Timing Belt / Tensioner Recommendation

#46

Three Wheelin'

This is a special tool you can get from any of our suppliers (or Porsche dealer). I forget the p/n. About $60 or if someone has one locally, you're in luck.

Cam gears you'll be looking for pitting of the coating. Any shiny metal indicates the coating is wearing and 'most' think about buying new cam, oil gear and potentially crank gear. You can also consider recoating them for $15-20 each at places like finishlinecoatings.com. All TB gears are subject to wear so careful inspection is warrented. Note the cam gear may be aluminum (original) and a steel replacement will not need the washer/spacer that is behind the aluminum one.

Good luck..great thread started by Dwayne on the process.

Cam gears you'll be looking for pitting of the coating. Any shiny metal indicates the coating is wearing and 'most' think about buying new cam, oil gear and potentially crank gear. You can also consider recoating them for $15-20 each at places like finishlinecoatings.com. All TB gears are subject to wear so careful inspection is warrented. Note the cam gear may be aluminum (original) and a steel replacement will not need the washer/spacer that is behind the aluminum one.

Good luck..great thread started by Dwayne on the process.

#47

Race Car

#48

2 Newbie questions:

How does one check that the belt tension warning system is working?

What technological advances are applicable and used in the new tensioners vs 35 years ago?

Ron

How does one check that the belt tension warning system is working?

What technological advances are applicable and used in the new tensioners vs 35 years ago?

Ron

#49

Addict

Rennlist Member

Rennlist Member

A few comments on timing belts and tensioners:

First, I have never seen a pktensioner. The other products that Ken has developed are nothing short of FABULOUS. Especially the cam timing tool. I have done it the Porsche way and it takes many hours and is probably not as accurate as Ken's tool.

I have never seen a cam belt failure. After doing many cam belt services, I am very impressed that the original Porsche system works so good with the lack of knowledge/workmanship that I have witnessed. Some examples below:

~30% have the right cam (passenger side) 1 tooth out of time. This is easy to do if you are not careful. It is VERY obvious if you look at the timing marks. The car runs much smother and faster when in time.

~50% have NO oil in the tensioner, usually a bad gasket that looks like it has never been replaced. Sometimes a boot that is rock hard and never been replaced. And a rock hard O ring on 90%.

~30% have missing or misplaced bimetal washers in the tensioner.

Most have worn out pivot bushings.

Very loose belts with the warning system grounded to eliminate that annoying light.

I have seen belt tension at 1 on the Porsche gauge and, in time. Other cars at 7 (should be 5 to 5.3).

When checking tension, you MUST be at TDC for cylinder 1. Any other place tension is different.

Kemph Gauge: If you are working on a 32 valve, the tension has to be all the way high in the window. That gauge was made for 16 valve cars.

Dr. Bob: As it turns out, I am doing a timing belt job on my own car ('91GT). I had the tensioner on the bench, so it was easy to try your suggestion of testing how much change in temperature affects the length. From ~50f to 160f it contracted .040". I was not sure how much pressure to put on the assembly, and it was awkward to compress the tension checker spring, so I compressed it until it was grounded to do the checks. Hopefully that put enough tension on the washers to get an accurate measurement.

.040" does not seem like much, but there are too many things moving with temperature change for me to comprehend.

With the abuse that I have seen with this system, I am amazed that there are not many more timing belt failures causing valve damage.

First, I have never seen a pktensioner. The other products that Ken has developed are nothing short of FABULOUS. Especially the cam timing tool. I have done it the Porsche way and it takes many hours and is probably not as accurate as Ken's tool.

I have never seen a cam belt failure. After doing many cam belt services, I am very impressed that the original Porsche system works so good with the lack of knowledge/workmanship that I have witnessed. Some examples below:

~30% have the right cam (passenger side) 1 tooth out of time. This is easy to do if you are not careful. It is VERY obvious if you look at the timing marks. The car runs much smother and faster when in time.

~50% have NO oil in the tensioner, usually a bad gasket that looks like it has never been replaced. Sometimes a boot that is rock hard and never been replaced. And a rock hard O ring on 90%.

~30% have missing or misplaced bimetal washers in the tensioner.

Most have worn out pivot bushings.

Very loose belts with the warning system grounded to eliminate that annoying light.

I have seen belt tension at 1 on the Porsche gauge and, in time. Other cars at 7 (should be 5 to 5.3).

