993 crank expert questions.

#16

Addict

Rennlist Member

Rennlist Member

Originally Posted by Jean

It would be interesting to know the weight of the car , I remember it was quite gutted.

.

.

#17

Intermediate

Join Date: Apr 2006

Location: Cambridge, UK

Posts: 41

Likes: 0

Received 0 Likes

on

0 Posts

Use a GT3R crank and don't try to cut corners with the 993 one. It sounds like the engineis going to be expensive anyway so you dont want to do it all again! The 993 crank is not up to the task. I used one about 6 years ago and broke it. Learn from my mistakes and go forward!

Cheers,

Richard.

Cheers,

Richard.

#18

Intermediate

Thread Starter

Join Date: Dec 2003

Location: Uppsala, Sweden

Posts: 45

Likes: 0

Received 0 Likes

on

0 Posts

Thank you all for your help!

I now have much better understanding of 993 crank issues. I also cheked Kevin's 8200 RPM thread and found heaps of useful info. We might even purchase red993tt's crank if everything works out.

I have additional question:

Is it true that 993tt heads were made in better heat resistant alloy and that 993 N/A heads also used this alloy from 95 onwards?

Also, were all 993tt heads made with dished recess that piston crown moved into (to make heads seal better) or is it true that only 94' year models had this feature?

Thank you one more time!

I now have much better understanding of 993 crank issues. I also cheked Kevin's 8200 RPM thread and found heaps of useful info. We might even purchase red993tt's crank if everything works out.

I have additional question:

Is it true that 993tt heads were made in better heat resistant alloy and that 993 N/A heads also used this alloy from 95 onwards?

Also, were all 993tt heads made with dished recess that piston crown moved into (to make heads seal better) or is it true that only 94' year models had this feature?

Thank you one more time!

#19

Addict

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Originally Posted by beepbeep

Is it true that 993tt heads were made in better heat resistant alloy and that 993 N/A heads also used this alloy from 95 onwards?

Also, were all 993tt heads made with dished recess that piston crown moved into (to make heads seal better) or is it true that only 94' year models had this feature?

Also, were all 993tt heads made with dished recess that piston crown moved into (to make heads seal better) or is it true that only 94' year models had this feature?

All 993TT and 993GT2 heads are made to suit a shorter barrel with the rebate you mention.

I cannot confirm the material that Porsche use (Geoffrey knows the spec) but I suspect that all turbo heads are made from the same stuff. What I can tell you is that the Porsche cylinder heads in racing are "lifed" for replacement every 30 hours due to the material softening at high temperature, the other issues being poor support for the sealing face at the sides of the heads and guide bore collapse leading to guides falling out in extreme circumstances.

Without attempting to turn this into a blatant plug, we are just finishing the first batch of 9m billet 993GT2/TT heads which are made from a stonger/more stable (at high temp) F1 piston alloy, have high velocity ports and run 9mm stem 49/41.5mm valves with 15mm diameter (std is 13mm) long life guides fitted as standard. The side seal support issue has been addressed by omitting the lower cooling fin - much in the same way that racers weld up the standard heads. The heads are only made in twin plug form to use the smaller diameter GT2 racing plugs which reduce the tendency to crack between the plug holes and the seats. The price is also pretty much the same as a new set of heads from Porsche.

#21

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

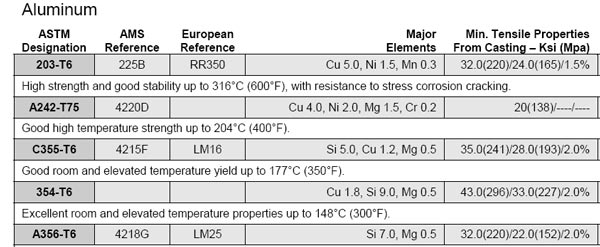

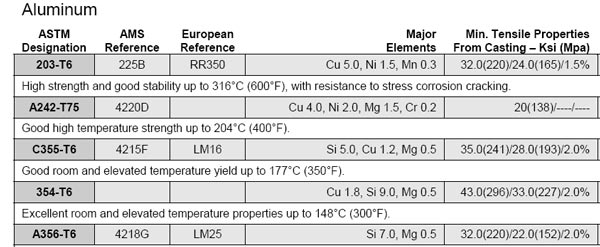

The European designation of the alloy is the RR350. It is a very high temperature resistant lightweight alloy that you also find on the 996GT3.

