strut tower failure

#991

Rennlist Member

Thanks. The challenge is that I can't really do any testing like Porsche could. All I can do is make something that I think will help prevent the failure, and time will then tell. I am in contact with a Porsche aftermarket parts supplier. Actually I recently machined some parts for him. So the two of us will put our heads together next week to see if my idea could work. He should have the distribution network and "store front" so that would certainly help move things right along.

Last edited by sonorous; 05-22-2019 at 04:13 PM.

#992

Rennlist Member

Join Date: Sep 2007

Location: Ontario & California

Posts: 436

Likes: 0

Received 57 Likes

on

32 Posts

I think it is the same p/n. They must have cut those ears off for some reason. Maybe because they were made for Motorstport, Porsche weren't worried about attaching it to the windshield wiper assembly on those cars, but figured (at first) that when mounting them to street cars they should not squeeze it under that assmebly? But clearly it fits.

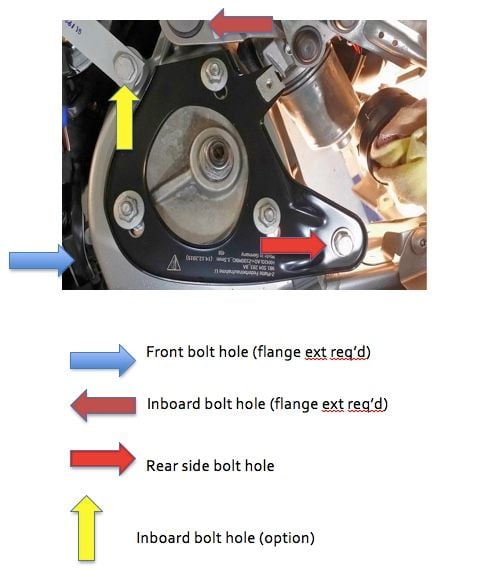

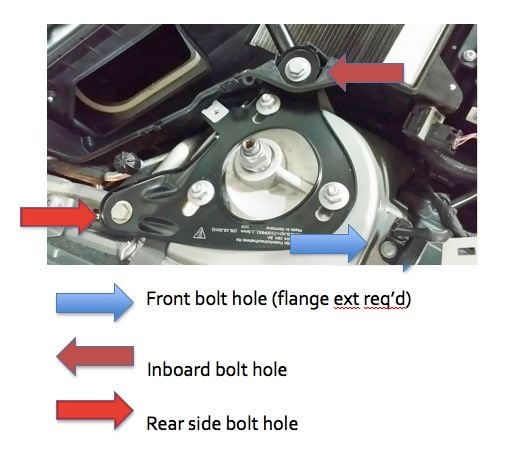

My 02 cents on these plates. While it looks like they strengthen the shock towers, I think there is some room for improvement (which is where my idea comes in to play). Based on the pictures I've seen of several failed towers, it looks to me like the first place they let go is towards the front/center, and these plates mostly strengthen the rear area, because that is where they are bolted in to two additional places. While I'm sure it prevents some of that load and transfers some of the pressure, I would feel better if they were attached to another area in the front/center, which I believe is possible.

I haven't taken it apart myself, so I can't say for sure, but I highly doubt it's secured with a rubber spacer in between. It might just be a rubber ring around a steel spacers to help dampen vibration from the windshield wiper assembly. Keep in mind this is where the strut, that connects the shock tower and firewall, mounts to. I don't think they would have held that down with rubber spacer in between.

My 02 cents on these plates. While it looks like they strengthen the shock towers, I think there is some room for improvement (which is where my idea comes in to play). Based on the pictures I've seen of several failed towers, it looks to me like the first place they let go is towards the front/center, and these plates mostly strengthen the rear area, because that is where they are bolted in to two additional places. While I'm sure it prevents some of that load and transfers some of the pressure, I would feel better if they were attached to another area in the front/center, which I believe is possible.

I haven't taken it apart myself, so I can't say for sure, but I highly doubt it's secured with a rubber spacer in between. It might just be a rubber ring around a steel spacers to help dampen vibration from the windshield wiper assembly. Keep in mind this is where the strut, that connects the shock tower and firewall, mounts to. I don't think they would have held that down with rubber spacer in between.

#993

Go Kart, your plates are different than mine & I welded a flange onto the spot where Porsche trimmed it off, so my plate is now like the newer ones. That bolt on the windshield wiper mechanism mount is a specially designed bolt from Porsche & quite different than a regular bolt. I also believe the tower is too weak towards the front, & the second flange shown in my photos (sitting there loose & not mounted in the picture) does bolt on almost directly in front of the forward strut bolt, only ~ 4 inches lower.

#994

Rennlist Member

Join Date: Sep 2007

Location: Ontario & California

Posts: 436

Likes: 0

Received 57 Likes

on

32 Posts

I thought the same thing for the longest time, but the more I look at it, the more I actually do think they help. My theory is that the front/center of the strut towers still would want to crack and could, but these plates should transfer some of the load towards the back and that is a good thing. They kind of act like a hinged lid on a pot for lack of better terminology. So while it would be better if the "lid" was secured on the side it wants to lift up, it still should be better to have one on it, even if it is clamped in the back. Also, keep in mind these plates are stamped with bends in them, which makes them very strong. The key really is that they bold in to a couple of places outside of the top. If it was just the top 3 strut bolts, then I would agree 100% that they are useless.