When checking tension, you MUST be at TDC for cylinder 1. Any other place tension is different.

Kemph Gauge: If you are working on a 32 valve, the tension has to be all the way high in the window. That gauge was made for 16 valve cars.

Dr. Bob: As it turns out, I am doing a timing belt job on my own car ('91GT). I had the tensioner on the bench, so it was easy to try your suggestion of testing how much change in temperature affects the length. From ~50f to 160f it contracted .040". I was not sure how much pressure to put on the assembly, and it was awkward to compress the tension checker spring, so I compressed it until it was grounded to do the checks. Hopefully that put enough tension on the washers to get an accurate measurement.

.040" does not seem like much, but there are too many things moving with temperature change for me to comprehend.

With the abuse that I have seen with this system, I am amazed that there are not many more timing belt failures causing valve damage.

#50

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

First question answer: The TB tension warning expects a ground contact to keep the warning off. OPen the circuit and you get the warning.

Easiest check is to pull the little wire connector from the center belt cover. There's a small plug connector with an o-ring that fits a connector molded into the cover. Top corner of the center cover on the right (pass side on US cars) side of the center cover, an inch or so from where that pass side belt cover meets the center cover. You can use a screwdriver from the top, or a small pliers from the front to pull the connector. Once the connector is removed, start the car and let it run for a few minutes. Sometime around the two-minutes-of-running mark, the belt tension warning will come on.

Easiest check is to pull the little wire connector from the center belt cover. There's a small plug connector with an o-ring that fits a connector molded into the cover. Top corner of the center cover on the right (pass side on US cars) side of the center cover, an inch or so from where that pass side belt cover meets the center cover. You can use a screwdriver from the top, or a small pliers from the front to pull the connector. Once the connector is removed, start the car and let it run for a few minutes. Sometime around the two-minutes-of-running mark, the belt tension warning will come on.

#51

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Thanks for the verification Earl. It proves that the washers do in fact compensate for temp variation in the engine. I stand down from my "I call BS" position on their function.

#52

Inventor

Rennlist Member

Rennlist Member

Actually, I did have an "ah ha" moment. This came after carefully studing the design of Porken's tensioner and then calling him and asking him what kept his tensioner from collapsing when there was a "backforce" applied to the tensioner that was larger than the spring pressure that kept the belt tight.

One cannot have a a genuine 'ah ha', without having installed the Audi parts on a PKsn'r bracket, and tried to rotate the pulley inward when cold.

Note that the 928 design has a "smooth" wheel that tensions the belt and that the 968 design has a wheel with "teeth". This makes tooth 'slippage" much harder on the 968 design, since the belt needs to actually "jump a tooth" at the tensioner to "jump a tooth at the crankshaft". Not so, with the 928 design.

)

)Assuming a slack belt from a stock 928 tensioner on a cold engine which was shut off when hot, rotating the engine counter-clockwise will cause the crank gear to slip over the belt. The belt does not need to move.

A 'kickback' from a backfire won't occur until the engine is spun CW by the starter at least a partial revolution, by which time the belt would be tight on a dynamically tensioned system like the PKsn'r. Belt tension is higher when cold with a PKsn'r.

The need for real damping to keep the belt on the gears is greatest when the engine is cold. With a PKsn'r, you can see the tensioner working hard to dampen the uneven pulsations of cold running. There is no comparable damping of any consequence with the stock tensioner.

Note that the 928 belt design pushes the belt towards the center of the engine. This "direction change" makes any backwards leverage on that pulley very extreme. Note that the 968 design pushes the belt from the center of the engine towards the outside of the engine, reducing the effect of any backforce.

No other engine that I could find has so many accessory pulleys or a tension warning system (with a 3 minute delay at startup) like the 928. All of these additions are to compensate for a poor design, which cannot increase tension when the engine is cold.

#53

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Flywheel Lock Tool is $53 from 928sRus

__________________

Does it have the "Do It Yourself" manual transmission, or the superior "Fully Equipped by Porsche" Automatic Transmission? George Layton March 2014

George Layton March 2014

928 Owners are ".....a secret sect of quietly assured Porsche pragmatists who in near anonymity appreciate the prodigious, easy going prowess of the 928."

Does it have the "Do It Yourself" manual transmission, or the superior "Fully Equipped by Porsche" Automatic Transmission?

