Smoke at idle

#61

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Thread Starter

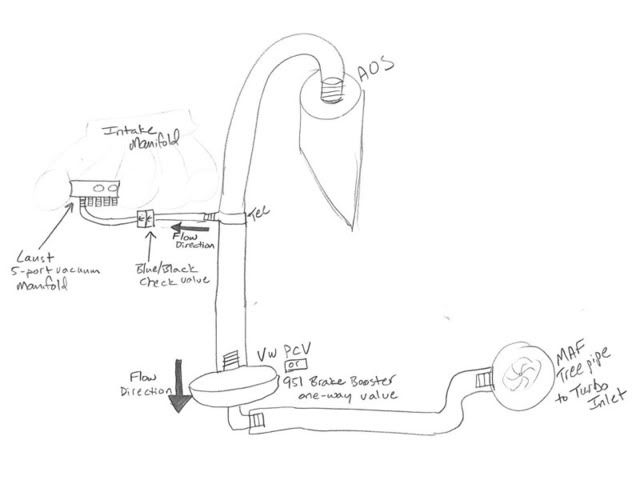

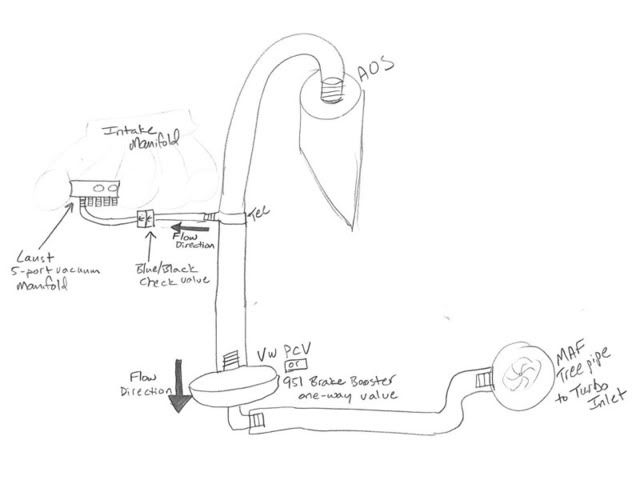

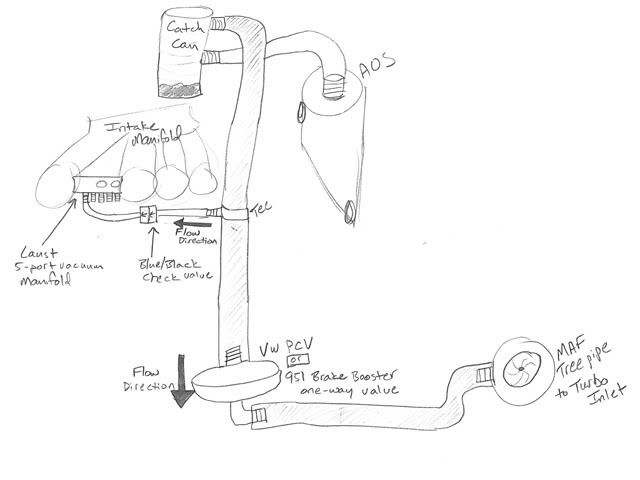

So it sounds like I need to add a very small amount of vacuum to the crankcase at idle, but allow for positive pressure to be vented out of the crankcase during higher RPM's and boost conditions. How about this... keeping in mind that I have a LR oil vent can:

1. Tap the hose between the IAC and IC pipe, tee off that with a small vacuum line tapped into the AOS top. Place a blue/black one-way valve to prevent boost pressure in this line from pushing back to the crankcase or venting "charge air" to the atmosphere.

2. Place a low-restriction check valve on my catch can hose on the catch can side of the tap mentioned above that will not allow air to be sucked in (to the intake manifold), yet allow for crankcase pressure to vent to the catch can under boost.

Does that make sense? It seems like this would provide crankcase vacuum at idle, but still allow positive pressure to flow out through the catch can.

