9M Prototype intercooler test report

#31

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Yes I have it done, but need to find out how to translate the volt signal to boost levels so that the data in the scale is readable... Felix, maybe you can help?

#32

Addict

Rennlist Member

Rennlist Member

Thread Starter

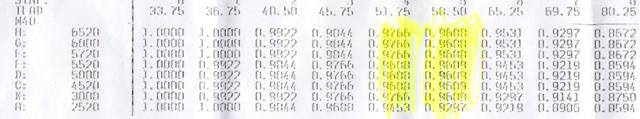

Here is the boost reduction chart (again caveat is that it is for my engine so may or may not be valid for others) you can see at 33degC you get 1.00 ie 100% of programmed boost and then it drops as the heat goes up so at 58degC it is around 0.96 ie 96% of programmed boost - the reductions are not as great as one might imagine 96% of 1.2bar is still 1.15bar !

#33

Addict

Rennlist Lifetime Member

Rennlist Lifetime Member

The formula to convert the recorded voltage to the boost level is:

(((VAR_0203/5+0.04)/0.004)-102.7)/100

where VAR_0203 is the output voltage and the 102.7 represents the ambient air pressure in mbar/10. Truth be told ambient was probably more like 1013 on the day but that's a minute error.

#34

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Thanks Felix!!

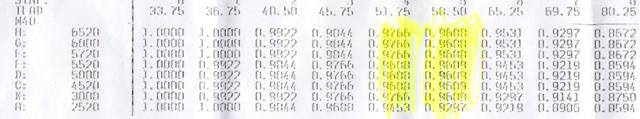

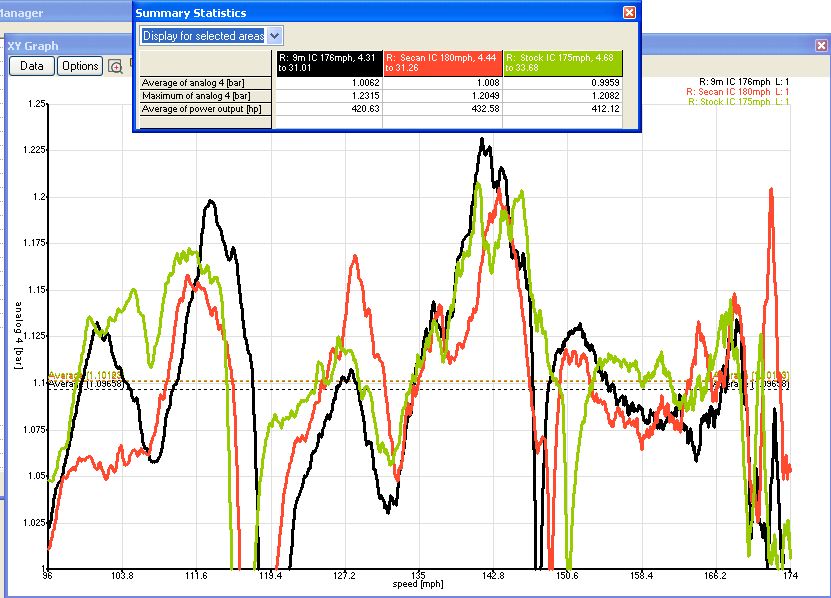

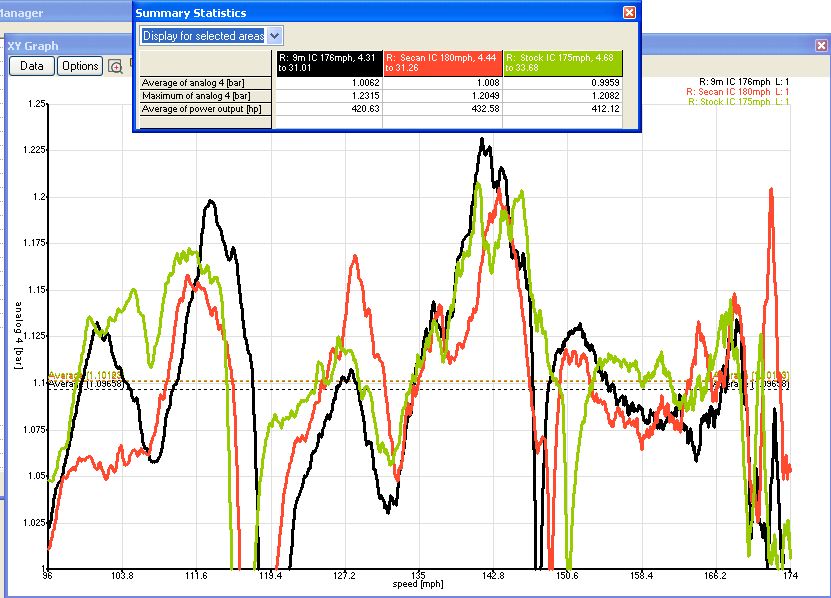

Here are the findings, not much that I can get out of them honestly.