George Layton March 2014

George Layton March 2014928 Owners are ".....a secret sect of quietly assured Porsche pragmatists who in near anonymity appreciate the prodigious, easy going prowess of the 928."

#56

Former Vendor

I don't understand your point here...aren't all the tensioner pulleys designed to rotate?

I've only ever seen this happen when using an aftermarket "big rubber band" timing belt. I had one of those pieces of crap tightened to 5.2 "belt units" on one of Anderson's race engines. Brand new engine...it "coughed" when starting and jumped cam timing. The belt was still at 5.2 "belt units". I have not used anything by genuine Factory belts, since that day. The price savings of using an "aftermarket" crap belt could never begin to be worth a valve job.

Look...I'm not a closed minded fool....I look at all new products and study them at length...sometimes even try them....but I'm not an idiot. I'm not going to use something that I see or experience a problem with.

Wow, now you are really scaring me, not helping me more comfortable!

The stock tensioner is designed to be adjusted to 5.0-5.2 "belt units" when the belt is cold. This is really tight. The belt tension, because of the design, is supposed to stay close to this number when the engine gets warm, which it does. The "belt tension" warning light comes on at approximately 3.5-3.8 "belt units", which is still pretty darn tight.

There is no "comparable damping of any consequence" from the stock tensioner, because none is needed. The belt is tight and properly adjusted.

Now, you claim that you can see your tensioner "working hard to dampen the uneven pulsations of cold running". Well, let's think about this. Obviously, the belt is not getting longer and shorter (if it is a high quality belt). That must mean that the tensioner is responding to pressures exerted on it by the engine wanting to "kick backwards" when it is cold....that is the only variable when the engine is cold (aside from preset tension). Since the spring pressure provided by Audi tensioner is constant force and the belt can't be changing length, that means that any movement by your tensioner has to be in the "loosening direction", which is what my point has been all along. There simply is no positive stop in the "backwards direction" when the engine "kicks back".

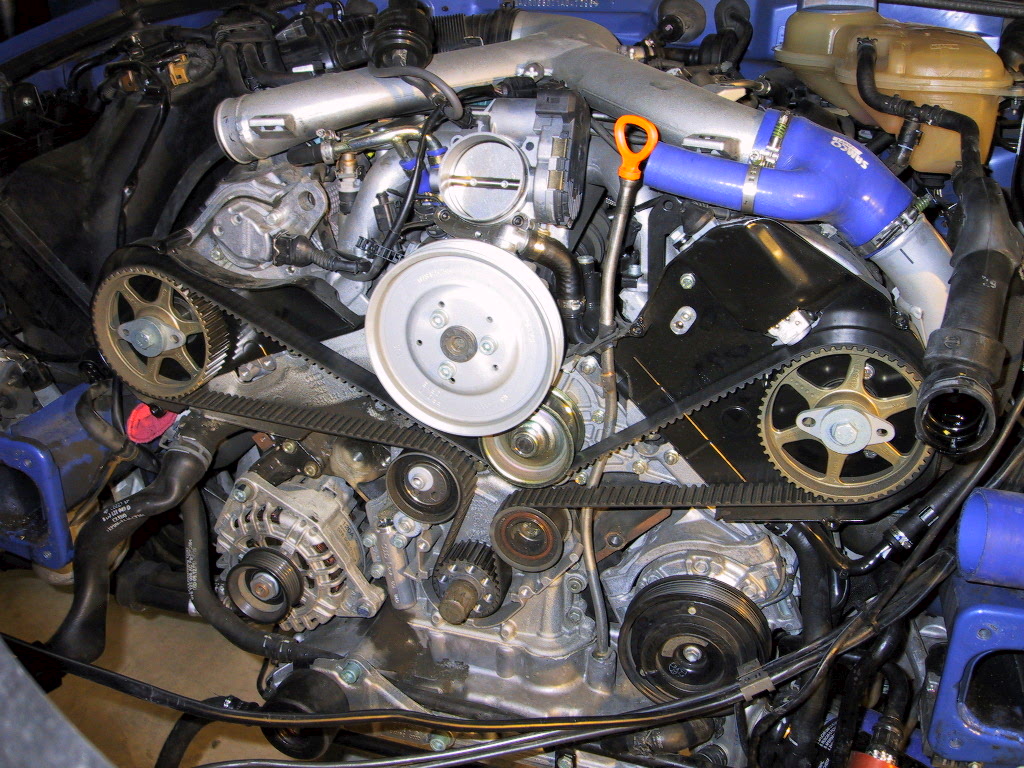

Note your picture of the Audi engine and the location of the tensioning roller. Now look at a Porsche 928 engine. Note that the roller is dramatically closer to the crankshaft and that the belt makes a much "harder" turn around the roller on the Porsche design. This means that the force exerted on that roller, by the belt in the Porsche design is much higher on the Porsche design than on the Audi design....it's simple physics. If there is a "backwards" force applied to your tensioner, without a positive stop, it is going to compress. Your example of your tensioner moving when the engine is cold is proof of that!

