Rules on Fuel Tank *Straps* or welding?

#1

Rennlist Member

Thread Starter

I am putting in a fuel tank into my 928. *Jeers roll over the crowd* okay.. Now that we have that out of the way.

Obviously the car came with one, but it was... plastic. And plastic will not work with the fuel I am using. At least not THAT 30 year old plastic. Crap. 31 years old.

Anyway, I have devised, with help from people here like John and others - a two tank system. A larger, 20+ gallon tank and a "swirl pot" smaller tank to draw from for the engine.

I have devised a system wherein there is no welding. Steel square tube is used as the support for the main tank, and also partially supporting the second smaller tank. The outer rails of the car support the main weight of the smaller tank.

The steel supports are bolted with 10mm bolts either to aluminum 1/2 plate which is then rivet-threaded to the car frame with 4 6mm bolts. That is the front, and at the rear, the steel support will either have two 6mm bolts threadserted to the body, or I will try to hole-drill into the fram rail at the back so I can just drill a hole and stick a nut on a larger 10mm bolt going up through the steel support.

The actual main tank will be supported by two steel straps running under the tank and then bolted to the steel supports on either side of the top of the tank.

Does anyone not think this would pass muster in some mid level race-tech checks? The original plastic tank was strapped the body with 4 8mm bolts and a steel strap assembly.

Obviously the car came with one, but it was... plastic. And plastic will not work with the fuel I am using. At least not THAT 30 year old plastic. Crap. 31 years old.

Anyway, I have devised, with help from people here like John and others - a two tank system. A larger, 20+ gallon tank and a "swirl pot" smaller tank to draw from for the engine.

I have devised a system wherein there is no welding. Steel square tube is used as the support for the main tank, and also partially supporting the second smaller tank. The outer rails of the car support the main weight of the smaller tank.

The steel supports are bolted with 10mm bolts either to aluminum 1/2 plate which is then rivet-threaded to the car frame with 4 6mm bolts. That is the front, and at the rear, the steel support will either have two 6mm bolts threadserted to the body, or I will try to hole-drill into the fram rail at the back so I can just drill a hole and stick a nut on a larger 10mm bolt going up through the steel support.

The actual main tank will be supported by two steel straps running under the tank and then bolted to the steel supports on either side of the top of the tank.

Does anyone not think this would pass muster in some mid level race-tech checks? The original plastic tank was strapped the body with 4 8mm bolts and a steel strap assembly.

#2

Addict

Rennlist Member

Rennlist Member

My head hurts...

Pics/drawings, please.

------------------------------------------------------------------------------------

By the way, if you want to whittle your sig down to its essence, then quote the estimable Lady Thatcher; "The problem with Socialism is that eventually you run out of other people's money."

Pics/drawings, please.

------------------------------------------------------------------------------------

By the way, if you want to whittle your sig down to its essence, then quote the estimable Lady Thatcher; "The problem with Socialism is that eventually you run out of other people's money."

