Ben's 1982 928 S "restoration"

#196

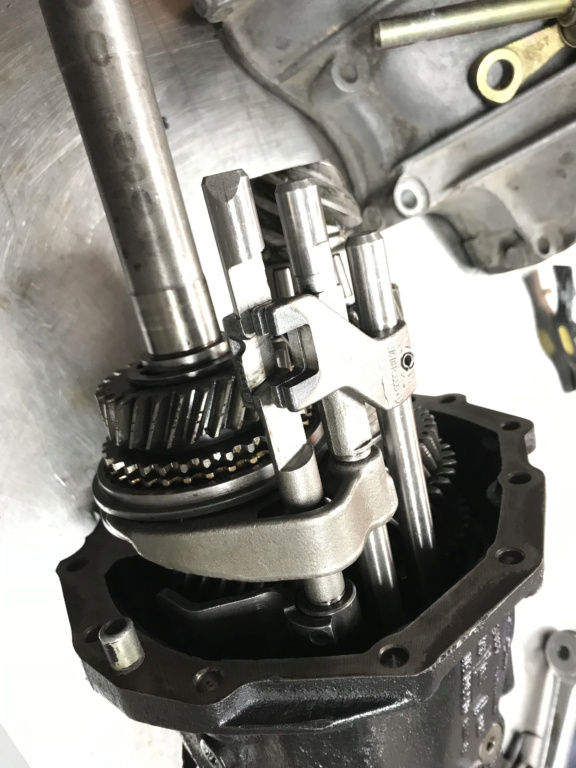

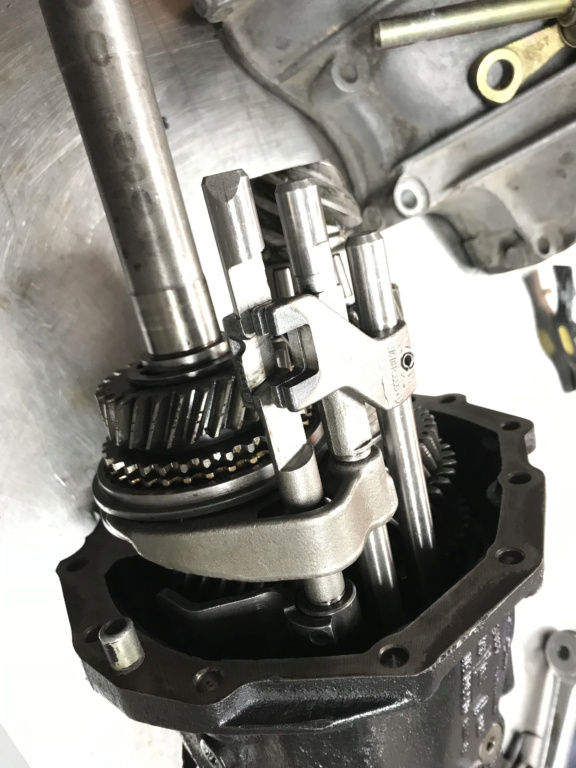

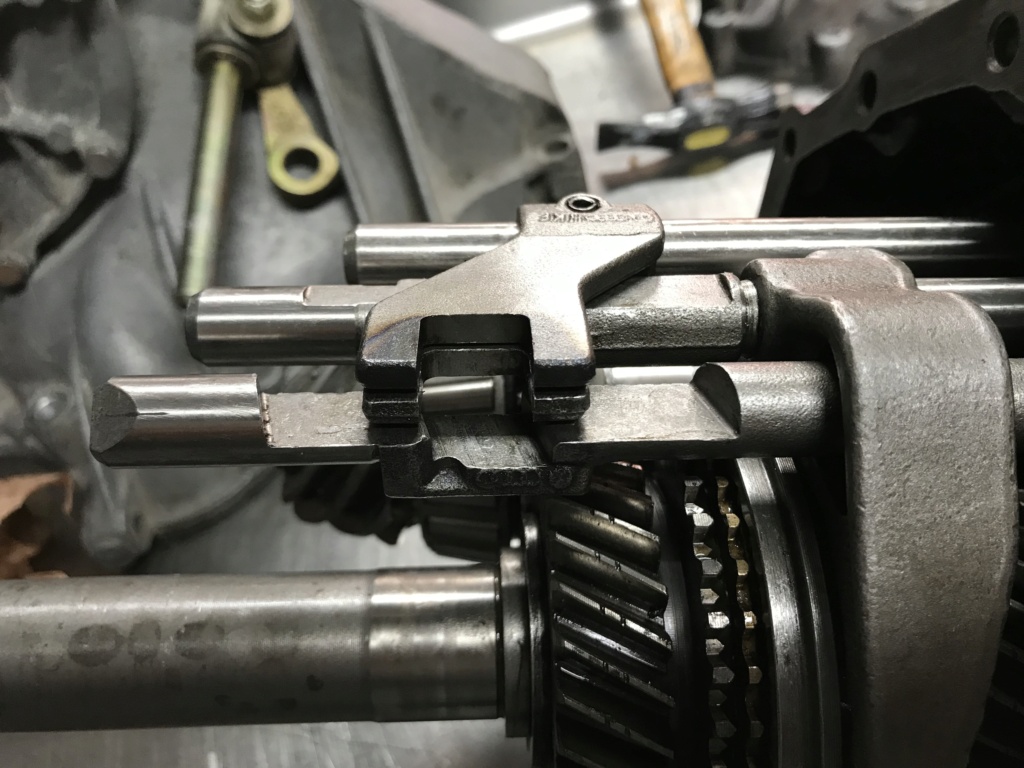

I'm Done with the 944 Gearbox, only thing I forgot is to scan it !

And voilà !

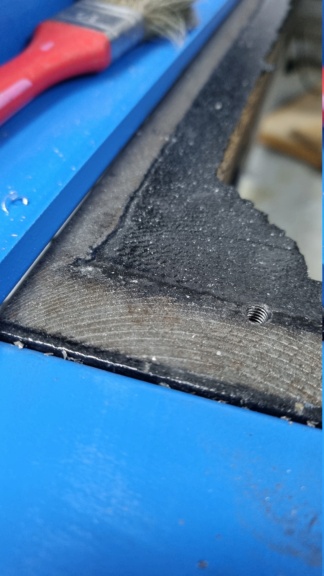

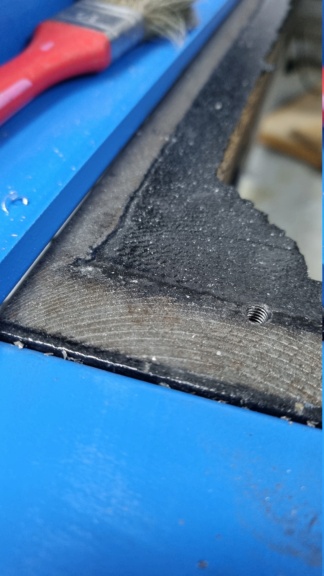

Loctite anaerobic sealant :

Done

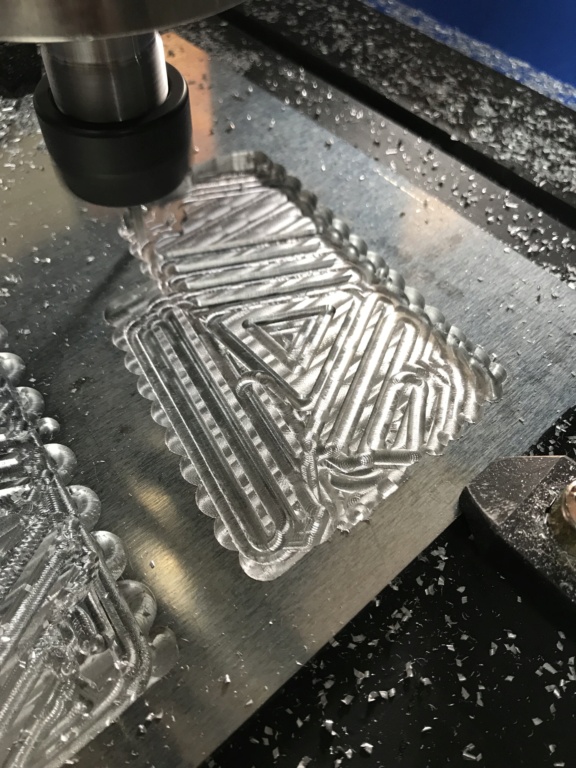

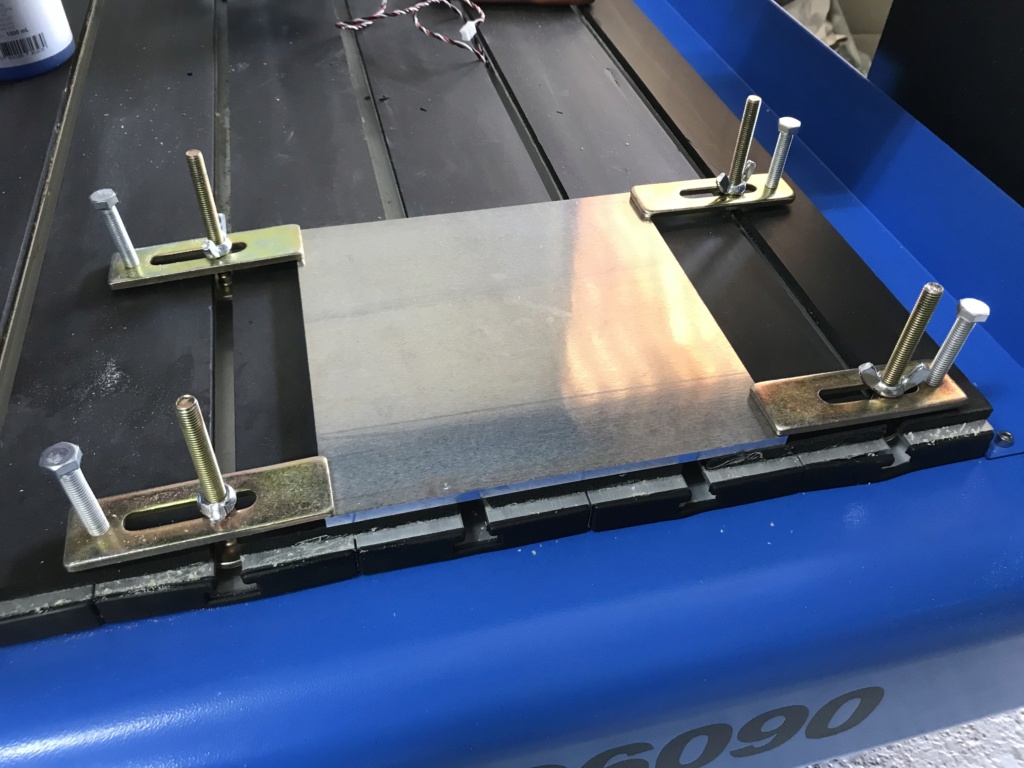

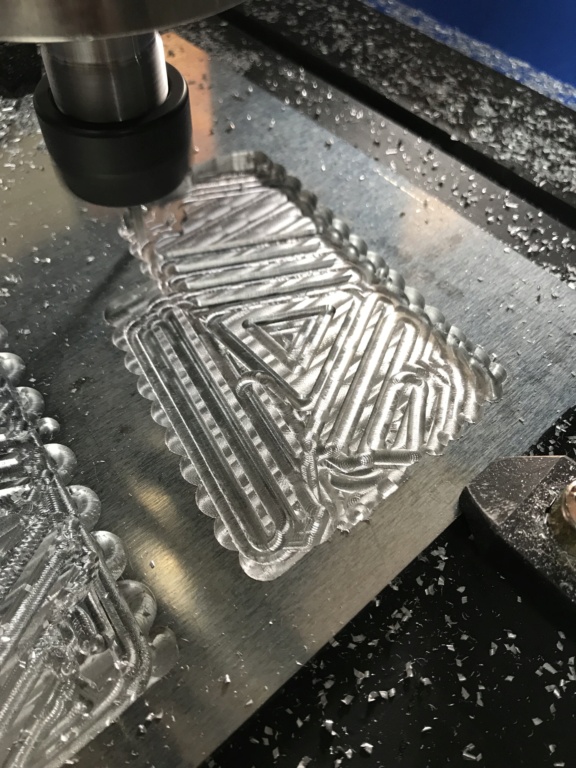

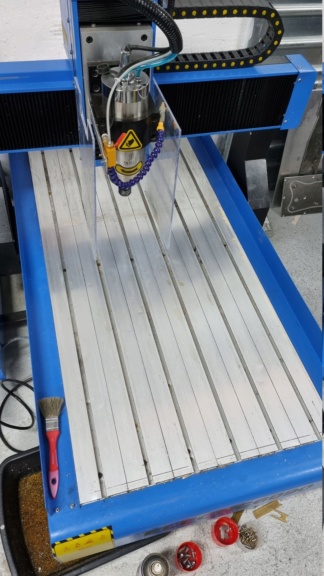

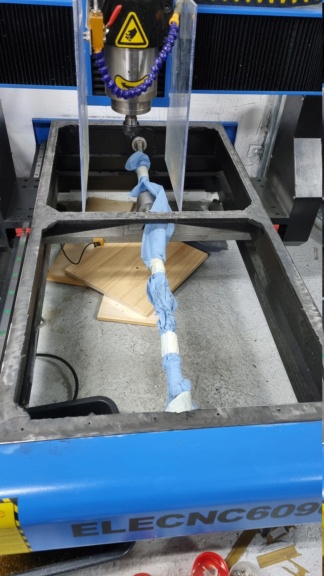

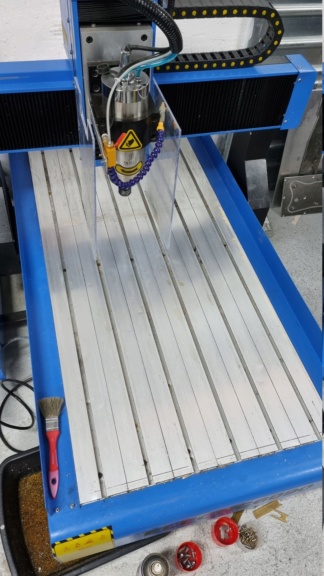

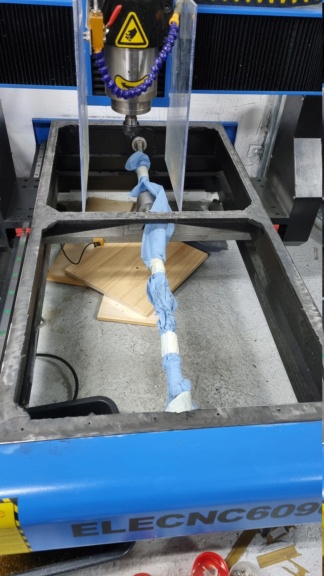

I fired up the CNC machine !

