Port and Polish by Comiittee thread (Cool pics throughout)

#76

The downside of CNC porting is that it is also possible to duplicate crappy ports......exactly! You can ruin ports in volume! However, the good news is that they will be ruined exactly the same way! So, the first step is to make a port that works, then duplicate it as close as possible.

To develop a port and CNC duplicate it for under $10,000.00 is not going to happen! The time required to do the development work, build fixtures to hold the head, and then program a 4 axis machine to dupicate that port takes a zillion hours. I think Mike Simmard can shed light on how tough it would be and the time required to fixture and program a port for machining. The good news is that the next 1000 would be quick and cheap.

That being said, here's what I won't do and what I actually do. I will not cut a cast iron port. Too slow, too dirty, way too hard. I do heads that I've developed and have patterns for. I don't have the time to develop heads that I've not worked up in the past. When I need a trick head for one of my big blocks Chevys, I call and buy heads from the best people I can find. I like Air Flow Research heads and I've had success with Dart.

So, what you think? Too boring? Too much effort. Let me know and I'll quit or continue.

greg brown

this being said leads me to what I stated earlier.......

$1000 for a pair of heads (regardless of flavor--Euro 16V or 32V) to sacrifice.

then over $10,000 in development, spread over how many customers? 100 maybe? that would be very good Greg, but you have to find 100 customers willing to pay what ever your price is......

so are there actually have 100 customers in the 928 community that would be willing to shell out over a grand for their heads to be opened up? How much would someone be willing to pay for CNC machined high flow heads...? $1500, $2500...?

you can easily do the math on this Greg. with 100 customers, at $2500 per customer/pair, that's $2.5 million. A couple of grand in sacrifice heads, $10K in development, that's $238,000 profit. This assumes you already have the CNC machine and the software/operator to do the deal......you would have to figure what the operating cost of the machine is, and then you have your profit margin.

As I also said earlier, the number of folks that are actually doing the big motor route is very, very small. Not to mention that fewer than a handful are doing any kind of head/cam work other than what's available from factory parts.

I'd be very interested to see those numbers.......

Now that I've done the math for you, you can just send me $100K for showing the math.......you can keep the $138K for yourself.

Call it a consulting fee-----

--Russ

#79

I'm back. I didn't get lost, I just have a really full schedule and needed to get some mechaincal things done at the shop. Pretty wide variety of stuff to do. Yesterday, I was beginning the assembly of a transmission for the most perfect '54 Speedster I've ever seen. The restoration is 6 years in and it is amazing to see. The owner is a fanatic. He even found a perfect tool kit for this car. Imagine finding a 50+ year old tool kit.....only $5000, but at least he found one.

Anyway, I'm going to try to get the ability to load pictures, this afternoon. Need to go, this morning, and pick-up a used Triumph motorcycle engine I bought. Yeah, I've got an entire garage full of British motorcycle stuff, also. I do a wide variety of things. I'm rounding up pieces for 5 different Triumphs that I'm working on...kind of all at the same time. One would be boring.

You guys have been busy. Impressive logic and math, Russ. Everything made sense right up to writing the check for the consulting fee. I called the bank and they said I enough funds to send a check for about $10.00. However, Mary has taken away all of the blank checks and hidden them from me, so I think we might be in trouble.

Here's what I've found out about surface finish, over the years. Some heads (notice "some") are very sensitive to intake surface finish. This can be a real pain in the butt, when one is "working" up a port design on the flow bench. I've had situations where heads will have significant flow gains, when rough ported and then loose all those gains (and sometimes more than what was gained, when the roughness is removed and retested.) Air flow is laminar through the port. This means that the air that is moving along the walls of the port is moving completely different than the air through the rest of the port. I think that what I've learned is that the air that flows along the walls is essentially rolling along in little circles. The smoother the finish, the bigger the circles are, in most ports. There needs to be texture there to "break" the air circles up and make them smaller. I clean up the intake ports with 60 grit sanding cones...sometimes 80, but certainly no finer. The best consistant surface i've found is a very smooth 60 to 80 grit surface that is then bead blasted with "D" beads at about 80 psi. This tends to re-expose the little holes in the casting, which really improves the flow.