1. Tap the hose between the IAC and IC pipe, tee off that with a small vacuum line tapped into the AOS top. Place a blue/black one-way valve to prevent boost pressure in this line from pushing back to the crankcase or venting "charge air" to the atmosphere.

2. Place a low-restriction check valve on my catch can hose on the catch can side of the tap mentioned above that will not allow air to be sucked in (to the intake manifold), yet allow for crankcase pressure to vent to the catch can under boost.

Does that make sense? It seems like this would provide crankcase vacuum at idle, but still allow positive pressure to flow out through the catch can.

#62

Race Car

If I were to do this I would add a pcv in addition to the aos closed loop vent. I would use a 3/8" one way valve. The brake booster fitting is such a valve.

#63

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Thread Starter

My LR catch can hose is 1", and I don't want to run out the top of that back to the MAF tree pipe if I don't have to. The biggest one-way valve I can find is the 20mm VW part I mentioned above. That valve should close when the intake pulls vacuum, but open to allow positive pressure to vent into my catch can. I don't have it yet, but I hope there isn't a spring to overcome, hopefully it works just like the brake booster valve, but larger.

Based on what I'm reading above, only a minimal amount of volume is required to create negative pressure in the crankcase, so a small vacuum line with a blue/black one-way calve should do the trick there.

#64

Race Car

I would certainly route it back to the air intake track (your catch can) The reason is that it is free horsepower and keeps the rings sealed better. It is very similiar to using a vacuum pump. Also, I don't care for the smell of oil while I'm driving and every setup I have had that vents to atmo smells of oil fumes.

I would add the 3/8 to one of the cam tower plugs along with a fitting to deflect oil.

I would add the 3/8 to one of the cam tower plugs along with a fitting to deflect oil.

#65

Hi Mikjel, thanks for your feedback.

I haven't done the thin plastic bag test over the oil filler cap, but I have had my hand over with the engine idling and it felt like there was very slight pressure.

I wish I had done the plastic bag test to get a more accurate feel of what was going on, but the intake/turbo/exhaust is all off the engine now, and I for sure won't put it all back together with the breather set up the same way as before to do just this test.

In my case, the idea of using the AOS cover from the 968 came from the fact that I wanted to add the pressure release valve that I had skipped during the build (I used a vacuum tube from an '86 turbo, with the short rubber elbow that doesn't have the fitting for this release valve).

I had noticed that the AOS cover from the 968 had its top opening horizontal, which allows to use a straight rubber hose instead of the original elbowed hose, which cracks over time right at the inner angle, which is difficult to check in situ.

As I checked the 968 AOS cover I noticed this vacuum plug, with which I was first intending to monitor crankcase vacuum/pressure with a boost gauge.

Now if you think that such a small vacuum line will help draw enough pressure from the crankcase I can fit a T and both monitor crankcase vacuum/pressure and draw pressure from the crankcase with the intake manifold.

I may need to readjust idle parameters but that should be easy with my aftermarket ECU - by the way, did you notice any difference in your idle with your new set up?

As for oil consumption I noticed the engine hates running with the oil level topped. Oil would make its way in the exhaust through turbine seals until the oil level stabilises to about 75% of the dipstick, and by then I would see very little to no smoke out of the exhaust with the engine idling. Other than that, oil consumption is nil, but I must add I have not tracked the car yet.

The exhaust has never ever smoked apart from when the engine is sat idling for more than about half a minute. Logic wants that I should also have seen smoke when driving with the engine under vacuum (typically, overrun conditions on long slopes), but whenever I have had a friend following behind he couldn't see the exhaust puffing out any smoke.

I had the intake pressure/smoke-tested at a holding 5 bar, so I'm pretty sure pistons rings are sealing as they should.

As for you still seeing smoke under track use - do you have the vacuum line from the AOS top to the inlet of the turbo or do you use some kind of oil catch can venting to atmosphere? As I can see from ZerMATT's post above, using a can venting to atmosphere may not be desirable (I use a Saikou Michi oil catch can, which works fine in the standard, closed loop set up).

