what is normal wear for ignition rotor and rotor cover points

#1

Burning Brakes

Thread Starter

Join Date: Sep 2006

Location: Myrtle Beach, South Carolina

Posts: 1,203

Likes: 0

Received 0 Likes

on

0 Posts

Sorry if I have the nomenclature wrong but here's my question:

Each plug wire terminates at a copper electrical contact in the rotor dust cover that the rotor tip passes coil voltage to when it swings past.

The contacts for each on mine are showing signs of carbon dust around them and arcing on the surfaces that leaves them rough and discolored. The rotor tips seem unmarked only slightly 'shiny' from the process where the stationary contacts are quite dirty and roughed up.

I imagine a certain amount of this is unavoidable but don't know what is normal and what is excessive.

Does anyone have some pictures of acceptable, or bad contact surfaces?

Second question:

What affect, if any, would bad contacts have on the engines idle?

Many thanks!

Each plug wire terminates at a copper electrical contact in the rotor dust cover that the rotor tip passes coil voltage to when it swings past.

The contacts for each on mine are showing signs of carbon dust around them and arcing on the surfaces that leaves them rough and discolored. The rotor tips seem unmarked only slightly 'shiny' from the process where the stationary contacts are quite dirty and roughed up.

I imagine a certain amount of this is unavoidable but don't know what is normal and what is excessive.

Does anyone have some pictures of acceptable, or bad contact surfaces?

Second question:

What affect, if any, would bad contacts have on the engines idle?

Many thanks!

Last edited by aggravation; 03-07-2009 at 01:50 PM.

#2

Rennlist Member

Take a pointed probe and dig at the contacts inside the cap. Is the metal sponge-like and weak, flaking off? If so you can clean it up and run it while waiting for parts, but they should be replaced.

If it's just surface discoloration, you can clean it up with a points file or emory board, then clean the inside of the cap with a soft brush and some solvent that won't leave a residue, like denatured alcohol. Get all of the dust tracks off the inside of the caps. Flush it thoroughly once all the crud is loosened. Be 100% sure that whatever solvent you use has completely evaporated before reassembly. I know of people who got impatient and tried to run the car too soon after working with flammable liquids inside distributor caps on other cars, and while the explosion can be entertaining, it can be hazardous and, on these cars, expensive.

If it's just surface discoloration, you can clean it up with a points file or emory board, then clean the inside of the cap with a soft brush and some solvent that won't leave a residue, like denatured alcohol. Get all of the dust tracks off the inside of the caps. Flush it thoroughly once all the crud is loosened. Be 100% sure that whatever solvent you use has completely evaporated before reassembly. I know of people who got impatient and tried to run the car too soon after working with flammable liquids inside distributor caps on other cars, and while the explosion can be entertaining, it can be hazardous and, on these cars, expensive.

