The 133,333 mile engine rebuild thread

#226

#228

Rennlist Member

The following users liked this post:

latonnelier (02-21-2020)

#229

#230

Rennlist Member

You can't balance it but you can send it to LN to have the gears heli arced in place after checking shaft runout.

#231

Rennlist Member

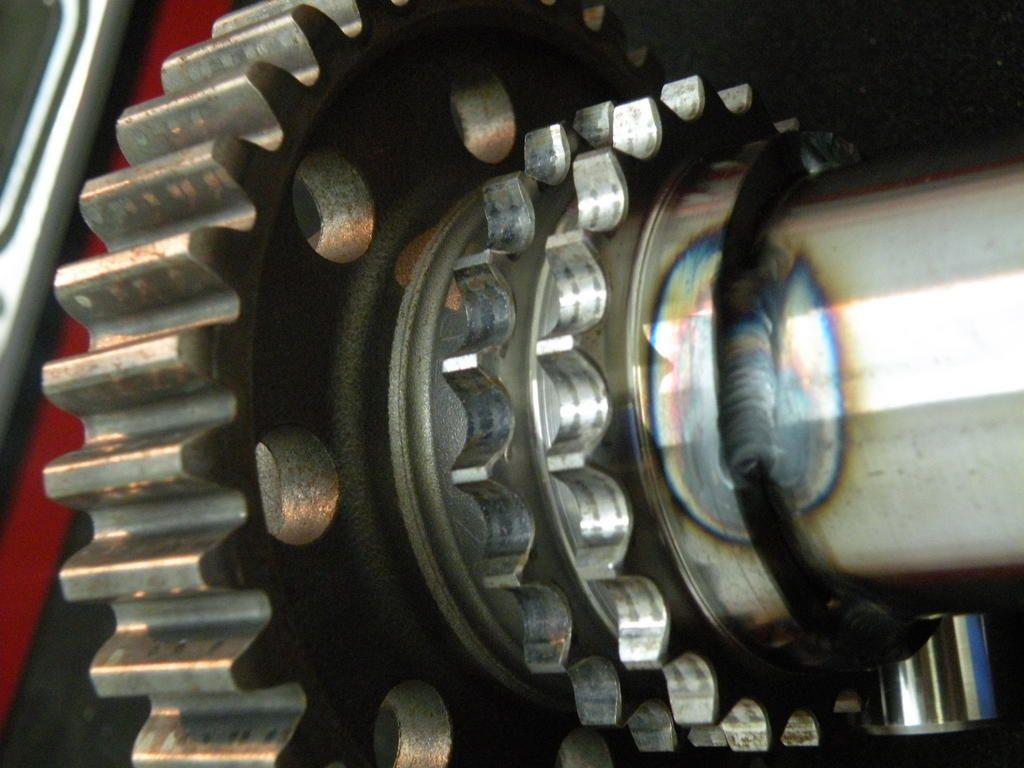

"In addition to ball-bearing failures, the intermediate shaft can suffer other failures including but not limited to slippage of drive sprockets which can lead to valve timing related failures. Again, as a cost saving measure, the sprockets were not secured to the intermediate shaft. The center bearing support stud was manufactured with an o-ring groove cut into it, reducing its cross-sectional thickness to less than the diameter of the threads used to secure the IMS bearing assembly. As such, it is common to have the center bearing support stud break during operation, resulting in a large oil leak, and is often an indicator of a failing or failed IMS bearing."

I had LN do mine. Also upgraded to the IMS Solution at the same time. Took advantage of their Black Friday sale.

#232

#233

Just a car guy

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Jan 2002

Location: South Lyon, Michigan, Ewe Ess Eh

Posts: 9,927

Received 835 Likes

on

524 Posts

Oh - and I just saw that movie a couple of weeks ago.