All that being said, I would like to find a way to anchor them on the front side, and I have some ideas on how to do that.

All that being said, I would like to find a way to anchor them on the front side, and I have some ideas on how to do that.

Last edited by G-forceGT4; 05-22-2019 at 11:27 PM. Reason: grammar

#995

On the front side of the tower, lower down ~ 4-6 inches, there is a sensor of some kind bolted to a flat L shelf which is part of the tower. That "shelf" is sort of covered by that square sensor. It's straighforward to use that bolt hole or drill a new hole adjacent to it. I mentioned previously all photos I've seen, showing fractured tops, NONE of the breakages extend into available bole holes lower down on the tower.

#996

Rennlist Member

Join Date: Jan 2016

Location: On a pygmy pony over by the dental floss bush

Posts: 3,309

Received 618 Likes

on

422 Posts

I attempted to buy a new strut tower part with the plan to do a 3D scan, then have a piece of the part analyzed to determine specifically the alloy and any post-processing done (heat treating, etc.). Then was going to do a full FEA using the GT upper shock tower mount and the non-GT upper shock mount under various loads to compare both. Then do another FEA with various reinforcement strategies. Was impossible to obtain a new part, they are tightly controlled by Porsche. I even searched salvage sites looking for a car I could pull parts off of so I could take a recip saw and remove a whole part for analysis. Have to buy a whole salvage car from what I found, and gave up on that. I could do a scan of my own car if I removed enough parts, and take a piece of a broken tower donated by a RL user with the failure for metal analysis, but haven't had the desire to disassemble my car to do the scan. I have a scan tool I can borrow from work.

#997

I attempted to buy a new strut tower part with the plan to do a 3D scan, then have a piece of the part analyzed to determine specifically the alloy and any post-processing done (heat treating, etc.). Then was going to do a full FEA using the GT upper shock tower mount and the non-GT upper shock mount under various loads to compare both. Then do another FEA with various reinforcement strategies. Was impossible to obtain a new part, they are tightly controlled by Porsche. I even searched salvage sites looking for a car I could pull parts off of so I could take a recip saw and remove a whole part for analysis. Have to buy a whole salvage car from what I found, and gave up on that. I could do a scan of my own car if I removed enough parts, and take a piece of a broken tower donated by a RL user with the failure for metal analysis, but haven't had the desire to disassemble my car to do the scan. I have a scan tool I can borrow from work.

I'm going to try to come up with something that is realistically simple, but hopefully effective. Along the lines of a strut tower brace, except the bracing will be somewhere else.

#998

Rennlist Member

Join Date: Jan 2016

Location: On a pygmy pony over by the dental floss bush

Posts: 3,309

Received 618 Likes

on

422 Posts

It's definitely a challenge to reverse engineer, which is why it is disappointing Porsche isn't doing anything, because it would be relatively easy for them to do so, but of course once they do, it would be admitting that it was a design flaw.

I'm going to try to come up with something that is realistically simple, but hopefully effective. Along the lines of a strut tower brace, except the bracing will be somewhere else.

I'm going to try to come up with something that is realistically simple, but hopefully effective. Along the lines of a strut tower brace, except the bracing will be somewhere else.

#999

Rennlist Member

Join Date: Sep 2007

Location: Ontario & California

Posts: 436

Likes: 0

Received 57 Likes

on

32 Posts

After my mechanical engineer friend (>30 years experience), looked at the "fix", I feel more reassured it's safe to go over some bumps & dips in the road. : )

It's like you said, kind of a steel lid for the tower, the strut is secured in 6 places & not just at the top.

Last edited by G-forceGT4; 05-23-2019 at 06:44 PM. Reason: adding text

#1001

I attempted to buy a new strut tower part with the plan to do a 3D scan, then have a piece of the part analyzed to determine specifically the alloy and any post-processing done (heat treating, etc.). Then was going to do a full FEA using the GT upper shock tower mount and the non-GT upper shock mount under various loads to compare both. Then do another FEA with various reinforcement strategies. Was impossible to obtain a new part, they are tightly controlled by Porsche. I even searched salvage sites looking for a car I could pull parts off of so I could take a recip saw and remove a whole part for analysis. Have to buy a whole salvage car from what I found, and gave up on that. I could do a scan of my own car if I removed enough parts, and take a piece of a broken tower donated by a RL user with the failure for metal analysis, but haven't had the desire to disassemble my car to do the scan. I have a scan tool I can borrow from work.

#1003

#1004

Rennlist Member

Join Date: Sep 2007

Location: Ontario & California

Posts: 436

Likes: 0

Received 57 Likes

on

32 Posts

Any suggestions/new ideas for something that can structurally reinforce this weak spot on our GT4's is greatly appreciated. I'd like to have a solid steel one piece unit that would cover the top & might try to convince my engineer friend to make one (he has his own CNC machine in his garage shop!)

I realize what I've done is not bullet proof, however I think of it as wel, l as a steel lid on an aluminium pot.