Destructive Torsional Harmonics or How to keep your cam bolts from backing out...

#31

Pulley replacement DIY here.... The most controversy seemed to be how you hold the crank in place while you tighten the bolt; might want to include a specialty tool in the kit (easy/cheap to make).

Is this an issue for stock engines? There must be some kind a resonance that causes

engines to break at low rpms. There have been a lot of street miles put on a lot of

GT3's and I haven't heard of this problem.

If I was doing a 4.2L build, I would definitely look at something like this. I'm just

wondering if there's any evidence that this would help either performance or engine

life in a stock engine.

engines to break at low rpms. There have been a lot of street miles put on a lot of

GT3's and I haven't heard of this problem.

If I was doing a 4.2L build, I would definitely look at something like this. I'm just

wondering if there's any evidence that this would help either performance or engine

life in a stock engine.

This is the problem I understand from reading the post about these failures. There are different failures and the results show bolts coming loose and pump gears breaking.

I have not read of any engine failures in GT3 engine other than these. I had an engine fail at the track after only a few laps. The engine was removed at the dealer and a new one installed under warranty. The engine was shipped back to Germany and I never knew what went wrong. What I do know, the Oil Tank was "empty" and all the Oil was in the engine. This happens when the Oil Pump ceases to work correctly. I'm thinking the pump gears broke as explained in the long post. The 2nd engine had the actuators come loose twice. The same one. Passenger side Intake.

I'm not an expert but I have to think that they are all interconnected. The problem has to stemming from the same cause. Whatever the vibration is and at whatever RPM, it has to be the cause for all of these problems.

BTW, I have had my fair share of these sorts of problems. I had a 6 Cyl Panamera and it broke the LHS Intake camshaft in two. I was told by the dealer this had happened before. They had a campaign to remedy this along with different actuators. Seems the GT3 is not alone.

I have not read of any engine failures in GT3 engine other than these. I had an engine fail at the track after only a few laps. The engine was removed at the dealer and a new one installed under warranty. The engine was shipped back to Germany and I never knew what went wrong. What I do know, the Oil Tank was "empty" and all the Oil was in the engine. This happens when the Oil Pump ceases to work correctly. I'm thinking the pump gears broke as explained in the long post. The 2nd engine had the actuators come loose twice. The same one. Passenger side Intake.

I'm not an expert but I have to think that they are all interconnected. The problem has to stemming from the same cause. Whatever the vibration is and at whatever RPM, it has to be the cause for all of these problems.

BTW, I have had my fair share of these sorts of problems. I had a 6 Cyl Panamera and it broke the LHS Intake camshaft in two. I was told by the dealer this had happened before. They had a campaign to remedy this along with different actuators. Seems the GT3 is not alone.

#32

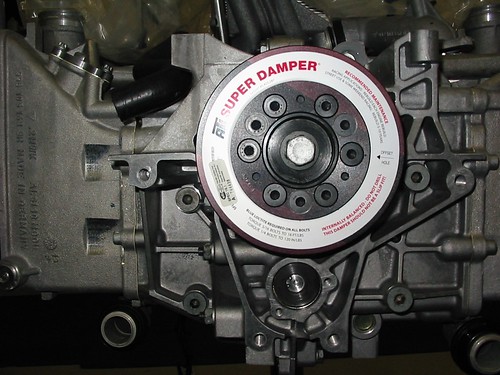

So I spoke with our partners on our 4.2L engine and damper project. See the fruit of our conversation:

The company that is building my engine are in the race and Performance engine business. This is how they make their money. This is how they put food on the table.

The business of engine building has some glamour attached particularly when one of our engines wins a race or championship. However, most of the time it’s all about fixing broken blown up engines. Some due to driver error, some due to mechanical inadequacies. Whatever it is, it takes knowledge, experience and lots of money. Patience too and a rigid determination to stay the course even under intense scrutiny. I would say the forums can be a place where we are put under the spotlight.

We rely upon our experience and knowledge to understand and determine what went wrong, what the cause is and how to fix it. They have spent years doing this. They have been fortunate enough to be involved in engine development since the 1970’s. Their time in Formula One showed me the limits and the necessary requirements to solve the most extreme examples of engines pushed to their limits. I have a saying I tell my people every day. “Nothing can humble a man more than an engine or an angry wife”.

Now in business, the work is a lot less extreme but still requires us to draw upon the same disciplines we were taught to use in our past. The Porsche GT3 and Turbo engines that are having problems are just another issue we have to deal with if you want to be successful in this business. We have to take the good with the bad.

