Guide to Repairing a PDK Transmission

#1321

Rennlist Member

I love it and thanks for the follow up!

Where'd you end up getting the pressure sensor? What's funny is that Porsche sells them as the same part is used in other places on other models. But they won't replace them on the PDK instead insisting you but a remanufactured transmission. Pretty messed up.

Where'd you end up getting the pressure sensor? What's funny is that Porsche sells them as the same part is used in other places on other models. But they won't replace them on the PDK instead insisting you but a remanufactured transmission. Pretty messed up.

As another update, I just mated the PDK to the engine. Pretty easy- just required a lot of clever wiggling/jiggling/movement and there is always that satisfying "pop" when everything aligns and it slides together. Once it was aligned, the six screws could easily be hand-threaded.

Through all this effort, I have inadvertently cracked the plastic pan- but I have an aluminum version on the shelf I will install!

The following users liked this post:

stjoh (07-21-2023)

#1322

Three Wheelin'

Thread Starter

I actually ended up grabbing a spare from @stjoh but I did find Porsche ATL had it in stock and my local dealer (Suncoast) could easily order it. I think the other use cases, the sensor is externally replaceable but they are internal on the PDK- hence the hesitation of Porsche recommending their replacement.

As another update, I just mated the PDK to the engine. Pretty easy- just required a lot of clever wiggling/jiggling/movement and there is always that satisfying "pop" when everything aligns and it slides together. Once it was aligned, the six screws could easily be hand-threaded.

Through all this effort, I have inadvertently cracked the plastic pan- but I have an aluminum version on the shelf I will install!

As another update, I just mated the PDK to the engine. Pretty easy- just required a lot of clever wiggling/jiggling/movement and there is always that satisfying "pop" when everything aligns and it slides together. Once it was aligned, the six screws could easily be hand-threaded.

Through all this effort, I have inadvertently cracked the plastic pan- but I have an aluminum version on the shelf I will install!

Kind of surprising that Porsche won't let the dealers replace it as it doesn't require opening the case. But they won't let then replace the clutch either so I guess it's not too surprising. Speaking of clutches I updated the main post (actually Bruce did it for me) to note that Raybestos now sells a clutch friction rings and a shop that overhauls torque convertors should be able to open and close it.

#1323

So what is happening during a PDK calibration procedure?

I posted this elsewhere on Rennlist, and I thought it might be worth a repeat here as general information relating to the transmission. This information is for the 9X1 as this is the platform I'm working on. I can't be 100% sure the process is identical for the 9X7.

Having done a load of cals and looked into the PIWIS code a bit to see what is happening, here's my understanding of the two cal procedures.The calibration consists of 5 separate routines, a-e below.

The calibration with part replacement carries out all 5 routines a-e. When I've had failures where the distance sensor response was fine, it fails in routine d, the hydraulic teach in (valve body cal).

The calibration without part replacement only carries out routines c and e, that being the shift distance (DS numbers) and the clutch cal. All the other routines are ignored, so there is no adaptation delete and no cal of the valve body. If the distance sensor response is within the prescribed limits set in the TCU, I've never had this fail.

Either routine will not begin until you have the clutch fluid temp above 60C. PIWIS will list a bunch of prerequisites like park brake on and the foot brake pressed. Same prerequisites for both.

Routines are as follows:

a. Reprogramming. I don’t know exactly what is happening here, but it seems like all the adaptations are wiped. Takes about a minute.

b. Pressure sensor calibration. Engine isn’t running. Key is turned off and on a few times. Progressive instructions given by PIWIS. Does it twice that take 30 secs each with about 10 secs between each one.

c. Shift distance calibration. This is where it tests the distance sensor response. Engine is running. Takes about 7 minutes, but sometimes takes a lot less if the numbers it has stored are similar to previously held. Will change through all gears and preselections to get the distances for any possible combination. It will sit there seemingly doing nothing for long periods. This is normal.

d. Hydraulic teach in. This is the valve body cal. You don’t really know what’s going on in the background, but if it fails it will give you the individual steps of the hyd teach in and tell you which it failed on. These are the 12 steps below. Below each is the English courtesy of google translate. A german speaker might give better translations so we can have a better understanding of what is actually happening.

Note that EDS 1 and 2 are the clutch controlling solenoids. EDS 3 and 4 control overall system pressure, cooling and lubrication. MV 1 & 2, and EDS 5 & 6 control gear shifting, and don’t seem to be checked at all in this procedure.

