Torque Tube to Gearbox bolts - helicoil repair possible insitu ? Update YES it is.

#1

Addict

Rennlist Member

Rennlist Member

Thread Starter

In my now 3 week long hunt for a squeak going over bumps I've been checking torque on all the bolts/nuts under the car I discovered tonite that one of the M10x1.5 G10.9 bolts that connect the rear of the TT was loose (all the other 3 OK) and it wouldn't torque up at all.

Does anyone have any experience of helicoiling the hole in the gearbox without removing the box ? I reckon I can get a right angle drill in OK to drill out to the oversixe hole the helicoil requires - just not sure about tapping the hole before fitting the helicoil.

This has been an enlightening exercise - so far I've tightened caliper bolts, removed cleaned and replaced a front wheel bearing, removed the broken bits of a a front shock abosrber dust sleeve, replaced from the undertray an AC compressor mounting bolt, and removed a spanner I have never owned from the front PU (That's been there for at least 5 years) as well as tightened numerous other looseish bolts.

Does anyone have any experience of helicoiling the hole in the gearbox without removing the box ? I reckon I can get a right angle drill in OK to drill out to the oversixe hole the helicoil requires - just not sure about tapping the hole before fitting the helicoil.

This has been an enlightening exercise - so far I've tightened caliper bolts, removed cleaned and replaced a front wheel bearing, removed the broken bits of a a front shock abosrber dust sleeve, replaced from the undertray an AC compressor mounting bolt, and removed a spanner I have never owned from the front PU (That's been there for at least 5 years) as well as tightened numerous other looseish bolts.

Last edited by jon928se; 04-25-2009 at 03:28 AM.

#2

If you have enough space to get a right angled drill in there, then you can get a right angled tap holder with a ratchet drive to tap the hole.

I used one a few years back when I had to drill and tap the 38 openings for the headbolts in situ in the block of my Mercedes.

I used one a few years back when I had to drill and tap the 38 openings for the headbolts in situ in the block of my Mercedes.

#4

Rest in Peace

Rennlist Member

Rennlist Member

Join Date: May 2006

Location: Bird lover in Sharpsburg

Posts: 9,903

Likes: 0

Received 2 Likes

on

2 Posts

IIRC there are 6 bolts that hold the TT to the trans 4 of them are obvious the other 2 are on the top.

I dont think that you can do a helicoil as the TT bolt slot isnt big enough. (you would have to drill this opening bigger for the insert to go through)

In other words it would be better to separate the TT from trans to install the Helicoil

I dont think that you can do a helicoil as the TT bolt slot isnt big enough. (you would have to drill this opening bigger for the insert to go through)

In other words it would be better to separate the TT from trans to install the Helicoil

#5

Addict

Rennlist Member

Rennlist Member

Thread Starter

Should have noted that it's only one of the bolts at the underside of the TT.

The Right angle tap holder sounds like it should work. Cheers Ben

The Right angle tap holder sounds like it should work. Cheers Ben

#6

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Yep, I think you will probably have to anyway.

The drill bit used to create the hole to install the insert is probably larger than the current hole in the TT. Sure you could sightly enlarge the hole passing through the TT flange, BUT I think the countersink bit is too large. Hence the insert itself is due to the shoulder. I looked up the countersink and it is 0.5 inch across for an M10.