Our first contact with any problem with the GT3 engine was after building a customer a 4.0L engine for his late model 997 RS car. The lightweight Flywheel came loose after a short period of time. Upon disassembly it was found that the shop that installed this aftermarket Flywheel, that the heads of the Bolts dug themselves into the Aluminum Flywheel. It was at this time determined that this was the cause of the bolts coming loose. Soon after this, after driving the car at highway speeds we had the failure with the Oil Pump gears. Once we saw how the gears had failed it immediately pointed to a harmonic issue. This is when you think back into the past and remember other engines that have shown similar failures. The earlier version of this engine was the race 962C engine. We knew right away the problem we were facing. First problem was convincing the owner what the problem was. Show someone a burnt Rod bearing and they get it. Show someone a broken pump gear with no signs of anything “going” through the pump to break them, and you are staring a deer in headlights!

Our first task was to do research and see if this was an isolated problem or others had had similar failures. We found the document produced by Porsche regarding the swapping of Dual Mass Flywheels for Single types. This eluded to a low speed harmonic where the Pulley bolts were coming loose. Now it is starting to make sense. Our failure was after low speed driving. Further research uncovered a slew of Cam Actuators coming loose. Now we knew for sure we had a harmonic problem, very similar to the 962 engine. It is easy to fall into the trap and think these Boxer engines are well balanced. They are better than most but to think they are void of any balance or harmonic issue is short sighted and narrow minded.

Now we had to instrument an engine and run it on the dyno to acquire what, where and when these damaging forces occurred. Once this data was collected it was analyzed and used to determine what kind of damper should be used. There are different types of dampers that are used on engines. Elastomer O-ring, Vicious, Semi Rigid tuned rubber element types, (two steel rings with a rubber band vulcanized between, Porsche 993 type) Pendulum types etc. But the main types are typically Elastomer, Viscous and Rubber element. All have their particular unique points of favor.

Our job is to choose which one is better suited to these particular engines. Choosing includes the use, who runs the engines, are we controlling the use, will we see the engine on a regular basis for inspection and many other factors. We looked at the use particularly and soon decided upon the Elastomer type for these reasons.

The Elastomer types are less frequency sensitive because they have a wider frequency range, can absorb large amounts of energy and have a long life if looked after. As these engines are getting bigger and bigger, plus we have no control over the speeds these engines are used, choosing this type of damper allows for a wider dynamic speed range as the Elastomer Ring of these types never goes resonate at any one particular frequency. The Semi rigid rubber element type of damper is tuned for a specific frequency. This could and will change by outside influence we cannot control. The owner may choose the build a big engine, fit heavier Pistons, etc.

Elastomer dampers do need special attention too. They will turn the energy they absorb into heat when run for long periods of time. This would be in a distance race of some length. Adding cooling just like you do for Brakes is typical. The ability to rebuild these also gives the user long life. If used in racing only, they should be serviced at each engine rebuild. For street driving and the occasional track day, you should consider servicing the damper somewhere between 5- 10 years. It will all depend upon how many track days and how many races and their length. Common sense will dictate the service life. Just another factor we had to consider.

Once we decided upon the type, we then chose a damper manufacture that has a proven record of producing quality parts (ATI).

We are just one of many companies that cater to the Porsche community. It’s not a closed shop and the same opportunity to supply parts is given to all. We do not hold any sort of claim on supplying any particular parts over anyone. However, to give up proprietary information that has cost us time and money is not something we do.

We understand that this may not be what some are looking for but understand from our side as well. We are trying to tackle a problem that even Porsche is choosing not to. The damper we have is the first and is being fitted to our 4.2L project and quite frankly I am putting my money where my mouth is. For those that need proof, stay tuned. I'll update as we get the engine installed, tuned etc...

As others have said, the damper can only help things, not hurt them...

The company that is building my engine are in the race and Performance engine business. This is how they make their money. This is how they put food on the table.

The business of engine building has some glamour attached particularly when one of our engines wins a race or championship. However, most of the time it’s all about fixing broken blown up engines. Some due to driver error, some due to mechanical inadequacies. Whatever it is, it takes knowledge, experience and lots of money. Patience too and a rigid determination to stay the course even under intense scrutiny. I would say the forums can be a place where we are put under the spotlight.

We rely upon our experience and knowledge to understand and determine what went wrong, what the cause is and how to fix it. They have spent years doing this. They have been fortunate enough to be involved in engine development since the 1970’s. Their time in Formula One showed me the limits and the necessary requirements to solve the most extreme examples of engines pushed to their limits. I have a saying I tell my people every day. “Nothing can humble a man more than an engine or an angry wife”.

