Carl's new Intake vs AMV8 project intake (pros and cons)Discussion

#106

Rennlist Member

Thread Starter

the spacing of the outer legs should be possible to mate up . I have two of these AM intakes in case we make some terminal errors or come up with a better idea.

almost ready to start cutting and fitting.

#107

Developer

Regards pricing of the 654 manifold... at the moment that one was hand-made, and I feel, too expensive to net very many sales.

When it gets to California (shipping this week on Caltrano's engine) he is going to look into having a casting made to replicate it. As a cast intake, the per-piece costs would be much lower.

More to come when it is known...

When it gets to California (shipping this week on Caltrano's engine) he is going to look into having a casting made to replicate it. As a cast intake, the per-piece costs would be much lower.

More to come when it is known...

#108

Rainman

Rennlist Member

Rennlist Member

Actually, the runner design's most important and critically advantageous part, is the inlet and the progressive tapper. you kind of have to laugh when you look at what the air does in the S4 intake path.

what i see, is runners with the correct angle, but a side angle will be introduced by a cut at the base, ( and re weld) and an appropriate cut at the mating point with a weld . the welder will have to use the artistry to make the upper transition point work. Sure, there will be some turbulence, but the opening size and inlets should much more than make up for the losses.we can always flow bench it when it is done and i guarantee it will be night and day vs the S4 intake and probably near equal to what we have seen so far. maybe not the Carl's intake, as that thing looks like a beast!

what i see, is runners with the correct angle, but a side angle will be introduced by a cut at the base, ( and re weld) and an appropriate cut at the mating point with a weld . the welder will have to use the artistry to make the upper transition point work. Sure, there will be some turbulence, but the opening size and inlets should much more than make up for the losses.we can always flow bench it when it is done and i guarantee it will be night and day vs the S4 intake and probably near equal to what we have seen so far. maybe not the Carl's intake, as that thing looks like a beast!

