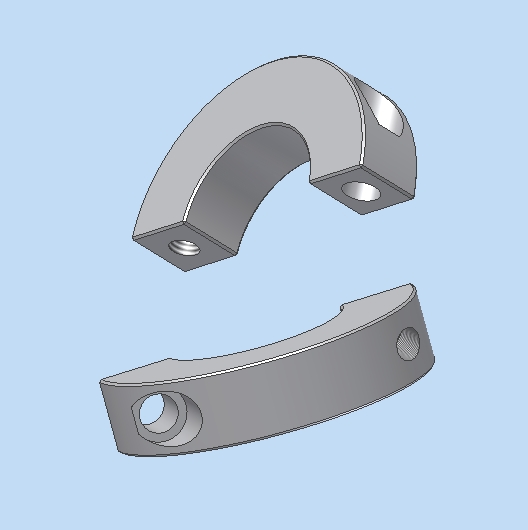

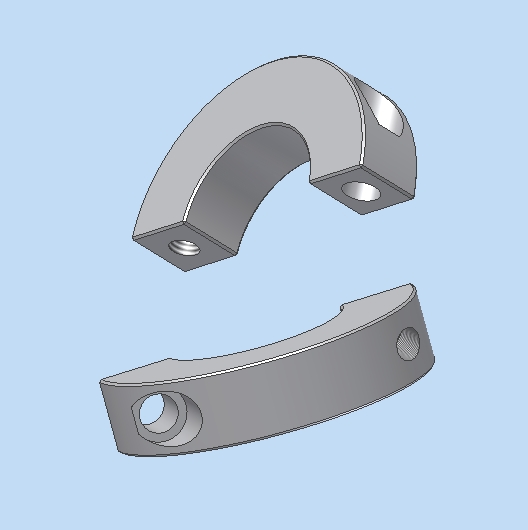

New PKlamp & Hatch Receiver Insert from 928sRus

#46

Rennlist Member

I posed this question to Roger during a recent call and would open it up to the 'List specificaly to Ken and Constantine for input.

We know the auto transmission 928s have a potential catastrophic engine failure issue with the thrust bearing.

The early 928s (not sure if it was all or just auto trans) had a machined slot to accept a 'circlip' in the shaft that prevented movement.

The 'superclamp' permenantly removes the issue. The PKlamp is perhps a temp fix, time will tell.

My question is can we not, along with Constantins torque tube rebuild, have shafts machined with the older style 'C' clip?

I've not read all threads but is there evidence for the older shafts with the C clips and auto trans not having TBF hence the solution?

We know the auto transmission 928s have a potential catastrophic engine failure issue with the thrust bearing.

The early 928s (not sure if it was all or just auto trans) had a machined slot to accept a 'circlip' in the shaft that prevented movement.

The 'superclamp' permenantly removes the issue. The PKlamp is perhps a temp fix, time will tell.

My question is can we not, along with Constantins torque tube rebuild, have shafts machined with the older style 'C' clip?

I've not read all threads but is there evidence for the older shafts with the C clips and auto trans not having TBF hence the solution?

#47

Rennlist Member

The circlip was deleted by the factory because it is a PITA to adjust, even when the complete drivetrain is removed out of the car. As long as the clamp is not moving anymore, what is the problem?

#49

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

The WSM has a convoluted measurement procedure in Volume II, section 39, pages 51-53 and again in volume III, section 39, pages 141-143.

It boils down to having 0.3 mm of forward preload on the flexplate, with the flywheel levered to the rear. I am not sure why you want any proload, but that is what it calls for.

You can establish this by unbolting the flexplate from the flywheel surface and installing shims until there is gap of 0.3 mm between the flexplate arms and the flywheel surface, then refastening the flexplate and tightening the clamp. This is done with the flywheel pushed to the rear of its endplay. When the flywheel moves back to a forward position, this removes more than half of the preload.

It boils down to having 0.3 mm of forward preload on the flexplate, with the flywheel levered to the rear. I am not sure why you want any proload, but that is what it calls for.

You can establish this by unbolting the flexplate from the flywheel surface and installing shims until there is gap of 0.3 mm between the flexplate arms and the flywheel surface, then refastening the flexplate and tightening the clamp. This is done with the flywheel pushed to the rear of its endplay. When the flywheel moves back to a forward position, this removes more than half of the preload.