You need to make sure you find an alloy with similar tensile properties to ensure high temp stability if you are welding the heads, it took my builder substantial time to get it right apparently.

Here are some of the components..

You need to make sure you find an alloy with similar tensile properties to ensure high temp stability if you are welding the heads, it took my builder substantial time to get it right apparently.

Here are some of the components..

#22

Intermediate

Join Date: Apr 2006

Location: Cambridge, UK

Posts: 41

Likes: 0

Received 0 Likes

on

0 Posts

Jean has said it all! RR350 is the material you want in my opinion and is better than all the billet or forging alloys I have found. Remember, it is the high temperature properties that you need here. Mechanical propeties at 200 celcius are unimportant (ish) as it is frighteneing the way the material strengh decays with high temperature. Highly stressed air cooled heads can easily reach 300 celcius - I have seen 350 celcius on the dyno - and most alloys will not live here! Air cooled heads get very, very hot around the exhaust port - see Colins post above - and will creep quite quickly when subjected to stress.

Another point to remember is that if you weld up the bottom cooling fins be very careful about the heat put into the head. It is very easy to anneal the head and make it almost useless. I would strongly advise re heat treating after any welding.

Cheers,

Richard.

Another point to remember is that if you weld up the bottom cooling fins be very careful about the heat put into the head. It is very easy to anneal the head and make it almost useless. I would strongly advise re heat treating after any welding.

Cheers,

Richard.

#23

Nordschleife Master

I would be surprised if you see cylinder head temps in the 300 to 350C range at the cylinder head temp sensor. For a long time now, I have been datalogging cylinder head temp on many of the engines I've done and with a good exhaust system, I see 170-180C for .7bar of boost, 200C for 1bar and 210-220C for 1.2bar of boost. I never ever let the engine go above 220c on the track or on the dyno. I assume that that the temp of the head will vary depending on location ie Exhaust port will be higher than the intake port and the sensor is probably near a mean temp. Are you seeing those temps at the sensor, or at various points in the head itself?

#24

Intermediate

Join Date: Apr 2006

Location: Cambridge, UK

Posts: 41

Likes: 0

Received 0 Likes

on

0 Posts

Geoffrey, I measure the temps within the body of the head under the exhaust port. From my experience this gives the highest temperature readings and is also the area which creeps first on the head.

I have tried various ceramic coatings in the exhaust port and I can see some improvement in temperatures but so far I have not seen anything that is very "special". I am still working on it though!

Cheers,

Richard.

I have tried various ceramic coatings in the exhaust port and I can see some improvement in temperatures but so far I have not seen anything that is very "special". I am still working on it though!

Cheers,

Richard.

#25

Intermediate

Thread Starter

Join Date: Dec 2003

Location: Uppsala, Sweden

Posts: 45

Likes: 0

Received 0 Likes

on

0 Posts

Hmm...so if I understand you guys right, optimal crank is GT3R. Is there a difference between GT3 and GT3R crank?

What do you think of this build-sheet:

993 N/A block

GT3R crank w/ h-beam steel rods

3.6 N/A heads w/ steel O-rings to help sealing

OEM 993tt pistons

Straight-blade 993tt fan with x1.3 gearing

As I said before, rest of system is probably as optimal is it gets. We have speed/density EFI, Garrett GT BB turbochargers from hell, well-made headers, huge intercoolers that cannot be fitted in ordinary 911, trick plenum etc.

My main concern this far is reliability. Is forementioned build sheet OK for couple of laps on ring, running 0.8 to 1.0 bar of boost (making around 600-650hp) and occasionally reving to 7400?

Are there any tricks to be done with oiling? I read Kevins thread about enlargening oiling feed on certain journal bearings?

Reading your posts about cylinder head thermal stability, I guess it's a good idea to mount a temperature sender in one of heads (which runs the hottest?), connect it to Dash-logger and make sure heads never go past 220 deg. C??

What do you think of this build-sheet:

993 N/A block

GT3R crank w/ h-beam steel rods

3.6 N/A heads w/ steel O-rings to help sealing

OEM 993tt pistons

Straight-blade 993tt fan with x1.3 gearing

As I said before, rest of system is probably as optimal is it gets. We have speed/density EFI, Garrett GT BB turbochargers from hell, well-made headers, huge intercoolers that cannot be fitted in ordinary 911, trick plenum etc.