#3

Rennlist Member

Thread Starter

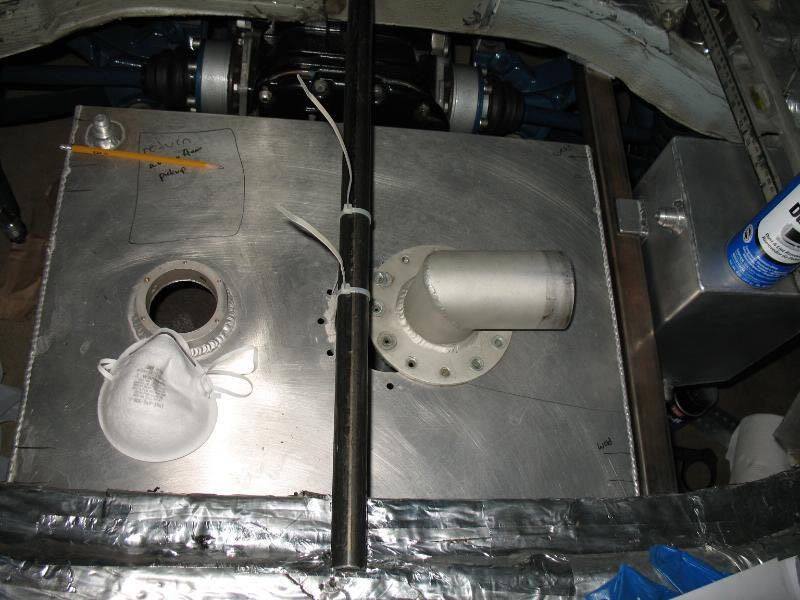

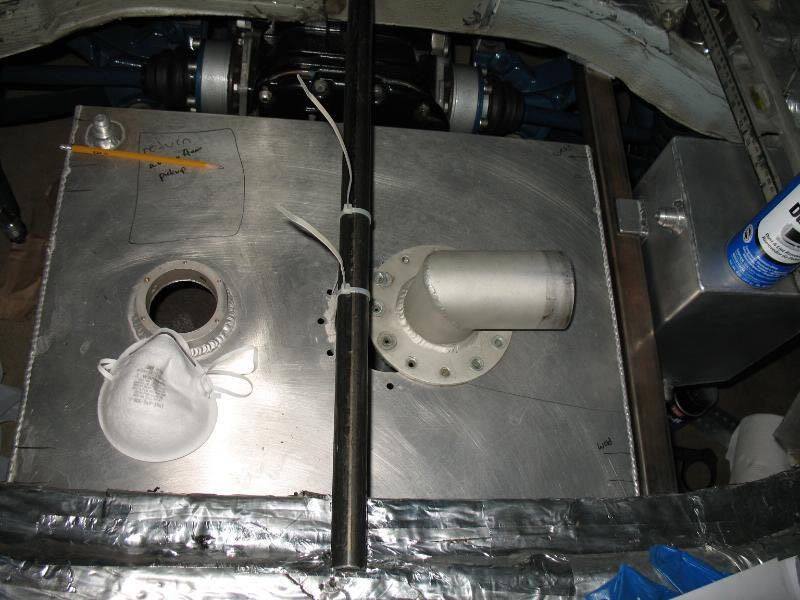

John - here are the pics:

The straps I was thinking of using:

Previous pictures of mockup

*****

1 clearance picture (tank/transmission)

The straps I was thinking of using:

Previous pictures of mockup

*****

1 clearance picture (tank/transmission)

#4

Burning Brakes

Not to be harsh, but....

Formula for disaster.

There is a reason why FIA cells...and stock tanks...suck out the top: Nothing out the sides or bottom to get snapped off when you go off-roading or smack a wall.

You whack that rear corner of the car, and the deranged, flying suspension pieces will tear that pump & fittings right off the tank. Start saving up for the skin grafts.

Formula for disaster.

There is a reason why FIA cells...and stock tanks...suck out the top: Nothing out the sides or bottom to get snapped off when you go off-roading or smack a wall.

You whack that rear corner of the car, and the deranged, flying suspension pieces will tear that pump & fittings right off the tank. Start saving up for the skin grafts.

#5

Rennlist Member

Thread Starter

I can always change that, there are two holes in the top, and the bottom draw creates a sump I can just pull from there, into the surge tank. I appreciate your message, and harshness does not dictate me not listening.

The STRAPS - are they a good idea? I was concerned over welding tabs at the top and having all the weight sitting on the tabs with no support from the bottom.

The STRAPS - are they a good idea? I was concerned over welding tabs at the top and having all the weight sitting on the tabs with no support from the bottom.

#6

Addict

Rennlist Member

Rennlist Member

Hmmmm...

Most fuel cells mount from the bolt flange on the can. Lots of surface area to carry the load. With how yours is constructed, you may have no choice but to strap it.

Make the Prof happier and bash plate those fuel lines and pumps. Or move'm.

Most fuel cells mount from the bolt flange on the can. Lots of surface area to carry the load. With how yours is constructed, you may have no choice but to strap it.

Make the Prof happier and bash plate those fuel lines and pumps. Or move'm.

#7

It is so hard to design a proper fuel tank and not get killed from your design. There are so many considerations being upside down, hit from multiple angles and the Professor's point surely implys that you have not thought this project through. You have done a lot of work I know but ATL and Fuelsafe both make proper well designed fuel cells. Why not at least start with one of those? They can also make a proper rubber bladder for your metal container at the very least. The cost of a proper cell is much cheaper and less painful than the professor's proposed skin grafts. One has to think very very carefully before ditching the OEM system which has most likely been tested and redesigned to death by some really smart guys. I'm such a paranoid that if I was doing a cell I would sheetmetal wall it off from the passenger compartment and I'll accept the weight for the added safety. Remember the Dale Jr. fire from the fuelcell exposed in the passenger compartment in that C5 corvette? I was flipped upsidown in a racecar once and a friend claimed I lost concisouness but I don't remember that. I had an OEM fuel system that did not leak a drop. I'm thankful. Just think "on fire" and "unconcious" = "not a good day."

Trending Topics

#8

Mr. Excitement

Rennlist Member

Rennlist Member

Caution uneducated opinion to follow. Hide the kids and put the dog outside. unending group con call to blame.