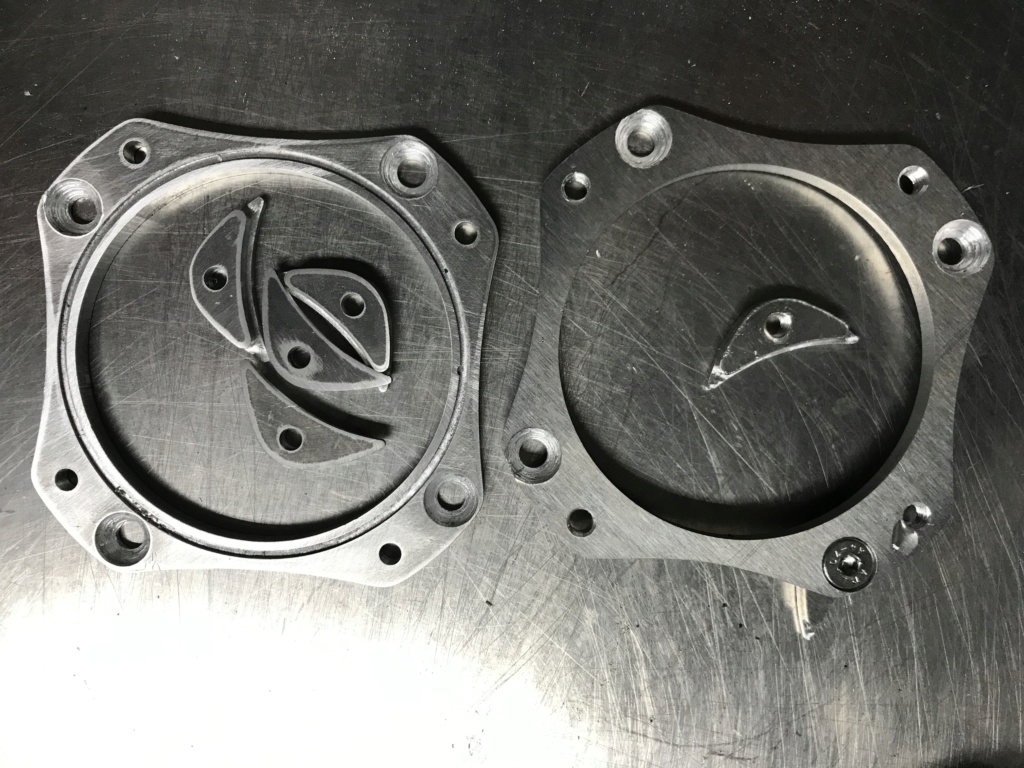

Before :

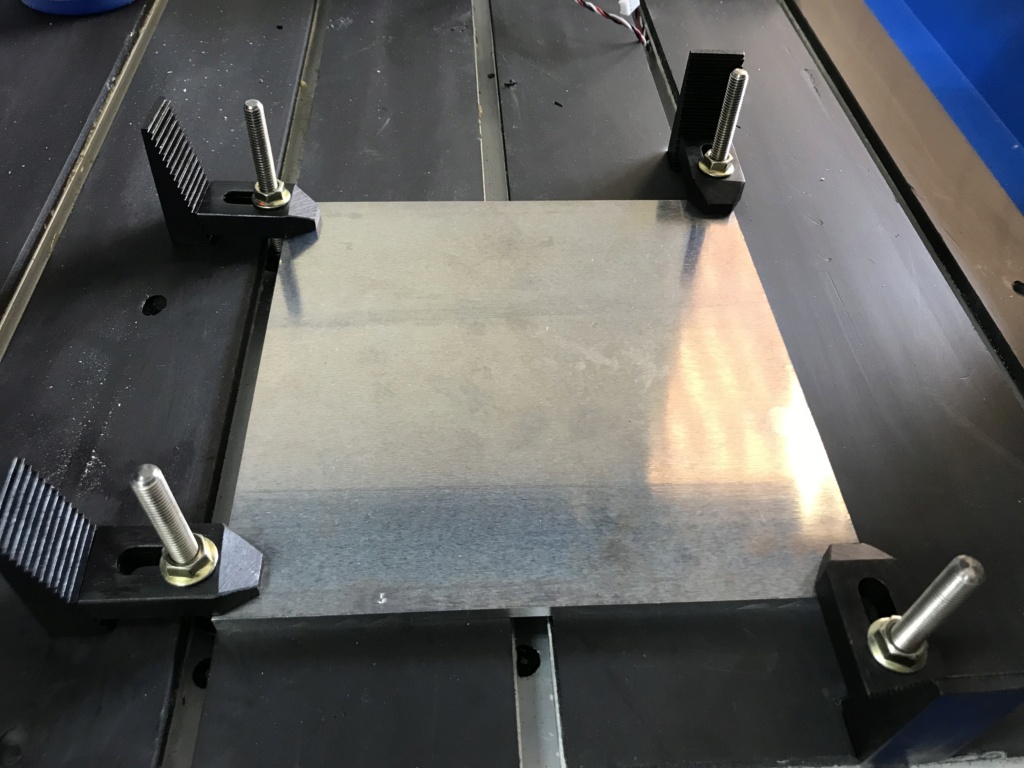

After :

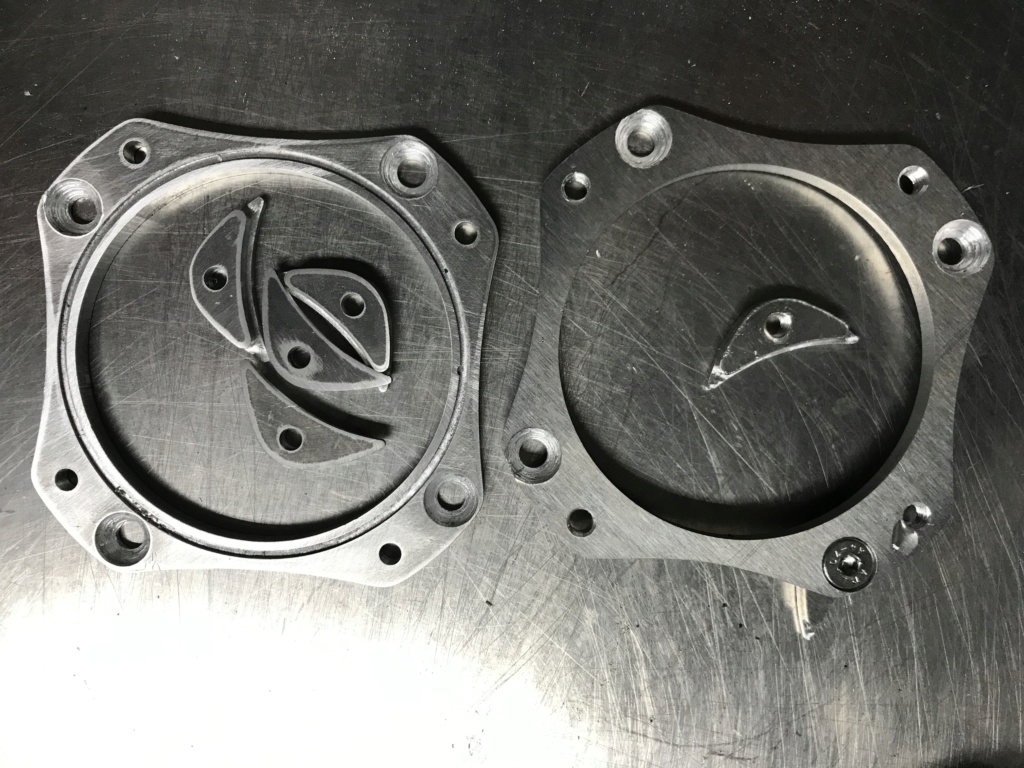

I machined the future base of the 944 Short Shifter

Made a plug for the oil level sensor :

Made some brake lines for the new calipers on the 928 !

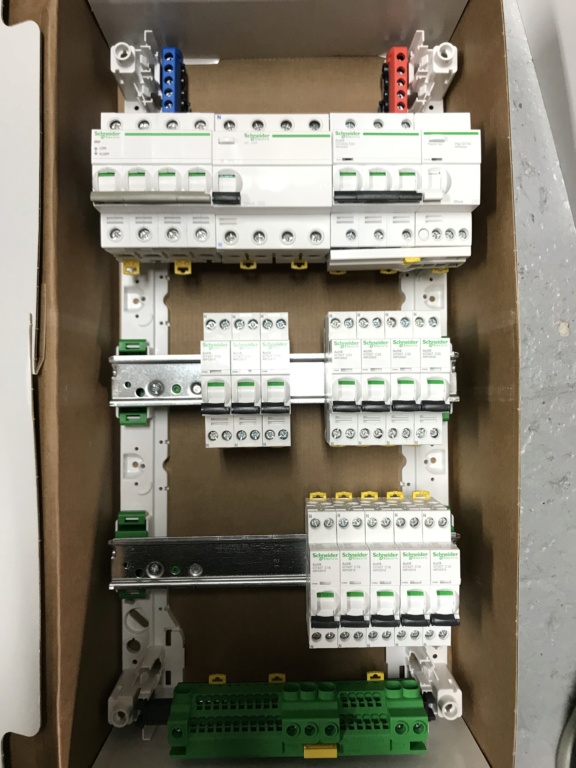

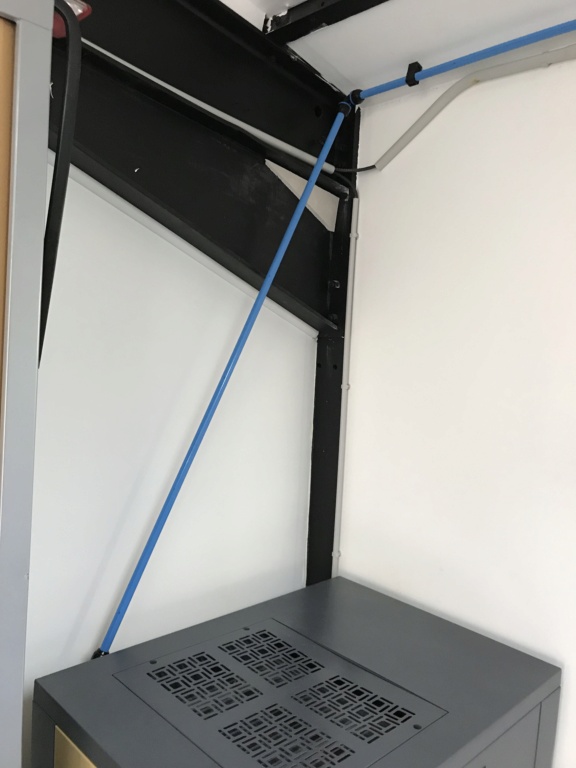

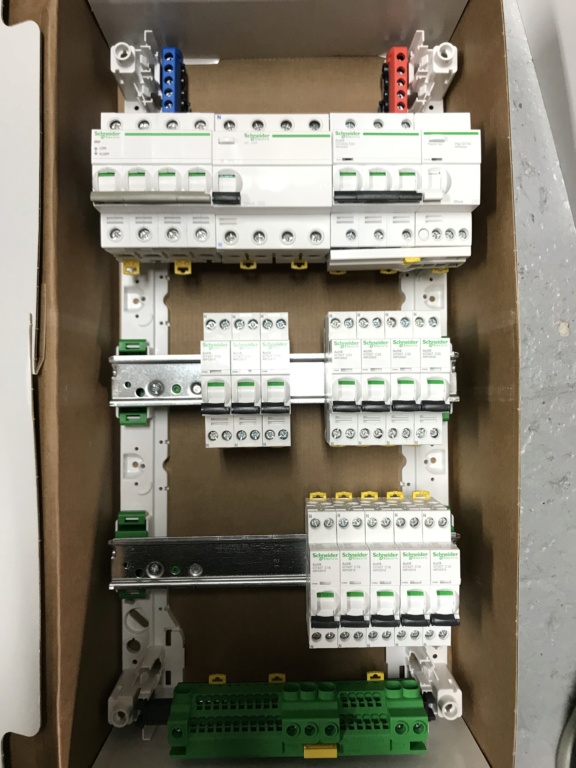

I had to redo the electrical system in the shop, I've been quoted 3000€... I don't have them so I did it myselft !

Set up the compressor too !

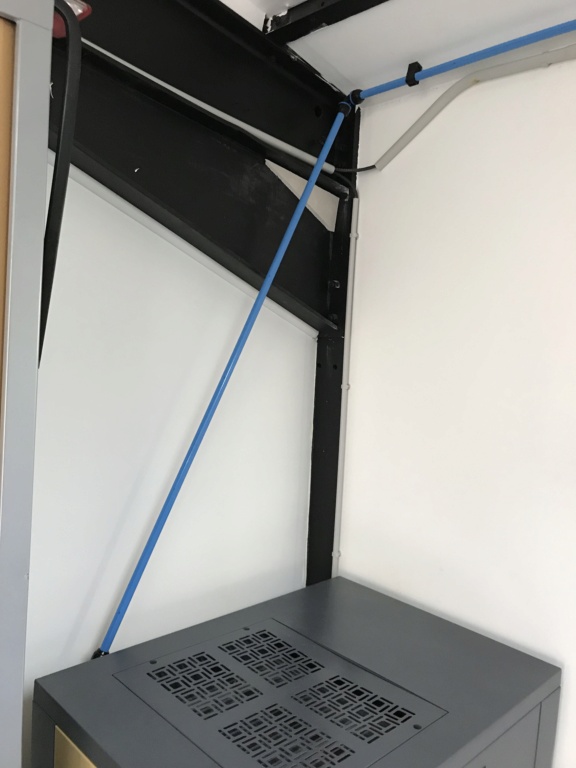

And the CNC watercooling :

I machined some prototypes :

Locked :

Also machined a throttle pedal extension.

It's in testing, there will be versions for most porsche

Sold my car that I bought a few months ago and bought a van !

Almost done with the 928 exhaust... Last thing missing is the muffler supports.