#4

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

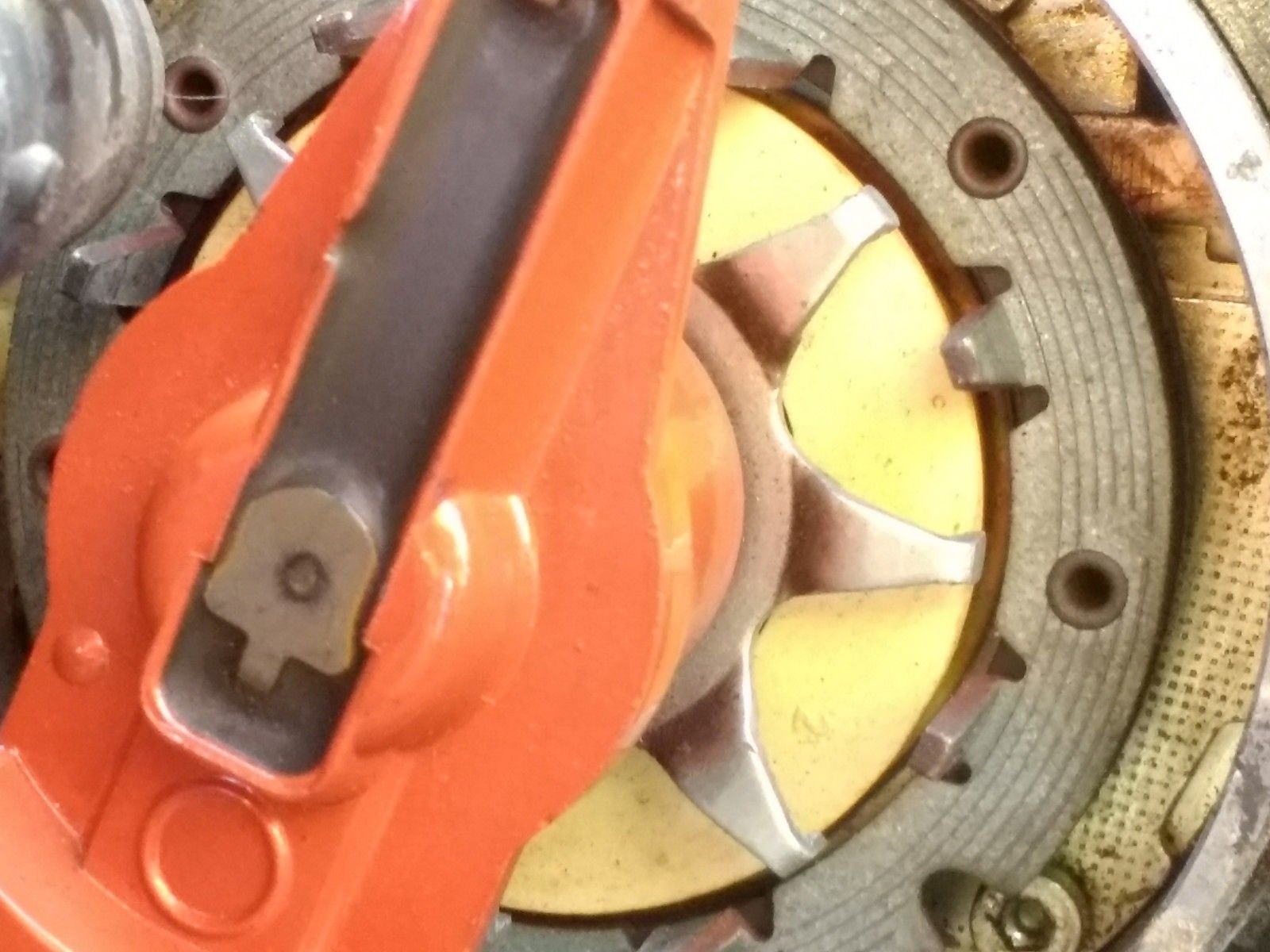

They look quite normal to me. The slight pitting is nothing to get too excited about. The spacing goal between the end of the rotor and the contact in the cap is "close but not touching". You can do a very definitive measurement I'm sure, but... At some point the arc distance will be big enough to start throwing arc-flash debris that will coat the area around the contact. Severe enough and the spark will track down the debris to the distributor base. Keep the cap clean in and out and you'll be fine for plenty more miles.

The technical side: Differing gaps will minimally affect individual spark timing as total firing voltage goes up. Excessive gap risks a firing voltage so high that spark energy starts looking for alternate paths to ground. Options for these include the plug wire insulation, the internal insulation in the coil windings, crud on the outside of the plugs, plus the aforementioned crud in or on the distributor cap(s).

The technical side: Differing gaps will minimally affect individual spark timing as total firing voltage goes up. Excessive gap risks a firing voltage so high that spark energy starts looking for alternate paths to ground. Options for these include the plug wire insulation, the internal insulation in the coil windings, crud on the outside of the plugs, plus the aforementioned crud in or on the distributor cap(s).