I have had to smoothen the data to 1 second to avoid all the spikes and make it more readible, this action compresses a little the spike values. The real maximum values recorded in Boost were:

Stock: 1.39 Bar

9M: 1.37 Bar

Secan: 1.35 Bar

Here are the findings, not much that I can get out of them honestly.

I have had to smoothen the data to 1 second to avoid all the spikes and make it more readible, this action compresses a little the spike values. The real maximum values recorded in Boost were:

Stock: 1.39 Bar

9M: 1.37 Bar

Secan: 1.35 Bar

#35

So, not much different in average but could you zoom that last speed value (166-174), there is that Secan's own territory !

Also if you have more powerful car and can boost like 1.2 @ 7200 (200mph), then the Secan is absolutely clear winner

I like to see also other choices like that massive protomotive IC. Does anybody have that to test?

Also if you have more powerful car and can boost like 1.2 @ 7200 (200mph), then the Secan is absolutely clear winner

I like to see also other choices like that massive protomotive IC. Does anybody have that to test?

#37

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Good eye.. I would be careful how to interpret the boost data though..Too much going on there and at those speeds, heat soak is not really the issue, it would be at slower speeds such as in 6th at 4k RPM sustained for example?

#38

Addict

Rennlist Lifetime Member

Rennlist Lifetime Member

Hey Jean, great data crunching and displaying yet again. Not to give you more work but I'm guessing that if you overlayed 2 or 3 boost plots from the same intercooler they would all be different?

#39

To quickly answer Jussi (and others) question on the core size of the three intercoolers.

Looking at the last picture of intercoolers on TB's post, you can see how the thicknesses of the three vary.

In the standard one the cores are actually thinner than the end tanks

In the 9m the cores are exactly the same thickness as the end tanks

In the Secan, the cores are a bit thicker than the end tanks.

As Jean says thickness can be a balance between resistance to flow of cooling air and resistance to flow of boosted air. That said the difference between the three options purely due to thickness is likely to be small. There may be a slight benefit in making the 9m slightly thicker.

In plan view the 9m core is only fractionally wider front to back than the stock core, whereas the Secan is a bit larger again. This is a more interesting question, as the larger area in plan is not adding a great deal of extra cooling ability if the extra rows are covered by the intercooler shroud. It does add a little bit of thermal mass, but this is not really relevant given the energy going through. That said if a new shroud with bigger holes was made for there would be a small benefit of going larger.

The important thing is that the effect of core size is only very minor in explaining the difference between these intercoolers.

If you made an intercooler with the same core material as the stock one, but made it the same dimensions as the Secan it is likely that it would be barely any better than stock (and could even be slightly worse in some situations).

By the same measure, if you made the an intercooler with Secan or 9m cores exactly the same size as stock, they would still be much better.

The difference is down to the technology of the cores. The 9m and Secan use the latest custom race cores. These are one-offs rather than off the shelf items, but do have higher cooling efficiency than traditional core materials.

Looking at the last picture of intercoolers on TB's post, you can see how the thicknesses of the three vary.

In the standard one the cores are actually thinner than the end tanks

In the 9m the cores are exactly the same thickness as the end tanks

In the Secan, the cores are a bit thicker than the end tanks.

As Jean says thickness can be a balance between resistance to flow of cooling air and resistance to flow of boosted air. That said the difference between the three options purely due to thickness is likely to be small. There may be a slight benefit in making the 9m slightly thicker.

In plan view the 9m core is only fractionally wider front to back than the stock core, whereas the Secan is a bit larger again. This is a more interesting question, as the larger area in plan is not adding a great deal of extra cooling ability if the extra rows are covered by the intercooler shroud. It does add a little bit of thermal mass, but this is not really relevant given the energy going through. That said if a new shroud with bigger holes was made for there would be a small benefit of going larger.