This is generally why ported heads work better after they have been run and get the next valve grind. The shops generally bead blast the ports....removing the polished surface...and airflow increases can be as high as 20%! It seems crazy, but it works. You can never go wrong with this surface finish on the entire intake track, including the intake manifold.

During a port work-up, this can be a real pain. You can find an increase in airflow, rough ported, loose all the gains when smoothed, and then pick it back up when it is blasted. This means that ever little cut that is made, must be tested the same way, each time....in order to be consistant. This sucks up hours and hours of cutting, smoothing, bead blasting, cleaning, assembly, and then testing. However, this is what it takes. Believe me, you can cut out a port, have great gains in airflow and then polish that surface and have a head that flows less air than when you started. it sucks, but it is reality.

Anyway, got to run. I'll work on the picture thing, this afternoon and evening. I'll also look closely at Brendan's pictures and throw out some ideas....his pictures are always so detailed and very close-up. They're great.

greg brown

Anyway, I'm going to try to get the ability to load pictures, this afternoon. Need to go, this morning, and pick-up a used Triumph motorcycle engine I bought. Yeah, I've got an entire garage full of British motorcycle stuff, also. I do a wide variety of things. I'm rounding up pieces for 5 different Triumphs that I'm working on...kind of all at the same time. One would be boring.

You guys have been busy. Impressive logic and math, Russ. Everything made sense right up to writing the check for the consulting fee. I called the bank and they said I enough funds to send a check for about $10.00. However, Mary has taken away all of the blank checks and hidden them from me, so I think we might be in trouble.

Here's what I've found out about surface finish, over the years. Some heads (notice "some") are very sensitive to intake surface finish. This can be a real pain in the butt, when one is "working" up a port design on the flow bench. I've had situations where heads will have significant flow gains, when rough ported and then loose all those gains (and sometimes more than what was gained, when the roughness is removed and retested.) Air flow is laminar through the port. This means that the air that is moving along the walls of the port is moving completely different than the air through the rest of the port. I think that what I've learned is that the air that flows along the walls is essentially rolling along in little circles. The smoother the finish, the bigger the circles are, in most ports. There needs to be texture there to "break" the air circles up and make them smaller. I clean up the intake ports with 60 grit sanding cones...sometimes 80, but certainly no finer. The best consistant surface i've found is a very smooth 60 to 80 grit surface that is then bead blasted with "D" beads at about 80 psi. This tends to re-expose the little holes in the casting, which really improves the flow.

This is generally why ported heads work better after they have been run and get the next valve grind. The shops generally bead blast the ports....removing the polished surface...and airflow increases can be as high as 20%! It seems crazy, but it works. You can never go wrong with this surface finish on the entire intake track, including the intake manifold.

During a port work-up, this can be a real pain. You can find an increase in airflow, rough ported, loose all the gains when smoothed, and then pick it back up when it is blasted. This means that ever little cut that is made, must be tested the same way, each time....in order to be consistant. This sucks up hours and hours of cutting, smoothing, bead blasting, cleaning, assembly, and then testing. However, this is what it takes. Believe me, you can cut out a port, have great gains in airflow and then polish that surface and have a head that flows less air than when you started. it sucks, but it is reality.

Anyway, got to run. I'll work on the picture thing, this afternoon and evening. I'll also look closely at Brendan's pictures and throw out some ideas....his pictures are always so detailed and very close-up. They're great.

greg brown

#80

Brendan:

Most of the little flaws that you see in the combustion chamber will not do much for the output of the engine. Certainly any sharp edges should be removed. Unshrouding the combustion chambers back to the size of the cylinder will certianly help the gas exchange....if you can afford the loss of compression. Most people polish the combustion chambers to make the carbon not have anywhere to stick, which keeps the compression ratio where you designed the engine to be at. A combustion and piston full of carbon can significantly raise the compression ratio.

The short wall and the short wall radius (which is the floor of the port), is where most of the increases in air flow are going to be found. There is generally very little improvement to be found in the valve guide area. You can have shorter guides and have them tapered for flow, reduce the stem diameter of the valves...and find no change in air flow.