And the Bumper is not opened like an S4

Et pour finir, encore une installation du nouveau levier de vitesse ! Sur un 987.1

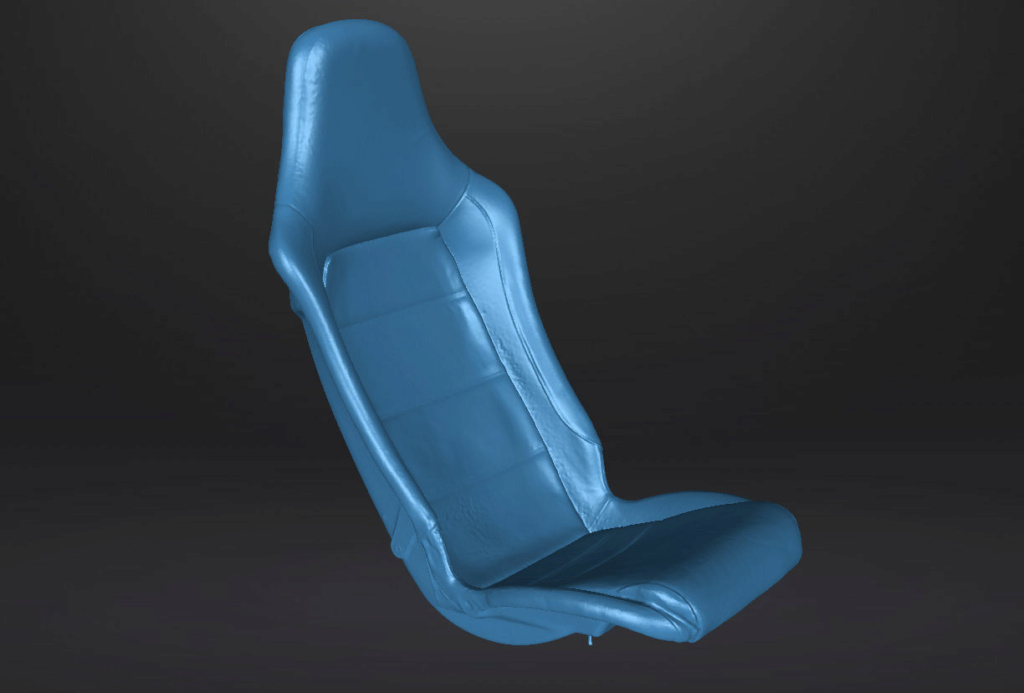

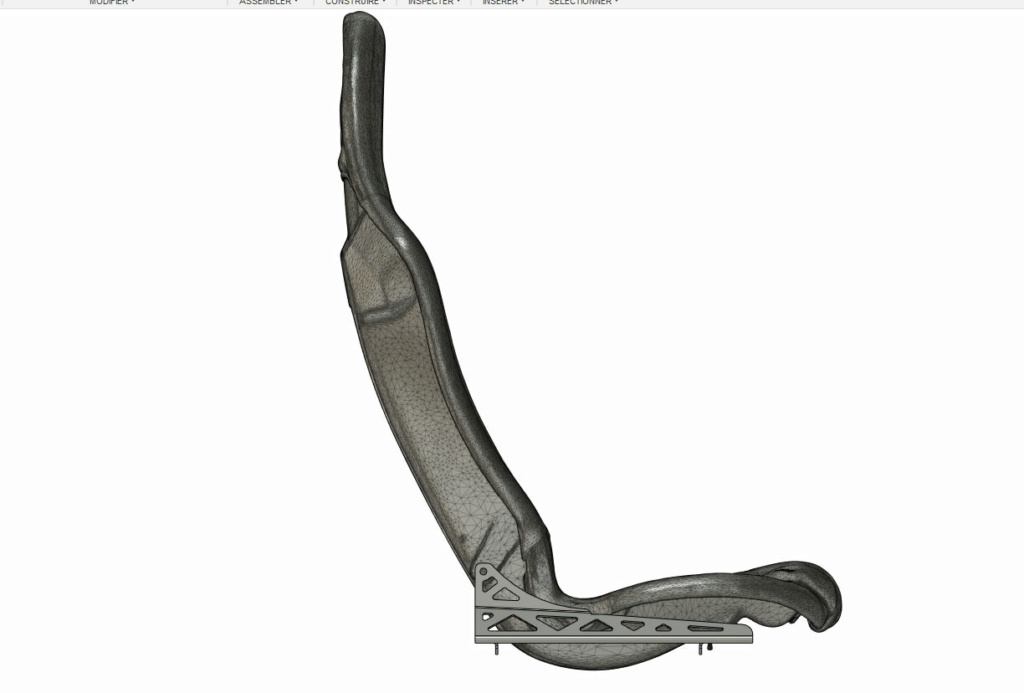

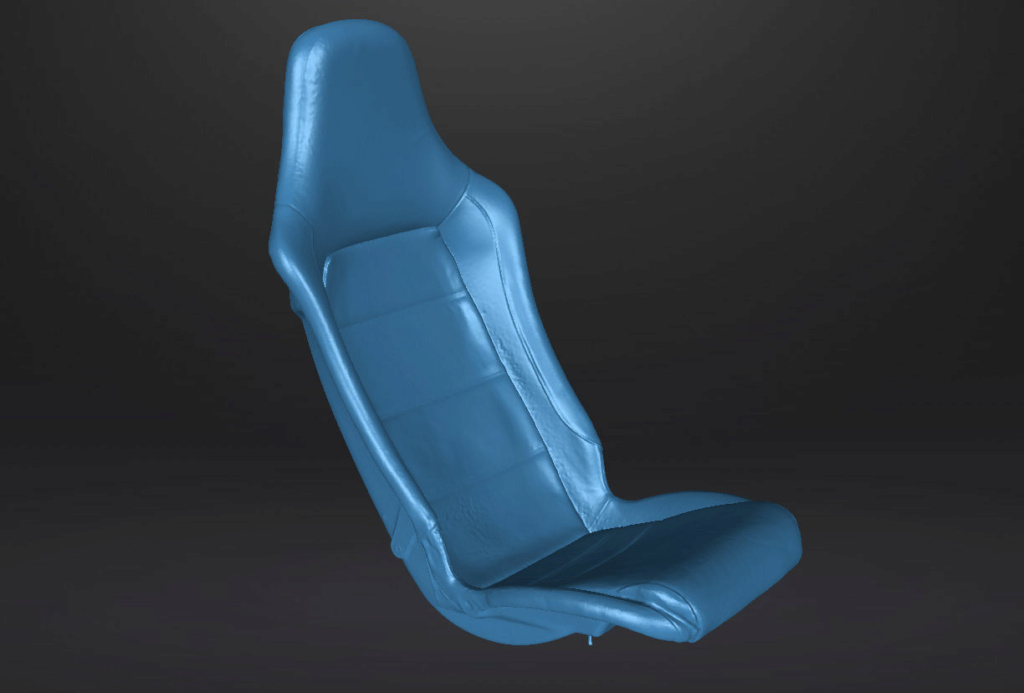

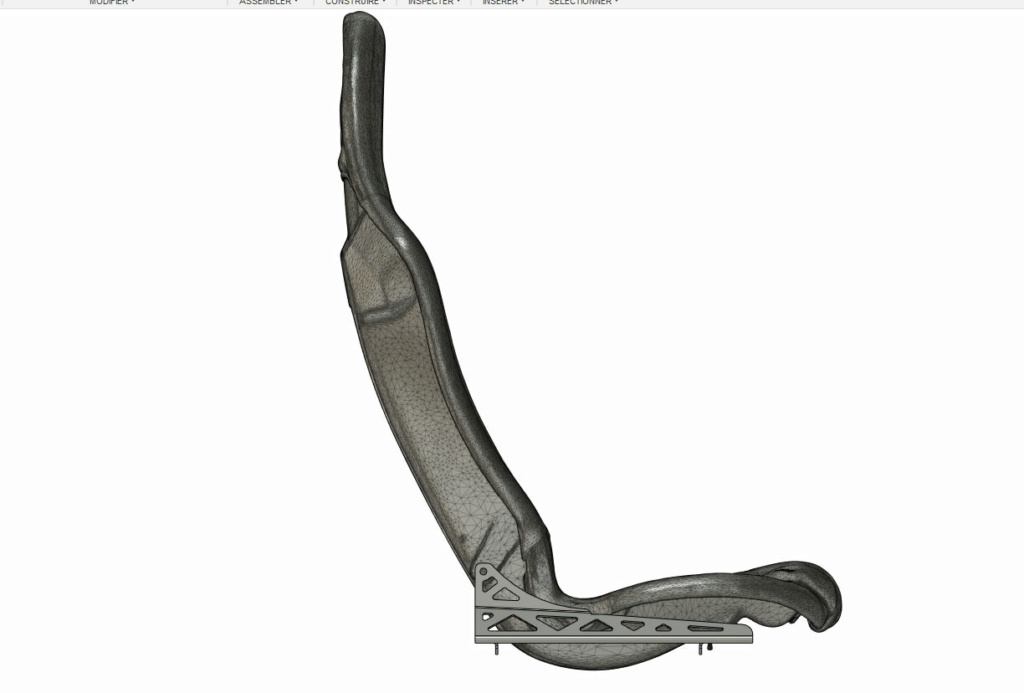

I scanned the Lotus seat to redesign the supports again...

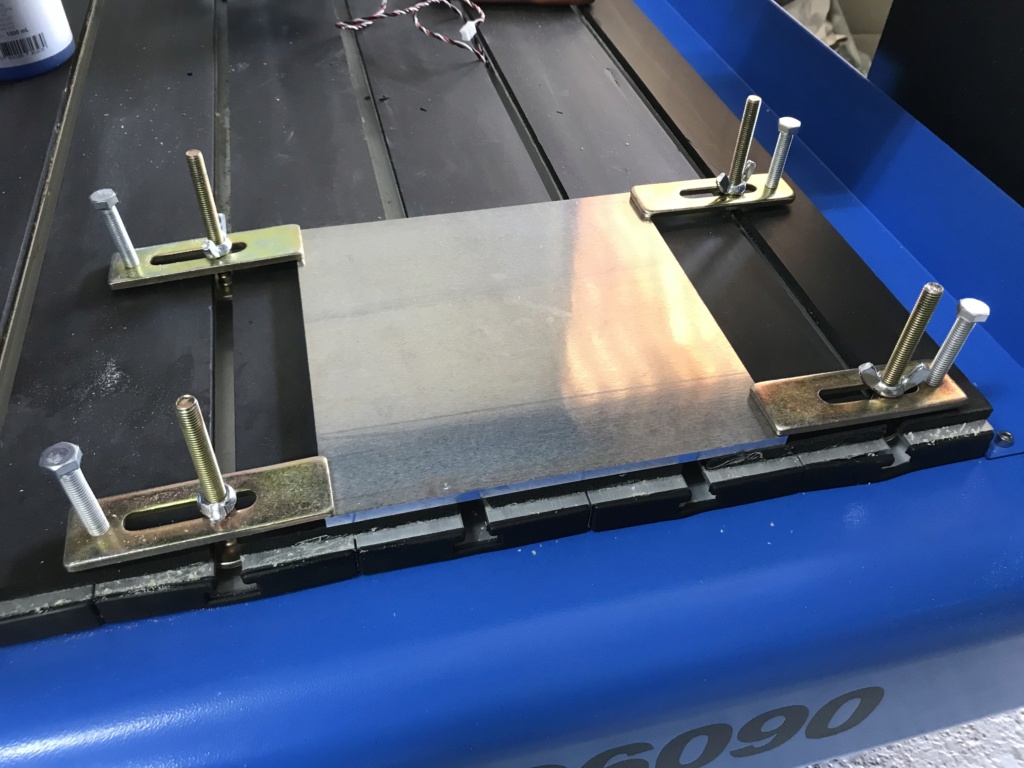

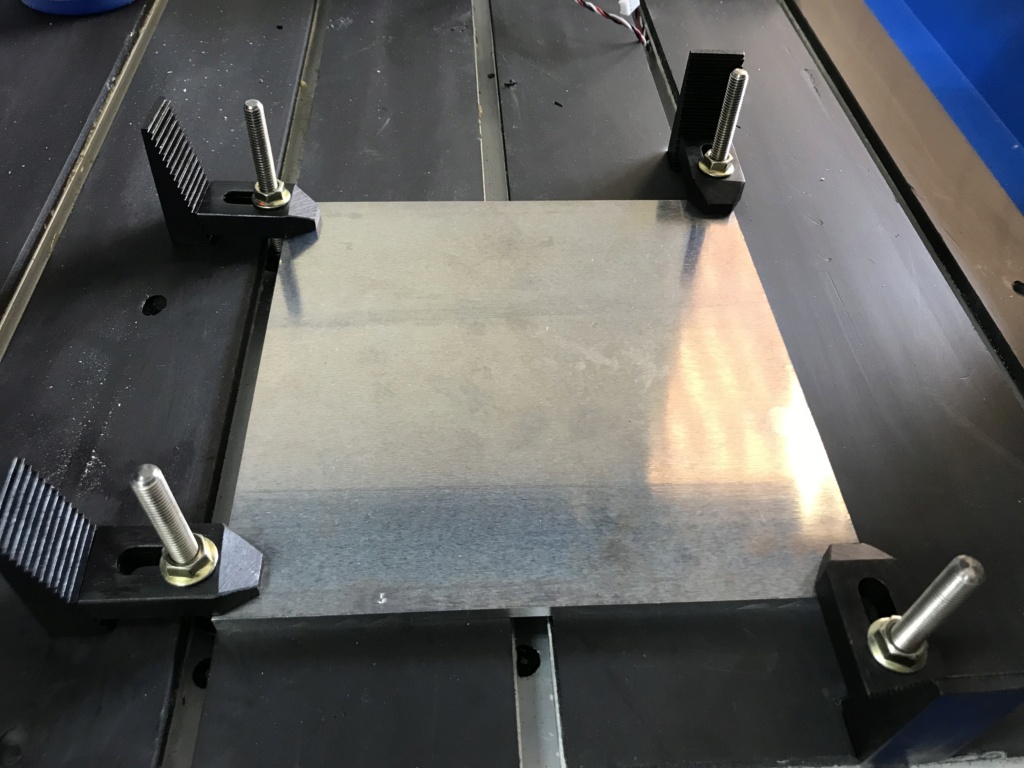

I tried cutting steel with the CNC ! With 0.2mm passes it's fine

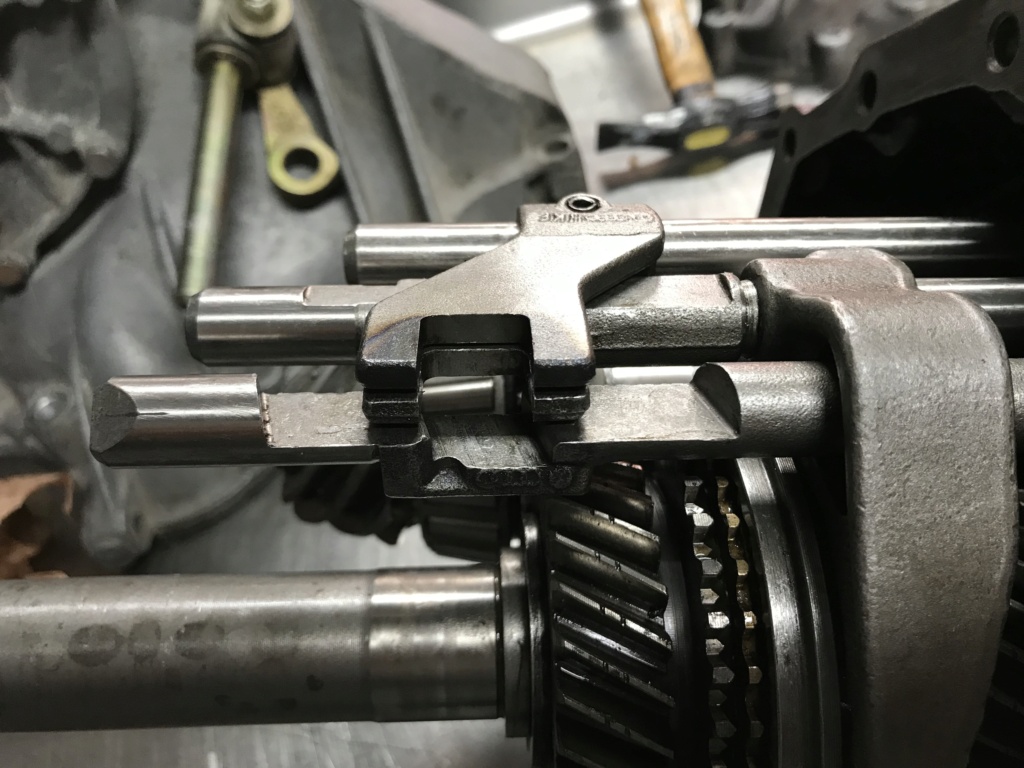

Shortened the levers by 7.5mm

Got the correct pads for the rear of the 928 :

