87+ manual transmission destruction, rebuilding, discussion etc....

#167

Nordschleife Master

Thread Starter

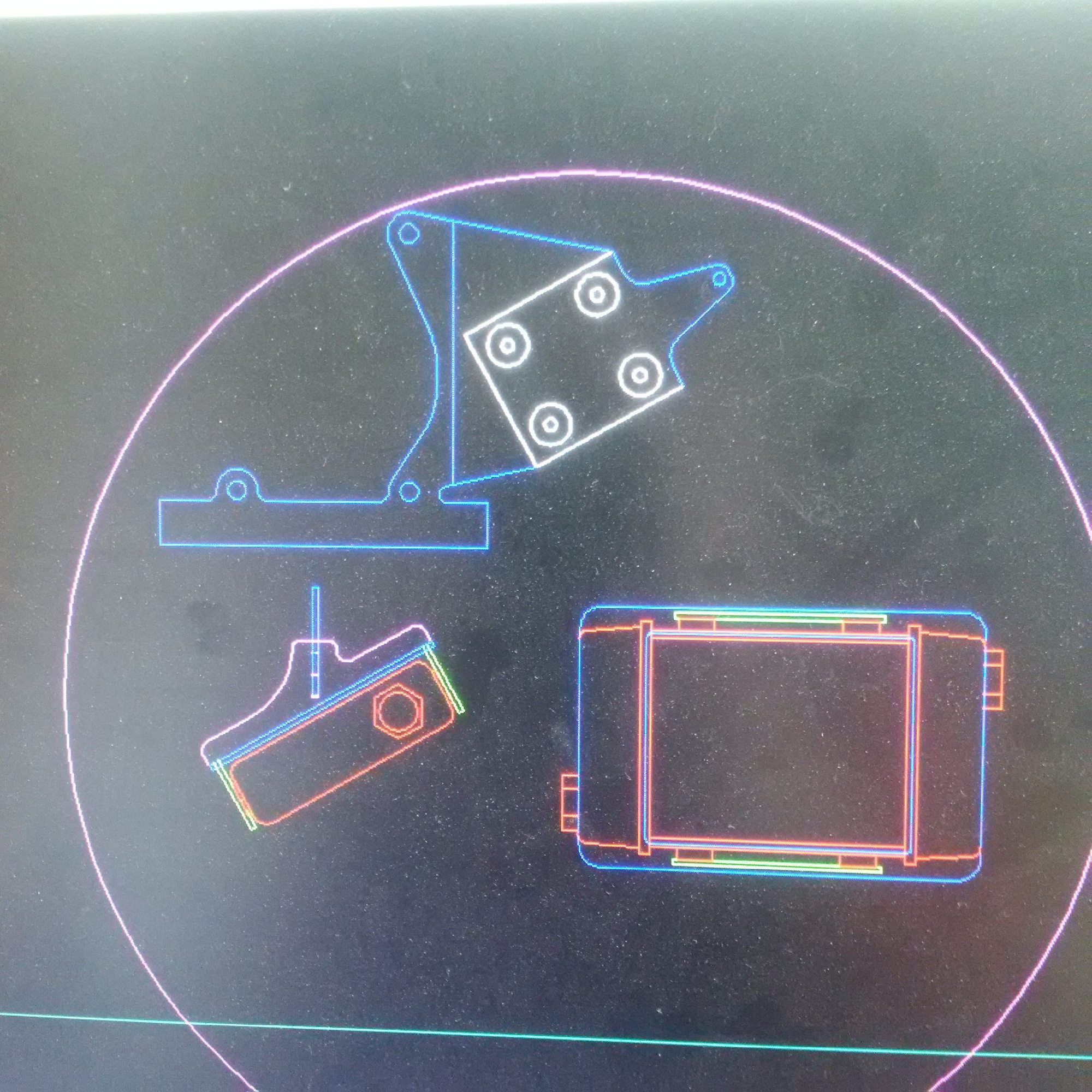

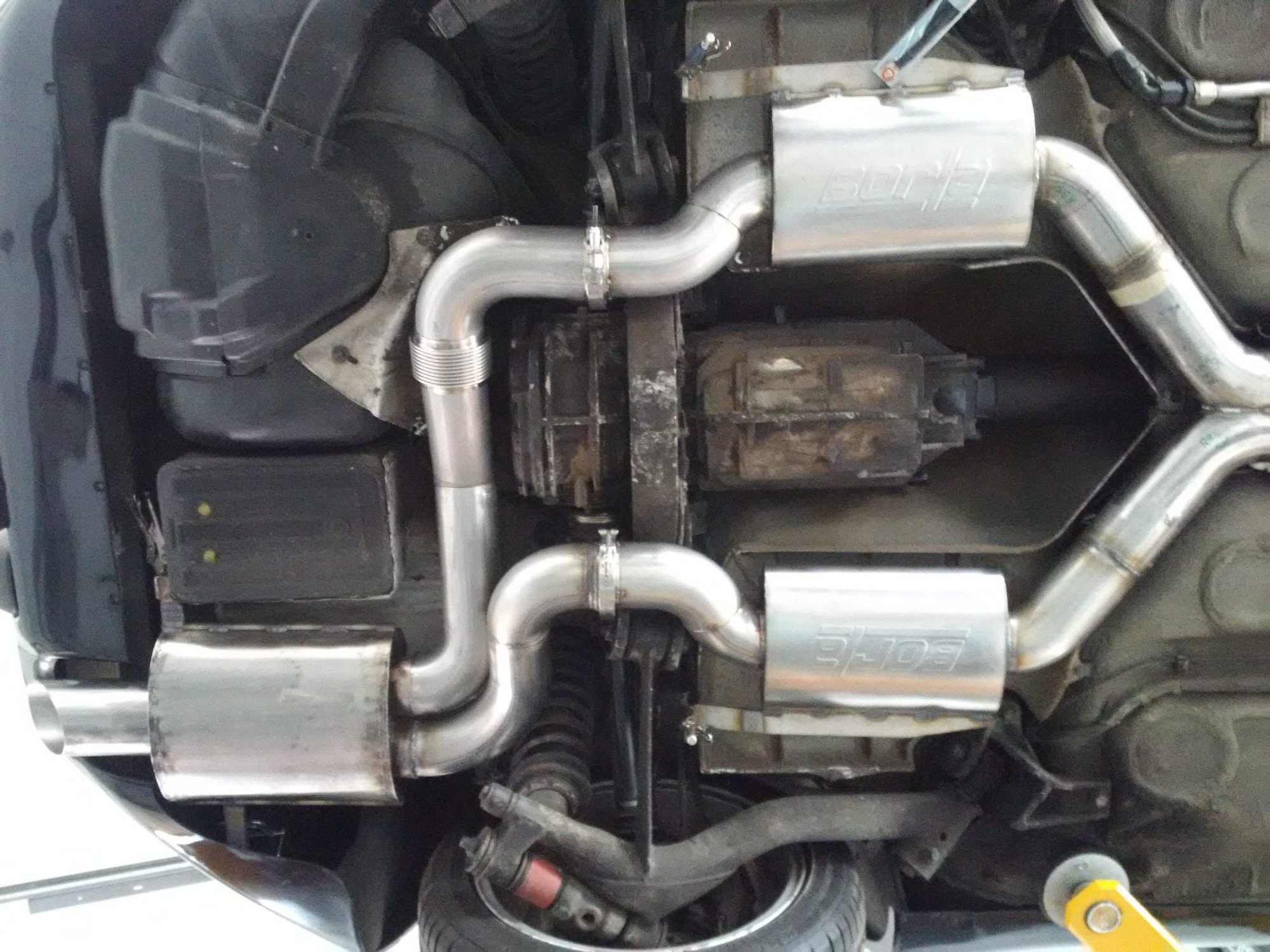

Anyone got pictures of good rear cooler setup for the five speed? Itís kind of tight there with the 3.5Ē dual pipes. Itís also a trade off between protection and cool air flow.

#170

Nordschleife Master

Thread Starter

These super bearings appear a big step up from the Porsche original bearings. Thatís Johnís judgment, and heís designed material handling solutions with thousands or tens of thousands of bearings.

#172

Rennlist Member

Nice...

#173

Nordschleife Master

Thread Starter

#174

That is a very elegant solution and seeing the confined spacing, really the only workable option.

This is an epic 928 project and can't wait to see it concluded.

Good wishes on the rest of the work to get this done.

This is an epic 928 project and can't wait to see it concluded.

Good wishes on the rest of the work to get this done.

#175

Nordschleife Master

Thread Starter

The car is a couple of weeks away from being (temporarily) dynoable and drivable, at which point itís time to conclude this thread until the transmission breaks again.

LEGAL NOTICE: THIS IS NOT A SOLICITATION TO BUY ANOTHER G28.13 LSD TRANSMISSION.

#176

This kind of project is where "overkill" is needed.

The hard part is to identify where it's needed and having someone with the mechanical/electrical/fabrication acumen to actually make it all happen. John's skill set and engineering background couldn't have been a better combination for this build.

Still amazed the stock drive shaft in the TT survived all those previous dyno tests!

Have fun.

The hard part is to identify where it's needed and having someone with the mechanical/electrical/fabrication acumen to actually make it all happen. John's skill set and engineering background couldn't have been a better combination for this build.

Still amazed the stock drive shaft in the TT survived all those previous dyno tests!

