Pictures of Grooved Bearings, Question

#1

Rennlist Member

Thread Starter

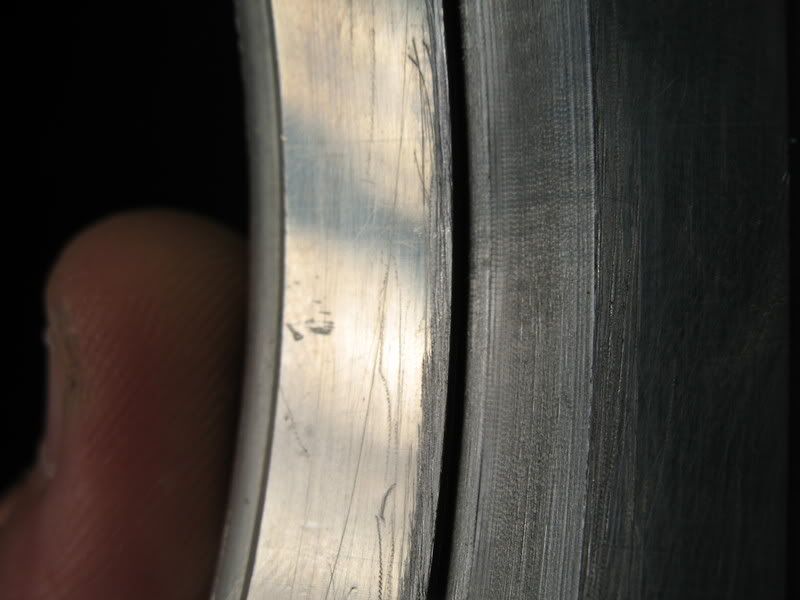

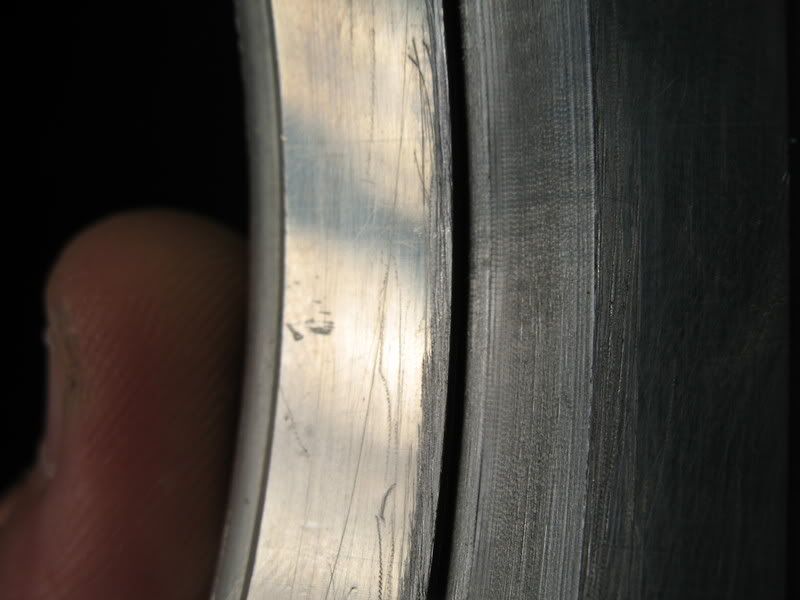

So I don't think I can use these now. I had them grooved, and was going to put the bottom end together this weekend.

I can get the scratched half from the dealer, and use the non-scratched half in the top, but then I thought about the other, smaller scratches by the groove, and I am concerned about these as well.

I should have taken Mike Simard up on his CNC grooving when he offered! It looks like I have to pay another 50 bucks for the bearing set, and get someone to groove it again.

Unless someone can tell me the small scratches are okay, or even the larger scratch?

I can get the scratched half from the dealer, and use the non-scratched half in the top, but then I thought about the other, smaller scratches by the groove, and I am concerned about these as well.

I should have taken Mike Simard up on his CNC grooving when he offered! It looks like I have to pay another 50 bucks for the bearing set, and get someone to groove it again.

Unless someone can tell me the small scratches are okay, or even the larger scratch?

#2

Rennlist Member

I'd start fresh B.C., the big scratch looks nasty. I would think you would want an unscratched surface around the channel to help promote the ability of a thinner film of oil suspending the crank.

If you can get the bearing for $50 (not too bad), why not do it over and make it perfect.

By the way, my bearing channel cut by Motorsport SLC is identical to yours. Are you going to stick with the same dimensions if you do over?

If you can get the bearing for $50 (not too bad), why not do it over and make it perfect.

By the way, my bearing channel cut by Motorsport SLC is identical to yours. Are you going to stick with the same dimensions if you do over?

#3

Rennlist Member

Thread Starter

Thanks Adam.