#109

Rennlist Member

Thread Starter

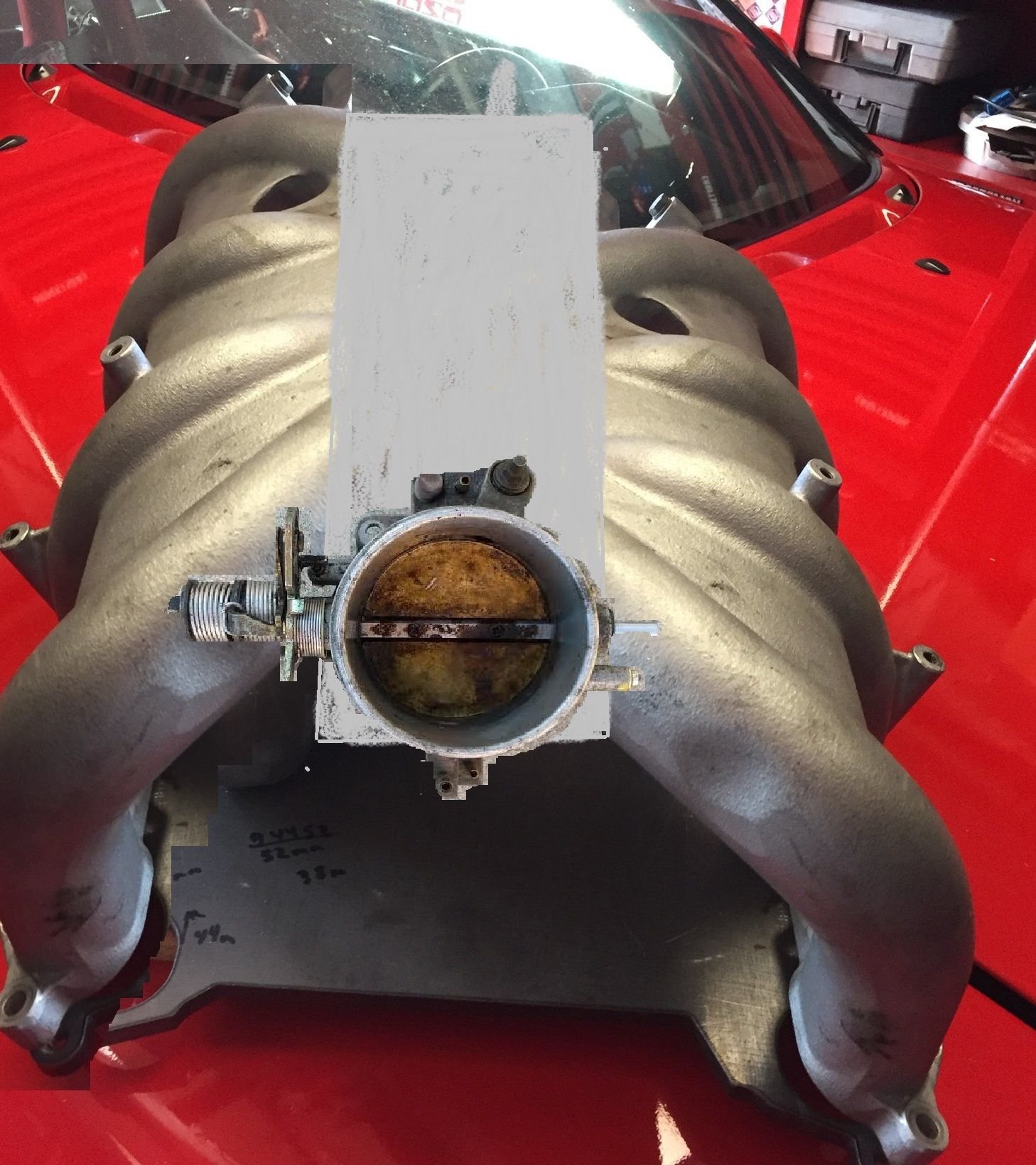

if you look at this picture, you can see the 944 intake needs to be cut at about at the point where the middle two runners start to disappear. Then, you would have 4 tubes. pretty close together, andyou need to bell mouth them and then put a box around them, (all guessing at proper spacing , volume, etc) and then mate some kind of opening to mount a Throttle body. before you know it, you have exactly what Carl made and it was no small effort, i can assure you and he can attest.

my way, only needs to blend the legs of the 944S2 intake to the runner bottoms of the AmV8 intake. i thnk the higher up you go the better as we can smooth the transition at that point downward.

I dont know for sure, as im not a welder, but ive seen things like this made and if it is even close to my vision, it will be a HECK of a lot better than two 944s2 intakes joined together via a box.

the AM intake takes all sorts of flow characteristics into consideration. it is a work of art in itself. sure, joining angled legs at the base is not optimal, but heck, just look at the MESS that the S4 intake is.

#111

Nordschleife Master

I'd agree with that. I'd worry much less about runner length and taper, and much more about getting the runners to be as straight as possible and have the best (average) cross-sectional area. Look at the modular Ford intake manifolds, the best ones (most average power) are the ones with no obvious tuned length but they are straight as an arrow.

#113

Rennlist Member

Thread Starter

the ONLY thing i have as an issue, is the transition point just below the aMV8 plenum where i will be joining the 944S2 intake runner. that little problem, may or may not be possible to even join. .. the least of my worries is the 45 degree angle that the outer legs will be forced to follow. im more worried about the transition of the different rounded box shapes of the AM runners and the 944S2 intake. I was doing some measurements internally to the AM intake, and it does get quite a bit wider near the plenum. again, im not a welder, but i think it looks very possible to make it have a nice transition. PLUS, the extra size can make up for a lot of any flow disturbances. i dont even know if the shape matching is even possible. but ill find out soon. I have two AMV8 intakes, i might start chopping one up just to size things up)

#114

Rennlist Member

Thread Starter

I'd agree with that. I'd worry much less about runner length and taper, and much more about getting the runners to be as straight as possible and have the best (average) cross-sectional area. Look at the modular Ford intake manifolds, the best ones (most average power) are the ones with no obvious tuned length but they are straight as an arrow.

