Screw it: "Sheet Metal" intakes

#31

Three Wheelin'

Yes sir. I did some cams. They have 10 degrees and .025 more lift on both sides. The centerlines are the same as stock.

Intake is 263 duration at .417

Exhaust 246 duration at .379

Yes, I got the EA Pro

(can the intake resonance be done by the "secondary throttles" option at 4000? Probably not)

Intake is 263 duration at .417

Exhaust 246 duration at .379

Yes, I got the EA Pro

(can the intake resonance be done by the "secondary throttles" option at 4000? Probably not)

#32

Rennlist Member

Thread Starter

The cams are modified S3 cams with the base circle cut.

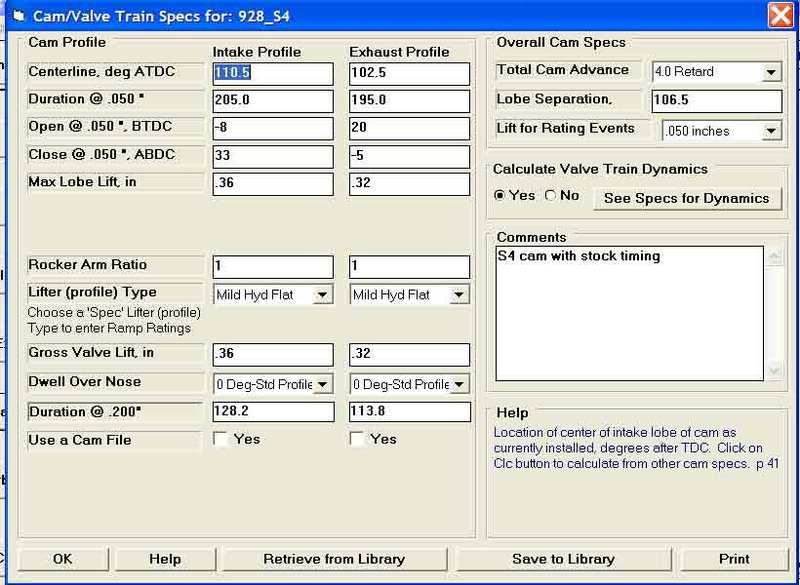

What should I put in this screen for these cams?

#33

Rennlist Member

Thread Starter

For some reason I have "valve toss" at 1rpm. So I obviously have my cam specs in there totally wrong.

#34

Advanced

Join Date: Apr 2006

Location: Carlsbad, CA USA

Posts: 78

Likes: 0

Received 0 Likes

on

0 Posts

#35

Rennlist Member

Thread Starter

Yes, that was what I was thinking. Those are very large pipes.

#36

Three Wheelin'

#37

Three Wheelin'

On this page in your illustration you'll see in the upper right hand area, a box to set at what lift the cam settings are taken. It's titled "Lift for rating events". This one shows 0.050". Click on the arrow on the right side of the data field and you'll be presented with other choices. Choose 1mm (0.040") lift. That's the lift where the cam specs are taken in the 928 WSM. Go to WSM vol. 1, page 0.28 in my book and you'll see the cam specs for the 32v US '85/'86 engine. It gives intake and exhaust opening and closing degrees. On the left side of the Cam/Valve train spec window is where you enter these numbers. If you enter the opening and closing values, the program calculates the duration. If on your cams, the duration was increased by an equal amount on opening and closing, then add/subtract from the WSM values to get yours. The lobe centers will be the same as before. The WSM doesn't give lift values, but I think the S3 cams are the same as GT which is 9mm for exhaust and 10mm for intake. When you click on a data entry field, instructions pertaining to that field will appear in the Comments window.

One thing to remember with the 928 cam timing specs is that these are taken with a cold engine and they will advance about 3 crank degrees when the engine is hot. Don't be surprised to see the "Total cam advance" show a few degrees retarded after you enter the data. To get the EAP to show more real world results, go to the "Total cam advance" field and choose 3 degrees advance. This will change all your numbers in the cam event fields, but don't worry because that's how it should be when the engine is hot.