In what condition is your turbo?

In my case I needed only a very slight vacuum from the intake manifold to the cranckase. I use a thin hose which I made

restrictions in to keep the air flow as low as possible. I put two pcv-valves (opening in one direction and closing the other direction) in series to be sure I will not get boost pressure in the crankcase.

This is air entering the intake without going through the MAF (air not being "measured") and turbo (not spinning it - not good for draining), so it is best to keep the air flow at absolute minimum. For me it solved the problem with smoke at idle comlpletely, but I am still having some smoke on trackdriving and higher oil consumption than before I mounted the new turbo + maf. Do you ever see any smoke when driving Thom, and how is your oil consumption?

I think it will! I did not know the 968 had a hose / aos top like that.

I did not measure it. The vacuum was very low, not easy/possible to feal with my hand when I held it over the oil filler hole with the cap off. I "measured it" by holding a piece of a thin plastic bag over the oil filler hole. I could see that the plastic was sucked down on my friends stock setup (vacuum) and pushed up on my car with maf setup (positive pressure).

restrictions in to keep the air flow as low as possible. I put two pcv-valves (opening in one direction and closing the other direction) in series to be sure I will not get boost pressure in the crankcase.

This is air entering the intake without going through the MAF (air not being "measured") and turbo (not spinning it - not good for draining), so it is best to keep the air flow at absolute minimum. For me it solved the problem with smoke at idle comlpletely, but I am still having some smoke on trackdriving and higher oil consumption than before I mounted the new turbo + maf. Do you ever see any smoke when driving Thom, and how is your oil consumption?

I think it will! I did not know the 968 had a hose / aos top like that.

I did not measure it. The vacuum was very low, not easy/possible to feal with my hand when I held it over the oil filler hole with the cap off. I "measured it" by holding a piece of a thin plastic bag over the oil filler hole. I could see that the plastic was sucked down on my friends stock setup (vacuum) and pushed up on my car with maf setup (positive pressure).

I wish I had done the plastic bag test to get a more accurate feel of what was going on, but the intake/turbo/exhaust is all off the engine now, and I for sure won't put it all back together with the breather set up the same way as before to do just this test.

In my case, the idea of using the AOS cover from the 968 came from the fact that I wanted to add the pressure release valve that I had skipped during the build (I used a vacuum tube from an '86 turbo, with the short rubber elbow that doesn't have the fitting for this release valve).

I had noticed that the AOS cover from the 968 had its top opening horizontal, which allows to use a straight rubber hose instead of the original elbowed hose, which cracks over time right at the inner angle, which is difficult to check in situ.

As I checked the 968 AOS cover I noticed this vacuum plug, with which I was first intending to monitor crankcase vacuum/pressure with a boost gauge.

Now if you think that such a small vacuum line will help draw enough pressure from the crankcase I can fit a T and both monitor crankcase vacuum/pressure and draw pressure from the crankcase with the intake manifold.

I may need to readjust idle parameters but that should be easy with my aftermarket ECU - by the way, did you notice any difference in your idle with your new set up?

As for oil consumption I noticed the engine hates running with the oil level topped. Oil would make its way in the exhaust through turbine seals until the oil level stabilises to about 75% of the dipstick, and by then I would see very little to no smoke out of the exhaust with the engine idling. Other than that, oil consumption is nil, but I must add I have not tracked the car yet.

The exhaust has never ever smoked apart from when the engine is sat idling for more than about half a minute. Logic wants that I should also have seen smoke when driving with the engine under vacuum (typically, overrun conditions on long slopes), but whenever I have had a friend following behind he couldn't see the exhaust puffing out any smoke.

I had the intake pressure/smoke-tested at a holding 5 bar, so I'm pretty sure pistons rings are sealing as they should.

