3 Liter Turbo Registry

#901

Addict

Rennlist Member

Rennlist Member

Ouch. Nightmare.

#902

Rennlist Member

That is the same as issue I had with these pistons. However I could not verify 100% what the reason for failure was. Mahle's analysis said everything was ok with the pistons. All clearances checked out perfect and rings was confirmed to be alusil rings. That leaves the bore prep since I had my block done to 100,5. However I still believe that the new coating is an issue. My hopes now are that all will work well with Nikasil.

Tell me what was the issues you were having that got you to investigate further what was going on?

In my case I was having alot of blowby oil ending up in my catch can. This I noticed almost right away from the fresh build. This got me to check with a borescope which revealed the same scenario as in your pics.

Tell me what was the issues you were having that got you to investigate further what was going on?

In my case I was having alot of blowby oil ending up in my catch can. This I noticed almost right away from the fresh build. This got me to check with a borescope which revealed the same scenario as in your pics.

#903

Nordschleife Master

That is the same as issue I had with these pistons. However I could not verify 100% what the reason for failure was. Mahle's analysis said everything was ok with the pistons. All clearances checked out perfect and rings was confirmed to be alusil rings. That leaves the bore prep since I had my block done to 100,5. However I still believe that the new coating is an issue. My hopes now are that all will work well with Nikasil.

Tell me what was the issues you were having that got you to investigate further what was going on?

In my case I was having alot of blowby oil ending up in my catch can. This I noticed almost right away from the fresh build. This got me to check with a borescope which revealed the same scenario as in your pics.

Tell me what was the issues you were having that got you to investigate further what was going on?

In my case I was having alot of blowby oil ending up in my catch can. This I noticed almost right away from the fresh build. This got me to check with a borescope which revealed the same scenario as in your pics.

#904

Rennlist Member

The piston manufacturer thinks the pistons were perfect and not to blame. There's a shocker right there! It's always something else according to them, but in my opinion their new coating simply doesn't work on these 944/928 Alusil bores and customers end up holding the bag. Flame away, but that's what I think.

#905

Nordschleife Master

Just to prove the point, someone should run two stock pistons with fresh rings and two new-coating Mahle pistons in re-etched stock bores in the same motor. I'm willing to wager money that the two new pistons will cause the motor to fail, and Mahle "analysis" will come back with everything perfect with the pistons and something else must have been wrong with the motor.

#906

Three Wheelin'

Well sorry to here that gentlemen but thank you for sharing your piston woes it appears these pistons have to much of a question mark to run them in a alusil bore. There supposed to be able to run in a 104.5mm finish bore but clearly can't handle that task. My first thought points to alloy blend they used to make them and/or the iron coating they used or didn't use on the whole surface in manufacturing the teflon skirt coating is just for looks and ends up causing more problems with thermal dynamics of the actual piston not being up to snuff.

So thw hunt for the real mahle 104.5mm pistons from 10-15 years ago begins the ones with 360 degree skirts for proper windage in bore and the right iron coating thanks again and better luck on future motor builds

So thw hunt for the real mahle 104.5mm pistons from 10-15 years ago begins the ones with 360 degree skirts for proper windage in bore and the right iron coating thanks again and better luck on future motor builds

#907

We also had more oil in the catch can, and measured about 10 to 25% leakage at the end of the season.

The engine block with the old pistons ran without any problems for 3 racing seasons with the same specs and is back in the car now for another season.

I would not use the new pistons again without a good explenation from mahle.

The engine block with the old pistons ran without any problems for 3 racing seasons with the same specs and is back in the car now for another season.

I would not use the new pistons again without a good explenation from mahle.

#908

Rennlist Member

We also had more oil in the catch can, and measured about 10 to 25% leakage at the end of the season.

The engine block with the old pistons ran without any problems for 3 racing seasons with the same specs and is back in the car now for another season.

I would not use the new pistons again without a good explenation from mahle.

The engine block with the old pistons ran without any problems for 3 racing seasons with the same specs and is back in the car now for another season.

I would not use the new pistons again without a good explenation from mahle.

#909

Addict

Rennlist Member

Rennlist Member

Teflon won't work with alusil, new type powerpak mahles that will work are covered with same grey phosphate but skirts MUST be Ferroprint, not teflon. User Ski had custom powerpak's made some time ago and those worked with alusil no problem. Milledge used those in more then few engines iirc.

#910

Rennlist Member

Teflon won't work with alusil, new type powerpak mahles that will work are covered with same grey phosphate but skirts MUST be Ferroprint, not teflon. User Ski had custom powerpak's made some time ago and those worked with alusil no problem. Milledge used those in more then few engines iirc.

#911

Addict

Rennlist Member

Rennlist Member

#912

Rennlist Member

#913

Addict

Rennlist Member

Rennlist Member

That's the problem.

Ive read somewhere that skirt coating has protective layer that is supposed to wear off..

Ive read somewhere that skirt coating has protective layer that is supposed to wear off..

#914

Nordschleife Master

Just wondering out loud, how does the ring design cause Ferroprint coating to come off from the piston skirt? I don't recall hearing different ring packs wearing off Ferrostan or Ferrocoat iron coating from older pistons.

#915

Addict

Rennlist Member

Rennlist Member

The cylinder damage on rbuilt's block should be measured in depth and determined if damage is along complete piston lenght or just where rings travel.

If it's complete piston travel then I would conclude piston expansion vs cylinder/piston clearance is wrong and it's part of the failure.

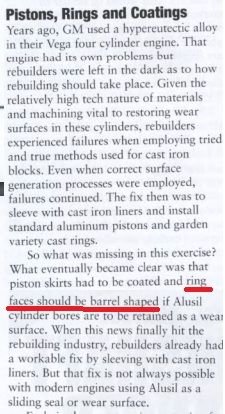

The other part could be the rings which I can't see which are on rbuilt's pistons but PF's were imo wrong as all the literature I've read about alusil say rings must be alusil compatible. Which tapered type are not according to article I posted above and some other mahle/kolbenschmidt literature.

Ferrostan has protective tin layer over the actual ferrostan which protects it from corosion when pistons are new, it removes itself on the sliding part of piston and that's why all used pistons look like they have wear on the skirts when in fact it's perfectly normal.

I suspect the same protective coat is this dark green coat and silver thing under it is actual ferroprint.

If it's complete piston travel then I would conclude piston expansion vs cylinder/piston clearance is wrong and it's part of the failure.

The other part could be the rings which I can't see which are on rbuilt's pistons but PF's were imo wrong as all the literature I've read about alusil say rings must be alusil compatible. Which tapered type are not according to article I posted above and some other mahle/kolbenschmidt literature.

Ferrostan has protective tin layer over the actual ferrostan which protects it from corosion when pistons are new, it removes itself on the sliding part of piston and that's why all used pistons look like they have wear on the skirts when in fact it's perfectly normal.

I suspect the same protective coat is this dark green coat and silver thing under it is actual ferroprint.

Last edited by Voith; 03-27-2017 at 01:37 PM.