The Ultimate quest for 8500 RPM engine build

#1

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

Thread Starter

I have been working on my Stage 3 engine project for a while. It has required me to engineer a new intercooler solution (not finished), build 70mm 100 cell cats (almost finished), design and build a new set of turbochargers, K24/26's with the latest compressor wheel designs out of KKK (finished and tested with dyno sheet), build a new head sealing ring solution (finished), design a lightweight forged rod for the GT3R crankshaft (done), secure 2200 degree lightweight large diameter (43mm) exhaust valves and 52.5mm lightweight intake valves, camshaft selections and a few other interesting things..

I realize that there are many good engine combinations and some very good engine builders. This thread is about my project and how it relates to my views and what I have learned over 23 years of wrenching on/owning turbocharged Porsches. I will try to technically explain what I am posting and sharing, please feel free to ask all the questions if I haven't explained myself.. Alot of things that I will post, many DIY's can and will be able to emulate what I have done..

It is my goal to safely build a "Capable" 8500 RPM 993TT engine with modest amounts of boost. It will be Motronic 5.2 based.. The key to this engine success is extensive engine case prep, line boring shuffle pinning, windage mods, oil flow modifications.. And the installation of a GT3R crankshaft and oil pump. I have successfully tested similar engine builds and have hit 7800-8000RPM while using weaker components.

I realize that there are many good engine combinations and some very good engine builders. This thread is about my project and how it relates to my views and what I have learned over 23 years of wrenching on/owning turbocharged Porsches. I will try to technically explain what I am posting and sharing, please feel free to ask all the questions if I haven't explained myself.. Alot of things that I will post, many DIY's can and will be able to emulate what I have done..

It is my goal to safely build a "Capable" 8500 RPM 993TT engine with modest amounts of boost. It will be Motronic 5.2 based.. The key to this engine success is extensive engine case prep, line boring shuffle pinning, windage mods, oil flow modifications.. And the installation of a GT3R crankshaft and oil pump. I have successfully tested similar engine builds and have hit 7800-8000RPM while using weaker components.

Last edited by Kevin; 02-16-2006 at 01:10 AM.

#2

Rennlist Member

why the quest for the high revs?

Turbocharged engines are good for a certain RPM range thay lies within its efficiency chart. Boost higher than that and ur just blowing hot air.

Turboed engines you want to match a compressor map with your motors flow rate. it could be at any rpm you wish, but the higher the rpm you got means the more turbo lag you are going to experience before you get "into the boost"

enlighten me on your thinking

Turbocharged engines are good for a certain RPM range thay lies within its efficiency chart. Boost higher than that and ur just blowing hot air.

Turboed engines you want to match a compressor map with your motors flow rate. it could be at any rpm you wish, but the higher the rpm you got means the more turbo lag you are going to experience before you get "into the boost"

enlighten me on your thinking

#3

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

Thread Starter

It has been known for many years that on Porsche race cars that were turbocharged, the cylinder heads were welded to prevent warpage and holes being blown through. What I noticed first hand that when you increase your displacement to a 3.8 ltr or 102mm pistons and liners, the heads get dangerously thin. I took a set of calipers and measured the aluminum between the 2nd fin (thinest area) and the top edge of the combustion chamber. The measurement was <.110".. A stock engine will have more material since it has not be cut open for the larger liner.. To get support for the flame-ring and edges of the cylinder head I needed to weld them.

The following pictures show the cylinder head welding prior to machine work. What one must do is physically grind away the 2nd cooling fin next to the cylinder head surface. One must also acid treat the aluminum area. I media blasted the cylinder heads prior to grinding and welding. Contamination of the weld is what we are trying to prevent.. It was interesting that I could tell which cylinders were what when welding. Number 3 and 6 which are closest to your tire spray definately was/were more contaminated. The cylinder heads were heated in a bake oven to 250 degrees.. Using a laser temp gun, welding would stop when the head reached 295 degrees F.. I just set the head on the steel welding table and pulled the next head out of the oven.. This was done to prevent cracks in these valuable heads..

The below picture shows the welded heads next to unwelded TT heads. You can see the 2nd fin that basically needs to be removed. If you weld this area without taking out that fin, you will not get good penetration with your weld. You will also tend to use more heat to place the bead of weld. You do not want to super-heat the head, so grind out the fin and apply single pass welds and build up the area.. The bead of weld that you see on the head surface will get surfaced and my new flame ring will get installed..