These are the measurements I got from Mike Simard when he was discussing his cuts made on his CNC equipment. 6mm wide, I think, and 50 thousands deep (I know, two different standards, I think its less than 1.5MM)

I don't quite know who will be doing the work this time.

These are the measurements I got from Mike Simard when he was discussing his cuts made on his CNC equipment. 6mm wide, I think, and 50 thousands deep (I know, two different standards, I think its less than 1.5MM)

I don't quite know who will be doing the work this time.

#4

Rennlist Member

Thread Starter

#5

Former Sponsor

The little scratches happen when the groove is being cut. The removed metal "bounces" around inside the bearing while it turns in the lathe and makes marks in the "super soft" break-in surface. You can hit this with a really mild scotch brite pad and remove probably all of it. The center main is almost always supplied from Porsche as a "yellow" bearing and it can use some additional clearance anyway....so we "scotch brite" all these bearings, anyway. The small scratch that runs from the center to the edge isn't big enough to ever worry about. Not enough oil will escape down this little scratch to ever measure. If you are worried about it, install it so that the little scratch points towards the rear and if any oil escapes, it will help lubricate the side of the thrust bearing that always has problems.

BTW: I can't see if this is the early bearing with the "narrow" thrust surface or the late bearing with the "wide" thrust surface, but if it is the wide bearing, let me know where you are getting these for $50.00 per set.

BTW: I can't see if this is the early bearing with the "narrow" thrust surface or the late bearing with the "wide" thrust surface, but if it is the wide bearing, let me know where you are getting these for $50.00 per set.

#7

Former Sponsor

Trending Topics

#8

Rennlist Member

So that's why ours don't look like that, we use a mill not a lathe. It's not very easy to do a 270 degree groove on a lathe.

#9

Rennlist Member

Thread Starter

This set was part of the entire main's set bought from 928intl, oh, lets say 4 years ago. Sitting in a drawer waiting for life to pass by.

I mentioned the price from the above link.

#10

Rennlist Member

Thread Starter

#11

Three Wheelin'

Heck, bearings are mallable and those would probably work but why use them and be nagged by a flaw at the center of your engine? I could be pursuaded to do some more but it will be a few weeks before I get machine time, if anyone else wants them it would certainly happen soon. You can have 928Intl ship a thrust set to me.

That was a good point Greg brought up about clearances. I noticed that my new bearing set along with the factory block/crank specs would yield a tight fit. I aligned honed my block and wound up aiming for something like .001" over what the manual would recommend, the Moldex crank is on size.

Speaking of ugly chewed up bearings, yours are not as ugly as the Z06 bearings I recently got from a GM dealer, they're genuine GM parts (from Mexico) and packed with a stick of third world styrofoam in the box to seperate them, in most boxes that stupid method doesn't work and the bearings were heavily nicked. That purchase and my trip to the dealership to return them happened during your Z06 lust thread Brendan, I didn't have the heart to lump THAT on you

That was a good point Greg brought up about clearances. I noticed that my new bearing set along with the factory block/crank specs would yield a tight fit. I aligned honed my block and wound up aiming for something like .001" over what the manual would recommend, the Moldex crank is on size.

Speaking of ugly chewed up bearings, yours are not as ugly as the Z06 bearings I recently got from a GM dealer, they're genuine GM parts (from Mexico) and packed with a stick of third world styrofoam in the box to seperate them, in most boxes that stupid method doesn't work and the bearings were heavily nicked. That purchase and my trip to the dealership to return them happened during your Z06 lust thread Brendan, I didn't have the heart to lump THAT on you

#12

Former Sponsor

Porsche has significantly changed their prices on bearings. I had bought a dozen sets back when I suspected that they were going to "bump" the prices, but I've used them all and am now buying bearings at the higher prices, too.

#13

Former Sponsor

Mike:

Be careful about reducing the "crush" on the bearings from the outside. It is usually better to reduce the size of the crank slightly, or remove some from the ID of the bearing, than to reduce the crush from the outside.

Be careful about reducing the "crush" on the bearings from the outside. It is usually better to reduce the size of the crank slightly, or remove some from the ID of the bearing, than to reduce the crush from the outside.

#14

Nordschleife Master

#15

Rennlist Member

Hi.

I would highly recommend just using some 1500 grit sand paper with some WD40 and smoothing out the bearing. I will work for 100k plus miles with no problems if your clearance are correct. I think it will be perfect. Just after sanding, take a plastic brush and some wheel cleaner with water and gently scrub the surface to get all the loose metal out of the bearing. A few scratches really won't matter.

Good luck.

I would highly recommend just using some 1500 grit sand paper with some WD40 and smoothing out the bearing. I will work for 100k plus miles with no problems if your clearance are correct. I think it will be perfect. Just after sanding, take a plastic brush and some wheel cleaner with water and gently scrub the surface to get all the loose metal out of the bearing. A few scratches really won't matter.

Good luck.