OMG, that is funny! dont worry, i was looking to size it up , picturing where the openings would end up and what it would take to box it

#115

Nordschleife Master

Since you're looking build a race car motor, you should look at the 120% or so VE engines that aren't emissions controlled and that use wave tuning to supercharge the engine. Those have straight intake ports and runners. They must have straight intake ports and runners, because straightness is required for high air speeds without a pressure loss and high air speeds are required for strong wave tuning.

Slight curvature in the same direction is acceptable. S-curves are not. This is IMO a good example of a well-designed intake manifold that curves somewhat:

http://st.hotrod.com/uploads/sites/2...ram-design.jpg

AM intake on AM engine is probably similarly good. Adding an S-curve to the legs is going to screw it up.

I believe that one can't hope oneself out of this issue. Straight is very important for normally aspirated engines, especially close to the port if the runner tapers.

#116

Nordschleife Master

I dont think it will. the 928 intake has 5-6 problems per leg. all get the flow from underneath, through a vent hole with 180 degree curve. then, it finds a runner opening, where its faced off by a plate with little side access, and poor bell mouth design, then, it travels 90 degree angle path, with an incredibly tight radius for 4 of the runners., and the runners are small in diameter as well.

The throttle body element and the feeding of the plenums is not a meaningful restriction at 320hp. At 600hp it's obviously a big restriction and loses a lot of power.

#117

Official Bay Area Patriot

Fuse 24 Assassin

Rennlist Member

Fuse 24 Assassin

Rennlist Member

If the S4 intake runners would be straight, they'd be about right sized in terms of diameter for maybe 600hp. It's not that the runners are too small. It's that they are curved.

The throttle body element and the feeding of the plenums is not a meaningful restriction at 320hp. At 600hp it's obviously a big restriction and loses a lot of power.

The throttle body element and the feeding of the plenums is not a meaningful restriction at 320hp. At 600hp it's obviously a big restriction and loses a lot of power.

#118

Rennlist Member

Thread Starter

Based on what?

Since you're looking build a race car motor, you should look at the 120% or so VE engines that aren't emissions controlled and that use wave tuning to supercharge the engine. Those have straight intake ports and runners. They must have straight intake ports and runners, because straightness is required for high air speeds without a pressure loss and high air speeds are required for strong wave tuning.

Slight curvature in the same direction is acceptable. S-curves are not. This is IMO a good example of a well-designed intake manifold that curves somewhat:

http://st.hotrod.com/uploads/sites/2...ram-design.jpg

AM intake on AM engine is probably similarly good. Adding an S-curve to the legs is going to screw it up.

I believe that one can't hope oneself out of this issue. Straight is very important for normally aspirated engines, especially close to the port if the runner tapers.

Since you're looking build a race car motor, you should look at the 120% or so VE engines that aren't emissions controlled and that use wave tuning to supercharge the engine. Those have straight intake ports and runners. They must have straight intake ports and runners, because straightness is required for high air speeds without a pressure loss and high air speeds are required for strong wave tuning.

Slight curvature in the same direction is acceptable. S-curves are not. This is IMO a good example of a well-designed intake manifold that curves somewhat:

http://st.hotrod.com/uploads/sites/2...ram-design.jpg

AM intake on AM engine is probably similarly good. Adding an S-curve to the legs is going to screw it up.

I believe that one can't hope oneself out of this issue. Straight is very important for normally aspirated engines, especially close to the port if the runner tapers.

#119

Nordschleife Master

#120

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Everyone knows that a Z flows better than an S........ But this is all still just words, opinions, ideas, and dreams ! Time to start cutting and hope the welder can glue it back together.