My main concern this far is reliability. Is forementioned build sheet OK for couple of laps on ring, running 0.8 to 1.0 bar of boost (making around 600-650hp) and occasionally reving to 7400?

Are there any tricks to be done with oiling? I read Kevins thread about enlargening oiling feed on certain journal bearings?

Reading your posts about cylinder head thermal stability, I guess it's a good idea to mount a temperature sender in one of heads (which runs the hottest?), connect it to Dash-logger and make sure heads never go past 220 deg. C??

#26

Addict

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Since we are comparing notes, here is the mechanical specification for the 9m billet head material:

Hardness, Brinell 115 (Typical; 500 g load; 10 mm ball)

Hardness, Knoop 144 (Converted from Brinell Hardness Value)

Hardness, Rockwell A 45.5 (Converted from Brinell Hardness Value)

Hardness, Rockwell B 72 (Converted from Brinell Hardness Value)

Hardness, Vickers 130 (Converted from Brinell Hardness Value)

Ultimate Tensile Strength 441 MPa (Typical)

Tensile Yield Strength 372 MPa (Typical)

Modulus of Elasticity 74.5 GPa (Average of tension and compression, Compression modulus is about 2% greater than tensile modulus)

Compressive Strength 370 MPa

Poisson's Ratio 0.33

Fatigue Strength 124 MPa (500,000,000 cycles completely reversed stress)

Shear Modulus 27 GPa (Calculated)

Shear Strength 262 MPa (Typical)

It is described by the supplier as:

Principal Design Features:

This alloy containing copper and magnesium is age hardenable for good strength in applications that involve exposure to heat up to 575 F.

Applications:

Commonly used in the manufacture of aircraft engines.

If anyone needs any more info, please ask.

Hardness, Brinell 115 (Typical; 500 g load; 10 mm ball)

Hardness, Knoop 144 (Converted from Brinell Hardness Value)

Hardness, Rockwell A 45.5 (Converted from Brinell Hardness Value)

Hardness, Rockwell B 72 (Converted from Brinell Hardness Value)

Hardness, Vickers 130 (Converted from Brinell Hardness Value)

Ultimate Tensile Strength 441 MPa (Typical)

Tensile Yield Strength 372 MPa (Typical)

Modulus of Elasticity 74.5 GPa (Average of tension and compression, Compression modulus is about 2% greater than tensile modulus)

Compressive Strength 370 MPa

Poisson's Ratio 0.33

Fatigue Strength 124 MPa (500,000,000 cycles completely reversed stress)

Shear Modulus 27 GPa (Calculated)

Shear Strength 262 MPa (Typical)

It is described by the supplier as:

Principal Design Features:

This alloy containing copper and magnesium is age hardenable for good strength in applications that involve exposure to heat up to 575 F.

Applications:

Commonly used in the manufacture of aircraft engines.

If anyone needs any more info, please ask.

#27

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

You can't use 993TT pistons with 993NA aspirated heads.. Yes, you can spend hours repositioning the deck height and moving the seats. In the end, you can buy a set of new heads.. Please realize that the 993TT pistons protude out of the cylinders .250" into the combustion chamber in the heads.

#28

Intermediate

Thread Starter

Join Date: Dec 2003

Location: Uppsala, Sweden

Posts: 45

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Kevin

You can't use 993TT pistons with 993NA aspirated heads.. Yes, you can spend hours repositioning the deck height and moving the seats. In the end, you can buy a set of new heads.. Please realize that the 993TT pistons protude out of the cylinders .250" into the combustion chamber in the heads.

Hmm...are you sure about this? We built a 964 engine with 964 heads and 993tt pistons that worked for five years. I also talked to Andial and got information that 993tt pistons do not portrude into heads but it's heads that are skirted down around pistons. With other words, 993tt cylinders are shorter and heads dish around the piston.

If what you were saying was true, pistons or rods would should have to be longer to accomodate the portion that "goes into heads".

#30

Intermediate

Thread Starter

Join Date: Dec 2003

Location: Uppsala, Sweden

Posts: 45

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Rickard 993 Turbo

Yes we are sure, here are some pictures from Micke Svens home page when he builds a 993 gt2

When fitted on 993 N/A engine, pistons shouldn't portrude from jugs anymore as jugs are deeper on N/A engines?