Valve reliefs on 951 pistons for 16v head (photos)

#1

Three Wheelin'

Thread Starter

I'm so slow with the progess of my 2.5 16v turbo engine but it's getting there.

Today I finished machining valve reliefs on 951 pistons. At first I thought the pistons could be used without but test-fitting the head to block showed that at least exhaust valves would hit the head.

Since I wanted perfectly machined and without deviations in size etc between pistons, I chose to do it accordingly.

I used old block and crank together with usable 944 S head and stock S2 valves. I had the valves machined on CNC machine so that valve heads are now cutters and took a stock 944 S piston as a depth sample.

Process was simple: put the S piston into block, push the valves (read: cutters) as deep as they go into stock reliefs, fasten the fixating bolts, install 951 piston and use electric drill.

Here's some photos also:

Stock S2 valves that are machined to appear as cutters and they cut through aluminium like through butter (valve stem ends are machined square in order to enable fitting to drill extension):

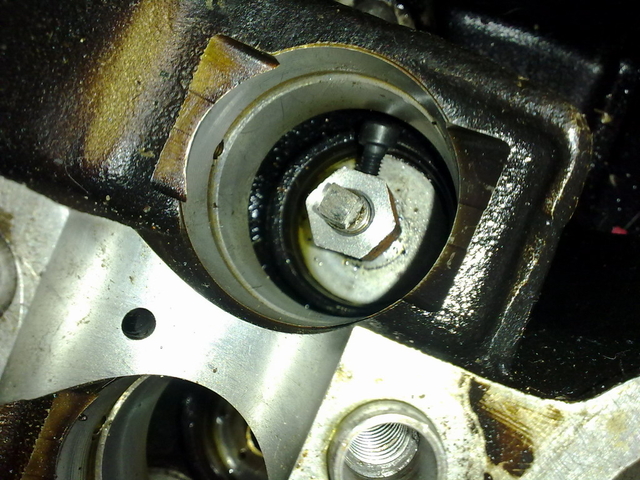

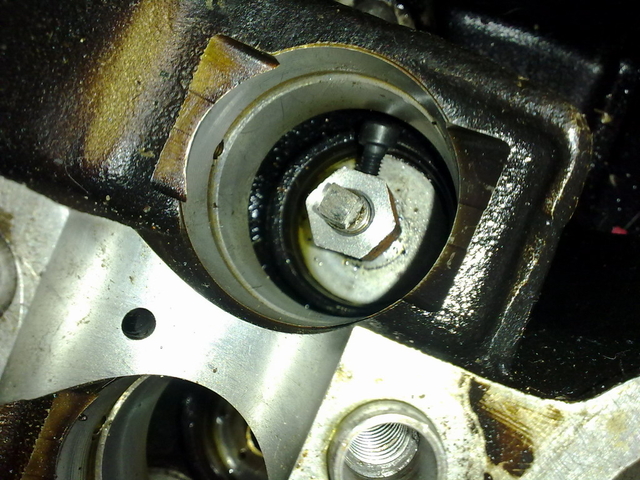

Fixating guide with fastening screw (4 mm allen head):

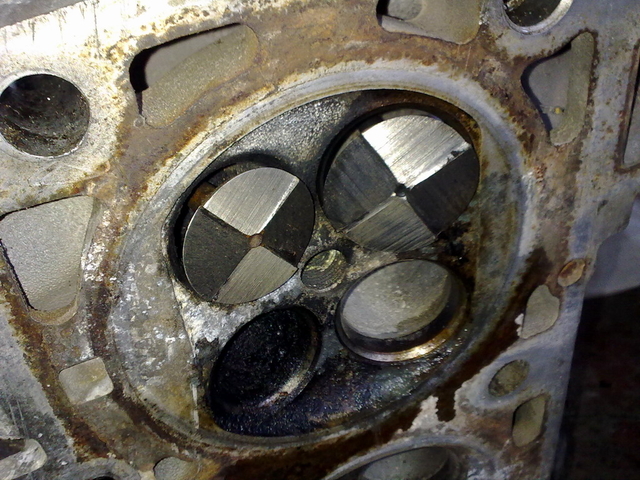

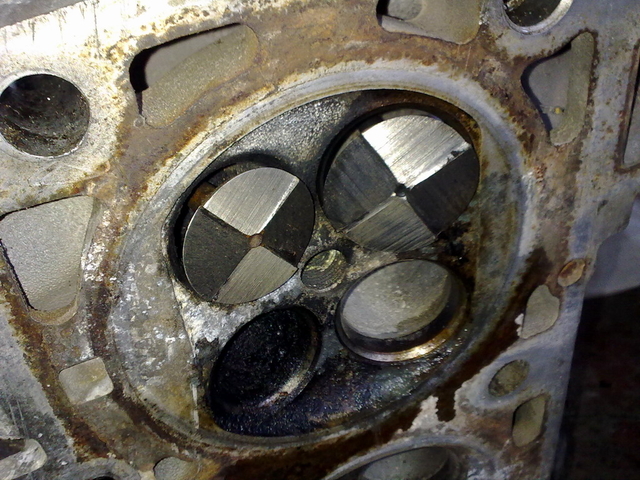

And the end product:

Today I finished machining valve reliefs on 951 pistons. At first I thought the pistons could be used without but test-fitting the head to block showed that at least exhaust valves would hit the head.