As for you still seeing smoke under track use - do you have the vacuum line from the AOS top to the inlet of the turbo or do you use some kind of oil catch can venting to atmosphere? As I can see from ZerMATT's post above, using a can venting to atmosphere may not be desirable (I use a Saikou Michi oil catch can, which works fine in the standard, closed loop set up).

In what condition is your turbo?

Last edited by Thom; 09-13-2011 at 05:08 AM.

#66

Just another thought.

What is the difference between the 944 S2 and the 968?

The S2 still has the old style AFM with the flap, while the 968 has a MAF.

At this point it's tempting to think Porsche introduced on the 968 this vacuum line between the intake manifold and the AOS to compensate for the reduced level of vacuum in the J-boot ahead of the throttle body caused by the replacement of the flapper AFM with a free-er flowing MAF, as the vacuum line to the AOS connects to the top of the throttle body, and wouldn't be able to draw enough pressure from the crankcase all by itself.

What do you think of this theory?

If this is correct then replacing the factory AFM in favour of a free-er flowing intake may necessarily be done along with adding such a vacuum line to release turbine seals from excessive pressure.

What is the difference between the 944 S2 and the 968?

The S2 still has the old style AFM with the flap, while the 968 has a MAF.

At this point it's tempting to think Porsche introduced on the 968 this vacuum line between the intake manifold and the AOS to compensate for the reduced level of vacuum in the J-boot ahead of the throttle body caused by the replacement of the flapper AFM with a free-er flowing MAF, as the vacuum line to the AOS connects to the top of the throttle body, and wouldn't be able to draw enough pressure from the crankcase all by itself.

What do you think of this theory?

If this is correct then replacing the factory AFM in favour of a free-er flowing intake may necessarily be done along with adding such a vacuum line to release turbine seals from excessive pressure.

Last edited by Thom; 09-13-2011 at 07:39 AM.

#67

I am not sure which hose you mean, but you need to get vacuum from where the vacuum is gratest at idle (after throttle body).

Now if you think that such a small vacuum line will help draw enough pressure from the crankcase I can fit a T and both monitor crankcase vacuum/pressure and draw pressure from the crankcase with the intake manifold.

I may need to readjust idle parameters but that should be easy with my aftermarket ECU - by the way, did you notice any difference in your idle with your new set up?

Other than that, oil consumption is nil, but I must add I have not tracked the car yet.

As for you still seeing smoke under track use - do you have the vacuum line from the AOS top to the inlet of the turbo or do you use some kind of oil catch can venting to atmosphere?

In what condition is your turbo?

I may need to readjust idle parameters but that should be easy with my aftermarket ECU - by the way, did you notice any difference in your idle with your new set up?

Other than that, oil consumption is nil, but I must add I have not tracked the car yet.

As for you still seeing smoke under track use - do you have the vacuum line from the AOS top to the inlet of the turbo or do you use some kind of oil catch can venting to atmosphere?

In what condition is your turbo?

I can check later today how much my idle is falling when I am squeezing my PCV-hose at idle (letting no vacuum through).

I do not ever see any smoke while driving on the street now, but sometimes a little at track when I am driving harder (never at idle): youtube.com/watch?v=3GvljS2tEDI (no smoke on this video, only inboard driving).

I still have the line from the top of the aos to the front of the turbo, no catch can.

I put on a new turbo and maf-system at the same time (3000 miles ago). Smoke at idle at first start up, no issues with stock setup.

I put on an extra oil cooler when I did the turbo/maf. I had an issue with my oprv when I was priming my new turbo (oprv was stuck - high oil pressure). I do not know for sure if this can have damaged my turbo sealings.

Last edited by mikjel; 09-13-2011 at 08:17 AM.

#68

Just another thought.

What is the difference between the 944 S2 and the 968?

The S2 still has the old style AFM with the flap, while the 968 has a MAF.

At this point it's tempting to think Porsche introduced on the 968 this vacuum line between the intake manifold and the AOS to compensate for the reduced level of vacuum in the J-boot ahead of the throttle body caused by the replacement of the flapper AFM with a free-er flowing MAF, as the vacuum line to the AOS connects to the top of the throttle body, and wouldn't be able to draw enough pressure from the crankcase all by itself.