Trending Topics

#8

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

The arc flash deposits are easily visible, a sure sign that the gaps between rotor and the contacts are too great. Good catch for your misfire! Hopefully you caught it and replaced before you lost a coil or two.

#9

Rennlist Member

Could this kind of wear pattern cause an uneven idle condition?

#10

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Calling it "wear" is somewhat misleading since it is erosion of the metal as the spark jumps from rotor to "contact" and vaporizes a tiny bit of metal in the process. As the gap widens the process accelerates and the spark starts looking for a shorter path. The rotor should never ever actually touch the "contacts".

#11

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Classic engineer's answer: Yes, but...

Idle conditions offer the lowest resistance at the plug, so a bit of arcing inside the cap is less likely in theory. Back at reality, idle speed is when we are most likely to feel uneven spark voltage. The uneven firing exists even more as engine RPM and loads go up, but our senses aren't good enough to feel the effect until there's a hard miss for a particular cylinder or cylinders. The difference in firing voltage can come from inconsistent plug gaps, minor breaks in plug wires, different gaps at the cap and rotor as illustrated hear, or a path to ground or to another cylinder in the cap.

If you have access to even a cheap oscilloscope, you can place a few wraps of solid copper wire around a coil secondary wire, and trigger from one of the plug leads with a similar "transformer". From the coil wire you can watch all the cylinders connected to that coil for firing voltage. The spikes should be about the same height if voltages are the same. "Arcs" (proper spark) at the plug have a pretty specific appearance, with the coil secondary collapsing all at once. Small leaks show as partial collapse as the voltage ramps up to plug firing. Modern COP ignitions add this firing voltage "feedback" to engine management for plug condition. They don't have distributors, rotors, or plug wires to worry about, so there's really only one possible cause for high firing voltage.

Idle conditions offer the lowest resistance at the plug, so a bit of arcing inside the cap is less likely in theory. Back at reality, idle speed is when we are most likely to feel uneven spark voltage. The uneven firing exists even more as engine RPM and loads go up, but our senses aren't good enough to feel the effect until there's a hard miss for a particular cylinder or cylinders. The difference in firing voltage can come from inconsistent plug gaps, minor breaks in plug wires, different gaps at the cap and rotor as illustrated hear, or a path to ground or to another cylinder in the cap.

If you have access to even a cheap oscilloscope, you can place a few wraps of solid copper wire around a coil secondary wire, and trigger from one of the plug leads with a similar "transformer". From the coil wire you can watch all the cylinders connected to that coil for firing voltage. The spikes should be about the same height if voltages are the same. "Arcs" (proper spark) at the plug have a pretty specific appearance, with the coil secondary collapsing all at once. Small leaks show as partial collapse as the voltage ramps up to plug firing. Modern COP ignitions add this firing voltage "feedback" to engine management for plug condition. They don't have distributors, rotors, or plug wires to worry about, so there's really only one possible cause for high firing voltage.

#12

Rennlist Member

Classic engineer's answer: Yes, but...

Idle conditions offer the lowest resistance at the plug, so a bit of arcing inside the cap is less likely in theory. Back at reality, idle speed is when we are most likely to feel uneven spark voltage. The uneven firing exists even more as engine RPM and loads go up, but our senses aren't good enough to feel the effect until there's a hard miss for a particular cylinder or cylinders. The difference in firing voltage can come from inconsistent plug gaps, minor breaks in plug wires, different gaps at the cap and rotor as illustrated hear, or a path to ground or to another cylinder in the cap.

If you have access to even a cheap oscilloscope, you can place a few wraps of solid copper wire around a coil secondary wire, and trigger from one of the plug leads with a similar "transformer". From the coil wire you can watch all the cylinders connected to that coil for firing voltage. The spikes should be about the same height if voltages are the same. "Arcs" (proper spark) at the plug have a pretty specific appearance, with the coil secondary collapsing all at once. Small leaks show as partial collapse as the voltage ramps up to plug firing. Modern COP ignitions add this firing voltage "feedback" to engine management for plug condition. They don't have distributors, rotors, or plug wires to worry about, so there's really only one possible cause for high firing voltage.