On the short wall, you need to be very careful not to lower the floor and reduce the radius of the turn to the seat. However, this radius needs to be as consistant as you can make it. If the air "breaks" off of this wall, at higher velocities, it simply crashes into the air that is trying to go down the center of the port and then slams into the long wall. This kills the airflow numbers. You can hear this happen on a flow bench...you don't even need to look at the flow meters to know that things just turned to crap. You will want to remove and blend the cut from the installation of the valve seats into the floor. You will need to gently cut this back and blend, all the time, trying to improve and make the radius consistant. Lowering the floor and making the radius tighter will help flow, right up to the point where it can't make the bend, so unless you are willing to guess at this, I'd just think a nice radius would do you well.

Most of the little flaws that you see in the combustion chamber will not do much for the output of the engine. Certainly any sharp edges should be removed. Unshrouding the combustion chambers back to the size of the cylinder will certianly help the gas exchange....if you can afford the loss of compression. Most people polish the combustion chambers to make the carbon not have anywhere to stick, which keeps the compression ratio where you designed the engine to be at. A combustion and piston full of carbon can significantly raise the compression ratio.

The short wall and the short wall radius (which is the floor of the port), is where most of the increases in air flow are going to be found. There is generally very little improvement to be found in the valve guide area. You can have shorter guides and have them tapered for flow, reduce the stem diameter of the valves...and find no change in air flow.

On the short wall, you need to be very careful not to lower the floor and reduce the radius of the turn to the seat. However, this radius needs to be as consistant as you can make it. If the air "breaks" off of this wall, at higher velocities, it simply crashes into the air that is trying to go down the center of the port and then slams into the long wall. This kills the airflow numbers. You can hear this happen on a flow bench...you don't even need to look at the flow meters to know that things just turned to crap. You will want to remove and blend the cut from the installation of the valve seats into the floor. You will need to gently cut this back and blend, all the time, trying to improve and make the radius consistant. Lowering the floor and making the radius tighter will help flow, right up to the point where it can't make the bend, so unless you are willing to guess at this, I'd just think a nice radius would do you well.

#81

Thanks for looking at the pictures greg.