As for your valve toss problem, I don't know why that happened. There is a place for you to enter valve/lifter mass and spring pressures both seated, open, and spring rate. Be sure you get those right. You'll see valve/lifter mass and spring pressure make a power difference at higher RPM. You enter that by clicking the "See specs for dynamics" button. The numbers in the file I sent you probably aren't correct. They should be ok enough to not give valve toss though. You will need different springs since the stock ones are barely adequate for an S4 and not for a GT. Most GT cams show pitting at the intake lobe due to the lifter flying off the lobe and smashing back after the lobe has passed. It's not so bad on the S3 possibly because of the smaller (lighter) intake valve. The installed spring heights are different between the S3 and S4 so that could account for it too. You can start with light weight valves/lifter and/or stiff springs just to see the effect of the differences, then go back and enter your real valve and spring data to see how much power it costs you. Then make a decision on whether you need to go lighter or different springs. Don't forget to add one half of the valve spring mass to the mass of the valve and lifter. The lifter should be full of oil when it's weighed. There is going to be a lot of valve train mass measurements, spring rate, installed spring height measurement in your future. Decisions, decisions...

To get decent results from the engine simulator, you have to input a lot of data and it has to be accurate.

#38

Rennlist Member

Thread Starter

Thanks again Louie. Some of that makes sense to me, and staring at it for a few more hours will allow me to understand the rest.

I need to get more cam specs from the grinder so I can put that in properly, and no matter what I do it always runs out of steam at 6k. Very weird.

I need to get more cam specs from the grinder so I can put that in properly, and no matter what I do it always runs out of steam at 6k. Very weird.

#39

Three Wheelin'

For throttle body size, that depends on how much air flow the engine needs. The S4 size TB seems adequate for power in the low/mid 300 hp range. You can observe the TBs other engines have for the power level you want. Figure the area of the single and use about 60% of the single TB area for a double TB. If you go too big on the TB size, you'll have weird throttle response in that with throttle only part open, the engine will get all the air it can use so the remaining throttle opening won't give you much power. I think we've all driven cars where the first 1/4 throttle seemed to give 75% of the max power. A big lunge, then not much more. On my 6.5L motor the opening into the air box at the front is about 12 sq in. It's not really big, but there is no power difference whether I have the top off of the air box, or running with all the air passing through that 12 sq in opening. The air does have a smooth transition into the opening so can accelerate to the high velocity without loss and the air box volume is large so the flow into the box is smooth and not pulsating. If I were to have a similar intake, but not using ITBs, I'd use four 2" TBs at the front of the box. I can't use much larger because I don't have the height. I'd have the 4 TBs sequential probably operating in pairs so I'd have more linear throttle response. You could have TBs on the sides of the box if they wouldn't interfere with the fuel rails. If the engine would make less than 500 or so rwhp, then you could get away with less.

One improvement that can be made to the S4 intake is to fit TBs to the side plates. You need to make different side plates, but that works. Tom Cloutier did that and runs it on his '89. We tried it on my '87 too and it made 15 more hp above about 4700 rpm with no loss below that. It's a big job to do that and I figured not really worth the effort for myself. He has intakes coming from each side throttle going to a Y in front where the MAF is with an air filter in front of the radiator. The normal throttle isn't used. It does work.

Not sure if this answered what you wanted, but is about the best I can do.

#40

Rennlist Member

Thread Starter

The stock throttle body seems like it could only be increased so much.

Working with this analyzer software seems to be confusing me more than helping me.

Probably, even though the current intake helps below a certain RPM, It is a considerable restriction above 3700rpm, especially when a supercharger is trying to cram enough air that it causes 12psi down its throat, going to 25psi at 6800rpm.

How did TomC manage to cap off that bottom area in the intake so he could come in from the side instead of the bottom?

Working with this analyzer software seems to be confusing me more than helping me.

Probably, even though the current intake helps below a certain RPM, It is a considerable restriction above 3700rpm, especially when a supercharger is trying to cram enough air that it causes 12psi down its throat, going to 25psi at 6800rpm.

How did TomC manage to cap off that bottom area in the intake so he could come in from the side instead of the bottom?

#41

Three Wheelin'

The stock throttle body seems like it could only be increased so much.

Working with this analyzer software seems to be confusing me more than helping me.

Probably, even though the current intake helps below a certain RPM, It is a considerable restriction above 3700rpm, especially when a supercharger is trying to cram enough air that it causes 12psi down its throat, going to 25psi at 6800rpm.

How did TomC manage to cap off that bottom area in the intake so he could come in from the side instead of the bottom?