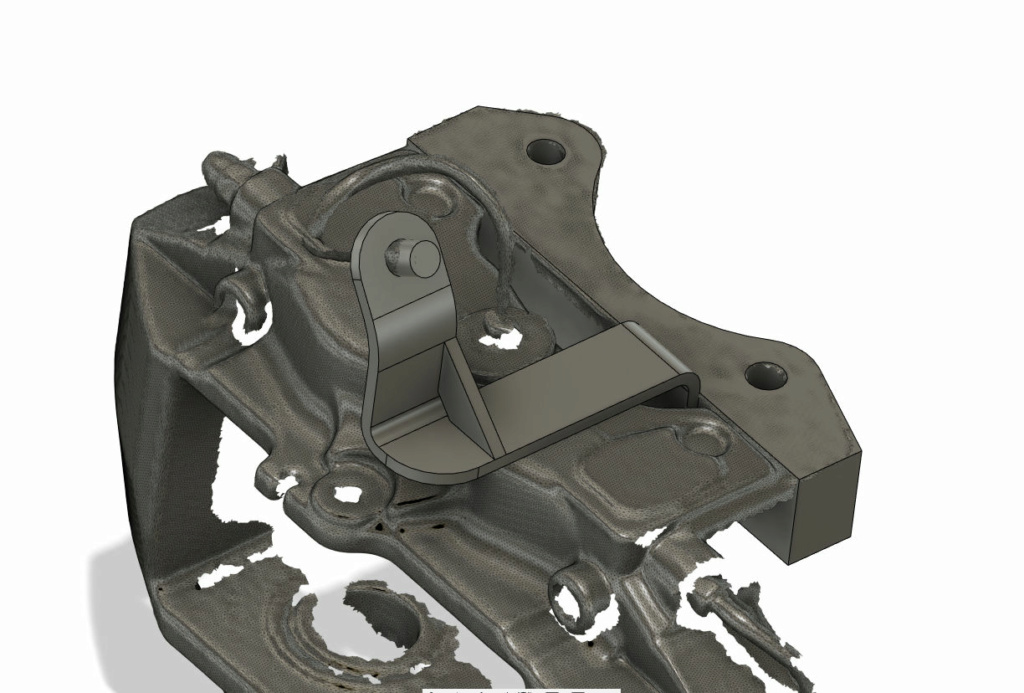

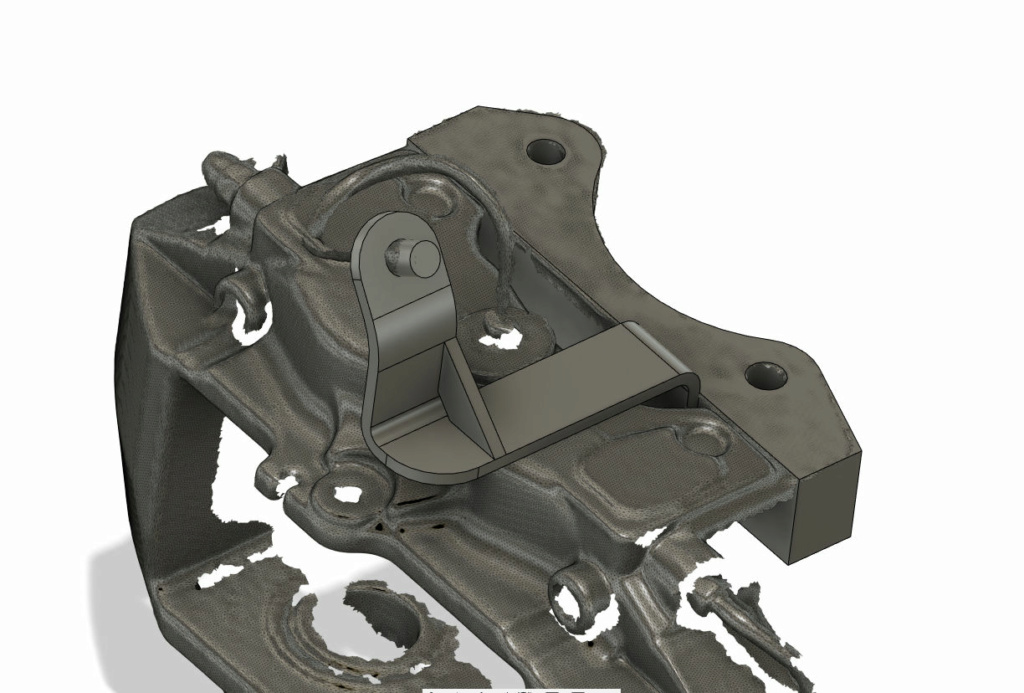

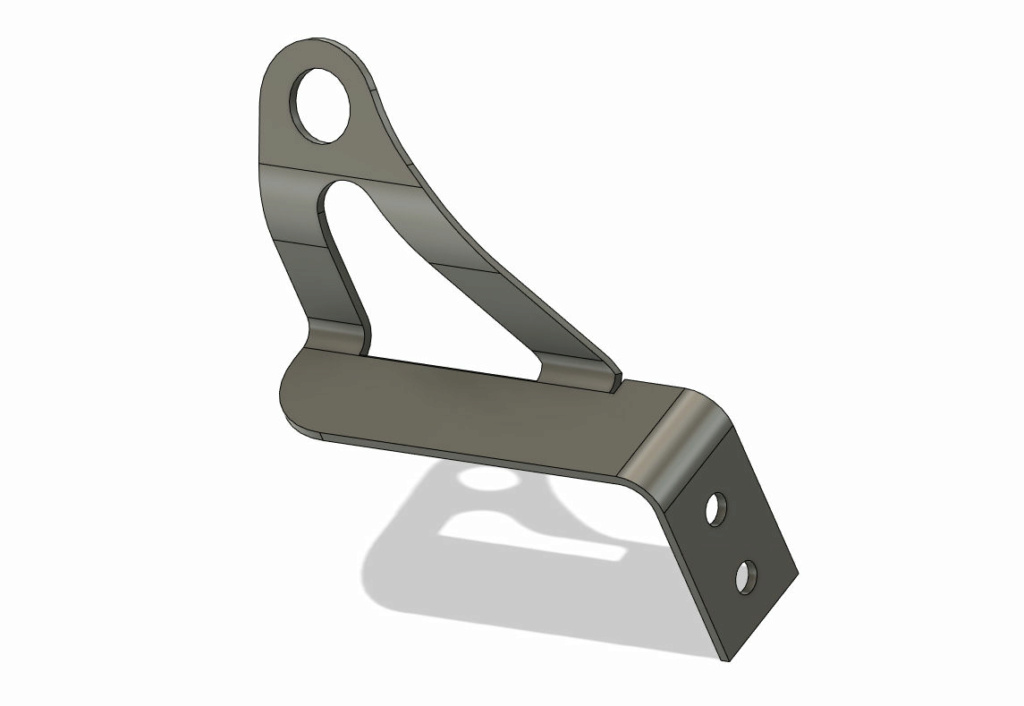

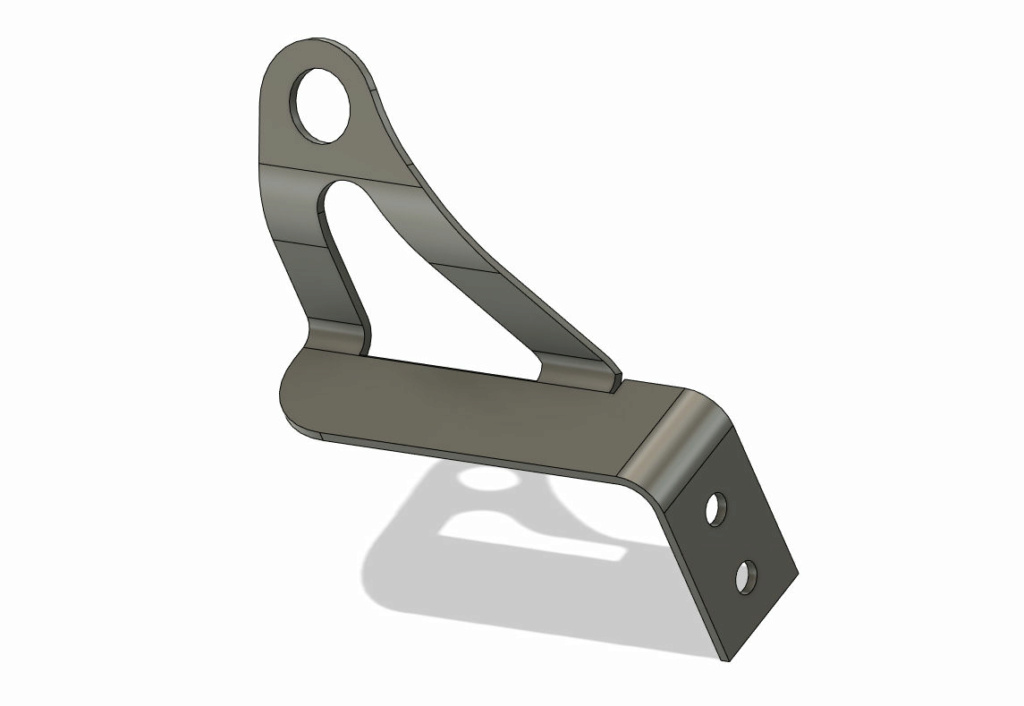

Now that I know I can machine steel I scanned the calipers with the new lines to design a support for them :

Ben

And voilà !

Loctite anaerobic sealant :

Done

I fired up the CNC machine !

Before :

After :

I machined the future base of the 944 Short Shifter

Made a plug for the oil level sensor :

Made some brake lines for the new calipers on the 928 !

I had to redo the electrical system in the shop, I've been quoted 3000€... I don't have them so I did it myselft !

Set up the compressor too !

And the CNC watercooling :

I machined some prototypes :

Locked :

Also machined a throttle pedal extension.

It's in testing, there will be versions for most porsche

Sold my car that I bought a few months ago and bought a van !

Almost done with the 928 exhaust... Last thing missing is the muffler supports.

And the Bumper is not opened like an S4

Et pour finir, encore une installation du nouveau levier de vitesse ! Sur un 987.1

I scanned the Lotus seat to redesign the supports again...

I tried cutting steel with the CNC ! With 0.2mm passes it's fine

Shortened the levers by 7.5mm

Got the correct pads for the rear of the 928 :

Now that I know I can machine steel I scanned the calipers with the new lines to design a support for them :

Ben

#197

UPDATES !

I was hired to work on an early 928 ! A 78 with the weird battery box !

it's old ^^

I designed new brake line holders :

I'm almost done with the Vapor blasting machine !

Works wonder on steel too, but i'm waiting on a more potent media !

This one was already sandblasted, with a crappy result...

Et hop :

Same here :

I don't have light in the cabinet yet ^^

before :

I love it, it cleans so well without compromising the part !

A 996 CUP representing !

I receive some stuff :

Done

Feels good :

Got the brake line supports :

A mix of porsche parts but it fits !

For the front I couldn't use drity parts...

Alors hop :

There it is for now.

i have to do two last stuff to the exhaust and it's done.

Then I will finish the brakes.

Then the radiator.

Then the intake...

Then the Seat mounts...

Oh crap...

Ben

I was hired to work on an early 928 ! A 78 with the weird battery box !

it's old ^^

I designed new brake line holders :

I'm almost done with the Vapor blasting machine !

Works wonder on steel too, but i'm waiting on a more potent media !

This one was already sandblasted, with a crappy result...

Et hop :

Same here :

I don't have light in the cabinet yet ^^

before :

I love it, it cleans so well without compromising the part !

A 996 CUP representing !

I receive some stuff :

Done

Feels good :

Got the brake line supports :

A mix of porsche parts but it fits !

For the front I couldn't use drity parts...

Alors hop :

There it is for now.

i have to do two last stuff to the exhaust and it's done.

Then I will finish the brakes.

Then the radiator.

Then the intake...

Then the Seat mounts...

Oh crap...

Ben

#200

Racer

Join Date: Mar 2009

Location: Flower Mound, TX

Posts: 494

Likes: 0

Received 0 Likes

on

0 Posts

I think that if you can get a whole kit together to convert a CIS car to EFI with the cpu, your cool intake, fuel rails, cps bracket, etc that there might be a market for it. It might be a little limited due to emissions requirements in many locations, but still there are folks who are unhappy with CIS and don't want to tackle the conversion process from scratch. You might not have to provide the actual electronics, so much as point to a vendor and supply the customized maps.

Was the Crank trigger wheel necessary for that MaxxECU? The one on the Triumph works by looking at the signal from the electric pickup on the distributor. So step 1 in their conversion from carbs and points was to convert the ignition to electronic, and then it uses that signal to determine timing. Does that not work in this case, or did it not provide enough control for what you wanted to do?

Last edited by Richter12x2; 10-26-2021 at 04:15 PM.

#201

Racer

Join Date: Mar 2009

Location: Flower Mound, TX

Posts: 494

Likes: 0

Received 0 Likes

on

0 Posts

I was reading through your thread today, and may have missed it skimming, but one thing you can check if you're still having trouble with the engine needing more tuning. When I installed the MaxxECU in the Triumph, mine came shipped with the ignition locked at 10 degrees, for initial startup testing. Once you're done startup testing and ready to actually drive it, you untick the box and then it advances and retards and learns, etc. In my case, I could start it and move it around the shop pretty easily, but you wouldn't have been able to drive it.

One other thought, and you're probably already aware of this, too... I did a lot of 3D printed brackets for my 1955 GMC Truck EV Conversion, some PLA and some PETG, and even with the PLA I knew it has a fairly low melting point (or softening point is probably more accurate) but figured I would be well within specs, even then it's not been holding up too well. I printed a 2mm thick cover for my front doorbell on my house, and it's already melted, just from ambient temperatures. I made a kind of clamp for a bluetooth speaker to use for a radio for the truck, and even not driving it, it kinda lost it's tension and hangs open under the weight of the bluetooth speaker. The PETG has been holding up pretty well so far, and ABS would be even better, but I didn't see where you said what you were 3D printing from.

Awesome progress! Thanks for sharing so much of what you're doing!

Oh, I also love the color of your 928! Very nice!