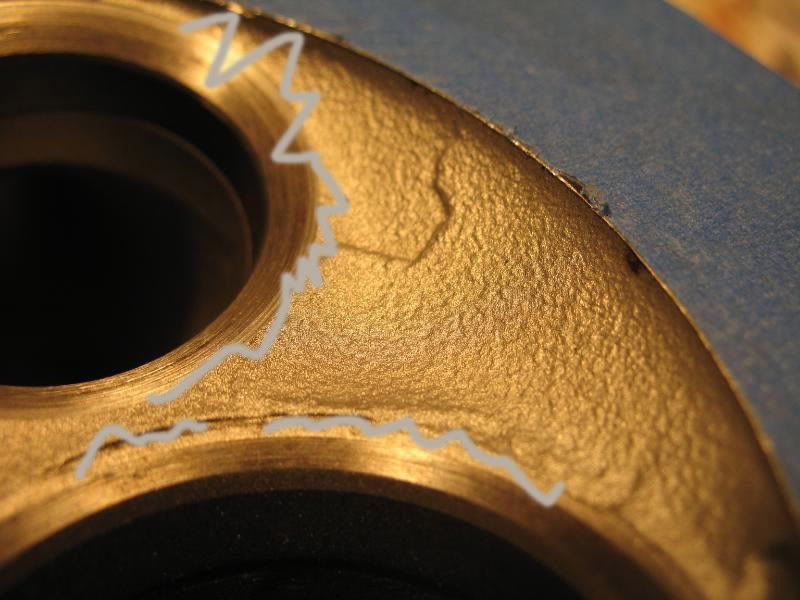

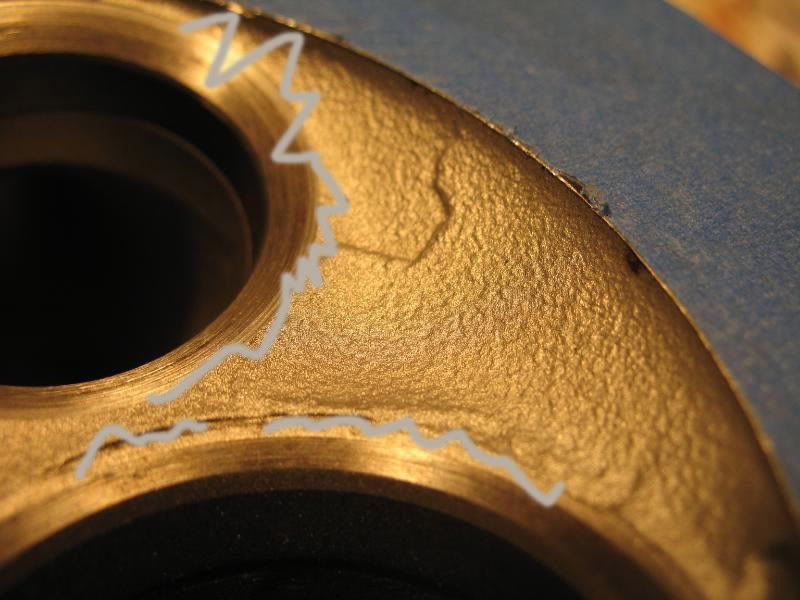

So you are saying essentially, that it is a good idea in most cases to remove or smooth this transition in the casting just "above" the seat:

Would you suggest that I focus in the areas I have marked and leave the rest alone?

So you are saying essentially, that it is a good idea in most cases to remove or smooth this transition in the casting just "above" the seat:

Would you suggest that I focus in the areas I have marked and leave the rest alone?

