Timing Belt / Tensioner Recommendation

#121

Rennlist Member

Join Date: Sep 2003

Location: Mansfield, TX

Posts: 669

Likes: 0

Received 0 Likes

on

0 Posts

I will stay with a 60k mile interval. With the stock tensioner, I have heard of belt failures in as little as 30k miles

What about the TIME piece of this? I keep hearing 5 years regardless of mileage as being "gospel".

Any reason Ken's tensioner should change that any and do you folks agree that the 5 year gospel is correct?

Lots of references to Audi's here, they have a 5 year requirement as well? Is the time piece simply a function of deterioration of the belt material or is there another factor involved?

Thanks.

#122

Race Car

It is my opinion that Ken's tensioner will only affect the mileage aspect of the belt. The time aspect is due to the materials the belt is made of degrading, and no tensioner will change this. There are some that say the belts made today are made of much better materials than they were 20 years ago, YMMV. In my post I never considered the time aspect because I know I will go 60k miles before 5 - 6 years is up. I would not drive a 32-valve 928 with a belt that's older than 6 years.

Dan

'91 928GT S/C 475hp/460lb.ft

475hp/460lb.ft

Dan

'91 928GT S/C

475hp/460lb.ft

475hp/460lb.ft

#123

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

The time and mileage belt-life numbers are arbitrary IMHO, and depend tremendously on how you drive the car and where you live.

The time issue is related to heat and smog, contamination by car fluids, and how hot the engine runs. Here in relatively smoggy Los Angeles, the five year number might not be too far off. In places with no smog, belts may last longer.

The mileage issue really isn't mileage as much as it is how the belt has lived. Engine revoluions count would be a better measure than mileage, like the recording tachs used on airplanes. We don't have those, so odometer is the next best thing. If you drive the car hard enough with a lot of lower-gear driving, your engine will turn over a lot more often than somebody who feather-foots the throttle and does mostly real top-gear freeway driving. The most practical measurement might be related to gallons of fuel consumed. It wouldn't be too hard to make a case for a new belt after every four thousand gallons of fuel consumed.

-------------

As I've mentioned previously, belt life predictions also assume that the belt is runnning over pulleys and rollers, gears and drive sprockets that are in like-new condition, and remain in fully serviceable condition throughout the life of the belt. Thay also asssume that the belt tension will be maintained correctly through that life. Ken's tensioner takes care of a couple of those things handily. Correct tension is part of the promise, and it looks like it does a great job. The pivot bolt wear and and related plastic bushing issues are gone, and the two rollers onthe tensioner arm are replaced with a single more robust roller. Loss of oil issues in the stock tensioner are a thing of the past too. No need to retension the belt after 1000-1500 miles either. So Ken's tensioner takes several very common maintenance-neglect issues off the table right from the start. For most DIY owners, the benefits are obvious.

My hesitation on using it is personal, since I just had the excitement of having the warning light come on (correctly) in the last few weeks. Cause of the problem is simple-- cam drive sprockets are worn. The rest of the system looks perfect, including bearings and rollers, the belt and the tensioner boot. It's almost five years, less than 25k miles on the belt and rollers, original cam drive sprockets. Those parts looked great when I did the belt last time so they weren't replaced. This drives a couple points though-- When you inspect parts in the belt drive system, including all the rollers and sprockets, they need to be good not just now, but for the life of the new belt. A bearing or roller that's 'worn a little but OK now' needs to be replaced now with the belt. Wear o parts follows an exponential curve, where a little wear begets more wear, a little grumble in a bearing turns into a big one in a hurry, and ANY wear to the hard anodizing on the gears is cause for gear replacement. That tiny bit of wear will only get worse, and once the anodizing is worn the base aluminum will waer very quickly. That transfers to belt wear, which wears the sprockets even faster, more belt wear, until you have a premature belt failure.

The warning light came on to warn me of the wear in the system. If Ken's tensioner was on the job, the belt tension would have remained constant as the belt tore itself up on the wearing drive sprockets. I would not have been aware of the problem until there was a total failure. I do love the idea of using Ken's part, since it removes so many normal maintenence issues completely. I just need to figure out a way to put a telltale needle on the tensioner arm where I can see it just looking in the engine bay. Maybe something I could wire to a little copper contact I could attach a wire to, maybe the existing warning system wire, so it could warn me that there is some excessive wear or stretch someplace, and give me a chance to do something before catastrophic failure. To me, that early pre-disaster warning is the critical missing element.

I need to buy one of Ken's tensioners and figure out how to add back the warning function. Then it will be a complete solution for me.

Please read the disclaimer in my sig line. It's very serious in this case.

The time issue is related to heat and smog, contamination by car fluids, and how hot the engine runs. Here in relatively smoggy Los Angeles, the five year number might not be too far off. In places with no smog, belts may last longer.