#51

Hi Malcolm,

Porsche decided sometime in MY 1984 to do away with the circlip, washers and bearing at the front of the older 25mm constant diameter drive shafts. From what we learned during our research into the 928 automatic TBF problem, this was due to Porsche field techs having problems adjusting the measurement needed between the flexplate and flywheel correctly. Even after sending one of their drive line engineers on a world tour to teach their field techs the proper procedure to install these parts, Porsche finally decided to remove these pieces altogether from use.

As far as making a new drive shaft to incorporate these parts back in, we have done this already and debuted such a drive shaft, made from much stronger material, at last years SITM along with our Super Bearings. We replicated the front portion of the older shaft perfectly just in case owners wanted to install these pieces instead of the Super Clamp. But due to the projected cost of the new shafts being more expensive than the Super Clamps, we have currently decided to shelve them at this time.

Also we made a larger purchase of the Super Clamps to be able to offer them at the lowest prices ever. Compared to the circlip, bearing and washers, the Super Clamp outshines them in ease of use and stops drive shaft creep completely.

Porsche did have a good idea to do away with these old parts to un-complicate the procedure, they just should have redesigned the front clamp at the same time.

HTH,

Constantine

Porsche decided sometime in MY 1984 to do away with the circlip, washers and bearing at the front of the older 25mm constant diameter drive shafts. From what we learned during our research into the 928 automatic TBF problem, this was due to Porsche field techs having problems adjusting the measurement needed between the flexplate and flywheel correctly. Even after sending one of their drive line engineers on a world tour to teach their field techs the proper procedure to install these parts, Porsche finally decided to remove these pieces altogether from use.

As far as making a new drive shaft to incorporate these parts back in, we have done this already and debuted such a drive shaft, made from much stronger material, at last years SITM along with our Super Bearings. We replicated the front portion of the older shaft perfectly just in case owners wanted to install these pieces instead of the Super Clamp. But due to the projected cost of the new shafts being more expensive than the Super Clamps, we have currently decided to shelve them at this time.

Also we made a larger purchase of the Super Clamps to be able to offer them at the lowest prices ever. Compared to the circlip, bearing and washers, the Super Clamp outshines them in ease of use and stops drive shaft creep completely.

Porsche did have a good idea to do away with these old parts to un-complicate the procedure, they just should have redesigned the front clamp at the same time.

HTH,

Constantine

I posed this question to Roger during a recent call and would open it up to the 'List specificaly to Ken and Constantine for input.

We know the auto transmission 928s have a potential catastrophic engine failure issue with the thrust bearing.

The early 928s (not sure if it was all or just auto trans) had a machined slot to accept a 'circlip' in the shaft that prevented movement.

The 'superclamp' permenantly removes the issue. The PKlamp is perhps a temp fix, time will tell.

My question is can we not, along with Constantins torque tube rebuild, have shafts machined with the older style 'C' clip?

I've not read all threads but is there evidence for the older shafts with the C clips and auto trans not having TBF hence the solution?

We know the auto transmission 928s have a potential catastrophic engine failure issue with the thrust bearing.

The early 928s (not sure if it was all or just auto trans) had a machined slot to accept a 'circlip' in the shaft that prevented movement.

The 'superclamp' permenantly removes the issue. The PKlamp is perhps a temp fix, time will tell.

My question is can we not, along with Constantins torque tube rebuild, have shafts machined with the older style 'C' clip?

I've not read all threads but is there evidence for the older shafts with the C clips and auto trans not having TBF hence the solution?

#54

Drifting

Nice looking product for sure, but with the screws on the same side its not balanced. This would worry me since that shaft spins up to redline. PKs cad drawing would be much more balanced than the one that was produced. Am I missing something?

#55

Craic Head

Lifetime Rennlist

Member

Lifetime Rennlist

Member

#56

Drifting

The real one in the pic and the design drawing in CAD are not the same. In the CAD design there is supposed to be one bolt head on each half of the clamp. In the produced version both bolt heads are on the same side of the clamp. Look closely. The bolt heads are supposed to be on opposite halves and on opposing sides like in the CAD drawing.

#57

Rennlist Member

Your correct about the one pictured being different than the drawing but I believe It is merely a prototype and what the are saying is that the production part will match the CAD drawing.

#59

Drifting

#60

Owns the Streets

Needs Camber

Lifetime Rennlist

Member

Needs Camber

Lifetime Rennlist

Member

I've never poked around the front clamp area.

So with opposing bolt heads, is there room to tighten both bolts down without rotating the TT?

So with opposing bolt heads, is there room to tighten both bolts down without rotating the TT?