Looks like a large tank that will want to flex from the weight of the fuel. L tabs welded to un reinforced tank walls can act like can openers and should be avoided IMO. The tabs will have concentrated stress in the corners where they meet the tank as well as on some areas of the welds. With aluminum I would use full length continuous mounting strips all around the upper perimeter. Even top mounting can fail and expose the fuel as well but if the tank splits at the top it will but be less likely to puke all the fuel on the ground unless you are rolled over. I might be inclined to make a socket frame that the tank rests in supporting the tank from an added top rim. Single plane mounting can reduce the chance of tank deformation and failure during a frame bending impact. The mounting rim should be designed so it will not open the tank if it gets get pulled or deformed a bit. Adding steel strapping will not hurt and could reduce drumming some. Be sure to protect the tank from rubbing against the steel and don’t use Home Depot HVAC hanger strap, it is made from imported scrap mud metal.

(Super unasked for opinion, welding goggles and gloves a must, nearby trash can you can boot into recommended) Aluminum is nice and light but... aluminum does not resist vibration or stress as well as steel and I avoid it for flat wall automotive tanks of anything. Un-reinforced corner welds on large flats are more prone to cracking from drumming vibration than the same weight single wall steel tank. Add in heat affected zones formed during welding and you are even weaker in the places you need stress resistance the most. Unless the tank walls are thick enough or well supported with good internal baffles the fuel will make the sides drum as it sloshes and is shaken by the car movement. I did not notice any weld zones showing on the flats of the tank walls that might indicate baffels inside. Does this tank have any internal baffling welded in? Internal reinforcement is sometimes better than external as it reinforces without making external protrusions that can be pulled on/off and open the tank during an impact. If your tank does not have a bladder it is a great candidate for internal welded in baffling. Aluminum also soaks in and transfers heat better than many other materials. Insulate it well from tail pipe and gear box heat or your fuel will heat up in the tank causing safety and performance to go down.

If you stay with the setup you posted it might be a good idea to go from tank bung fitting to flex tubing anywhere you come out of the tank. Hard mounted devices suffer from failure due to vibration or impact. Even a short run of tubing between the tank and anything connected reduces this. The fuel pump setup is a lever against the tank bung or will fail through the exposed threads in a male fitting. Being on the bottom of the tank this will dump all the fuel.

Looks like a large tank that will want to flex from the weight of the fuel. L tabs welded to un reinforced tank walls can act like can openers and should be avoided IMO. The tabs will have concentrated stress in the corners where they meet the tank as well as on some areas of the welds. With aluminum I would use full length continuous mounting strips all around the upper perimeter. Even top mounting can fail and expose the fuel as well but if the tank splits at the top it will but be less likely to puke all the fuel on the ground unless you are rolled over. I might be inclined to make a socket frame that the tank rests in supporting the tank from an added top rim. Single plane mounting can reduce the chance of tank deformation and failure during a frame bending impact. The mounting rim should be designed so it will not open the tank if it gets get pulled or deformed a bit. Adding steel strapping will not hurt and could reduce drumming some. Be sure to protect the tank from rubbing against the steel and don’t use Home Depot HVAC hanger strap, it is made from imported scrap mud metal.

(Super unasked for opinion, welding goggles and gloves a must, nearby trash can you can boot into recommended) Aluminum is nice and light but... aluminum does not resist vibration or stress as well as steel and I avoid it for flat wall automotive tanks of anything. Un-reinforced corner welds on large flats are more prone to cracking from drumming vibration than the same weight single wall steel tank. Add in heat affected zones formed during welding and you are even weaker in the places you need stress resistance the most. Unless the tank walls are thick enough or well supported with good internal baffles the fuel will make the sides drum as it sloshes and is shaken by the car movement. I did not notice any weld zones showing on the flats of the tank walls that might indicate baffels inside. Does this tank have any internal baffling welded in? Internal reinforcement is sometimes better than external as it reinforces without making external protrusions that can be pulled on/off and open the tank during an impact. If your tank does not have a bladder it is a great candidate for internal welded in baffling. Aluminum also soaks in and transfers heat better than many other materials. Insulate it well from tail pipe and gear box heat or your fuel will heat up in the tank causing safety and performance to go down.

If you stay with the setup you posted it might be a good idea to go from tank bung fitting to flex tubing anywhere you come out of the tank. Hard mounted devices suffer from failure due to vibration or impact. Even a short run of tubing between the tank and anything connected reduces this. The fuel pump setup is a lever against the tank bung or will fail through the exposed threads in a male fitting. Being on the bottom of the tank this will dump all the fuel.

#9

Rennlist Member

Thread Starter

The steel straps would be the main support, from the bottom.

That way all the weight is being supported from the bottom, and it seemed like there would be less stress on all the welds on the tank (large tank) as the fuel sloshes around.

I had also planned some good protection of the fuel lines and filters and pumps back there.

An original idea was to make it all break away. The idea that you are rolling around and hitting stuff - but the first hit back there and the tank just flies off on its own - safely away from where the car is.