Working with this analyzer software seems to be confusing me more than helping me.

Probably, even though the current intake helps below a certain RPM, It is a considerable restriction above 3700rpm, especially when a supercharger is trying to cram enough air that it causes 12psi down its throat, going to 25psi at 6800rpm.

How did TomC manage to cap off that bottom area in the intake so he could come in from the side instead of the bottom?

Tom put some plates over the holes that lead from the side plenums down to the lower common plenum. They didn't make an air tight seal because that's where his idle air still comes from through the idle speed control valve.

#42

Rennlist Member

Brendan,

I've ordered one of the M5 "intake funnels" (those Bavarians are a crack up ) for modeling purposes. I can forward it to you when I'm done if you think it would do you some good.

) for modeling purposes. I can forward it to you when I'm done if you think it would do you some good.

The M5 uses 6 identical stacks...err funnels, and two unique. I ordered one of the 6 identical, its part no. 11617830453. The unique ones, for cyl's 1 and 5, are the same part number except the last digit which is "2" and "4" respectively.

Price I got is is $43.25 each from Pelican. I've been hunting around the dismantler sights hoping to get a used set, but unlikely I'd find a set separated from the engine.

I've ordered one of the M5 "intake funnels" (those Bavarians are a crack up

) for modeling purposes. I can forward it to you when I'm done if you think it would do you some good.

) for modeling purposes. I can forward it to you when I'm done if you think it would do you some good.The M5 uses 6 identical stacks...err funnels, and two unique. I ordered one of the 6 identical, its part no. 11617830453. The unique ones, for cyl's 1 and 5, are the same part number except the last digit which is "2" and "4" respectively.

Price I got is is $43.25 each from Pelican. I've been hunting around the dismantler sights hoping to get a used set, but unlikely I'd find a set separated from the engine.

#43

Rennlist Member

Thread Starter

I talked to a local engine parts fabricator (and "Zuper Tuner") guy, and he showed me this:

He suggested this as an option. While I understand that the V6 has a different firing order, and that the balance tube would possibly need a butterfly in it, this may be an option, as I was also going to do an air-to-air intercooler.

Obviously, the runners would be shaped so that there would be hood clearance. BUt this idea affords two, smaller throttle bodies for better throttle response.

Just some options.

http://www.speedforceracing.com/imag...g35nos_1_1.jpg

He suggested this as an option. While I understand that the V6 has a different firing order, and that the balance tube would possibly need a butterfly in it, this may be an option, as I was also going to do an air-to-air intercooler.

Obviously, the runners would be shaped so that there would be hood clearance. BUt this idea affords two, smaller throttle bodies for better throttle response.

Just some options.

http://www.speedforceracing.com/imag...g35nos_1_1.jpg

#44

Rennlist Member

Thread Starter

Brendan,

I've ordered one of the M5 "intake funnels" (those Bavarians are a crack up ) for modeling purposes. I can forward it to you when I'm done if you think it would do you some good.

) for modeling purposes. I can forward it to you when I'm done if you think it would do you some good.

The M5 uses 6 identical stacks...err funnels, and two unique. I ordered one of the 6 identical, its part no. 11617830453. The unique ones, for cyl's 1 and 5, are the same part number except the last digit which is "2" and "4" respectively.

Price I got is is $43.25 each from Pelican. I've been hunting around the dismantler sights hoping to get a used set, but unlikely I'd find a set separated from the engine.

I've ordered one of the M5 "intake funnels" (those Bavarians are a crack up

) for modeling purposes. I can forward it to you when I'm done if you think it would do you some good.

) for modeling purposes. I can forward it to you when I'm done if you think it would do you some good.The M5 uses 6 identical stacks...err funnels, and two unique. I ordered one of the 6 identical, its part no. 11617830453. The unique ones, for cyl's 1 and 5, are the same part number except the last digit which is "2" and "4" respectively.

Price I got is is $43.25 each from Pelican. I've been hunting around the dismantler sights hoping to get a used set, but unlikely I'd find a set separated from the engine.

#45

Rennlist Member

Thread Starter

Funny how the 928 is mentioned in this thread about a balance tube:

http://www.eng-tips.com/viewthread.c...=194338&page=1

http://www.eng-tips.com/viewthread.c...=194338&page=1