Now in business, the work is a lot less extreme but still requires us to draw upon the same disciplines we were taught to use in our past. The Porsche GT3 and Turbo engines that are having problems are just another issue we have to deal with if you want to be successful in this business. We have to take the good with the bad.

Our first contact with any problem with the GT3 engine was after building a customer a 4.0L engine for his late model 997 RS car. The lightweight Flywheel came loose after a short period of time. Upon disassembly it was found that the shop that installed this aftermarket Flywheel, that the heads of the Bolts dug themselves into the Aluminum Flywheel. It was at this time determined that this was the cause of the bolts coming loose. Soon after this, after driving the car at highway speeds we had the failure with the Oil Pump gears. Once we saw how the gears had failed it immediately pointed to a harmonic issue. This is when you think back into the past and remember other engines that have shown similar failures. The earlier version of this engine was the race 962C engine. We knew right away the problem we were facing. First problem was convincing the owner what the problem was. Show someone a burnt Rod bearing and they get it. Show someone a broken pump gear with no signs of anything “going” through the pump to break them, and you are staring a deer in headlights!

Our first task was to do research and see if this was an isolated problem or others had had similar failures. We found the document produced by Porsche regarding the swapping of Dual Mass Flywheels for Single types. This eluded to a low speed harmonic where the Pulley bolts were coming loose. Now it is starting to make sense. Our failure was after low speed driving. Further research uncovered a slew of Cam Actuators coming loose. Now we knew for sure we had a harmonic problem, very similar to the 962 engine. It is easy to fall into the trap and think these Boxer engines are well balanced. They are better than most but to think they are void of any balance or harmonic issue is short sighted and narrow minded.

Now we had to instrument an engine and run it on the dyno to acquire what, where and when these damaging forces occurred. Once this data was collected it was analyzed and used to determine what kind of damper should be used. There are different types of dampers that are used on engines. Elastomer O-ring, Vicious, Semi Rigid tuned rubber element types, (two steel rings with a rubber band vulcanized between, Porsche 993 type) Pendulum types etc. But the main types are typically Elastomer, Viscous and Rubber element. All have their particular unique points of favor.

Our job is to choose which one is better suited to these particular engines. Choosing includes the use, who runs the engines, are we controlling the use, will we see the engine on a regular basis for inspection and many other factors. We looked at the use particularly and soon decided upon the Elastomer type for these reasons.

The Elastomer types are less frequency sensitive because they have a wider frequency range, can absorb large amounts of energy and have a long life if looked after. As these engines are getting bigger and bigger, plus we have no control over the speeds these engines are used, choosing this type of damper allows for a wider dynamic speed range as the Elastomer Ring of these types never goes resonate at any one particular frequency. The Semi rigid rubber element type of damper is tuned for a specific frequency. This could and will change by outside influence we cannot control. The owner may choose the build a big engine, fit heavier Pistons, etc.

Elastomer dampers do need special attention too. They will turn the energy they absorb into heat when run for long periods of time. This would be in a distance race of some length. Adding cooling just like you do for Brakes is typical. The ability to rebuild these also gives the user long life. If used in racing only, they should be serviced at each engine rebuild. For street driving and the occasional track day, you should consider servicing the damper somewhere between 5- 10 years. It will all depend upon how many track days and how many races and their length. Common sense will dictate the service life. Just another factor we had to consider.

Once we decided upon the type, we then chose a damper manufacture that has a proven record of producing quality parts (ATI).

We are just one of many companies that cater to the Porsche community. It’s not a closed shop and the same opportunity to supply parts is given to all. We do not hold any sort of claim on supplying any particular parts over anyone. However, to give up proprietary information that has cost us time and money is not something we do.

We understand that this may not be what some are looking for but understand from our side as well. We are trying to tackle a problem that even Porsche is choosing not to. The damper we have is the first and is being fitted to our 4.2L project and quite frankly I am putting my money where my mouth is. For those that need proof, stay tuned. I'll update as we get the engine installed, tuned etc...

As others have said, the damper can only help things, not hurt them...

#33

Jay (UR20V) and I are working out some real world quantification of harmonic dampening for all of you. Will let you know.

Costs for the damper including an installation kit (also working on a tool to help remove the old pulley) is $1250.00.

For the group guy we'll run them at $1150 each for as many as can commit in the next week.

Costs for the damper including an installation kit (also working on a tool to help remove the old pulley) is $1250.00.

For the group guy we'll run them at $1150 each for as many as can commit in the next week.

#35

Group Buy List:

1. Mvez

2. P.J.S.

3. Eddie-RPW

4. Hershann

5. UR20V

Just continue from here, who ever else would like to be on the list...

1. Mvez

2. P.J.S.

3. Eddie-RPW

4. Hershann

5. UR20V

Just continue from here, who ever else would like to be on the list...