The mileage issue really isn't mileage as much as it is how the belt has lived. Engine revoluions count would be a better measure than mileage, like the recording tachs used on airplanes. We don't have those, so odometer is the next best thing. If you drive the car hard enough with a lot of lower-gear driving, your engine will turn over a lot more often than somebody who feather-foots the throttle and does mostly real top-gear freeway driving. The most practical measurement might be related to gallons of fuel consumed. It wouldn't be too hard to make a case for a new belt after every four thousand gallons of fuel consumed.

-------------

As I've mentioned previously, belt life predictions also assume that the belt is runnning over pulleys and rollers, gears and drive sprockets that are in like-new condition, and remain in fully serviceable condition throughout the life of the belt. Thay also asssume that the belt tension will be maintained correctly through that life. Ken's tensioner takes care of a couple of those things handily. Correct tension is part of the promise, and it looks like it does a great job. The pivot bolt wear and and related plastic bushing issues are gone, and the two rollers onthe tensioner arm are replaced with a single more robust roller. Loss of oil issues in the stock tensioner are a thing of the past too. No need to retension the belt after 1000-1500 miles either. So Ken's tensioner takes several very common maintenance-neglect issues off the table right from the start. For most DIY owners, the benefits are obvious.

My hesitation on using it is personal, since I just had the excitement of having the warning light come on (correctly) in the last few weeks. Cause of the problem is simple-- cam drive sprockets are worn. The rest of the system looks perfect, including bearings and rollers, the belt and the tensioner boot. It's almost five years, less than 25k miles on the belt and rollers, original cam drive sprockets. Those parts looked great when I did the belt last time so they weren't replaced. This drives a couple points though-- When you inspect parts in the belt drive system, including all the rollers and sprockets, they need to be good not just now, but for the life of the new belt. A bearing or roller that's 'worn a little but OK now' needs to be replaced now with the belt. Wear o parts follows an exponential curve, where a little wear begets more wear, a little grumble in a bearing turns into a big one in a hurry, and ANY wear to the hard anodizing on the gears is cause for gear replacement. That tiny bit of wear will only get worse, and once the anodizing is worn the base aluminum will waer very quickly. That transfers to belt wear, which wears the sprockets even faster, more belt wear, until you have a premature belt failure.

The warning light came on to warn me of the wear in the system. If Ken's tensioner was on the job, the belt tension would have remained constant as the belt tore itself up on the wearing drive sprockets. I would not have been aware of the problem until there was a total failure. I do love the idea of using Ken's part, since it removes so many normal maintenence issues completely. I just need to figure out a way to put a telltale needle on the tensioner arm where I can see it just looking in the engine bay. Maybe something I could wire to a little copper contact I could attach a wire to, maybe the existing warning system wire, so it could warn me that there is some excessive wear or stretch someplace, and give me a chance to do something before catastrophic failure. To me, that early pre-disaster warning is the critical missing element.

I need to buy one of Ken's tensioners and figure out how to add back the warning function. Then it will be a complete solution for me.

Please read the disclaimer in my sig line. It's very serious in this case.

#124

#125

Race Car

Looks pretty easy. It's a body mount on a bracket that has threaded holes, so disconnect the lines, remove the 4 bolts and slide it out. Now if it was a top ear-mount like the 80's 928's...

Dan

'91 928GT S/C 475hp/460lb.ft

475hp/460lb.ft

Dan

'91 928GT S/C

475hp/460lb.ft

475hp/460lb.ft

#126

Dan - I see BODY and CAR almost in a 360 degree area around that AC unit. Its sent shivers....

#128

Inventor

Rennlist Member

Rennlist Member

Apologize for my opinion that using the stock tensioner with a high torque engine is irresponsible? You can't make the belt wider, so you should have the best tensioning and damping system available to control the stock belt. Greg has a different opinion. The quantity and quality of someone's morals or integrity are not under my pervue.

Greg misinterpreted confidence as arrogance, but had the sense to bow out quickly, when he realized his position was untenable. It took many tens of pages to correct Kibort, when he failed to understand how the 32V'r worked.

I'm upset that he characterized my flourishes as 'cheap'.

Like my products, each was crafted for maximum effect, with a minimum of pieces.

Like my products, each was crafted for maximum effect, with a minimum of pieces.

#129

#130

Inventor

Rennlist Member

Rennlist Member

The time and mileage belt-life numbers are arbitrary IMHO, and depend tremendously on how you drive the car and where you live.

I just need to figure out a way to put a telltale needle on the tensioner arm where I can see it just looking in the engine bay. Maybe something I could wire to a little copper contact I could attach a wire to, maybe the existing warning system wire, so it could warn me that there is some excessive wear or stretch someplace, and give me a chance to do something before catastrophic failure.

I just need to figure out a way to put a telltale needle on the tensioner arm where I can see it just looking in the engine bay. Maybe something I could wire to a little copper contact I could attach a wire to, maybe the existing warning system wire, so it could warn me that there is some excessive wear or stretch someplace, and give me a chance to do something before catastrophic failure.