What do you think of this theory?

If this is correct then replacing the factory AFM in favour of a free-er flowing intake may necessarily be done along with adding such a vacuum line to release turbine seals from excessive pressure.

What is the difference between the 944 S2 and the 968?

The S2 still has the old style AFM with the flap, while the 968 has a MAF.

At this point it's tempting to think Porsche introduced on the 968 this vacuum line between the intake manifold and the AOS to compensate for the reduced level of vacuum in the J-boot ahead of the throttle body caused by the replacement of the flapper AFM with a free-er flowing MAF, as the vacuum line to the AOS connects to the top of the throttle body, and wouldn't be able to draw enough pressure from the crankcase all by itself.

What do you think of this theory?

If this is correct then replacing the factory AFM in favour of a free-er flowing intake may necessarily be done along with adding such a vacuum line to release turbine seals from excessive pressure.

I got very close to 10% on all cylinders. To me, 10% seems to be very good with the new style tester (on top of the green area). I do not think 10% with this tester is comparable with 10% on the old style high pressure leak down testers (where 10% is not very good), but I am not sure..

#69

I still have the line from the top of the aos to the front of the turbo, no catch can.

I put on a new turbo and maf-system at the same time (3000 miles ago). Smoke at idle at first start up, no issues with stock setup.

I put on an extra oil cooler when I did the turbo/maf. I had an issue with my oprv when I was priming my new turbo (oprv was stuck - high oil pressure). I do not know for sure if this can have damaged my turbo sealings.

I put on a new turbo and maf-system at the same time (3000 miles ago). Smoke at idle at first start up, no issues with stock setup.

I put on an extra oil cooler when I did the turbo/maf. I had an issue with my oprv when I was priming my new turbo (oprv was stuck - high oil pressure). I do not know for sure if this can have damaged my turbo sealings.

I am personally interested in the solution used on the 968 NA as I think the problem on my engine is caused by the combination of the extra 500cc (more crankcase pressure than on a 2.5) and the free-er intake.

The factory 968TS use the exact same breather set up as the latest 951 (with the pressure release valve on the rubber elbow) and the stock 951 airbox/AFM, and those that I have seen idling did not smoke at all.

Last edited by Thom; 09-13-2011 at 11:36 AM.

#70

I still have the line from the top of the aos to the front of the turbo, no catch can.

I put on a new turbo and maf-system at the same time (3000 miles ago). Smoke at idle at first start up, no issues with stock setup.

I put on an extra oil cooler when I did the turbo/maf. I had an issue with my oprv when I was priming my new turbo (oprv was stuck - high oil pressure). I do not know for sure if this can have damaged my turbo sealings.

I put on a new turbo and maf-system at the same time (3000 miles ago). Smoke at idle at first start up, no issues with stock setup.

I put on an extra oil cooler when I did the turbo/maf. I had an issue with my oprv when I was priming my new turbo (oprv was stuck - high oil pressure). I do not know for sure if this can have damaged my turbo sealings.

I am personally interested in a solution based on the 968 NA's as I think the problem on my engine is caused by both the extra 500cc (more blow by than on a 2.5) and the free-er intake.

The factory 968TS use the exact same breather set-up as the latest 951 (with the pressure release valve on the rubber elbow) and the stock 951 airbox/AFM, and the two I have seen running did not smoke at all when idling.

If your turbo is still smoking under boost then I would say turbine seals are not sealing.

This, and/or your turbo doesn't create enough vacuum in the AOS line when under boost, but I doubt it.

#71

Do you mean the OPRV in the cylinder head or in the engine block?

The factory 968TS use the exact same breather set up as the latest 951 (with the pressure release valve on the rubber elbow) and the stock 951 airbox/AFM, and those that I have seen idling did not smoke at all.