The important thing is that the effect of core size is only very minor in explaining the difference between these intercoolers.

If you made an intercooler with the same core material as the stock one, but made it the same dimensions as the Secan it is likely that it would be barely any better than stock (and could even be slightly worse in some situations).

By the same measure, if you made the an intercooler with Secan or 9m cores exactly the same size as stock, they would still be much better.

The difference is down to the technology of the cores. The 9m and Secan use the latest custom race cores. These are one-offs rather than off the shelf items, but do have higher cooling efficiency than traditional core materials.

#40

When going fast or doing 0-200mph acceleration tests,

I think that the best way would be use the whole available cooling area with modern core technic.

So the core would be same length (10.5 inch) for hot side (side to side) as original to be able to use original central part and end piping from turbos.

But it would be as wide as possible for cold side (front to back), original is 10.5 inch but it could be 13 inch.

And what comes to thickness, I would use 2.75 or max. 3.0 inch thick core.

And material or structure would be as in picture:

What do you say about these ideas?

I think that the best way would be use the whole available cooling area with modern core technic.

So the core would be same length (10.5 inch) for hot side (side to side) as original to be able to use original central part and end piping from turbos.

But it would be as wide as possible for cold side (front to back), original is 10.5 inch but it could be 13 inch.

And what comes to thickness, I would use 2.75 or max. 3.0 inch thick core.

And material or structure would be as in picture:

What do you say about these ideas?

#41

Increasing the width in plan, front to back by much over that of the stock core is difficult without changing the end tanks, as these are only 265mm (10.5 inch) wide. The Secan is probably about as wide as you can go with the standard tanks (although I don't have measurements for the Secan). An extra 2.5 inch width (as you suggest) would likely leave a step which in itself would give a flow loss. Keeping the end tanks is a good idea as they flow well and make fitment to the car easier. It should also be remembered that to gain the benefit of a wider core a new shroud would be needed. It think benefit of a gain in width is likely quite small.

On core thickness the 9m uses 2.75inch and my guess is that the Secan is fractionally over 3inch (although again I don't have Secan measurements). These tie up quite closely to your thoughts.

On material, modern race cores don't look like your picture. They use an enormous number and density of tiny curved vanes. These keep the air turning as it passes through the core. I believe that one of the benefits of this is that the boundary layer is reduced in thickness and hence the heat transfer rate increases.

On core thickness the 9m uses 2.75inch and my guess is that the Secan is fractionally over 3inch (although again I don't have Secan measurements). These tie up quite closely to your thoughts.

On material, modern race cores don't look like your picture. They use an enormous number and density of tiny curved vanes. These keep the air turning as it passes through the core. I believe that one of the benefits of this is that the boundary layer is reduced in thickness and hence the heat transfer rate increases.

#42

..

On material, modern race cores don't look like your picture. They use an enormous number and density of tiny curved vanes. These keep the air turning as it passes through the core. I believe that one of the benefits of this is that the boundary layer is reduced in thickness and hence the heat transfer rate increases.

On material, modern race cores don't look like your picture. They use an enormous number and density of tiny curved vanes. These keep the air turning as it passes through the core. I believe that one of the benefits of this is that the boundary layer is reduced in thickness and hence the heat transfer rate increases.

I can do aluminium welding myself and use original end and center tanks. End tanks can be made little larger from IC side by welding more aluminium sheet to it.

#43

Addict

Rennlist Member

Rennlist Member

Thread Starter

Even noting your analysis of the relative sizes it seems to me the data shows the Secan even when not utilising one of its rows (because of the ill fitting stock shroud

) is way ahead in terms of Performance and that is before the ambient temperature has been cranked up- We don't know what the cost of the 9M Marston unit will be but based on performance it wouild have to be 1/3 of the price of the Secan IMO ?

) is way ahead in terms of Performance and that is before the ambient temperature has been cranked up- We don't know what the cost of the 9M Marston unit will be but based on performance it wouild have to be 1/3 of the price of the Secan IMO ?

#44

Nordschleife Master

As Jean says thickness can be a balance between resistance to flow of cooling air and resistance to flow of boosted air.

#45

I wasn't making any judgement on the relative performance of the Secan and the 9m, simply trying to note that they were of different technology to that of the stock core and that this is where most of the difference lies rather than in the dimensions.

But this is more fun thatn driving'em!!

But this is more fun thatn driving'em!!