Have fun.

#177

Nordschleife Master

Thread Starter

This kind of project is where "overkill" is needed.

The hard part is to identify where it's needed and having someone with the mechanical/electrical/fabrication acumen to actually make it all happen. John's skill set and engineering background couldn't have been a better combination for this build.

Still amazed the stock drive shaft in the TT survived all those previous dyno tests!

Have fun.

The hard part is to identify where it's needed and having someone with the mechanical/electrical/fabrication acumen to actually make it all happen. John's skill set and engineering background couldn't have been a better combination for this build.

Still amazed the stock drive shaft in the TT survived all those previous dyno tests!

Have fun.

#178

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

What is amazing is how long the stock drive shaft lasted in Twin Turbo Todd's car with drag slicks and traction control on a race track with the sticky substance* sprayed on. It was rifle drilled which Todd attributed to it's extended longevity over a completely stock shaft.

What also helped it last longer is the torque Todd has dialed out of 1st gear.

His upgraded driveshaft for anyone that missed that thread:

https://rennlist.com/forums/928-foru...-the-back.html

It will be fun to see what your car can do on the strip once it's given the full beans off the line.

*If you don't know what that sticky substance is, drag strips are sprayed with a type of rubber / asphalt glue that's so sticky if your shoes are not tied on tight, they will be pulled off.

#179

Nordschleife Master

Thread Starter

There's not a whole lot of stress on the drive shaft on a dyno compared to actual real world launches.

What is amazing is how long the stock drive shaft lasted in Twin Turbo Todd's car with drag slicks and traction control on a race track with the sticky substance* sprayed on. It was rifle drilled which Todd attributed to it's extended longevity over a completely stock shaft.

What also helped it last longer is the torque Todd has dialed out of 1st gear.

His upgraded driveshaft for anyone that missed that thread:

https://rennlist.com/forums/928-foru...-the-back.html

It will be fun to see what your car can do on the strip once it's given the full beans off the line.

*If you don't know what that sticky substance is, drag strips are sprayed with a type of rubber / asphalt glue that's so sticky if your shoes are not tied on tight, they will be pulled off.

What is amazing is how long the stock drive shaft lasted in Twin Turbo Todd's car with drag slicks and traction control on a race track with the sticky substance* sprayed on. It was rifle drilled which Todd attributed to it's extended longevity over a completely stock shaft.

What also helped it last longer is the torque Todd has dialed out of 1st gear.

His upgraded driveshaft for anyone that missed that thread:

https://rennlist.com/forums/928-foru...-the-back.html

It will be fun to see what your car can do on the strip once it's given the full beans off the line.

*If you don't know what that sticky substance is, drag strips are sprayed with a type of rubber / asphalt glue that's so sticky if your shoes are not tied on tight, they will be pulled off.

If I recall correctly, the first stock driveshaft Todd Tremel broke was the necked-down 28mm automatic shaft. Do I recall that correctly? Did he also break a 25mm stock driveshaft?

Gun drilling can relieve some stresses from the center without impacting the basic strength calculation much at all, and the result is a (small) net benefit in strength under torsion.

What's the diameter of the new completely custom driveshaft in Todd's car? I am curious how the diameter and what appears to be a single center support bearing model in my spreadsheet.

#180

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

The 28mm lasted a little while, snapped at the usual location we are used to seeing.

The 25mm was rifle drilled in steps. 3/16 9", 1/4 6" deep both ends. Extra bearings installed (4-5 total he's not sure) with the balancer removed. He did note some harmonics at a certain RPM that were not present before.

This shaft did not fail in the traditional way. It never separated, the car was still driveable. The shaft looked like a tree branch twisted. He thought something broke in the transmission the way it felt when accelerating.

In his opinion, the stock shaft is strong enough if it were properly heat treated. He tested one and on the rockwell hardness scale is very low.

He doesn't have the specs of the DOM steel tube used for the new one in front of him. When he digs those up he'll let me know.

The video of his car turning the 10sec @ 150mph in the 1/4 was with the rifled drilled 25mm shaft.

The 25mm was rifle drilled in steps. 3/16 9", 1/4 6" deep both ends. Extra bearings installed (4-5 total he's not sure) with the balancer removed. He did note some harmonics at a certain RPM that were not present before.

This shaft did not fail in the traditional way. It never separated, the car was still driveable. The shaft looked like a tree branch twisted. He thought something broke in the transmission the way it felt when accelerating.

In his opinion, the stock shaft is strong enough if it were properly heat treated. He tested one and on the rockwell hardness scale is very low.

He doesn't have the specs of the DOM steel tube used for the new one in front of him. When he digs those up he'll let me know.

The video of his car turning the 10sec @ 150mph in the 1/4 was with the rifled drilled 25mm shaft.