One other thought, and you're probably already aware of this, too... I did a lot of 3D printed brackets for my 1955 GMC Truck EV Conversion, some PLA and some PETG, and even with the PLA I knew it has a fairly low melting point (or softening point is probably more accurate) but figured I would be well within specs, even then it's not been holding up too well. I printed a 2mm thick cover for my front doorbell on my house, and it's already melted, just from ambient temperatures. I made a kind of clamp for a bluetooth speaker to use for a radio for the truck, and even not driving it, it kinda lost it's tension and hangs open under the weight of the bluetooth speaker. The PETG has been holding up pretty well so far, and ABS would be even better, but I didn't see where you said what you were 3D printing from.

Awesome progress! Thanks for sharing so much of what you're doing!

Oh, I also love the color of your 928! Very nice!

#202

The car runs and drives but does need further tuning, especially for cold start and acceleration enrichment, but it hasn't moved for months...

I don't have much time to work on it, and every time I get stuck on the smallest thing that take months to arrive :/

Right now i'm waiting on some brake line retaining springs to put it back on the ground.

Then, i'll put the new intake on and see if it still starts.

I have to open up the bumper hole for the exhaust but I think I still made the exhaust point too high...

I don't think I will ever make a kit for efi conversion. It's way too much work and investment for a very little return. Even the brake conversion will not be for sale. Right now I will focus on making the parts I started designing for other cars.

The intake is printed in nylon PA12 GF50, so no worries about heat or fuel / oil

Ben

I don't have much time to work on it, and every time I get stuck on the smallest thing that take months to arrive :/

Right now i'm waiting on some brake line retaining springs to put it back on the ground.

Then, i'll put the new intake on and see if it still starts.

I have to open up the bumper hole for the exhaust but I think I still made the exhaust point too high...

I don't think I will ever make a kit for efi conversion. It's way too much work and investment for a very little return. Even the brake conversion will not be for sale. Right now I will focus on making the parts I started designing for other cars.

The intake is printed in nylon PA12 GF50, so no worries about heat or fuel / oil

Ben

#203

Rennlist Member

The battery box config is unique to the 78's. It is a standalone box with a separate lid.

#204

So, looong time no updates, but here we are !

As always, it's in chronological order so i'll go back and forth between stuff !

The Vapor Blasting machine is done and is wonderful !

Et voilà le résultat !

I love the finish !

Damaged parts are still damaged, no magic here, but they are damaged clean !

We keep that steering wheel for later

Works nice on steel parts too !

Made a nice keychain for my uncle's birthday

And trained to use the small endmill on aluminum.

I cut a steering wheel, it's 6mm aluminum H22, though, this version won't work, I need to make some revisions before making the first real ones. The rim will be carbon fiber

I went to a trade show to check on a CO2 cleaning machine, the ICS022 EVO !

Nice name, no use... They came two weeks later to test it for real at my shop, and it didn't work. It barely cleaned what I would have cleaned with a wet wipe... Why ? The machine is way too small ! You need the big boy ! With a compresseur three times as big as my 7.5Kw, and a huge dehydrator ! So out of budget for me...

Brakes are done on the 928 !

Calipers could use a rebuild... but not for now !

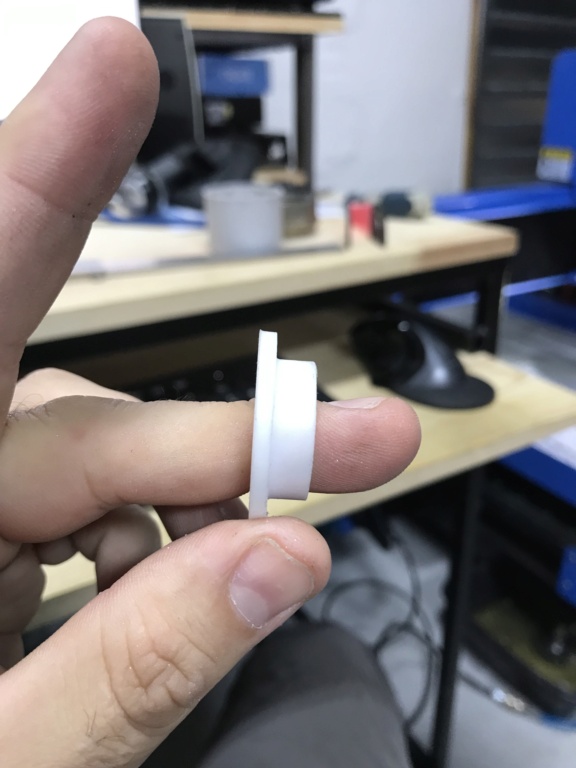

Problem : The new brake hoses were made for modern porsche, so they did not fit the 928 eyelet on the chassis, so i made little washers to hold them

Making new seat mounts : Machining didn't go well, I redid them. and I welded them backward ^^

J'y assemble (à l'envers bien sûr !) :

Then I made the front seat mount, but now I know it doesn't fit well, I have some tweaks to make

J'ai fait dépasser les tenons de 0.5mm pour essayer de les souder sans apport de matière

But how cool are they ?

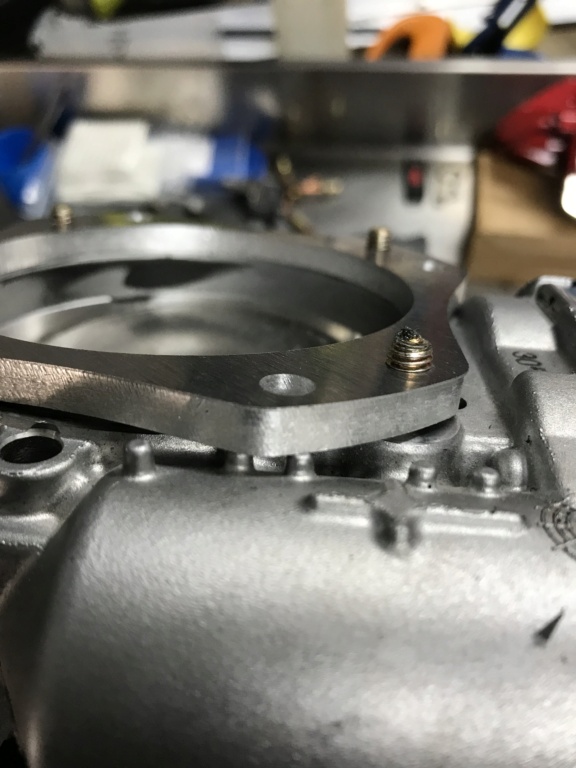

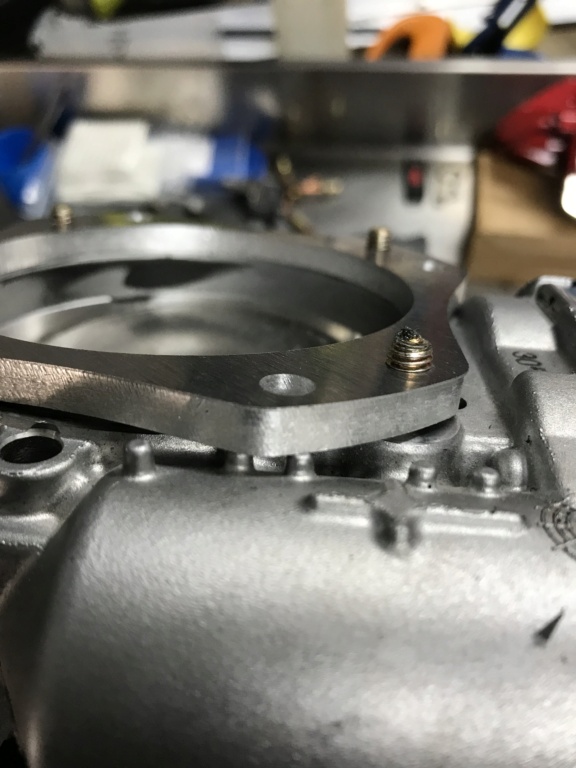

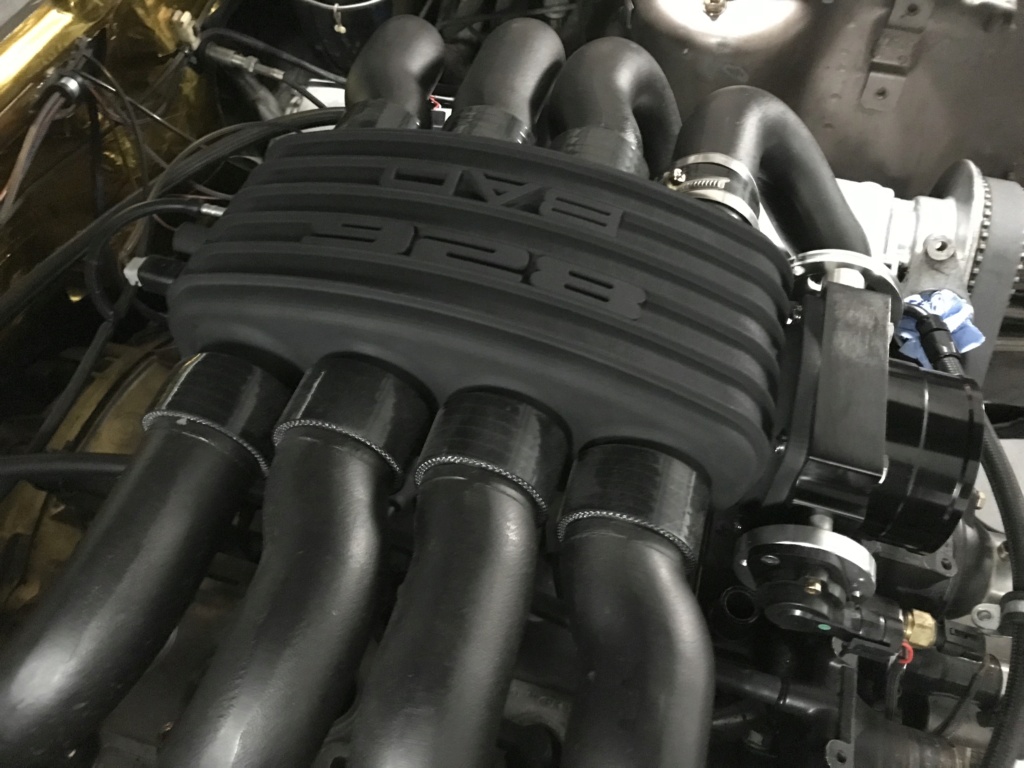

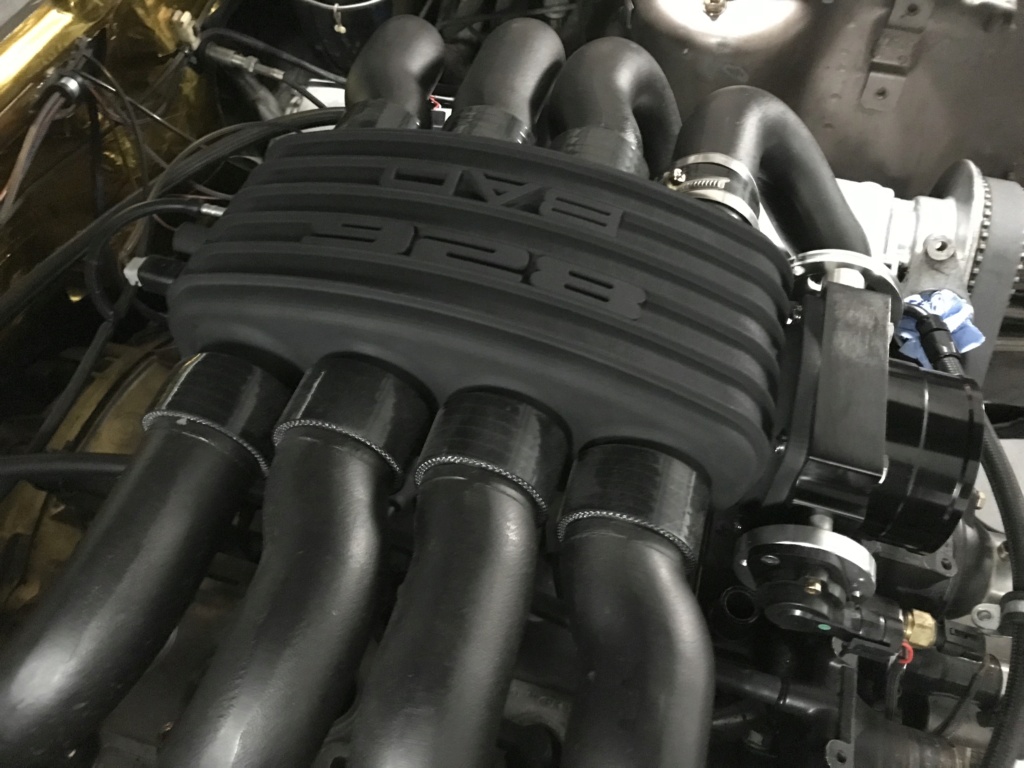

I went back to the car and replaced the intake plenum with the new one !

Out :

Old meets the new !

Et voilà !

The throttle body is higher than before to clear the water bridge better !