Note that steps 2 and 3 are for the two clutches, but it doesn’t do a clutch calibration like it will do next in routine e, which is much more comprehensive. It might be just doing a calibration of EDS 1 and 2.

1. überprüfung druckstellar beendet

pressure regulator test completed

2. kupplung 1 adaptiert

clutch 1 adapted

3. kupplung 2 adaptiert

clutch 2 adapted

4. notkonzept schwelle EDS 4 abwartsrampe

emergency concept threshold EDS4 downward ramp

5. einlernen notkonzeptschwelle EDS 4

learn emergency concept threshold EDS4

6. notkonzept schwelle EDS 3 abwartsrampe

emergency concept threshold EDS3 downward ramp

7. einlernen notkonzeptschwelle EDS 3

learn emergency concept threshold EDS3

8. systemdruckkennlinie EDS3 abwartsramp

system pressure characteristic EDS3 downward ramp

9. einlernen systemdruckkennlinie EDS3

Teach system pressure characteristic EDS3

10. umschaltschwelle EDS4 abwartsstufen

switching threshold EDS4 down steps

11. einlernen umschaltschwelle EDS4

Teach switchover threshold EDS4

12. einlernvorgang beedet

teach-in process finished

e. Clutch calibration. It increases engine RPM and gently applies each of the clutches over and over to get adaptations of how the clutches behave. Every time I do this it will stagnate at 24% and 74% complete for a few minutes. This seems to be normal.

I posted this elsewhere on Rennlist, and I thought it might be worth a repeat here as general information relating to the transmission. This information is for the 9X1 as this is the platform I'm working on. I can't be 100% sure the process is identical for the 9X7.

Having done a load of cals and looked into the PIWIS code a bit to see what is happening, here's my understanding of the two cal procedures.The calibration consists of 5 separate routines, a-e below.

The calibration with part replacement carries out all 5 routines a-e. When I've had failures where the distance sensor response was fine, it fails in routine d, the hydraulic teach in (valve body cal).

The calibration without part replacement only carries out routines c and e, that being the shift distance (DS numbers) and the clutch cal. All the other routines are ignored, so there is no adaptation delete and no cal of the valve body. If the distance sensor response is within the prescribed limits set in the TCU, I've never had this fail.

Either routine will not begin until you have the clutch fluid temp above 60C. PIWIS will list a bunch of prerequisites like park brake on and the foot brake pressed. Same prerequisites for both.

Routines are as follows:

a. Reprogramming. I don’t know exactly what is happening here, but it seems like all the adaptations are wiped. Takes about a minute.

b. Pressure sensor calibration. Engine isn’t running. Key is turned off and on a few times. Progressive instructions given by PIWIS. Does it twice that take 30 secs each with about 10 secs between each one.

c. Shift distance calibration. This is where it tests the distance sensor response. Engine is running. Takes about 7 minutes, but sometimes takes a lot less if the numbers it has stored are similar to previously held. Will change through all gears and preselections to get the distances for any possible combination. It will sit there seemingly doing nothing for long periods. This is normal.

d. Hydraulic teach in. This is the valve body cal. You don’t really know what’s going on in the background, but if it fails it will give you the individual steps of the hyd teach in and tell you which it failed on. These are the 12 steps below. Below each is the English courtesy of google translate. A german speaker might give better translations so we can have a better understanding of what is actually happening.

Note that EDS 1 and 2 are the clutch controlling solenoids. EDS 3 and 4 control overall system pressure, cooling and lubrication. MV 1 & 2, and EDS 5 & 6 control gear shifting, and don’t seem to be checked at all in this procedure.

Note that steps 2 and 3 are for the two clutches, but it doesn’t do a clutch calibration like it will do next in routine e, which is much more comprehensive. It might be just doing a calibration of EDS 1 and 2.

1. überprüfung druckstellar beendet

pressure regulator test completed

2. kupplung 1 adaptiert

clutch 1 adapted

3. kupplung 2 adaptiert

clutch 2 adapted

4. notkonzept schwelle EDS 4 abwartsrampe

emergency concept threshold EDS4 downward ramp

5. einlernen notkonzeptschwelle EDS 4

learn emergency concept threshold EDS4

6. notkonzept schwelle EDS 3 abwartsrampe

emergency concept threshold EDS3 downward ramp

7. einlernen notkonzeptschwelle EDS 3

learn emergency concept threshold EDS3

8. systemdruckkennlinie EDS3 abwartsramp

system pressure characteristic EDS3 downward ramp

9. einlernen systemdruckkennlinie EDS3

Teach system pressure characteristic EDS3

10. umschaltschwelle EDS4 abwartsstufen

switching threshold EDS4 down steps

11. einlernen umschaltschwelle EDS4

Teach switchover threshold EDS4

12. einlernvorgang beedet

teach-in process finished

e. Clutch calibration. It increases engine RPM and gently applies each of the clutches over and over to get adaptations of how the clutches behave. Every time I do this it will stagnate at 24% and 74% complete for a few minutes. This seems to be normal.