Idle conditions offer the lowest resistance at the plug, so a bit of arcing inside the cap is less likely in theory. Back at reality, idle speed is when we are most likely to feel uneven spark voltage. The uneven firing exists even more as engine RPM and loads go up, but our senses aren't good enough to feel the effect until there's a hard miss for a particular cylinder or cylinders. The difference in firing voltage can come from inconsistent plug gaps, minor breaks in plug wires, different gaps at the cap and rotor as illustrated hear, or a path to ground or to another cylinder in the cap.

If you have access to even a cheap oscilloscope, you can place a few wraps of solid copper wire around a coil secondary wire, and trigger from one of the plug leads with a similar "transformer". From the coil wire you can watch all the cylinders connected to that coil for firing voltage. The spikes should be about the same height if voltages are the same. "Arcs" (proper spark) at the plug have a pretty specific appearance, with the coil secondary collapsing all at once. Small leaks show as partial collapse as the voltage ramps up to plug firing. Modern COP ignitions add this firing voltage "feedback" to engine management for plug condition. They don't have distributors, rotors, or plug wires to worry about, so there's really only one possible cause for high firing voltage.

Unfortunately I do not have a scope [yet]- one of these days! I have been chasing down some unevenness at idle. Last year during my annual inspection I noticed some signs of flash on the terminals inside the distributor cover. I gently polished them out with a fine sander on my Dremel and even thug minimal metal was removed one wonders at what point a little is too much. The issue felt more like an occasional misfire as opposed to the ISV hunting but the reality is that the components in the system are now about 12 years old and the ISV is the original item. Even the HT leads could be near end of life due to heat exposure even though they have only covered about 30k km.

I surely hate changing things out to eliminate issues without knowing for sure what the culprit really is.

#13

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Fred--

Adding clearance via the Dremel is a step backwards. The finish on the (non)contact does nothing to improve the energy transfer, while the additional gap makes it worse. It's a good idea to carefully wash the inside of the cap so there's no metal film stuck on the insulation. Otherwise, make sure the carbon contact to the middle of the rotor is intact.

The o'scope tells a lot about how even the spark energy is among the cylinders, a real key to enabling the smooth idle. I confess that I've only used the scope on the 928 a couple times. Both showed that everything in the ignition is fine. FWIW, the biggest improvement to idle stability happened when the injectors were replaced s part of an intake refresh. That solved some NOx issues too, so no doubt I had some cylinders running a little lean. HC was still OK so not lean enough to see any misfire, but lean enough to have a few hot chambers.

The easiest and cheapest ignition maintenance is installing new correctly-gapped plugs. Good plugs will mask symptoms from leaky wires, but don't do a lot for cap and rotor issues.

Adding clearance via the Dremel is a step backwards. The finish on the (non)contact does nothing to improve the energy transfer, while the additional gap makes it worse. It's a good idea to carefully wash the inside of the cap so there's no metal film stuck on the insulation. Otherwise, make sure the carbon contact to the middle of the rotor is intact.

The o'scope tells a lot about how even the spark energy is among the cylinders, a real key to enabling the smooth idle. I confess that I've only used the scope on the 928 a couple times. Both showed that everything in the ignition is fine. FWIW, the biggest improvement to idle stability happened when the injectors were replaced s part of an intake refresh. That solved some NOx issues too, so no doubt I had some cylinders running a little lean. HC was still OK so not lean enough to see any misfire, but lean enough to have a few hot chambers.

The easiest and cheapest ignition maintenance is installing new correctly-gapped plugs. Good plugs will mask symptoms from leaky wires, but don't do a lot for cap and rotor issues.