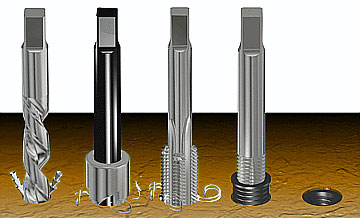

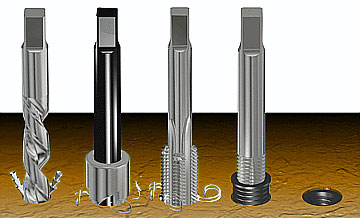

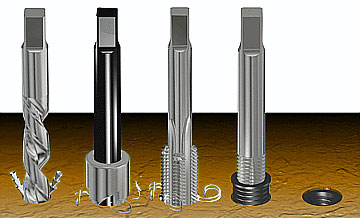

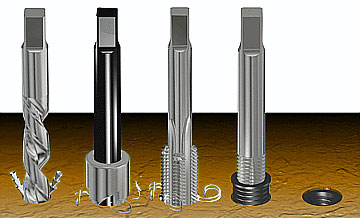

Timesert is what you want. Helicoil will not stand up to the torque. Get the proper Timesert and take a look at the drill bit they provide in the kit.

The drill bit used to create the hole to install the insert is probably larger than the current hole in the TT. Sure you could sightly enlarge the hole passing through the TT flange, BUT I think the countersink bit is too large. Hence the insert itself is due to the shoulder. I looked up the countersink and it is 0.5 inch across for an M10.

Timesert is what you want. Helicoil will not stand up to the torque. Get the proper Timesert and take a look at the drill bit they provide in the kit.

#7

Addict

Rennlist Member

Rennlist Member

Thread Starter

Yep, I think you will probably have to anyway.

]The drill bit used to create the hole to install the insert is probably larger than the current hole in the TT. Sure you could sightly enlarge the hole passing through the TT flange, BUT I think the countersink bit is too large. Hence the insert itself is due to the shoulder. I looked up the countersink and it is 0.5 inch across for an M10.

]The drill bit used to create the hole to install the insert is probably larger than the current hole in the TT. Sure you could sightly enlarge the hole passing through the TT flange, BUT I think the countersink bit is too large. Hence the insert itself is due to the shoulder. I looked up the countersink and it is 0.5 inch across for an M10.

Timesert is what you want. Helicoil will not stand up to the torque. Get the proper Timesert and take a look at the drill bit they provide in the kit.

Re torque on the bolts I'm using a double length insert - 12 threads long so approx 18mm threaded length Not far short of the original at about 22mm threaded length in the Aluminium.

Assuming that the gearbox case is Sand Cast T6 Alloy (Weakest figures I could find) by my calcs I only need about 22mm of threaded length of the helicoil into the case to equal the ultimate tensile strength of the Grade 10.9 Bolt.

Or putting it another way the 18mm of helicoil equates to about 21.5 mm of the original thread. Near enough.

Trending Topics

#8

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Jon:

Sounds like you done enough calcs that you are comfortable with Helicoil. What's the torque for this bolt? I wouldn't have thought a Helicoil would work with something like this, but I've not gone through calculations.

Sounds like you done enough calcs that you are comfortable with Helicoil. What's the torque for this bolt? I wouldn't have thought a Helicoil would work with something like this, but I've not gone through calculations.

#10

Addict

Rennlist Member

Rennlist Member

Thread Starter

Torque is only 58Nm (42ftlbs) - quite low for an M10 G10.9 Bolt.

#11

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Yeah, that's true - with a bolt this large, Helicoil may actually do OK due to the increased area. But looking at Helicoil specs, you may be stuck with the same countersink tap issue. May fit just fine, but I don't have a kit to be sure.

http://www.emhart.com/pdf/Heli%20Coi...%20Rev%204.pdf

http://www.emhart.com/pdf/Heli%20Coi...%20Rev%204.pdf

#12

Former Sponsor

Helicoil and Timesert use the same size tap, for their "standard" size repair.

Helicoil will certainly be substancial enough to repair this problem..if that's what you have, it will work.

If you don't have either, always buy the Timesert kit. The inserts are easier to start, are fully threaded, and will not back out, if properly installed.

I have both...from being in business for almost 40 years...the Timesert is just an "upgraded" version of the older Helicoil design, in my view.

Helicoil will certainly be substancial enough to repair this problem..if that's what you have, it will work.

If you don't have either, always buy the Timesert kit. The inserts are easier to start, are fully threaded, and will not back out, if properly installed.

