Intercooler concerns

#31

I hate to break it to everyone (Yasin) but the Protomotive intercooler is noting more than a Griffin core with end tanks welded onto it. As for data testing, good luck with that. They do work well, I have a full Proto 964T but the intercooler is nothing special. The welds in the first picture look like that of a high school shop class. Now Al's welds (second picture) were done by Protosport not Protomotive and they are done very nice.

#33

Banned

Join Date: Nov 2003

Location: En La Boca Del Raton

Posts: 1,341

Likes: 0

Received 0 Likes

on

0 Posts

I'm quite surprised looking at the pics, for some reason i always thought that Proto used bar and plate cores, but they are clearly tube and fin. The stock one is actually tube and fin too, which i mistakenly thought was the opposite. All the best coolers are bar and plate though right, Secan etc?

#34

Boost Junkie

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Join Date: Jan 2004

Location: Plymouth MN and Scottsdale AZ

Posts: 2,534

Received 42 Likes

on

34 Posts

it would seem that with todays CFD software, one could do a fairly decent job of modeling and predicting the performance of various intercooler designs. One day,I'll use my copious spare time to learn said software and try this out

#35

Rennlist Member

Nothing wrong with using Griffin cores, they make excellent cores. Most custom intercoolers use Griffin, Spearco, HKS etc cores with custom end tanks to fit the application.

The welds on the first pic are not the best but it is aluminum, and can be nicely and easily polished or ground down. Might be not using enough gas or not controlling temp on the tig..not a show stopper in my opinion.

Yasin

The welds on the first pic are not the best but it is aluminum, and can be nicely and easily polished or ground down. Might be not using enough gas or not controlling temp on the tig..not a show stopper in my opinion.

Yasin

#36

Not Forgotten

Join Date: Apr 2006

Location: South East, UK

Posts: 1,215

Likes: 0

Received 0 Likes

on

0 Posts

#37

Orange.

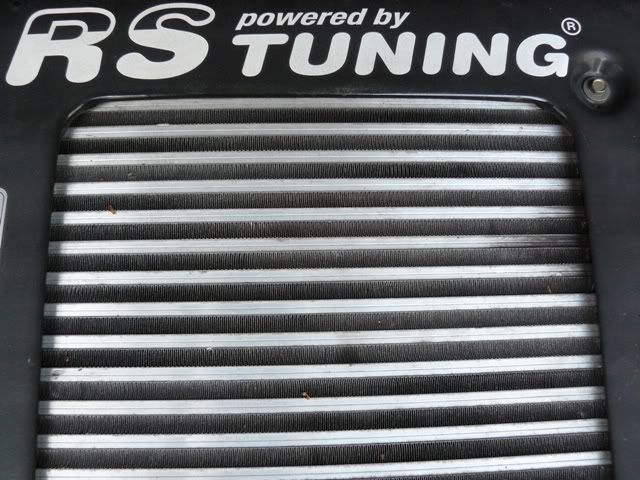

If you look at a Secan core it has about 1000 times the number of cooling fins as a Griffin. Not to mention a Secan cooler the size of the one on the 993tt will only cost you about $35K if you could even get them to make you one. They are also one of the only intercooler companies that guarantee their products for heat exchange differential above ambient air temp.

#38

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

The Protomotive ICs are bar and plate. The one on the OP's picture has welds that look like cr@p. I would be surprised if it was Todd Knighton who welded them as I have seen him weld in person and my IC welds look the same as Al's and the piping has very good welding, but who knows. Will this have an impact on cooling efficiency? I highly doubt it, things that look nice dont necessarily perform better. This workhorse seems to do the job assigned to it, at least for me, if I was a professional level racer that would be a different story, then again I would not be racing a 10 year-old 993.

Thanks to TB993TT we've been talking over here about Secan for what, 5 years now? We all know nothing almost is as good, and I can get one made in Germany in 3 weeks and almost one third of the money quoted here, I simply dont need it for my sprints, I can live with being 1 second per lap slower..and still run at Cup car pace.

We need to keep in mind the usage needs for each application and hardware, value for money.

Thanks to TB993TT we've been talking over here about Secan for what, 5 years now? We all know nothing almost is as good, and I can get one made in Germany in 3 weeks and almost one third of the money quoted here, I simply dont need it for my sprints, I can live with being 1 second per lap slower..and still run at Cup car pace.

We need to keep in mind the usage needs for each application and hardware, value for money.

Last edited by Jean; 02-21-2010 at 06:08 AM.

#40

Addict

Rennlist Member

RIP

Rennlist Member

RIP

Join Date: Feb 2002

Location: London

Posts: 802

Likes: 0

Received 0 Likes

on

0 Posts

I think there is a bit of confusion here (possibly from me).