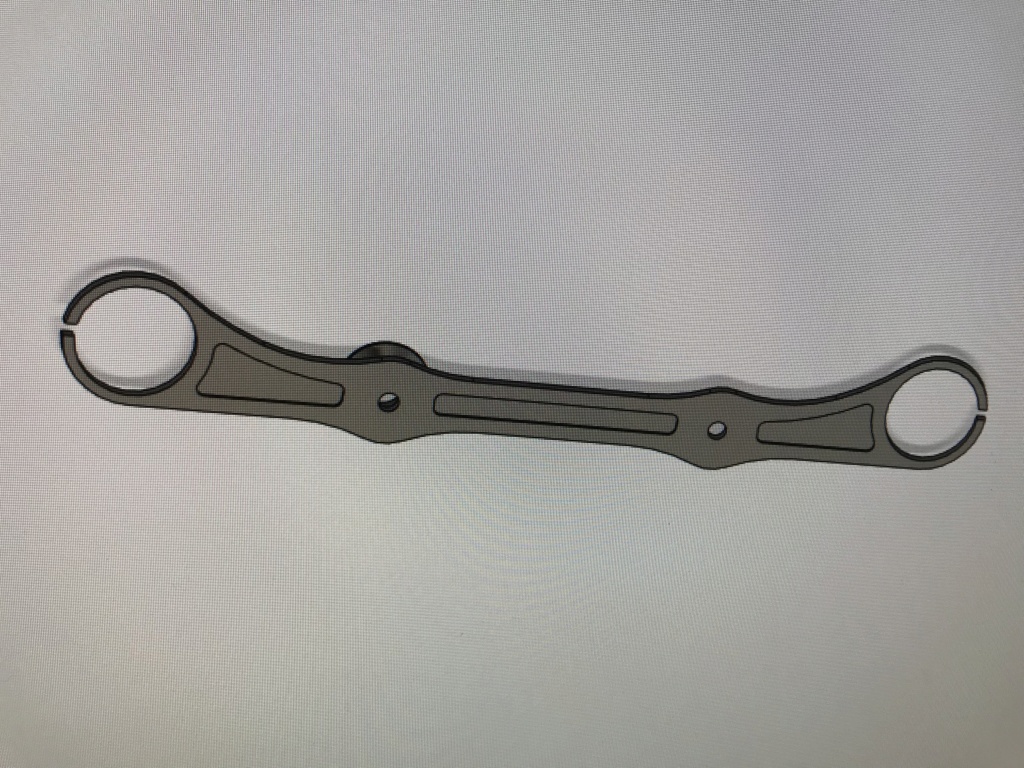

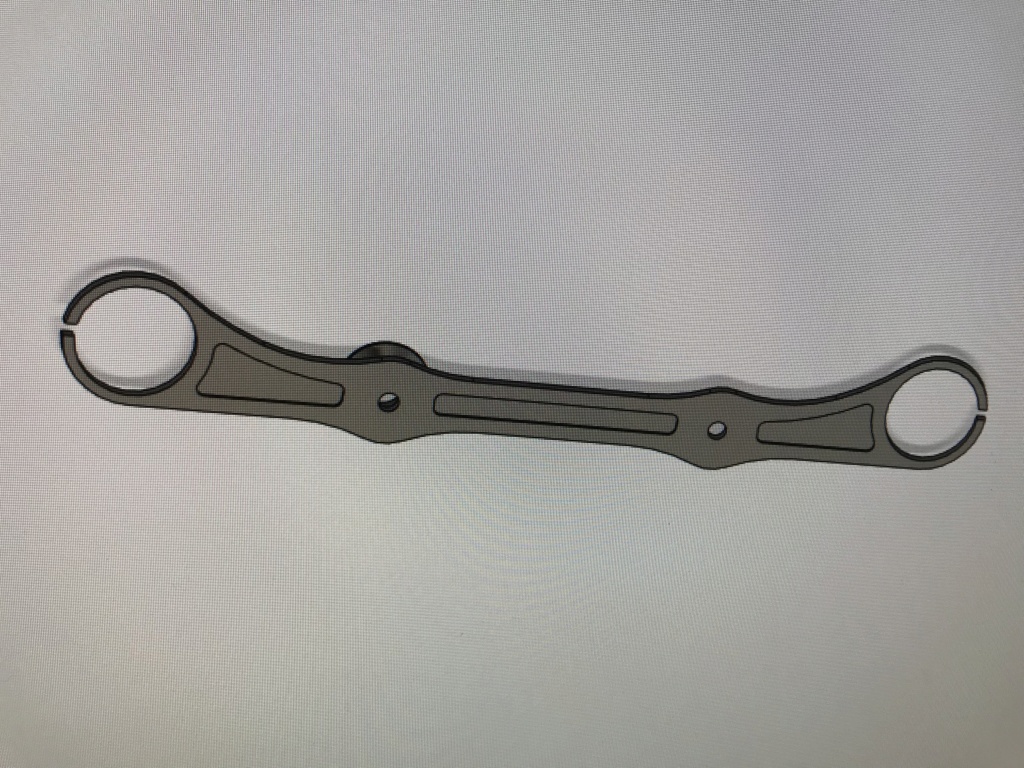

I still had a problem with the exhaust, it sagged because it had no center support. Here is my solution :

a flat piece that will clamp around the exhaust tubes, and mount to the subframe via conical bushings.

a client brought me a restauration project ^^

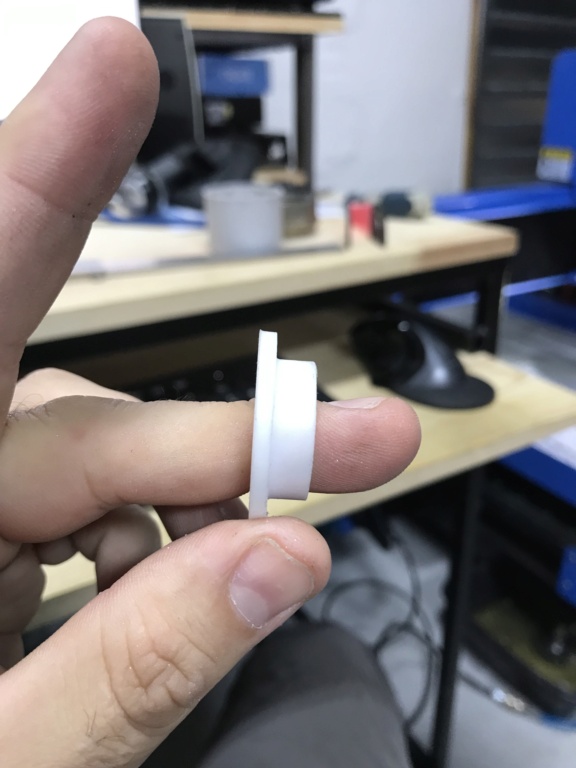

I remade a plastic part for a friend ! It was a way to test the precision of Teflon machining. it's messy but the result fit very nicely !

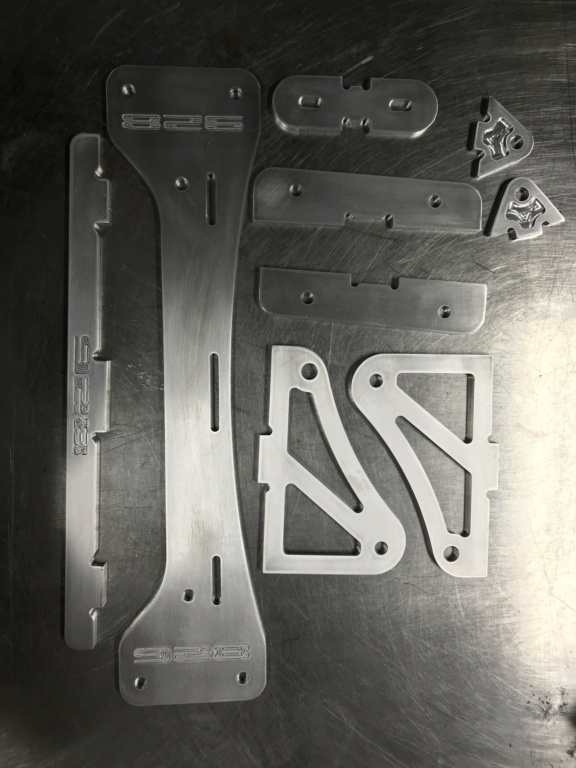

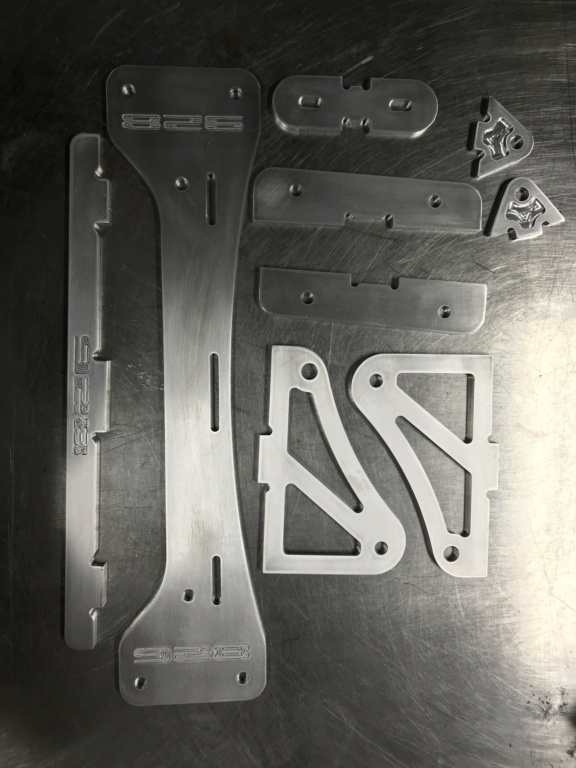

I cut some more stuff !

i still have to practice welding aluminum a bit ! I'm shaky...

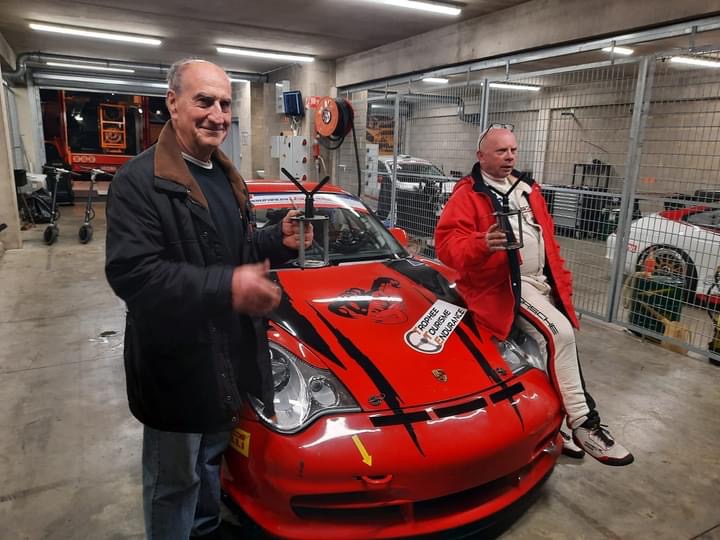

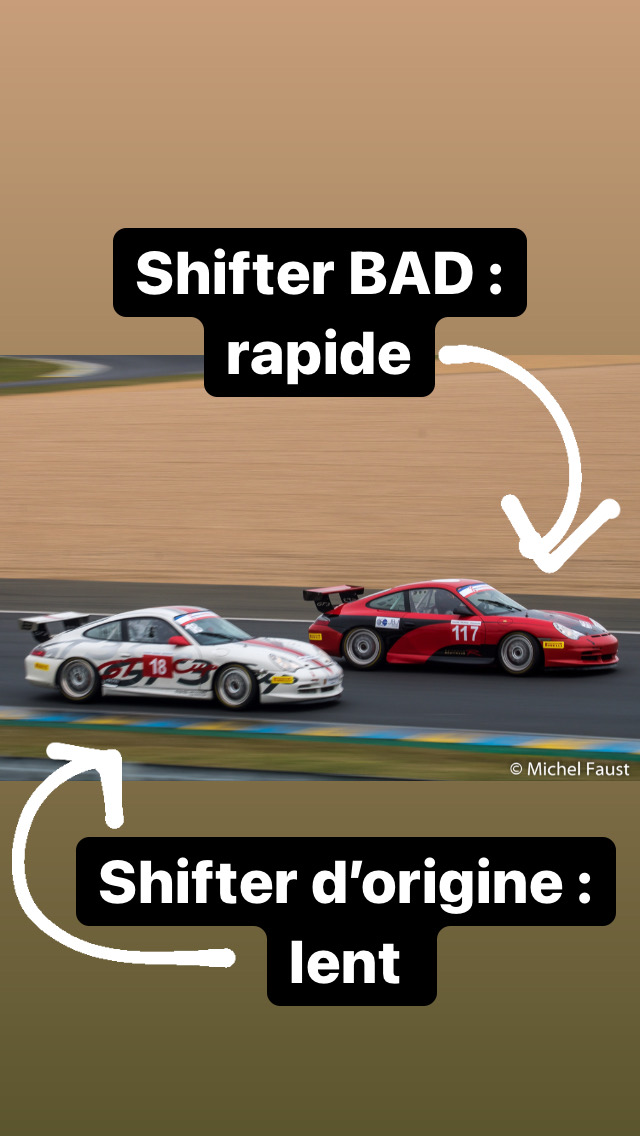

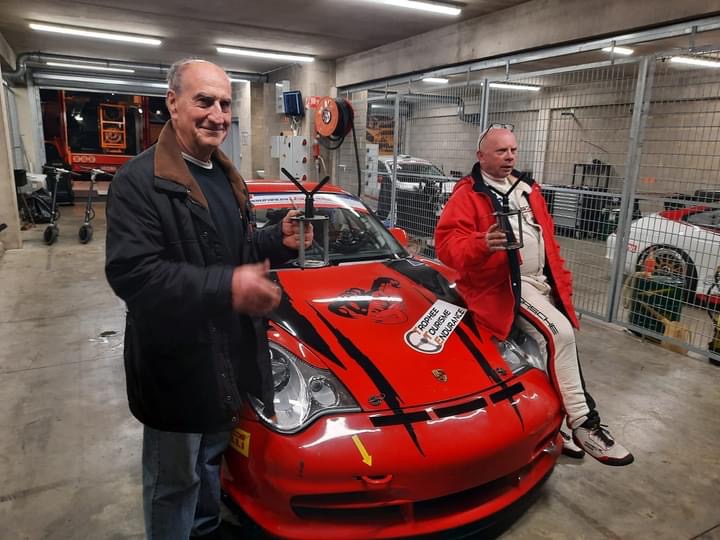

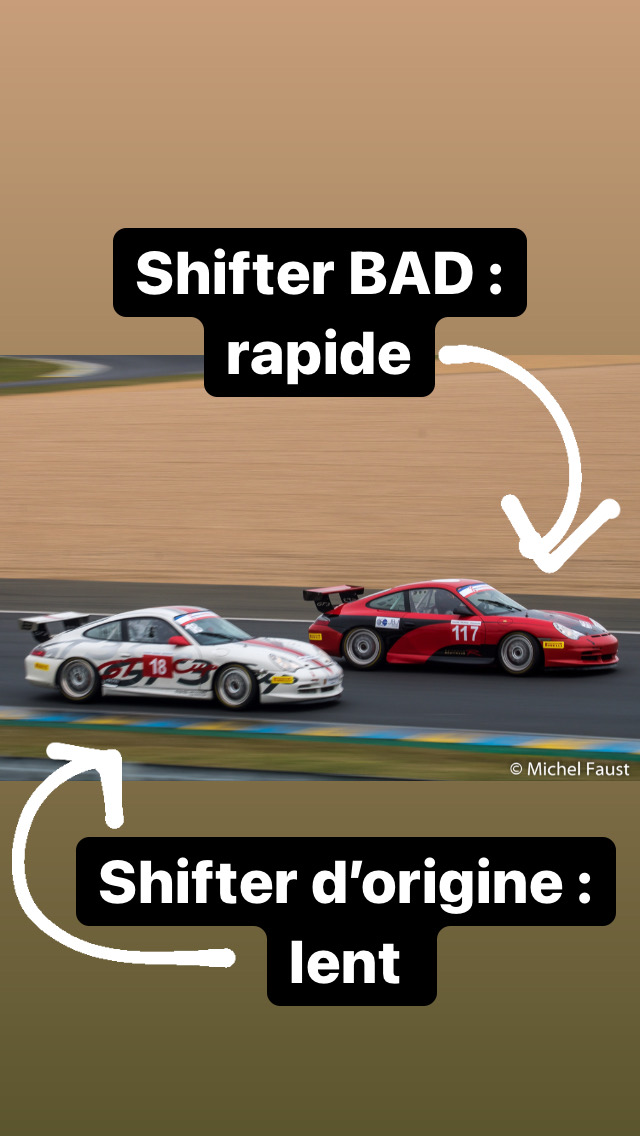

I went back to RBR to install a third Ben Auto Design short shifter on his third 996 GT3 Cup !

Then, they go in the truck and off to the race at Le Mans for a 6h race !

Back to vapor blasting stuff :

a 930 turbo 3.0 rear suspension arm !