Yes - I am aware of that service. I am making some serious improvements and consciously opting out of others. There are the "nice to have" items, and then there are the "must have". I figure lots of new parts, refurbished heads, re-lined cylinders and the Solution are on my must have list. There are plenty of things that could be done given a bigger budget. If I were in that position, this engine would be on FSI's wait list. Instead, I bought the DVD set and will build it myself. I am thinking the slipping gears on the IMS is a low risk concern. Hopefully, I am not proven wrong.

#234

Rennlist Member

"I am thinking the slipping gears on the IMS is a low risk concern. Hopefully, I am not proven wrong."

I wouldn't make that assumption. Doing it now (welding or pinning - I would think most machine shops that do automotive stuff would be able to do this accurately and inexpensively - especially compared to an engine failure) while everything is apart is a relatively simple proposition. Do you really want to take a chance after doing all this work?

I wouldn't make that assumption. Doing it now (welding or pinning - I would think most machine shops that do automotive stuff would be able to do this accurately and inexpensively - especially compared to an engine failure) while everything is apart is a relatively simple proposition. Do you really want to take a chance after doing all this work?

#235

Just a car guy

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Jan 2002

Location: South Lyon, Michigan, Ewe Ess Eh

Posts: 9,927

Received 835 Likes

on

524 Posts

"I am thinking the slipping gears on the IMS is a low risk concern. Hopefully, I am not proven wrong."

I wouldn't make that assumption. Doing it now (welding or pinning - I would think most machine shops that do automotive stuff would be able to do this accurately and inexpensively - especially compared to an engine failure) while everything is apart is a relatively simple proposition. Do you really want to take a chance after doing all this work?

I wouldn't make that assumption. Doing it now (welding or pinning - I would think most machine shops that do automotive stuff would be able to do this accurately and inexpensively - especially compared to an engine failure) while everything is apart is a relatively simple proposition. Do you really want to take a chance after doing all this work?

#236

Yes - I am aware of that service. I am making some serious improvements and consciously opting out of others. There are the "nice to have" items, and then there are the "must have". I figure...the Solution are on my must have list. There are plenty of things that could be done given a bigger budget.

#237

Originally Posted by dporto View Post

Feelin' good Louis!

Oh - and I just saw that movie a couple of weeks ago.

Feelin' good Louis!

Oh - and I just saw that movie a couple of weeks ago.

dporto gets a dozen internet cookies

Re: IMS sprockets -- I'd at least have a good welder tack the smaller sprockets in place.

The following users liked this post:

dporto (02-22-2020)

#238

Just a car guy

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Jan 2002

Location: South Lyon, Michigan, Ewe Ess Eh

Posts: 9,927

Received 835 Likes

on

524 Posts

Knowing your predilection for older movies, I would have thought you'd get that one.

dporto gets a dozen internet cookies

Re: IMS sprockets -- I'd at least have a good welder tack the smaller sprockets in place.

Sprockets

dporto gets a dozen internet cookies

Re: IMS sprockets -- I'd at least have a good welder tack the smaller sprockets in place.

Sprockets

I'll look into it. I have very few welders that I trust. Might have to send it to northern Michigan.

Are there any known images of where and how much "tack" to apply? Would be good to offer instruction, if I go that way.

#239

I know how you feel, luckily I have an uncle who is an aircraft welder--he also builds a lot of experimental aircraft --so I just go to him.

I know there is a pic from Jake somewhere on this forum (along with the 40 million other pics of everything else in the universe) but for the life of me I don't know where it is. Perhaps someone knows but I remember the bead being about 3/8 - 1/2 inch long, and maybe 2 welds on each sprocket. Someone correct me if I'm wrong.

I know there is a pic from Jake somewhere on this forum (along with the 40 million other pics of everything else in the universe) but for the life of me I don't know where it is. Perhaps someone knows but I remember the bead being about 3/8 - 1/2 inch long, and maybe 2 welds on each sprocket. Someone correct me if I'm wrong.

The following 2 users liked this post by Coopduc:

latonnelier (02-21-2020),

Scott at Team Harco (02-25-2020)