#10

Rennlist Member

Thread Starter

It is so hard to design a proper fuel tank and not get killed from your design. There are so many considerations being upside down, hit from multiple angles and the Professor's point surely implys that you have not thought this project through. You have done a lot of work I know but ATL and Fuelsafe both make proper well designed fuel cells. Why not at least start with one of those? They can also make a proper rubber bladder for your metal container at the very least. The cost of a proper cell is much cheaper and less painful than the professor's proposed skin grafts. One has to think very very carefully before ditching the OEM system which has most likely been tested and redesigned to death by some really smart guys. I'm such a paranoid that if I was doing a cell I would sheetmetal wall it off from the passenger compartment and I'll accept the weight for the added safety. Remember the Dale Jr. fire from the fuelcell exposed in the passenger compartment in that C5 corvette? I was flipped upsidown in a racecar once and a friend claimed I lost concisouness but I don't remember that. I had an OEM fuel system that did not leak a drop. I'm thankful. Just think "on fire" and "unconcious" = "not a good day."

Everything will be separated from the cabin with a not-thin ss or aluminum sheet sealed and bolted to the body. The filler will go through the body rail so as to not have anything protruding into the cabin.

I appreciate your comments and everyone elses. I will move forward with a much more serious mind set towards safety.

#11

Rennlist Member

Thread Starter

Kurt- there is no baffling in the tank. Its just a large welded aluminum box, though there are only welds at the sides and tops. The long sides at the bottom are bent.

#12

Rennlist Member

Thread Starter

Not to be harsh, but....

Formula for disaster.

There is a reason why FIA cells...and stock tanks...suck out the top: Nothing out the sides or bottom to get snapped off when you go off-roading or smack a wall.

You whack that rear corner of the car, and the deranged, flying suspension pieces will tear that pump & fittings right off the tank. Start saving up for the skin grafts.

Formula for disaster.

There is a reason why FIA cells...and stock tanks...suck out the top: Nothing out the sides or bottom to get snapped off when you go off-roading or smack a wall.

You whack that rear corner of the car, and the deranged, flying suspension pieces will tear that pump & fittings right off the tank. Start saving up for the skin grafts.

Couldn't I just spend extra time supporting and protecting that area?

Otherwise, I could draw from the top of THIS tank, but I would still draw from the bottom of the surge tank since that is how it is designed so there is no air-pickup.

#13

Burning Brakes

While the desire to "roll your own" and the associated "pride in accomplishment" is noble and valuable, you're literally playing with fire. Again...not to be harsh...but you don't seem to have a background and experience in the bad things that can happen to race cars traveling at race speeds. If you don't understand mice, you're not going to build a better mousetrap. In this case, the mousetrap might just kill you, or those around you.

I've seen a fuel cell ripped from a car in a multi-car incident...it wasn't pretty and those involved are still kinda wigged about it, a decade after it happened.

The filler will go through the body rail so as to not have anything protruding into the cabin.

Several questions:

How far off the ground will that tank be, at static ride height ? It looks like you will have problems with tank-to-ground distance requirements from at least several sanctioning bodies rules.

Why so large ? Fuel is lousy ballast. (I define anything that is highly flammable as "lousy ballast").

Stop. Just stop.

The fabrication work you've shown is really good-looking, BUT there is a difference between nice looking fabrication, and fabrication that is guided by experience and engineering. You need more of the latter.

#14

Race Car

Well, I'm sure no expert...

but that does not look like it can take a hit. and fuel fires are the worst! IMO.

The well prepped, hatchback type cars I've seen try to build in a enclosure / firewall around the fuel cell and pull fuel from the top out of a surge can...

Then rollover fuel pump shut off switch and a rollover cap on the fuel vent, run up high.

rule #1 is building to a GCR, and contacting a scrutineer for the series you want to run with. Besides the value added, (having a log book), there are decades safety research that go into the General Competition Rules.

Suggest you contac PCA/PBOC/NASA/SCCA chief of tech(s) in your area and ask if they would stop by...

(I'd at least put some flex hose bt the fuel pickup and the pump. mount that pump/filter up and out of the way... that solid setup won't take much vibration...)

-for what is worth...

but that does not look like it can take a hit. and fuel fires are the worst! IMO.

The well prepped, hatchback type cars I've seen try to build in a enclosure / firewall around the fuel cell and pull fuel from the top out of a surge can...

Then rollover fuel pump shut off switch and a rollover cap on the fuel vent, run up high.

rule #1 is building to a GCR, and contacting a scrutineer for the series you want to run with. Besides the value added, (having a log book), there are decades safety research that go into the General Competition Rules.

Suggest you contac PCA/PBOC/NASA/SCCA chief of tech(s) in your area and ask if they would stop by...

(I'd at least put some flex hose bt the fuel pickup and the pump. mount that pump/filter up and out of the way... that solid setup won't take much vibration...)

-for what is worth...

Last edited by mrbill_fl; 08-25-2009 at 08:33 PM.