Look...I'm not a closed minded fool....I look at all new products and study them at length...sometimes even try them....but I'm not an idiot. I'm not going to use something that I see or experience a problem with.

The stock tensioner is designed to be adjusted to 5.0-5.2 "belt units" when the belt is cold. This is really tight. The belt tension, because of the design, is supposed to stay close to this number when the engine gets warm, which it does. The "belt tension" warning light comes on at approximately 3.5-3.8 "belt units", which is still pretty darn tight.

There is no "comparable damping of any consequence" from the stock tensioner, because none is needed. The belt is tight and properly adjusted.

Now, you claim that you can see your tensioner "working hard to dampen the uneven pulsations of cold running". Well, let's think about this. Obviously, the belt is not getting longer and shorter (if it is a high quality belt). That must mean that the tensioner is responding to pressures exerted on it by the engine wanting to "kick backwards" when it is cold....that is the only variable when the engine is cold (aside from preset tension). Since the spring pressure provided by Audi tensioner is constant force and the belt can't be changing length, that means that any movement by your tensioner has to be in the "loosening direction", which is what my point has been all along. There simply is no positive stop in the "backwards direction" when the engine "kicks back".

Note your picture of the Audi engine and the location of the tensioning roller. Now look at a Porsche 928 engine. Note that the roller is dramatically closer to the crankshaft and that the belt makes a much "harder" turn around the roller on the Porsche design. This means that the force exerted on that roller, by the belt in the Porsche design is much higher on the Porsche design than on the Audi design....it's simple physics. If there is a "backwards" force applied to your tensioner, without a positive stop, it is going to compress. Your example of your tensioner moving when the engine is cold is proof of that!

#58

Instructor

Thread Starter

Good points for both tensioners. Should I decide to keep the stock tensioner; is there a complete rebuild kit for it, or just replace what's needed/worn?

#59

Inventor

Rennlist Member

Rennlist Member

Wow, now you are really scaring me, not helping me more comfortable!

The stock tensioner is designed to be adjusted to 5.0-5.2 "belt units" when the belt is cold. This is really tight. The belt tension, because of the design, is supposed to stay close to this number when the engine gets warm, which it does. The "belt tension" warning light comes on at approximately 3.5-3.8 "belt units", which is still pretty darn tight.

The stock tensioner is designed to be adjusted to 5.0-5.2 "belt units" when the belt is cold. This is really tight. The belt tension, because of the design, is supposed to stay close to this number when the engine gets warm, which it does. The "belt tension" warning light comes on at approximately 3.5-3.8 "belt units", which is still pretty darn tight.

What's really scary is fact that with a new belt, the belt tension is loose after a few hundred miles until the next belt check, which may be as long as 1500 miles later, or the amount of tension required to keep the belt on the gears from cold to hot with the stock 'tensioner', reducing the life of the water pump, accelerating sprocket wear, etc.

There is no "comparable damping of any consequence" from the stock tensioner, because none is needed. The belt is tight and properly adjusted.

Now, you claim that you can see your tensioner "working hard to dampen the uneven pulsations of cold running". Well, let's think about this. Obviously, the belt is not getting longer and shorter (if it is a high quality belt). That must mean that the tensioner is responding to pressures exerted on it by the engine wanting to "kick backwards" when it is cold....that is the only variable when the engine is cold (aside from preset tension). Since the spring pressure provided by Audi tensioner is constant force and the belt can't be changing length, that means that any movement by your tensioner has to be in the "loosening direction", which is what my point has been all along. There simply is no positive stop in the "backwards direction" when the engine "kicks back".