I have both...from being in business for almost 40 years...the Timesert is just an "upgraded" version of the older Helicoil design, in my view.

#13

Addict

Rennlist Member

Rennlist Member

Thread Starter

No it hasn't - I'm verging on recruiting Tom (Tom and Jerry)

It's a wierd one - it sounds like an exhaust pipe joint that is loose as it's a combination of a squeak a fraction of a second after a wheel hits a bump - like something swinging under the car. and sometimes but not always accompanied by a metalicc tinkling noise.

So far I've checked all the suspension mounting bolts, all the transmission, engine and steering rack mounting bolts, heat shields under the car and those little ones above the X member, exhaust joints and hangers, engine ancilliaries, Tied down the hatch to the tow loop to make sure it wasn't the hatch, checked the brake calipers, and brake backing plates, front wheel bearings, under trays.

At the moment in my increasingly delusional paranoid state I have convinced myself it is the starter motor that has loose mounting bolts because the noise from it sounds different! and it's hitting the undertray - Not sure I can cope with another evening under the car to confirm that but I may just have to to remove another possibility.

Edit - In and amongst all the above checking on the GT I fixed the ABS on the SE and discovered the washers on upper front suspension A arm polyurethane bushings are too small and are migrating into the bushings.

It's a wierd one - it sounds like an exhaust pipe joint that is loose as it's a combination of a squeak a fraction of a second after a wheel hits a bump - like something swinging under the car. and sometimes but not always accompanied by a metalicc tinkling noise.

So far I've checked all the suspension mounting bolts, all the transmission, engine and steering rack mounting bolts, heat shields under the car and those little ones above the X member, exhaust joints and hangers, engine ancilliaries, Tied down the hatch to the tow loop to make sure it wasn't the hatch, checked the brake calipers, and brake backing plates, front wheel bearings, under trays.

At the moment in my increasingly delusional paranoid state I have convinced myself it is the starter motor that has loose mounting bolts because the noise from it sounds different! and it's hitting the undertray - Not sure I can cope with another evening under the car to confirm that but I may just have to to remove another possibility.

Edit - In and amongst all the above checking on the GT I fixed the ABS on the SE and discovered the washers on upper front suspension A arm polyurethane bushings are too small and are migrating into the bushings.

#15

Addict

Rennlist Member

Rennlist Member

Thread Starter

Well the helicoil/recoil worked fine torqued up to the 58Nm no problems at all.

Triumph in the face of adversity. Right angle drill wasn't big enough to fit the 10.4mm drill bit so an air ratchet driving a socket onto a nut on the threads of an old chuck worked fine. Then I realised that the I couldn't quite get the full depth of the double depth recoil into the hole without using a bottoming tap - try finding one of those in the correct size. Some careful measuring and I reckon that I'ld have about one thread max hanging out of the gearbox case - thats OK then. Then realised that the hole in the TT was about 0.5mm to smaller a diameter - considered drilling it out to 13 mm the next biggest drill bit I had but realised it was better to just tap straight through the TT hole as I was only cutting threads about 0.25mm deep - far less loss of section than a 13mm drill.

Now back to searching for the squeak.

Triumph in the face of adversity. Right angle drill wasn't big enough to fit the 10.4mm drill bit so an air ratchet driving a socket onto a nut on the threads of an old chuck worked fine. Then I realised that the I couldn't quite get the full depth of the double depth recoil into the hole without using a bottoming tap - try finding one of those in the correct size. Some careful measuring and I reckon that I'ld have about one thread max hanging out of the gearbox case - thats OK then. Then realised that the hole in the TT was about 0.5mm to smaller a diameter - considered drilling it out to 13 mm the next biggest drill bit I had but realised it was better to just tap straight through the TT hole as I was only cutting threads about 0.25mm deep - far less loss of section than a 13mm drill.

Now back to searching for the squeak.

Last edited by jon928se; 04-25-2009 at 03:29 AM.