The factory 968TS use the exact same breather set up as the latest 951 (with the pressure release valve on the rubber elbow) and the stock 951 airbox/AFM, and those that I have seen idling did not smoke at all.

I am no expert , but I do not think the pressure release valve (that I have) has any function at idle when you have low pressure in the cranckase and hose. At high cranckshaft pressure at high boost (much leakdown) it will open (?).

As you mentioned earlier I have been thinking about monitoring cranckase pressure when driving / under boost. But I think it will be hard find data on what pressure is normal / to high.

#72

Well, if excessive crankcase pressure can push oil through turbo seals then I could imagine that excessive oil pressure could damage turbine seals as well.

Yes I agree, the pressure release valve has no function when the engine idles. As I said earlier in this thread its purpose is, I think, to release excessive pressure (it opens at ~0.5 bar) when the recirculating valve closes on a car using the stock intake (air box + flapper AFM).

I was just mentioning it again to insist that the factory 3.0T cars used the same breather system as the latest 951, as most of our American friends on here seem to run pre 89 cars that did not have this valve.

Talk your friend with the completely standard car into monitoring crankcase pressure. If you could map what crankcase pressure/vacuum is seen at what RPM/MAP level, we would have significant datas to work with (well, that is assuming his car has excellent leakdown results).

In any case, if the pressure release valve is rated to open at ~0.5 bar, this may be the absolute upper limit acceptable in terms of crankcase pressure on our cars.

Yes I agree, the pressure release valve has no function when the engine idles. As I said earlier in this thread its purpose is, I think, to release excessive pressure (it opens at ~0.5 bar) when the recirculating valve closes on a car using the stock intake (air box + flapper AFM).

I was just mentioning it again to insist that the factory 3.0T cars used the same breather system as the latest 951, as most of our American friends on here seem to run pre 89 cars that did not have this valve.

In any case, if the pressure release valve is rated to open at ~0.5 bar, this may be the absolute upper limit acceptable in terms of crankcase pressure on our cars.

Last edited by Thom; 09-13-2011 at 11:37 AM.

#73

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Thread Starter

I've got a new question: I just picked up another blue/black vacuum check valve from Zims ($10 for a Mercedes part #), and I'm going to use it to draw crankcase vacuum from the AOS back into the intake manifold through my Laust 5-port vacuum manifold. Should I be concerned about that little check valve getting clogged with oil over time?

I will provide another path for high pressure crankcase gas to escape through a larger (19/20mm) one-way valve that I mentioned above. That larger valve will connect back to the MAF tree pipe where the AOS hose would normally connect.

Something like this (please excuse my lack of artistic talent...):

I will provide another path for high pressure crankcase gas to escape through a larger (19/20mm) one-way valve that I mentioned above. That larger valve will connect back to the MAF tree pipe where the AOS hose would normally connect.

Something like this (please excuse my lack of artistic talent...):

#74

Good question - FWIW the 968 AOS cover I got was filthy and there was some mayonnaise in the tip for the vacuum line.

Not sure I understand the need for the brake booster valve in your diagram, as there will always be vacuum from the turbo inlet. If this valve fails (gets clogged) under boost then crankcase pressure shouldn't be able to be released anywhere!

Not sure I understand the need for the brake booster valve in your diagram, as there will always be vacuum from the turbo inlet. If this valve fails (gets clogged) under boost then crankcase pressure shouldn't be able to be released anywhere!

#75

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Thread Starter

If I remove that brake booster check valve from the diagram, the little blue check valve would serve no purpose other than allow fresh air into the intake manifold at idle via the path of least resistance - the MAF pipe.

This is incorrect. I have zero vacuum at my turbo inlet at idle because the turbo inlet is now only 6" away from a large cone filter attached to the MAF pipe. As soon as you pull off the stock air filter & AFM plumbing, vacuum dissapears at the turbo inlet, which is what is causing this whole problem in the first place. The only time I have vacuum at the turbo inlet when I'm on the throttle and the turbo spools up.

Last edited by zerMATT951; 09-13-2011 at 05:34 PM.