Since I wanted perfectly machined and without deviations in size etc between pistons, I chose to do it accordingly.

I used old block and crank together with usable 944 S head and stock S2 valves. I had the valves machined on CNC machine so that valve heads are now cutters and took a stock 944 S piston as a depth sample.

Process was simple: put the S piston into block, push the valves (read: cutters) as deep as they go into stock reliefs, fasten the fixating bolts, install 951 piston and use electric drill.

Here's some photos also:

Stock S2 valves that are machined to appear as cutters and they cut through aluminium like through butter (valve stem ends are machined square in order to enable fitting to drill extension):

Fixating guide with fastening screw (4 mm allen head):

And the end product:

#3

Rainman

Rennlist Member

Rennlist Member

well no ****....

personal preference but i think i would keep going a little bit with the piston out and make the reliefs slightly deeper for extra clearance (and it would drop compression a little more). are you going to polish the newly cut reliefs?

personal preference but i think i would keep going a little bit with the piston out and make the reliefs slightly deeper for extra clearance (and it would drop compression a little more). are you going to polish the newly cut reliefs?

#4

Three Wheelin'

Thread Starter

The reliefs are exactly the same depth as on stock "S" piston so I see no reason them to be deeper. Don't want CR to be under 9:1 anyway.

But yes, I plan on champhering the edges slightly and just in case CC'ing the pistons also after that followed by weight balancing.

But yes, I plan on champhering the edges slightly and just in case CC'ing the pistons also after that followed by weight balancing.

#6

Three Wheelin'

Thread Starter

I didn't find any information about how to machine the reliefs short of CNC machining when googling but I know that old school racers have used junk heads for that, except not with fixators nor machined valves but attaching a diamond cutter onto valve. That on the other hand makes measuring and cutting very painful and slow.

I think this method gives very good accuracy, ease of use and you don't have to waste mora than a day for it. Did I mention cheap?

I think this method gives very good accuracy, ease of use and you don't have to waste mora than a day for it. Did I mention cheap?

The following users liked this post:

Jay Wellwood (10-13-2023)

Trending Topics

#11

Addict

Rennlist Member

Rennlist Member

One word of caution: The cutting tool needs to have a slightly larger diameter than the valves eventually installed.

Hi Kevin,

I did it two different ways.

1. Cut the pockets with the piston(s) at TDC using electric drill on a commercial fly cutter (marked for depth) installed in the cylinder head. The piston to cylinder wall gap was sealed with duct tape.

Result looked good, but was not tested “in vivo”.

2. Used SolidWorks to dimension pocket location and depth from which I machined the dismounted pistons.

My 951 has been running with this on the occasional 25psi boost for the past 6 years with no problems at all.

The non-interference was tested statically: Piston #1 (and #4) at TDC and the cam would turn 360 degrees.

Strangely, I have no urge to test the non interference dynamically (a.k.a. broken timing belt at speed) and will let fait determine when that will happen.

Here is a link to my old “non-interference” thread.

Btw, it is funny (and at the same time sad) to read all the doomsday prophecies to the conversion.

Laust

The following users liked this post:

Dwizle (05-21-2020)

#12

Three Wheelin'

Thread Starter

Thanks Laust for input!

I read your thread and I'm very glad it turned out well and you proved doomsday prohpets being wrong

I've met the same attitude quite often and to be honest nothing feels better to accomplish something that everyone else considered impossible.

Now, where is the best (=cheapest) place to order 951 piston rings?

I read your thread and I'm very glad it turned out well and you proved doomsday prohpets being wrong

I've met the same attitude quite often and to be honest nothing feels better to accomplish something that everyone else considered impossible.

Now, where is the best (=cheapest) place to order 951 piston rings?

#14

Three Wheelin'

Thread Starter

By calculations it will be around 8.8-9:1 but I have yet to cc the pistons and then I can get the real values.

But apparently nothing too drastic.

But apparently nothing too drastic.

#15

Race Car

just re-reading your old thread. Did you determine that both the intake and exhaust valves need reliefs?

Also, do you know if there is a valve that is slightly larger to be used (like a 968 valve)?

Do you know the depth of the relief?

I'm considering buying pistons but the crown is very thick on the turbo pistons so I'm not sure its needed.

TIA

Also, do you know if there is a valve that is slightly larger to be used (like a 968 valve)?

Do you know the depth of the relief?

I'm considering buying pistons but the crown is very thick on the turbo pistons so I'm not sure its needed.

TIA