Last edited by jjrichar; 07-22-2023 at 03:52 AM.

The following users liked this post:

stjoh (07-21-2023)

#1324

Rennlist Member

Join Date: Jun 2023

Location: Mendon Ma

Posts: 7

Likes: 0

Received 0 Likes

on

0 Posts

Any help would be appreciated. Ive read through a lot of this thread and have gotten a lot of valuable information.

I tried to calibrate my Pdk on my 997.2 turbo after noticing 1st gear slipping on engagement from a stop. I used piwis 3 and hit recalibrate with new hardware and wiped my Pdk module of it programing. I was able to get piwis 2 and program the module and it automatically selected file CT1D82PVJ. While calibrating at the towards the end during I believe clutch calibration I get Calibration failed! Routine can not be performed; threshold not programmed or programmed incorrectly. From what I understand it automatically selected the wrong software. Can anyone tell me the correct software part number for 997.2 turbo or do I have to go in engineering mode and select each file until calibration is successful? Any help will be appreciated. Ive been dealing with this on and off for 2 weeks. Thanks.

I tried to calibrate my Pdk on my 997.2 turbo after noticing 1st gear slipping on engagement from a stop. I used piwis 3 and hit recalibrate with new hardware and wiped my Pdk module of it programing. I was able to get piwis 2 and program the module and it automatically selected file CT1D82PVJ. While calibrating at the towards the end during I believe clutch calibration I get Calibration failed! Routine can not be performed; threshold not programmed or programmed incorrectly. From what I understand it automatically selected the wrong software. Can anyone tell me the correct software part number for 997.2 turbo or do I have to go in engineering mode and select each file until calibration is successful? Any help will be appreciated. Ive been dealing with this on and off for 2 weeks. Thanks.

#1325

Any help would be appreciated. I’ve read through a lot of this thread and have gotten a lot of valuable information.

I tried to calibrate my Pdk on my 997.2 turbo after noticing 1st gear slipping on engagement from a stop. I used piwis 3 and hit recalibrate with new hardware and wiped my Pdk module of it programing. I was able to get piwis 2 and program the module and it automatically selected file CT1D82PVJ. While calibrating at the towards the end during I believe clutch calibration I get “Calibration failed! Routine can not be performed; threshold not programmed or programmed incorrectly. From what I understand it automatically selected the wrong software. Can anyone tell me the correct software part number for 997.2 turbo or do I have to go in engineering mode and select each file until calibration is successful? Any help will be appreciated. I’ve been dealing with this on and off for 2 weeks. Thanks.

I tried to calibrate my Pdk on my 997.2 turbo after noticing 1st gear slipping on engagement from a stop. I used piwis 3 and hit recalibrate with new hardware and wiped my Pdk module of it programing. I was able to get piwis 2 and program the module and it automatically selected file CT1D82PVJ. While calibrating at the towards the end during I believe clutch calibration I get “Calibration failed! Routine can not be performed; threshold not programmed or programmed incorrectly. From what I understand it automatically selected the wrong software. Can anyone tell me the correct software part number for 997.2 turbo or do I have to go in engineering mode and select each file until calibration is successful? Any help will be appreciated. I’ve been dealing with this on and off for 2 weeks. Thanks.

If it was slipping prior to attempting the cal and it fails on the clutch cal, that is pointing to a failed clutch pack in my opinion.

Last edited by jjrichar; 07-29-2023 at 07:23 PM.

#1326

Rennlist Member

Join Date: Jun 2023

Location: Mendon Ma

Posts: 7

Likes: 0

Received 0 Likes

on

0 Posts

I'd be surprised if it selected the incorrect software to load. Unless there have been other software changes you have made within PIWIS where you have changed what the model, year, country etc is, it should pick it up OK. If you do an extended identifications in PIWIS, what is the software it says is loaded?

If it was slipping prior to attempting the cal and it fails on the clutch cal, that is pointing to a failed clutch pack in my opinion.