The next picture shows the welded 6 heads and 2 non welded TT heads for comparison..

Audipwr1, These engines with correct camshafts will make power till 7,700-7,900. I will post a dyno sheet later on showing the power curve. Over the years I have had the request to have higher RPM's available. Yes, you need a larger more efficient intercooler and you need turbochargers that will stay in the efficiency range and provide boost. My goals are to try to make power to 8,000 RPM's.. The 936 race engine made peak power at 9000 RPM.. Regardless, the main purpose of this build is to have a bullet-proof lower end with a valvetrain that won't float and we will see how high we can go..

The following pictures show the cylinder head welding prior to machine work. What one must do is physically grind away the 2nd cooling fin next to the cylinder head surface. One must also acid treat the aluminum area. I media blasted the cylinder heads prior to grinding and welding. Contamination of the weld is what we are trying to prevent.. It was interesting that I could tell which cylinders were what when welding. Number 3 and 6 which are closest to your tire spray definately was/were more contaminated. The cylinder heads were heated in a bake oven to 250 degrees.. Using a laser temp gun, welding would stop when the head reached 295 degrees F.. I just set the head on the steel welding table and pulled the next head out of the oven.. This was done to prevent cracks in these valuable heads..

The below picture shows the welded heads next to unwelded TT heads. You can see the 2nd fin that basically needs to be removed. If you weld this area without taking out that fin, you will not get good penetration with your weld. You will also tend to use more heat to place the bead of weld. You do not want to super-heat the head, so grind out the fin and apply single pass welds and build up the area.. The bead of weld that you see on the head surface will get surfaced and my new flame ring will get installed..

The next picture shows the welded 6 heads and 2 non welded TT heads for comparison..

Audipwr1, These engines with correct camshafts will make power till 7,700-7,900. I will post a dyno sheet later on showing the power curve. Over the years I have had the request to have higher RPM's available. Yes, you need a larger more efficient intercooler and you need turbochargers that will stay in the efficiency range and provide boost. My goals are to try to make power to 8,000 RPM's.. The 936 race engine made peak power at 9000 RPM.. Regardless, the main purpose of this build is to have a bullet-proof lower end with a valvetrain that won't float and we will see how high we can go..

Last edited by Kevin; 02-16-2006 at 12:09 AM.

#4

Burning Brakes

Join Date: Jul 2001

Location: Orange Park Acres, CA

Posts: 982

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by audipwr1

why the quest for the high revs?

Turbocharged engines are good for a certain RPM range thay lies within its efficiency chart. Boost higher than that and ur just blowing hot air.

Turboed engines you want to match a compressor map with your motors flow rate. it could be at any rpm you wish, but the higher the rpm you got means the more turbo lag you are going to experience before you get "into the boost"

enlighten me on your thinking

Turbocharged engines are good for a certain RPM range thay lies within its efficiency chart. Boost higher than that and ur just blowing hot air.

Turboed engines you want to match a compressor map with your motors flow rate. it could be at any rpm you wish, but the higher the rpm you got means the more turbo lag you are going to experience before you get "into the boost"