Hopefully when Roger's fancy belt arrives, I may not worry about it much at all, except I will still remove the upper covers occasionally for a looksee.

The most workable sensor I've come up with is a micro-switch with a long arm through the cover opening which would rest on the top of the tensioner lever. Positioned correctly, it could warn both of full extension, or full retraction of the pulley. My biggest worry is that any sensor could get caught in the mechanism, and cause a problem, rather than solve it. Secondly, I forsee that I could spend a bunch of time developing it, and very few would actually buy one. It's sounds like something you'd need or want, but in practice, not so much.

#131

Instructor

Thread Starter

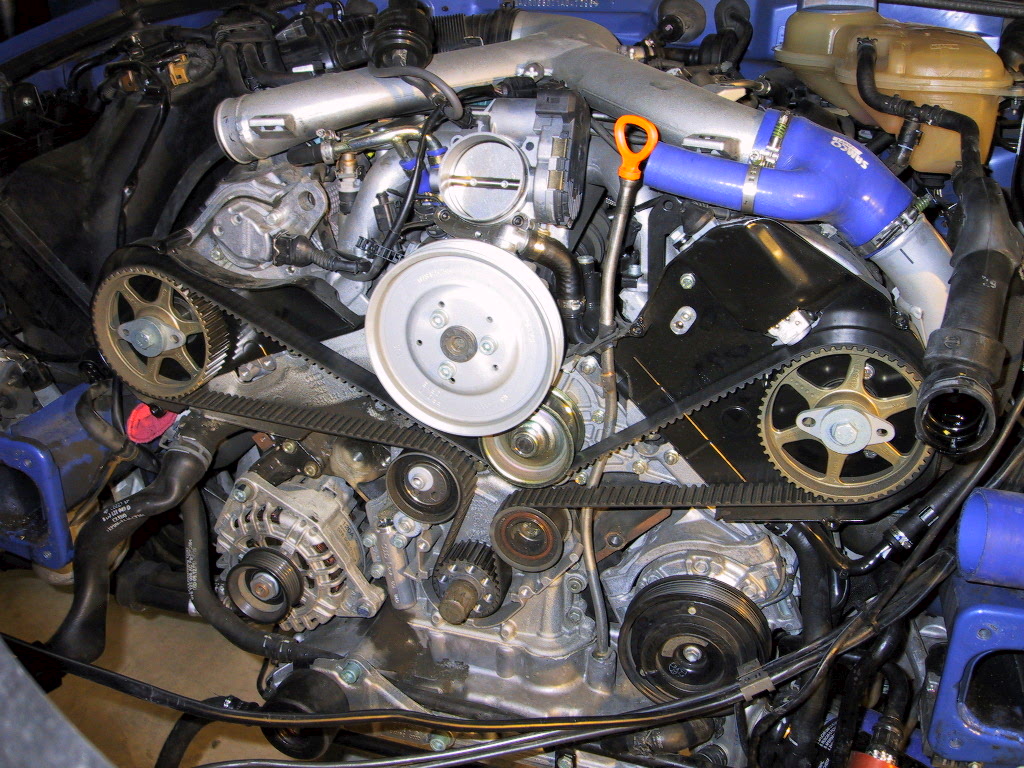

Driver's side cover off at last. I haven't been inside one of these yet but the belt appears to be a bit narrow. It seems like there are belt remnants (Dust like particles) inside of the cover as well.

Since I'm in here; is it time to do away with the air pump? There's no play in the pulley but it seems a little noisy.

Since I'm in here; is it time to do away with the air pump? There's no play in the pulley but it seems a little noisy.

#132

Drifting

This is teh internets. We do have protocols.

#133

Nordschleife Master

http://www.google.com/#hl=en&source=...sioner+failure

Arrogance, hubris, or typical vendor behavior, it doesn't lead to much discussion and its not polite.

Arrogance, hubris, or typical vendor behavior, it doesn't lead to much discussion and its not polite.

#134

Rennlist Member

Driver's side cover off at last. I haven't been inside one of these yet but the belt appears to be a bit narrow. It seems like there are belt remnants (Dust like particles) inside of the cover as well.

Since I'm in here; is it time to do away with the air pump? There's no play in the pulley but it seems a little noisy.

Since I'm in here; is it time to do away with the air pump? There's no play in the pulley but it seems a little noisy.

You, good sir, into that front cover none-too-early!

You will need to replace the alloy cam gears, as they are worn.

That may be the case deeper at the oil pump gear and at the crank gear.

Tracking is off, edge is worn, so your tensioner will need a rebuild. Probably the idler and tensioner pulley/bearings replaced as well. Idlers at base of crank pulley are probably in need of new bearings or unit replacement. In otherwords, full monte.

Since that is the case, I don't know if anyone's suggested it, but there is something called a "Porkensioner" that could be economically fitted ....