OK, the race week-end didn't go very well... one car crashed, and the other one broke the engine !

But the third one arrived 2nd in its category !

And another did best lap during qualifying !

I had a vision : A super nice subframe brace for the 928 !

Drawn, machined, done !

I had to redo the shape a bit to make room for the anti-roll bar, but it's in !

Now I need a guinea pig !

later, I'll make parts that tie the brace to the control arms to have a more rigid system.

how do you guys like it ?

Installed the last 996 plenum prototype !

I started to do subcontracting work for other garages, Friday, it was an Audi RS2 !

Solex carbs on a 356 replica :

My 928 ? It's on its wheels !

i ordered a new radiator, silicon hoses, and some other stuff, it will run soon !

Hopefully !

Another round of vapor blasting ?

These were dead 928 pistons, they are still dead, but clean ^^ (all this cleaning of unusable parts is to torture test the machine, see what works and how on various situations).

Both arms are done !

Without vapor blasting (well, using the machine with almost no media and a lot of elbow grease), you can see that the metal surface isn't very uniform and good looking !

And to finish it off :

You know what that is !

done :

love it !

Another one from a 928 !

That's it !

I just got another 928 in the shop, minor things to fix but plenty !

Then another one will come, a very nice S2 86.5 !!

And maybe the 78 will come for the oil leaks...

Ben

As always, it's in chronological order so i'll go back and forth between stuff !

The Vapor Blasting machine is done and is wonderful !

Et voilà le résultat !

I love the finish !

Damaged parts are still damaged, no magic here, but they are damaged clean !

We keep that steering wheel for later

Works nice on steel parts too !

Made a nice keychain for my uncle's birthday

And trained to use the small endmill on aluminum.

I cut a steering wheel, it's 6mm aluminum H22, though, this version won't work, I need to make some revisions before making the first real ones. The rim will be carbon fiber

I went to a trade show to check on a CO2 cleaning machine, the ICS022 EVO !

Nice name, no use... They came two weeks later to test it for real at my shop, and it didn't work. It barely cleaned what I would have cleaned with a wet wipe... Why ? The machine is way too small ! You need the big boy ! With a compresseur three times as big as my 7.5Kw, and a huge dehydrator ! So out of budget for me...

Brakes are done on the 928 !

Calipers could use a rebuild... but not for now !

Problem : The new brake hoses were made for modern porsche, so they did not fit the 928 eyelet on the chassis, so i made little washers to hold them

Making new seat mounts : Machining didn't go well, I redid them. and I welded them backward ^^

J'y assemble (à l'envers bien sûr !) :

Then I made the front seat mount, but now I know it doesn't fit well, I have some tweaks to make

J'ai fait dépasser les tenons de 0.5mm pour essayer de les souder sans apport de matière

But how cool are they ?

I went back to the car and replaced the intake plenum with the new one !

Out :

Old meets the new !

Et voilà !

The throttle body is higher than before to clear the water bridge better !

I still had a problem with the exhaust, it sagged because it had no center support. Here is my solution :

a flat piece that will clamp around the exhaust tubes, and mount to the subframe via conical bushings.

a client brought me a restauration project ^^

I remade a plastic part for a friend ! It was a way to test the precision of Teflon machining. it's messy but the result fit very nicely !

I cut some more stuff !

i still have to practice welding aluminum a bit ! I'm shaky...

I went back to RBR to install a third Ben Auto Design short shifter on his third 996 GT3 Cup !

Then, they go in the truck and off to the race at Le Mans for a 6h race !

Back to vapor blasting stuff :

a 930 turbo 3.0 rear suspension arm !

OK, the race week-end didn't go very well... one car crashed, and the other one broke the engine !

But the third one arrived 2nd in its category !

And another did best lap during qualifying !

I had a vision : A super nice subframe brace for the 928 !

Drawn, machined, done !

I had to redo the shape a bit to make room for the anti-roll bar, but it's in !

Now I need a guinea pig !

later, I'll make parts that tie the brace to the control arms to have a more rigid system.

how do you guys like it ?

Installed the last 996 plenum prototype !

I started to do subcontracting work for other garages, Friday, it was an Audi RS2 !

Solex carbs on a 356 replica :

My 928 ? It's on its wheels !

i ordered a new radiator, silicon hoses, and some other stuff, it will run soon !

Hopefully !

Another round of vapor blasting ?

These were dead 928 pistons, they are still dead, but clean ^^ (all this cleaning of unusable parts is to torture test the machine, see what works and how on various situations).

Both arms are done !

Without vapor blasting (well, using the machine with almost no media and a lot of elbow grease), you can see that the metal surface isn't very uniform and good looking !

And to finish it off :

You know what that is !

done :

love it !

Another one from a 928 !

That's it !

I just got another 928 in the shop, minor things to fix but plenty !

Then another one will come, a very nice S2 86.5 !!

And maybe the 78 will come for the oil leaks...

Ben

#205

Ready for some unrelated photos ? ^^

Made some parts for a pocket bike !

New top T, and bottom cylinder spacers to run a longer rod !

I'm done with the Red 928.

It had a problem with the heater valve and the switches. Amongst other things.

Took the time to clean the engine.

It's for sale !

Then I did a 1970 Camaro for rear brakes and bearings

It almost did not fit in the shop ! I had to remove the front bumper !

Done

Did some carbs on a fake 356

Then I finally put the 928 back in the shop !

Cable holders were previously 3D printed :

New seat support and exhaust supports:

I had to re-machine the front seat support too.

Since I got rid of the old air oil separator, I had to use another one ! And have another oil filler !

For now the bottom hole in the sump is plugged, but it will hold the oil temp sensor when I get it !

That's where the oil filler will be, the oil will use the same path as an S4.

You can see the oil baffle too !

For the separator, I'll use a jeep part, it's big and well designed !

Of course I had to machine a bespoke bracket...

Even if it's hidden...

Now I have to finish the aspiration tube that goes to the back of the plenum?

Though I might turn the plenum 180° so I can use the water box as an air box since I don't have anything in there now !

It would be a lot simpler than making a complete new airbox !

I made another exhaust support, it's 3 pieces.

I might do another one though ^^

It bolted directly on the subframe, but it's a racecar, we'll see !

Une fois le remplissage d'huile et le séparateur terminé, il manquera vraiment pas grand chose pour le démarrage !

Il faut aussi que je supprime le système de frein à main qui ne sert plus à rien...

I made the pedal extensions for 986 996, I should make some for 944 and 928 !

I assembled the prototype for the 944 shifter !

Next step after the holidays !

Ben

Made some parts for a pocket bike !

New top T, and bottom cylinder spacers to run a longer rod !

I'm done with the Red 928.

It had a problem with the heater valve and the switches. Amongst other things.

Took the time to clean the engine.

It's for sale !

Then I did a 1970 Camaro for rear brakes and bearings

It almost did not fit in the shop ! I had to remove the front bumper !

Done

Did some carbs on a fake 356

Then I finally put the 928 back in the shop !

Cable holders were previously 3D printed :

New seat support and exhaust supports:

I had to re-machine the front seat support too.

Since I got rid of the old air oil separator, I had to use another one ! And have another oil filler !

For now the bottom hole in the sump is plugged, but it will hold the oil temp sensor when I get it !

That's where the oil filler will be, the oil will use the same path as an S4.

You can see the oil baffle too !

For the separator, I'll use a jeep part, it's big and well designed !

Of course I had to machine a bespoke bracket...

Even if it's hidden...

Now I have to finish the aspiration tube that goes to the back of the plenum?

Though I might turn the plenum 180° so I can use the water box as an air box since I don't have anything in there now !

It would be a lot simpler than making a complete new airbox !

I made another exhaust support, it's 3 pieces.

I might do another one though ^^

It bolted directly on the subframe, but it's a racecar, we'll see !

Une fois le remplissage d'huile et le séparateur terminé, il manquera vraiment pas grand chose pour le démarrage !

Il faut aussi que je supprime le système de frein à main qui ne sert plus à rien...

I made the pedal extensions for 986 996, I should make some for 944 and 928 !

I assembled the prototype for the 944 shifter !

Next step after the holidays !

Ben

The following 3 users liked this post by Ben006:

#208

Oh man I didn't do a great job at keeping you updated again...

First, I flipped the intake 180° !

Before :

After :

Why ?

-way easier for the intake system ! I'll be using the windshield bay as an airbox ! It's a high pressure area and mine is empty !

-easier to make the air oil sperator / catch can too !

-easier access to the coils too !

That means I need a hole in the firewall !

Got the widebody 928 in the shop before I definitely closed the part where I'm working on cars...

Bien sûr, ça n'allait pas se passer facilement !

A long term fuel leak that lead to a cheesy tank support...

First, I flipped the intake 180° !

Before :

After :

Why ?

-way easier for the intake system ! I'll be using the windshield bay as an airbox ! It's a high pressure area and mine is empty !

-easier to make the air oil sperator / catch can too !

-easier access to the coils too !

That means I need a hole in the firewall !

Got the widebody 928 in the shop before I definitely closed the part where I'm working on cars...

Bien sûr, ça n'allait pas se passer facilement !

A long term fuel leak that lead to a cheesy tank support...

#209

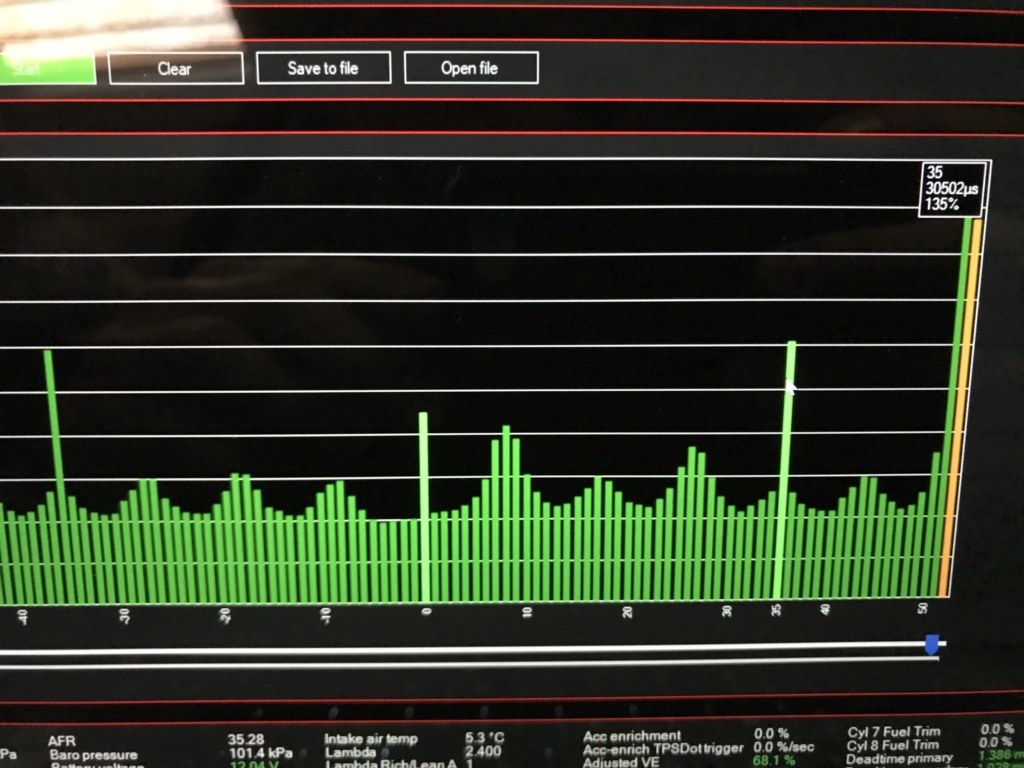

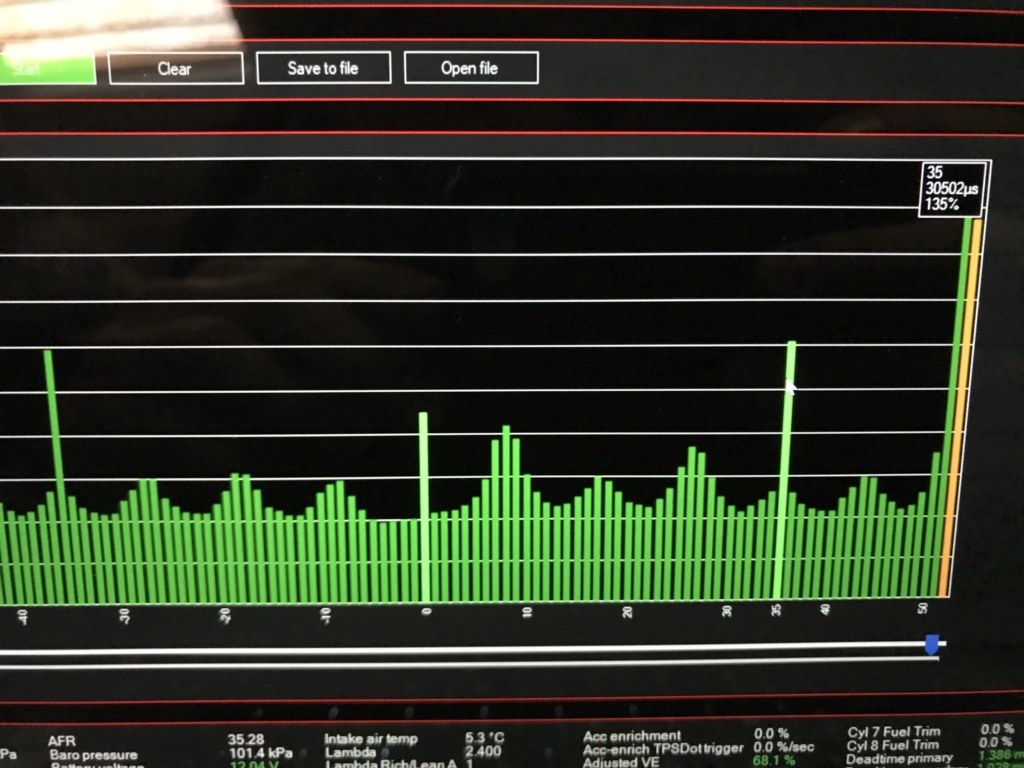

I started the 928 !!