Now, you claim that you can see your tensioner "working hard to dampen the uneven pulsations of cold running". Well, let's think about this. Obviously, the belt is not getting longer and shorter (if it is a high quality belt). That must mean that the tensioner is responding to pressures exerted on it by the engine wanting to "kick backwards" when it is cold....that is the only variable when the engine is cold (aside from preset tension). Since the spring pressure provided by Audi tensioner is constant force and the belt can't be changing length, that means that any movement by your tensioner has to be in the "loosening direction", which is what my point has been all along. There simply is no positive stop in the "backwards direction" when the engine "kicks back".

As has been repeated many many times, the tensioner/damper units will spring out quickly, but are hydraulically stopped from compressing more than a small amount unless the pressure is maintained for more than ~30 seconds when warm, and a few minutes when cold. To fully compress the tensioner/damper in a vise takes over 5 minutes when cold.

The other thing that is key is the hydraulic dampening. The Audi tensioner (and I assume others) have valving which allows them to take up any loose tension quickly, but they give it back only slowly. You can readily see this with Ken's tensioner-- pull the pin and it takes the slack right out, but in order to get it back you've got to lean on the wrench for a while to compress the rod again. Pretty slick, and exactly what is needed.

There is no "comparable damping of any consequence" from the stock tensioner, because none is needed. The belt is tight and properly adjusted.

Now, you claim that you can see your tensioner "working hard to dampen the uneven pulsations of cold running". Well, let's think about this. Obviously, the belt is not getting longer and shorter (if it is a high quality belt). That must mean that the tensioner is responding to pressures exerted on it by the engine wanting to "kick backwards" when it is cold....that is the only variable when the engine is cold (aside from preset tension). Since the spring pressure provided by Audi tensioner is constant force and the belt can't be changing length, that means that any movement by your tensioner has to be in the "loosening direction", which is what my point has been all along. There simply is no positive stop in the "backwards direction" when the engine "kicks back".

Now, you claim that you can see your tensioner "working hard to dampen the uneven pulsations of cold running". Well, let's think about this. Obviously, the belt is not getting longer and shorter (if it is a high quality belt). That must mean that the tensioner is responding to pressures exerted on it by the engine wanting to "kick backwards" when it is cold....that is the only variable when the engine is cold (aside from preset tension). Since the spring pressure provided by Audi tensioner is constant force and the belt can't be changing length, that means that any movement by your tensioner has to be in the "loosening direction", which is what my point has been all along. There simply is no positive stop in the "backwards direction" when the engine "kicks back".

The dramatic tensioner/damper movement seen when cold is not from compression, but from taking up of slack created by stronger cylinders firing with more force than others. As the belt turns, the small amount of momentary retraction allowed by the T/D releases this section of overtension that was in the belt on the other side of the crank gear, restoring the average tension. (If it were not able to retract, the average tension would keep increasing.) Flutter/flap doesn't go away when warm, it's just reduced.

Also affecting the belt at speed is the aforementioned valve spring events. As the cam gears come onto a sequence of high spring pressure, the belt stretches and slack forms in between both banks, and at the T/D. As each gear comes off the lobes it takes up this slack quickly (resulting in the GT lobe wear). Not only does the PKsn'r give a more even average tension, it also calms the cams, for more precise timing!

The stock 928 tensioner is not capable of momentarily increasing tension to take up slack from these uneven firings or cam events, so the belt flaps, requiring 'anti-flap' pulleys to limit it's travel! (The pulleys are not true idlers, as they do not normally touch the belt.) The tension warning system has a 3 minute delay in the Central Warning System so as to not advertise the flapping which would trigger a [BELT TEN.] warning. When the oil leaks out of the stock tensioner, the loss of the slight amount of damping the oil provides often triggers belt warnings from the flapping of the belt.

With the PKsn'r there is no belt flutter/flap between the crank gear and the 1-4 cam gear. When warm, if you rev the engine up to high rpm, you can see the belt flutter between the 1-4 gear and the water pump, but the belt is always dead flat at the PKsn'r.

#60

Race Car

Perhaps the most definitive way to solve this debate is to make a video of a 928 with the timing belt covers off showing the stock tensioner at different RPMs as the engine is warming up. Then compare this to a video of the PK tensioner in the same conditions. I have seen first-hand the belt flutter that occurs at certain RPM points with the stock tensioner and it made my stomach turn.

Dan

'91 928GT S/C 475hp/460lb.ft

475hp/460lb.ft

Dan

'91 928GT S/C

475hp/460lb.ft

475hp/460lb.ft