#83

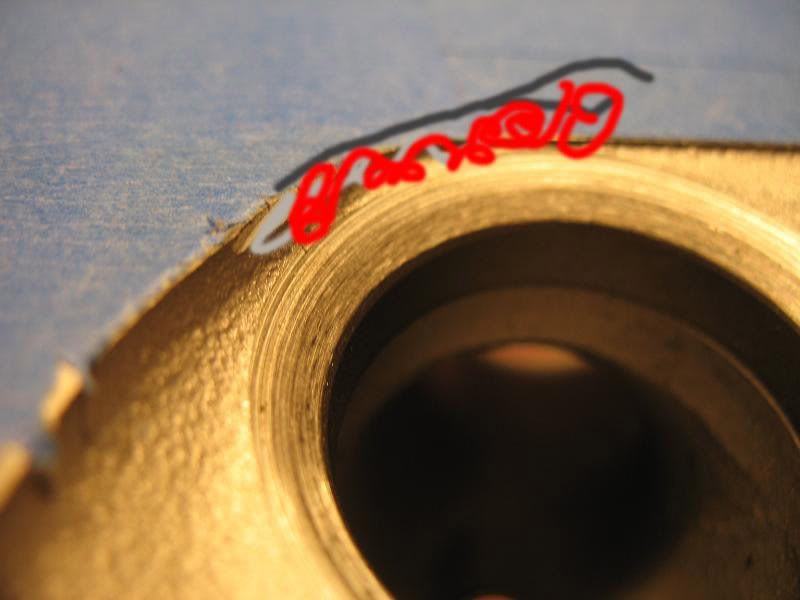

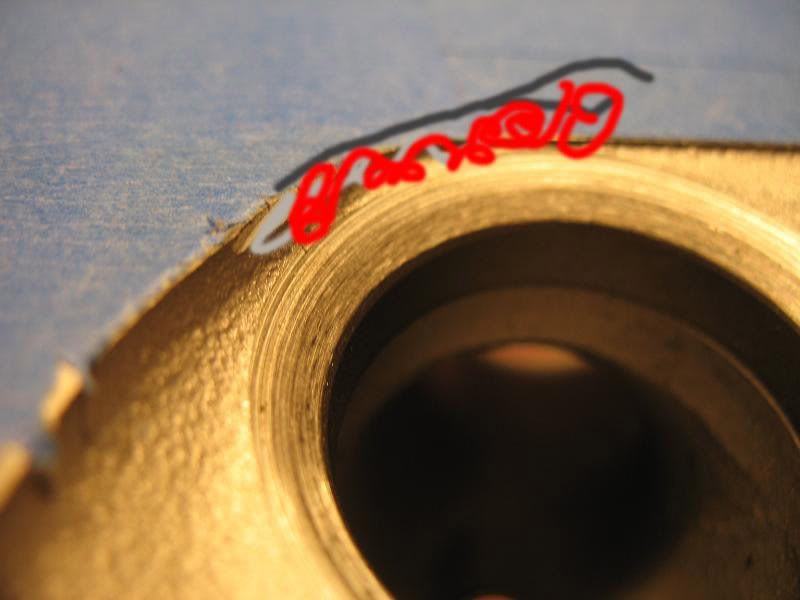

And also, I was thinking of some smoothing (blending, I guess) of the margin area between the actual seat and the chamber. It seems that if there is air that needs to get either from the port to the chamber, or the chamber to the port, it would improve things to make this area one surface:

#84

And with the topic of unshrouding valves, this includes both intake and exhaust right?

I was thinking of some areas here:

(red area, later scribed with gasket - seems to be a good area to remove)

Lowering the combustion will just allow more boost.

I was thinking of some areas here:

(red area, later scribed with gasket - seems to be a good area to remove)

Lowering the combustion will just allow more boost.

The following users liked this post:

firemn131 (12-22-2019)

#86

Actually if your going to get pissy about something thats already been said, i made the same point on page 2, post #19. No need to get pissy about someone saying the same thing you did, as it turns out your not covering any new ground here.

No thats not at all what i am talking about. Either you don't understand the concept or I have done a **** poor job describing it.

The mod i am reffering to turns the combustion chamber into an inverse of a golfball, think MANY MANY dimples not a single dimple. The pistons were also modified and the results were mainly in the area of drastically reduced fuel consumption, something in the area of 20% - 30%, or the engine could be retuned to flow the same amount of fuel for no mileage gain and more air could be found to go in the engine and you could gain more HP to the same tune of 20%-30%. Mind you this was on small engines but if the principle works for 1, 2, or 4 cylinder cars then there is no reason it cant work for other's. I will see if i can find some more information on the theory.

If Chrysler is doing it, I hardly consider it cutting edge. Those cars are just giant, heavy, mass produced tin cans.

Sorry but the minute we start talking about american cars and 8V Chrysler heads in a Porsche Forum is the moment i run away.

The mod i am reffering to turns the combustion chamber into an inverse of a golfball, think MANY MANY dimples not a single dimple. The pistons were also modified and the results were mainly in the area of drastically reduced fuel consumption, something in the area of 20% - 30%, or the engine could be retuned to flow the same amount of fuel for no mileage gain and more air could be found to go in the engine and you could gain more HP to the same tune of 20%-30%. Mind you this was on small engines but if the principle works for 1, 2, or 4 cylinder cars then there is no reason it cant work for other's. I will see if i can find some more information on the theory.

If Chrysler is doing it, I hardly consider it cutting edge. Those cars are just giant, heavy, mass produced tin cans.

Sorry but the minute we start talking about american cars and 8V Chrysler heads in a Porsche Forum is the moment i run away.

Last edited by RyanPerrella; 03-16-2008 at 08:07 PM.

#87

My only lingering concern is the exhaust port. With the fuel planned (E85) and the boost planned, there will be a lot of air and fuel being pushed in. More fuel per CFM of air (it may not be technically described that way, but it gets the point across) - thereby creating more mass to be exhausted out the normal-sized valves and ports and Devek LII headers.

I don't want to avoid the opportunity to decrease the amount of work taken away from total power by the pistons having to shove all that increased mass out the untouched exhaust ports.

#90

I am pretty sure GM uses SS valves for all their flex fuel (E85) vehicles. There are also different hose compounds needed for fuel likes in the entire chassis.

Have you looked into that? IIRC they replace valves with SS and they use other injectors as well as specific type of rubber compound hoses. There is quite a bit to change inside the engine although if your buying everything new its not an issue, but hopefully you've got the correct fuel lines and injectors. Did you ask RC if their injectors are suitable for E85 or Ethanol?

Have you looked into that? IIRC they replace valves with SS and they use other injectors as well as specific type of rubber compound hoses. There is quite a bit to change inside the engine although if your buying everything new its not an issue, but hopefully you've got the correct fuel lines and injectors. Did you ask RC if their injectors are suitable for E85 or Ethanol?