Last edited by RKAutowerks; 10-11-2013 at 01:15 PM.

#36

Rennlist Member

I'm interested but can you please post more details of your actual product? Lots of excellent explanations on the whys and hows. But in due course, would you really please describe your actual product--pics, construction details, weight, the usual (without compromising your craft or R&D)? I trust that the enthusiasm from other posters is well deserved, and my order is yours the moment I know this is well-thought, well-built and won't create a problem in a critical area of the engine when we lean on it at the track. Thanks in advance!

#37

Jay (UR20V) and I are working out some real world quantification of harmonic dampening for all of you. Will let you know.

Costs for the damper including an installation kit (also working on a tool to help remove the old pulley) is $1250.00.

For the group guy we'll run them at $1150 each for as many as can commit in the next week.

Costs for the damper including an installation kit (also working on a tool to help remove the old pulley) is $1250.00.

For the group guy we'll run them at $1150 each for as many as can commit in the next week.

I'll am hoping to spend some time over the weekend on the physical set up, might end get to do some modelling preamble before a base line dyno run. Will see when the dyno can give me access also. I'm sure between us we can give some empirical data

for the most hardened sceptic on RL which as we know is a bastion of commited sceptics unless its MT or CL's we are talking about

for the most hardened sceptic on RL which as we know is a bastion of commited sceptics unless its MT or CL's we are talking about

#38

I'm interested but can you please post more details of your actual product? Lots of excellent explanations on the whys and hows. But in due course, would you really please describe your actual product--pics, construction details, weight, the usual (without compromising your craft or R&D)? I trust that the enthusiasm from other posters is well deserved, and my order is yours the moment I know this is well-thought, well-built and won't create a problem in a critical area of the engine when we lean on it at the track. Thanks in advance!

http://www.atiracing.com/products/da...amper_tech.htm

#39

Thanks Jamie.

I'll am hoping to spend some time over the weekend on the physical set up, might end get to do some modelling preamble before a base line dyno run. Will see when the dyno can give me access also. I'm sure between us we can give some empirical data for the most hardened sceptic on RL which as we know is a bastion of commited sceptics unless its MT or CL's we are talking about

for the most hardened sceptic on RL which as we know is a bastion of commited sceptics unless its MT or CL's we are talking about

I'll am hoping to spend some time over the weekend on the physical set up, might end get to do some modelling preamble before a base line dyno run. Will see when the dyno can give me access also. I'm sure between us we can give some empirical data

for the most hardened sceptic on RL which as we know is a bastion of commited sceptics unless its MT or CL's we are talking about

for the most hardened sceptic on RL which as we know is a bastion of commited sceptics unless its MT or CL's we are talking aboutI happen to know who is involved in this. They are not your average shop.

I know they will not give up any of the info. This is typical of all companies in business.

At least they identified the problem and told us about it with a solution. Porsche has done nothing.

Any data you can supply would be very helpful in reassuring those sceptics who dont believe and will confirm what is already known.

#40

So we've been going back and forth on this, and we are suggesting professional installation for the pulley. This is due to the critical nature of the removal of the stock pulley and the risks associated with shearing the key off in the crank or damaging the nose of the crank.

I figure most of you will end up having in installed anyway. We will still be providing an install kit with the pulley, but recommend a shop with the tools and experience to R&R it

I figure most of you will end up having in installed anyway. We will still be providing an install kit with the pulley, but recommend a shop with the tools and experience to R&R it

Last edited by RKAutowerks; 10-11-2013 at 08:50 PM.

#42

Amen to that.

I happen to know who is involved in this. They are not your average shop.

I know they will not give up any of the info. This is typical of all companies in business.

At least they identified the problem and told us about it with a solution. Porsche has done nothing.

Any data you can supply would be very helpful in reassuring those sceptics who dont believe and will confirm what is already known.

I happen to know who is involved in this. They are not your average shop.

I know they will not give up any of the info. This is typical of all companies in business.

At least they identified the problem and told us about it with a solution. Porsche has done nothing.

Any data you can supply would be very helpful in reassuring those sceptics who dont believe and will confirm what is already known.

Jay

#44

I am hoping to do pre and post damper measurements and then again after LWFW. I believe the dual mass flywheel had been 'doing' the job of the damper and this may explain the PP failures seen on 3.8's and 4.0's also...

#45

I guess something's better than nothing.

I don't understand a word on the technical part, but if it cant hurt and your engine is out of warranty, I see no reason not to buy it some extra durability.

I don't understand a word on the technical part, but if it cant hurt and your engine is out of warranty, I see no reason not to buy it some extra durability.