SOPG or from somewhere else. Arrived at the appt, looked underneath and no oil. This told me it was either the dipstick extension junction (which was replaced with an OEM dipstick last night) or a result of boost pressure.

On the way back, I drove it normally, with some full throttle pulls holding it in boost. I never got that boost pressure release I was getting before and there was way less oil under the car when I threw it up on the lift when returning home, so the mass exodus of oil that would be dripping off the oil pan looks to have been from the dipstick extension. I've ordered a 90 degree silicone hose for my SC BOV so I can rotate it off to the side from where it sits now. That will give me space to get my hand in to the left of to to access the OEM dipstick.

There was still a little oil under there, but more on the A/C compressor bracket, the cross-member skid plate, and a few other places, and I don't know if that was residual that eventually dripped down or if I may have a small leak from the PS front cam seal. I'll keep an eye on it, but oil loss is now 1,000 less.

AFR #s, with the new advance/retard setup on the distributor, during light pedal driving, the AFR ranges from 13-14.5 depending on RPM, load, and pedal position. Under boost, it's at 12. Under vacuum like when coasting in gear it still goes full lean, but I'm happy with these #s for now.

Under boost, I feel like I've lost a little responsiveness from yesterdays earlier drives and think too much timing is being pulled when the vacuum advance line is seeing positive pressure. How much advance can I run when in a vacuum condition (idle, light throttle, etc) so that I can have a little more advance than I currently do under boost. I think from yesterdays testing I'm probably in the low 20s BTDC when under boost and around 30 when under vacuum. Can I move up to more advance under vacuum so I'm in the mid 20s under boost?

Last edited by Petza914; 09-23-2019 at 02:04 PM.

#596

RL Community Team

Rennlist Member

Rennlist Member

Thread Starter

Today's update - all pretty good.

Moved the timing up a few degrees this morning before taking it out. With vacuum applied I'm in the low 30s from idle up to 2,000 RPM. Without vacuum applied (hose pulled from distributor), I'm in the mid-20s. Car starts, idles, and drives fine. More responsive under boost today with the timing change than it was yesterday and smoother everywhere. Boost is not falling off at the higher pressures like it used to either.

AFR #s.

At idle - still lean around 16

Driving along coasting, no throttle - still lean, around 17

Driving along with any throttle I'm now in the 13-14 range all the time, sometimes I'll see it swing up as lean as 14.5

Under moderate boost I'm in the low 12s

Under full, long duration boost I'm at 11.8

Knocklink detector is not showing any knock under high rpm and full boost so the boost pressure retarding the timing seems to be working and preventing that.

Oil leak is minor or non-existent with no new oil sprayed at the engine on today's drive. Had to be the dipstick junction as the primary cause as the SOPG seems dry around the full perimeter currently. Is it also possible that the boost falling off around 4 psi was actually releasing that pressure from the same dipstick junction or would that boost pressure not get into the crankcase like that? If that is possible, that may be what I was suspecting as belt slippage on the SC pulley all along. No matter, the Sur-Grip pulley and larger tensioner roller are improvements to that setup nonetheless.

I'm going to run it this way for a while and see how it goes, then pull the 5-8 plugs again and see what they look like.

I'm also considering doing an oil change and running some SeaFoam in the oil (1-1.5 oz / quart) for a few miles before that change to see if maybe I have some gunked up rings or a hanging lifter that aren't helping the situation. I wasn't thrilled with what the engine internals looked like when I was installing the new pan gasket and would like to clean that up.

Moved the timing up a few degrees this morning before taking it out. With vacuum applied I'm in the low 30s from idle up to 2,000 RPM. Without vacuum applied (hose pulled from distributor), I'm in the mid-20s. Car starts, idles, and drives fine. More responsive under boost today with the timing change than it was yesterday and smoother everywhere. Boost is not falling off at the higher pressures like it used to either.

AFR #s.

At idle - still lean around 16

Driving along coasting, no throttle - still lean, around 17

Driving along with any throttle I'm now in the 13-14 range all the time, sometimes I'll see it swing up as lean as 14.5

Under moderate boost I'm in the low 12s

Under full, long duration boost I'm at 11.8

Knocklink detector is not showing any knock under high rpm and full boost so the boost pressure retarding the timing seems to be working and preventing that.

Oil leak is minor or non-existent with no new oil sprayed at the engine on today's drive. Had to be the dipstick junction as the primary cause as the SOPG seems dry around the full perimeter currently. Is it also possible that the boost falling off around 4 psi was actually releasing that pressure from the same dipstick junction or would that boost pressure not get into the crankcase like that? If that is possible, that may be what I was suspecting as belt slippage on the SC pulley all along. No matter, the Sur-Grip pulley and larger tensioner roller are improvements to that setup nonetheless.

I'm going to run it this way for a while and see how it goes, then pull the 5-8 plugs again and see what they look like.

I'm also considering doing an oil change and running some SeaFoam in the oil (1-1.5 oz / quart) for a few miles before that change to see if maybe I have some gunked up rings or a hanging lifter that aren't helping the situation. I wasn't thrilled with what the engine internals looked like when I was installing the new pan gasket and would like to clean that up.

#597

Developer

All sounds good.

The tune sounds good except I do not see what the AFR is at cruise. Fifth gear, throttle just in enough to maintain 55 or 60 MPH - what is the AFR then?

Yes - add a bottle of Sea-Foam to your motor oil and see if that helps those lifters loosen up. No harm in that.

The tune sounds good except I do not see what the AFR is at cruise. Fifth gear, throttle just in enough to maintain 55 or 60 MPH - what is the AFR then?

Yes - add a bottle of Sea-Foam to your motor oil and see if that helps those lifters loosen up. No harm in that.

#598

RL Community Team

Rennlist Member

Rennlist Member

Thread Starter

All sounds good.

The tune sounds good except I do not see what the AFR is at cruise. Fifth gear, throttle just in enough to maintain 55 or 60 MPH - what is the AFR then?

Yes - add a bottle of Sea-Foam to your motor oil and see if that helps those lifters loosen up. No harm in that.

The tune sounds good except I do not see what the AFR is at cruise. Fifth gear, throttle just in enough to maintain 55 or 60 MPH - what is the AFR then?

Yes - add a bottle of Sea-Foam to your motor oil and see if that helps those lifters loosen up. No harm in that.

#599

Developer

That'll do nicely. Sounds like it is functioning as designed. I'd say your tune is finished. I would be reluctant to give it any more ignition advance. Stay where you are.

#600

RL Community Team

Rennlist Member

Rennlist Member

Thread Starter

Good thing this one might have just gotten completed because I now have an issue with my 997 that needs to occupy the lift. Low manometer readings, leaned out fuel trims, an intake leak, and rich fouling on the rear bumper

It never ends.