If it was slipping prior to attempting the cal and it fails on the clutch cal, that is pointing to a failed clutch pack in my opinion.

#1327

So I was able to get the software loaded and transmission calibrated properly. I still had the laggy clutch engagement in 1st and reverse and also launch control does not work. Rpms slowly go up and it sits around 4500rpm. Sounds like an auto trans on torque converter. I read a post in here where a gentlemen had a caymen and had slow engagement in 1st and reverse and he swapped solenoids and recalibrated and his issue was fixed. I replaced solenoids and recalibrated after part replacement as well and it did not fix the issue.

It does sound like the clutch has failed. If you drive hard on a platform with that much power this from what I've read is an expected outcome. I'm assuming you drive it hard by you saying that launch control isn't working. What is the mileage? Track usage? Fluid changes?

#1328

Rennlist Member

Join Date: Jun 2023

Location: Mendon Ma

Posts: 7

Likes: 0

Received 0 Likes

on

0 Posts

Was the software loaded the same as what you mentioned above, or different by the time the you got the cal to work? Just interested if there are circumstances where the wrong flash file might be loaded into the TCU.

It does sound like the clutch has failed. If you drive hard on a platform with that much power this from what I've read is an expected outcome. I'm assuming you drive it hard by you saying that launch control isn't working. What is the mileage? Track usage? Fluid changes?

It does sound like the clutch has failed. If you drive hard on a platform with that much power this from what I've read is an expected outcome. I'm assuming you drive it hard by you saying that launch control isn't working. What is the mileage? Track usage? Fluid changes?

#1329

I do not think this is a file issue. The car is driven like it should be it has a custom tune and pdk flash through Cobb as well. I do not think it is a clutch issue since once the gear engages it does not slip under full power. If it was a clutch issue you would see slipping at point of high torque which I do not have. I did change the solenoids as well as all fluids and recalibrated again with new hardware. Fluid that came out was very clean no glitter or metallic which would show clutches. I am thinking there may be a blockage of some kind in valve body or there is some kind of speed sensor that is lazy.

If the grooves in the friction disks have been worn away then the behaviour of clutch engagement will be completely different. I'd expect there would be an aquaplaning like behaviour until there is physical contact between the adjacent disks. Like aquaplaning of a slick tyre. Once engaged with appropriate pressure they should stay locked. There is a constant flow of fluid into the clutch pack for cooling/lube, and without friction disk grooves the engagement behaviour might be like you are having. I don't know enough about the subject to really know, and I'm just spit balling based on my experience and what seems logical to me.

I was looking through the PIWIS code the other day to see the difference between the 9X7 and 9X1 cal procedures. They are different, and it seems that the 9X1 procedure does a far more extensive VB cal than the 9X7 when doing the cal with part replacement. If the car was 9X1 I'd be pretty confident the VB was fine if it passed this OK. Not so confident for the 9X7. Can you remember the individual stages of the cal? Were they the same as what I posted above?

#1330

Rennlist Member

Join Date: Jun 2023

Location: Mendon Ma

Posts: 7

Likes: 0

Received 0 Likes

on

0 Posts

I think there might still be the possibility of it being a clutch issue. When the clutch packs wear, it's the friction disks that wear the most from what I've seen. The steels don't. I've seen friction disks that have worn completely with the joining steels having no wear at all. Thinking about it I've never seen a steel that has any noticeable wear. They just get burn marks on them.

If the grooves in the friction disks have been worn away then the behaviour of clutch engagement will be completely different. I'd expect there would be an aquaplaning like behaviour until there is physical contact between the adjacent disks. Like aquaplaning of a slick tyre. Once engaged with appropriate pressure they should stay locked. There is a constant flow of fluid into the clutch pack for cooling/lube, and without friction disk grooves the engagement behaviour might be like you are having. I don't know enough about the subject to really know, and I'm just spit balling based on my experience and what seems logical to me.

I was looking through the PIWIS code the other day to see the difference between the 9X7 and 9X1 cal procedures. They are different, and it seems that the 9X1 procedure does a far more extensive VB cal than the 9X7 when doing the cal with part replacement. If the car was 9X1 I'd be pretty confident the VB was fine if it passed this OK. Not so confident for the 9X7. Can you remember the individual stages of the cal? Were they the same as what I posted above?