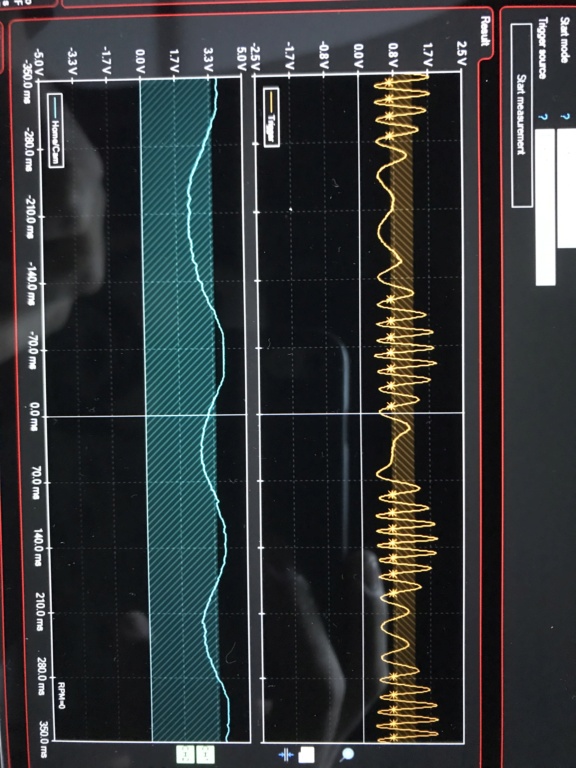

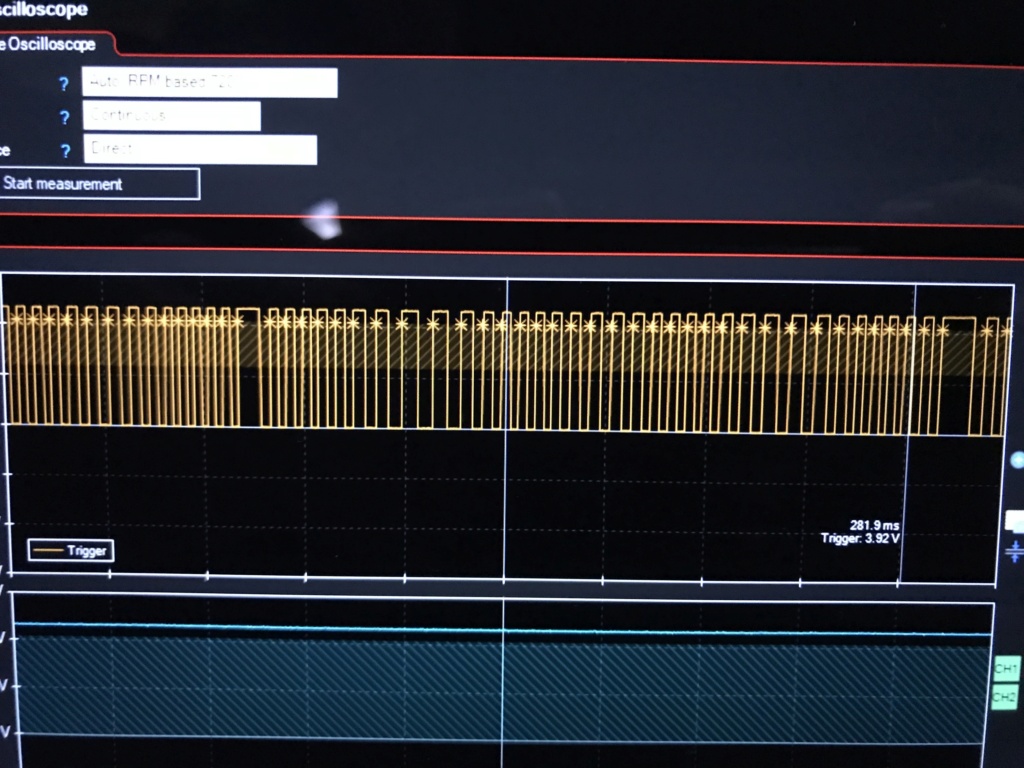

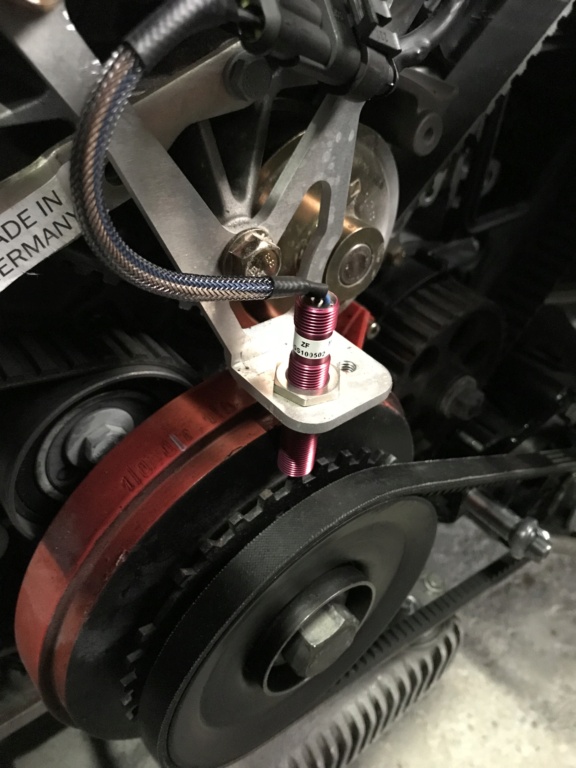

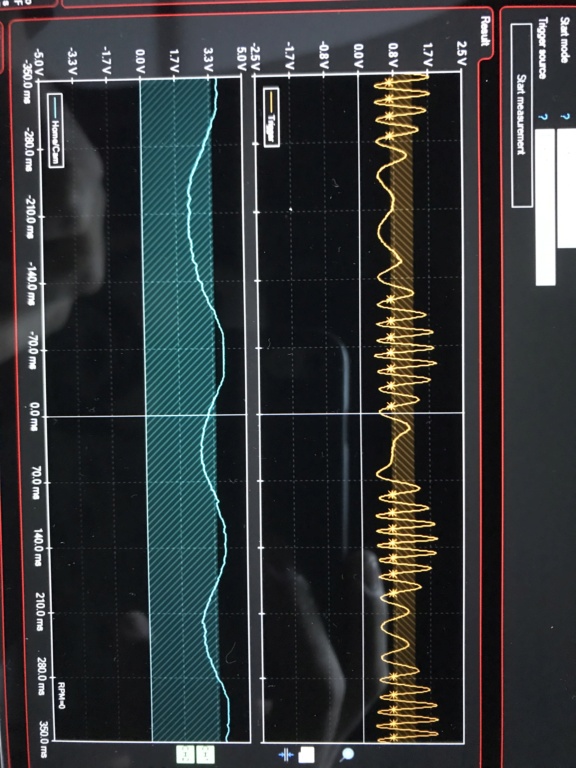

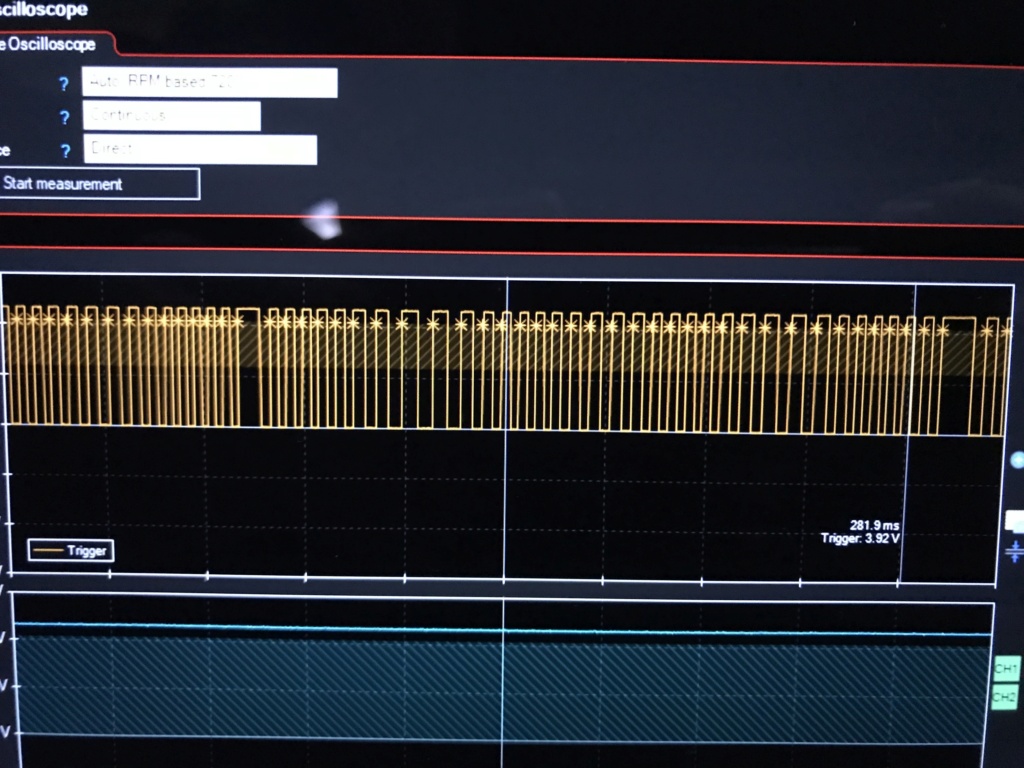

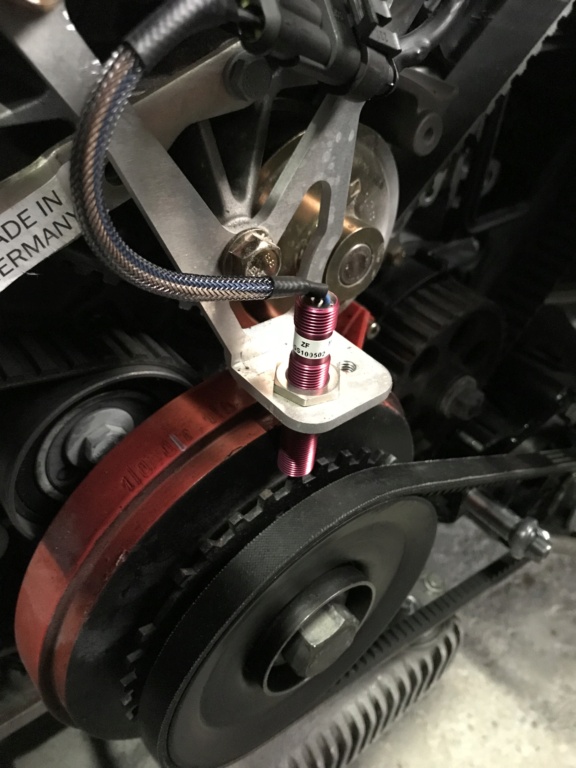

It wasn't easy... first, I changed the crankshaft position sensor technology, from inductive to hall effect !

Inductive sensor signal :

Hall effect sensor signal...

no need to be an expert to understand that one is a lot more understandable for the ECU than the other...

The ECU agrees... if it's green, it counts it as a tooth.

height of the column is the time since the last tooth. We see that we got all 36-1 teeth

The savior !

I had to run a new 12v wire.

Got my first paid vapor blasting job : 997 Turbo upper head :

Et hop :

L'oxydation était pas mal profonde mais c'est revenu !

Machined another subframe brace. It's still untested...

Did a trackday where I installed a shifter on a 997 GT3 in the paddock

Bon celle là, vous les avez vu et re-vu !

J'en ai profité pour monter un levier sur place, sur la 997 GT3 !

Ca a créer une petite animation c'était sympa !

Et surtout j'ai pu recueillir les avis de ceux qui ont roulé avec le matin et l'après-midi !

Je ne suis pas venu que pour ça, j'ai aussi peaufiner les réglages de boite du Cayman (boite séquentielle) !

Après la mise à jour du calculateur il a fallu remettre en place plusieurs paramètres qui se sont mal modifiés pendant la MAJ (comme l'affichage des vitesses au compteur par exemple).

C'est pas encore parfait mais avec un peu de boulot ça va le faire ! Le problème c'est qu'il n'a roulé que 20 minutes... Difficile d'accomplir de gros changements comme ça !

J'ai aussi donné un coup de main pour ranger les voitures à la fin de la journée, c'est toujours compliqué de les rentrer, ça passe au millimètre et les embrayages sont affreux !

I even threw a 996 Cup in the grass while filming a video for my shifter ahah

It wasn't easy... first, I changed the crankshaft position sensor technology, from inductive to hall effect !

Inductive sensor signal :

Hall effect sensor signal...

no need to be an expert to understand that one is a lot more understandable for the ECU than the other...

The ECU agrees... if it's green, it counts it as a tooth.

height of the column is the time since the last tooth. We see that we got all 36-1 teeth

The savior !

I had to run a new 12v wire.

Got my first paid vapor blasting job : 997 Turbo upper head :

Et hop :

L'oxydation était pas mal profonde mais c'est revenu !

Machined another subframe brace. It's still untested...

Did a trackday where I installed a shifter on a 997 GT3 in the paddock

Bon celle là, vous les avez vu et re-vu !

J'en ai profité pour monter un levier sur place, sur la 997 GT3 !

Ca a créer une petite animation c'était sympa !

Et surtout j'ai pu recueillir les avis de ceux qui ont roulé avec le matin et l'après-midi !

Je ne suis pas venu que pour ça, j'ai aussi peaufiner les réglages de boite du Cayman (boite séquentielle) !

Après la mise à jour du calculateur il a fallu remettre en place plusieurs paramètres qui se sont mal modifiés pendant la MAJ (comme l'affichage des vitesses au compteur par exemple).

C'est pas encore parfait mais avec un peu de boulot ça va le faire ! Le problème c'est qu'il n'a roulé que 20 minutes... Difficile d'accomplir de gros changements comme ça !

J'ai aussi donné un coup de main pour ranger les voitures à la fin de la journée, c'est toujours compliqué de les rentrer, ça passe au millimètre et les embrayages sont affreux !

I even threw a 996 Cup in the grass while filming a video for my shifter ahah

#210

Started to cut the firewall !

I slipped with the mill... i'll have to paint it...

Got the front spoiler in for the first time in 4 years...

Damn i love it !

i went to check out this gem ^^

It's a pos, with no legal registration, and he wanted a fortune for it... I would have saved it for a quarter of the price ! (engine is shot...)

I got a fiber laser demo from Keyance !

It's a 25 000€ laser marking machine... a bit too much for me ^^ but :

6seconds later...

White :

Black !

White, then black !

It's a wonderful machine, but it's way too much for me, and it does many things i will not need (for chain production puposes).

so, with the war and covid, I can't really have my parts made in another country without paying huge shipping... so I need to keep the production local, like, really local ! Like, just right there in my shop...

So I had to upgrade the cnc milling machine !

So I bought a big slab of aluminum !

tore down the machine

cleaned the mess

Et voilà !

There you go !

Now, just need to drill 900 holes...

I slipped with the mill... i'll have to paint it...

Got the front spoiler in for the first time in 4 years...

Damn i love it !

i went to check out this gem ^^

It's a pos, with no legal registration, and he wanted a fortune for it... I would have saved it for a quarter of the price ! (engine is shot...)

I got a fiber laser demo from Keyance !

It's a 25 000€ laser marking machine... a bit too much for me ^^ but :

6seconds later...

White :

Black !

White, then black !

It's a wonderful machine, but it's way too much for me, and it does many things i will not need (for chain production puposes).

so, with the war and covid, I can't really have my parts made in another country without paying huge shipping... so I need to keep the production local, like, really local ! Like, just right there in my shop...

So I had to upgrade the cnc milling machine !

So I bought a big slab of aluminum !

tore down the machine

cleaned the mess

Et voilà !

There you go !

Now, just need to drill 900 holes...