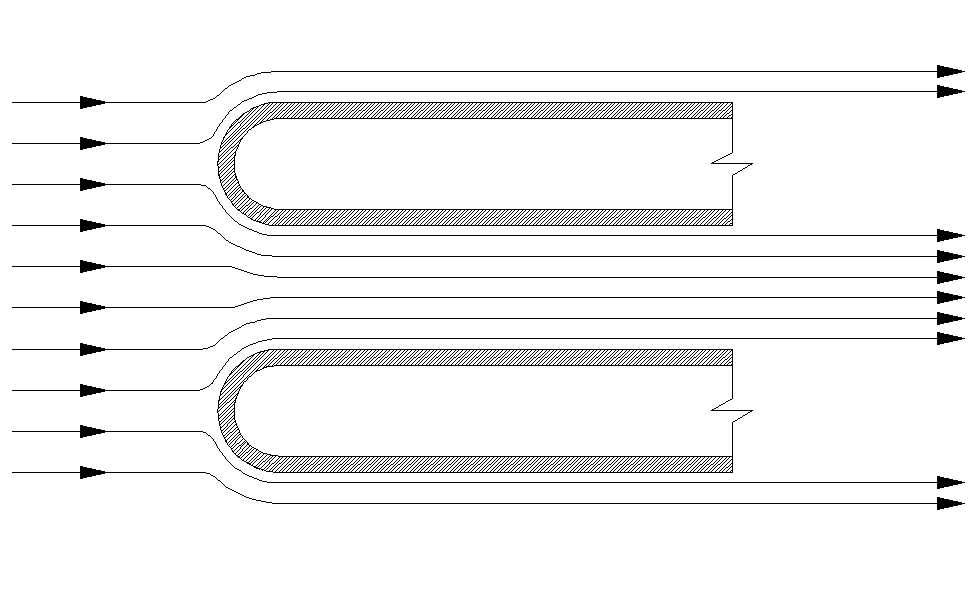

My understanding is that "Bar and Plate" refers to the "Tubes" being constructed, by hand, as a rectangular volume. By constructing them, by hand, the surface area to volume ratio can be maximised as the hand welding allows the flowing channels to be very close together. You still require fins. So more accurately, should it not be called "Bar and Plate and Fin"?

Tube and Fin is where the tube part is just "printed" off in strips. It is this manufacturing process that leaves the "tube" bit, tube shaped i.e. curved cross section.

This all suggests that it is quite possible for a Bar and Plate design to be no better than a good Tube and Fin.

The pictures above look like Tube and fin, but the bottom one at least has good fin density, the first looks terrible.

My understanding is that "Bar and Plate" refers to the "Tubes" being constructed, by hand, as a rectangular volume. By constructing them, by hand, the surface area to volume ratio can be maximised as the hand welding allows the flowing channels to be very close together. You still require fins. So more accurately, should it not be called "Bar and Plate and Fin"?

Tube and Fin is where the tube part is just "printed" off in strips. It is this manufacturing process that leaves the "tube" bit, tube shaped i.e. curved cross section.

This all suggests that it is quite possible for a Bar and Plate design to be no better than a good Tube and Fin.

The pictures above look like Tube and fin, but the bottom one at least has good fin density, the first looks terrible.

#41

Addict

Rennlist Member

Rennlist Member

Join Date: Aug 2003

Location: Raleigh, NC & North Myrtle Beach, SC

Posts: 4,146

Likes: 0

Received 2 Likes

on

2 Posts

Don't thnk I can help much this is the sides of my cooler. What do 'yall think. My car was basically a C4S but has had a Protomotive Stage 2 addition.

#42

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

As mentioned the cores used in these IC's are manufactured by Griffin. Griffin uses "tube and fin" construction. http://www.griffinrad.com/intercoolers.cfm

#44

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

I will try to get a close up picture of my cores when I get a chance to double check this info, my car is not with me. The IC seems to be doing its job though regardless, maybe because it is appropriately sized to my engine/turbo/map setup with engine dyno tuning given the strong performance of the car.

There is definitely room for improvement to drop IATs etc..So from a technical discussion point of vue, there are better ones out there, from a practical standpoint as I said earlier, the question is what is, or what is not needed..and at what cost.. I would not worry about how nice the welding is irrespectively.

There is definitely room for improvement to drop IATs etc..So from a technical discussion point of vue, there are better ones out there, from a practical standpoint as I said earlier, the question is what is, or what is not needed..and at what cost.. I would not worry about how nice the welding is irrespectively.

Last edited by Jean; 02-22-2010 at 08:41 AM.

#45

Just thought I would update folks who may be interested.

I talked with Todd @ Protomotive and sent pics of the cooler so he could see what I was inquiring of. He explained that this was one of the very early I/Cs and that originally they had planned on running a 2" hard pipe off the turbo to the I/C. When the cooler was build it uses a 2.5" inlet so they used a reducer to drop the size to 2". In the end the hard piping never came to pass so they just added back a 2.5" end so they could attach it to the rubber charge pipes. Only four or five coolers were built this way before a design change. Todd admitted that it looks a little goofy and that if I have someone that can change it back to 2" that's the way to go. That's probably what I'll do.

I talked with Todd @ Protomotive and sent pics of the cooler so he could see what I was inquiring of. He explained that this was one of the very early I/Cs and that originally they had planned on running a 2" hard pipe off the turbo to the I/C. When the cooler was build it uses a 2.5" inlet so they used a reducer to drop the size to 2". In the end the hard piping never came to pass so they just added back a 2.5" end so they could attach it to the rubber charge pipes. Only four or five coolers were built this way before a design change. Todd admitted that it looks a little goofy and that if I have someone that can change it back to 2" that's the way to go. That's probably what I'll do.