If the grooves in the friction disks have been worn away then the behaviour of clutch engagement will be completely different. I'd expect there would be an aquaplaning like behaviour until there is physical contact between the adjacent disks. Like aquaplaning of a slick tyre. Once engaged with appropriate pressure they should stay locked. There is a constant flow of fluid into the clutch pack for cooling/lube, and without friction disk grooves the engagement behaviour might be like you are having. I don't know enough about the subject to really know, and I'm just spit balling based on my experience and what seems logical to me.

I was looking through the PIWIS code the other day to see the difference between the 9X7 and 9X1 cal procedures. They are different, and it seems that the 9X1 procedure does a far more extensive VB cal than the 9X7 when doing the cal with part replacement. If the car was 9X1 I'd be pretty confident the VB was fine if it passed this OK. Not so confident for the 9X7. Can you remember the individual stages of the cal? Were they the same as what I posted above?

#1331

I do not remember the whole procedure but I do know there are a few more steps in the calibration after part replacement than calibration after customer concern. Your theory on aquaplaining makes sense but Im not ready to jump in to $10k Dodson clutches. If I let of the brake and give a good amount of throttle it slips and engages. If I let off the brake wait a brief .5 seconds and tap the throttle ever so slightly you can feel the gear engage and then roll into the throttle relatively quickly and it is fine. If I am driving and come to a 5mph roll and give 100% throttle no slip at all.

#1332

Instructor

Has anyone seen this? Shop put in the new distance sensor in the transmission shift fine. The only thing they are having trouble right now with is getting the clutches to calibrate.

they are getting these codes P17F0 Transmission over temp stage 1 exceeds limit value, P1871 Data record for clutch calibration is invalid ( no fault symptom available) The transmission temp sensor showing fluid temp is only 147F we are far from over temp.

they are getting these codes P17F0 Transmission over temp stage 1 exceeds limit value, P1871 Data record for clutch calibration is invalid ( no fault symptom available) The transmission temp sensor showing fluid temp is only 147F we are far from over temp.

#1333

Rennlist Member

Has anyone seen this? Shop put in the new distance sensor in the transmission shift fine. The only thing they are having trouble right now with is getting the clutches to calibrate.

they are getting these codes P17F0 Transmission over temp stage 1 exceeds limit value, P1871 Data record for clutch calibration is invalid ( no fault symptom available) The transmission temp sensor showing fluid temp is only 147F we are far from over temp.

they are getting these codes P17F0 Transmission over temp stage 1 exceeds limit value, P1871 Data record for clutch calibration is invalid ( no fault symptom available) The transmission temp sensor showing fluid temp is only 147F we are far from over temp.

#1334

Instructor

I remember there were cases ppl need a new TCU, did those people try reprogramming as well? Wonder if I should try a new TCU next...?

#1335

Instructor

Has anyone seen this? Shop put in the new distance sensor in the transmission shift fine. The only thing they are having trouble right now with is getting the clutches to calibrate.

they are getting these codes P17F0 Transmission over temp stage 1 exceeds limit value, P1871 Data record for clutch calibration is invalid ( no fault symptom available) The transmission temp sensor showing fluid temp is only 147F we are far from over temp.

they are getting these codes P17F0 Transmission over temp stage 1 exceeds limit value, P1871 Data record for clutch calibration is invalid ( no fault symptom available) The transmission temp sensor showing fluid temp is only 147F we are far from over temp.

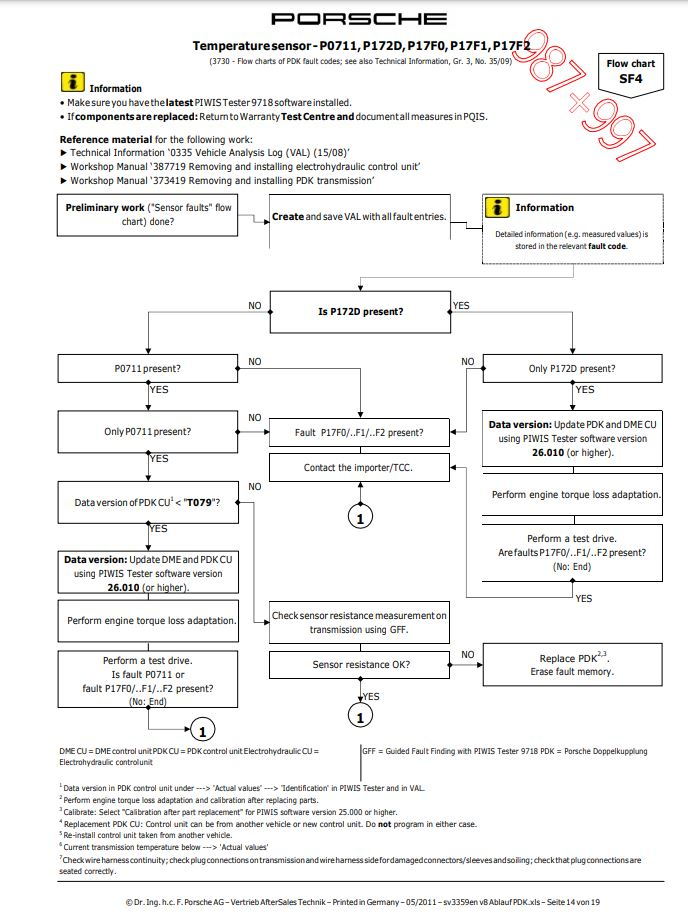

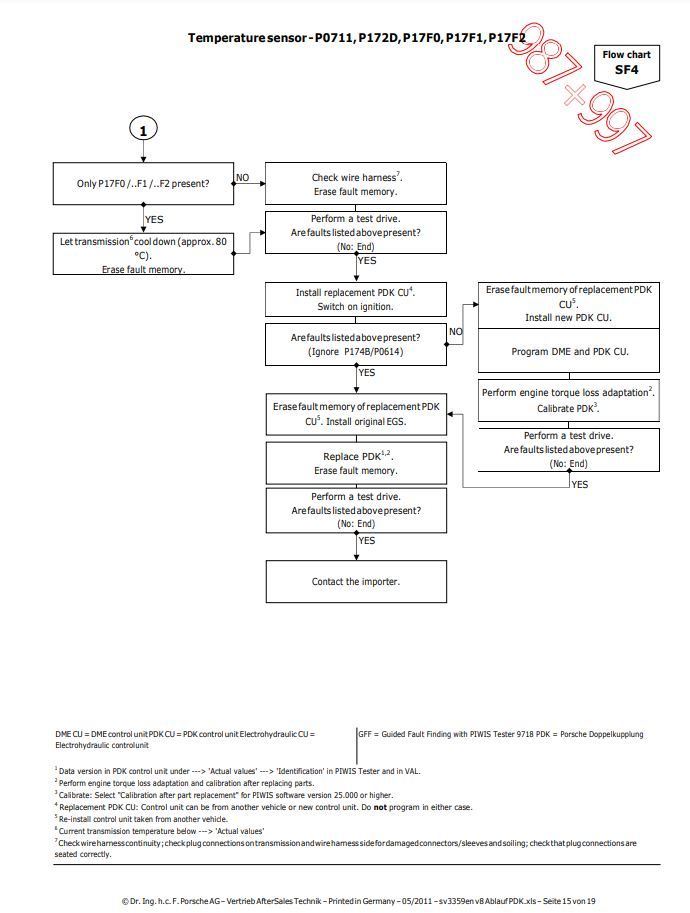

P17F0's flow chart is a bit weird (I have attached here) - going by the flow chart SF4, since we don't have P172D or P0711, it immediately flow to "Contact the importer/TCC" (which isn't particularly helpful...)? And looking at the whole 2 pages of flow chart, in no where it mentions replacing the temp sensor itself - given the temp sensor is available for sale from Porsche, shouldn't somewhere of the flow chart cover the case of bad temp sensor and point to an action item of replacing the sensor?

The whole sequence of event is just so weird - the overheat code wasn't there in the 1st place when I have the distance sensor error, it wasn't there after we put in the t-desgin distance sensor, but now we got it after replaced t-design with XeMODeX's. Another thought is, I saw P17F0 being mentioned as consequential fault companying speed sensor or pressor sensor error, maybe there is a possibility that those sensors problem is causing P17F0? @PV997 mentioned overtemp error could come from a "calculated temp" using speed sensor ( https://rennlist.com/forums/997-foru...l#post16737299 ), which could makes sense here because the sensor readout temp is normal while we're getting overheat error? And since the speed sensor connect to the same harness as the distance sensor, I guess there is a possibility that speed sensor is not connected properly, or damaged by the soldering heat etc in the process of putting in the distance sensor? Although, I do also see in a post from @notfastenough about a case they saw of overheat error as a result of bad speed sensor, there was a gear ratio error (i guess wrong speed -> wrong gear ratio calc - https://rennlist.com/forums/997-foru...l#post18619629 ), but here we are not getting an error that is more directly related to the speed sensor...

Last edited by byroncheung; 08-24-2023 at 12:32 PM.