enlighten me on your thinking

#6

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

Thread Starter

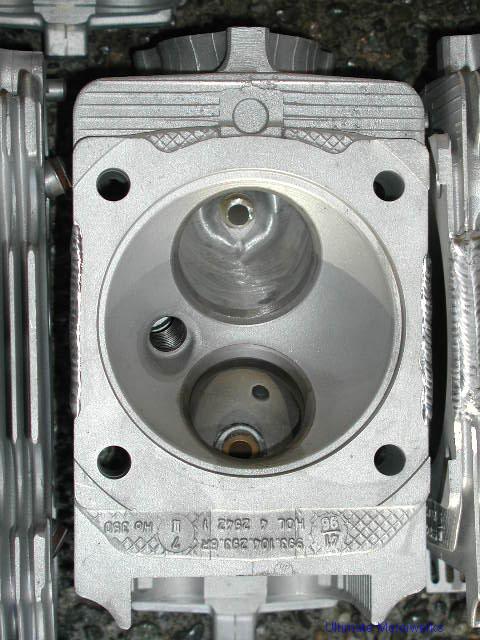

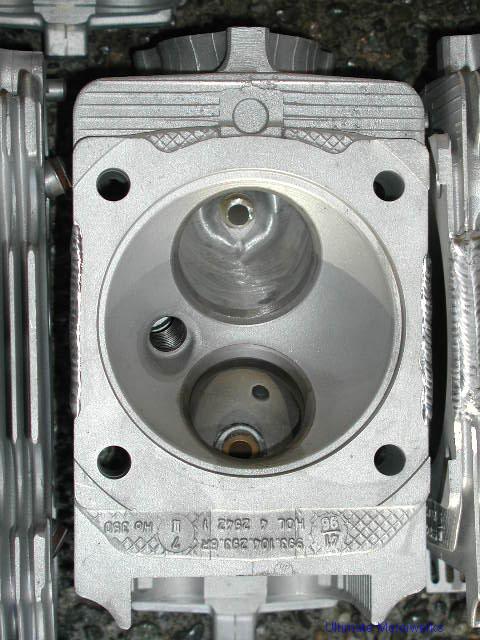

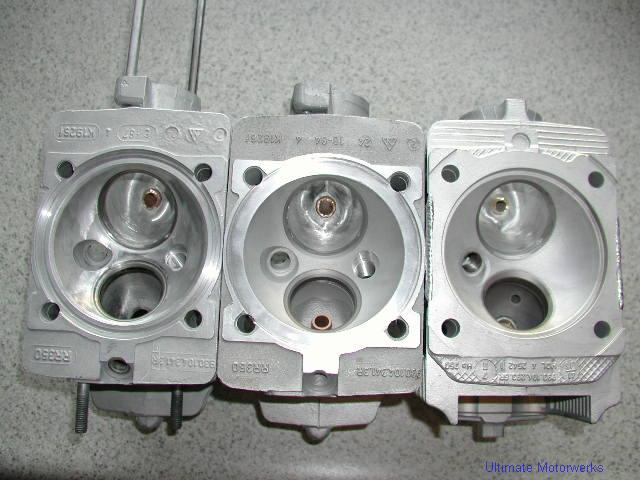

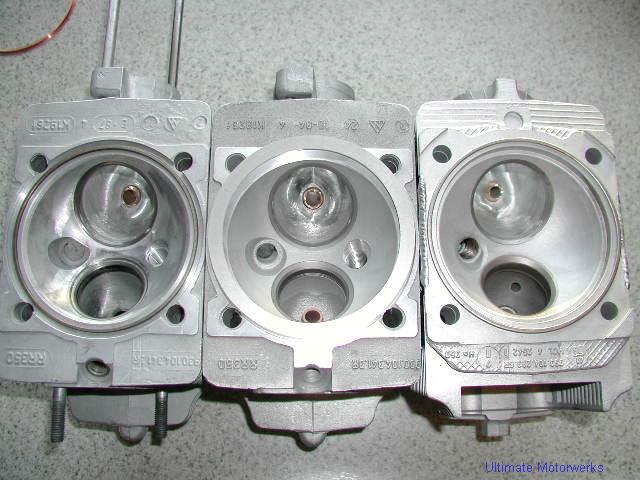

I will try to show with pictures and a few cylinder heads the different methods used to seal the cylinder heads to the cylinder liner. If one looks closely at this next picture you can actually see how there is a step or protrusion where the 993 TT piston goes into the cylinder head at TDC.

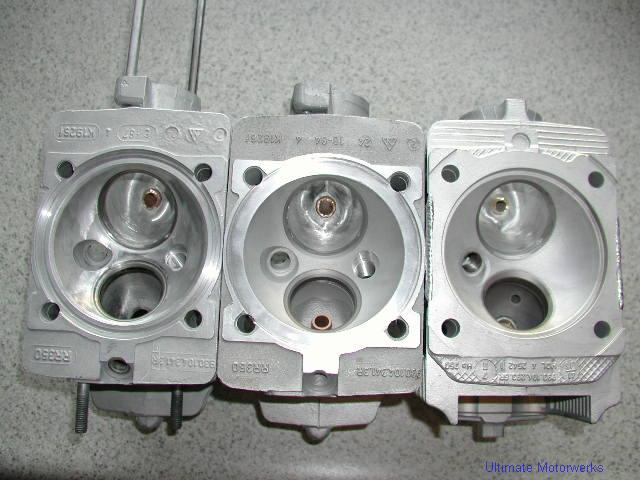

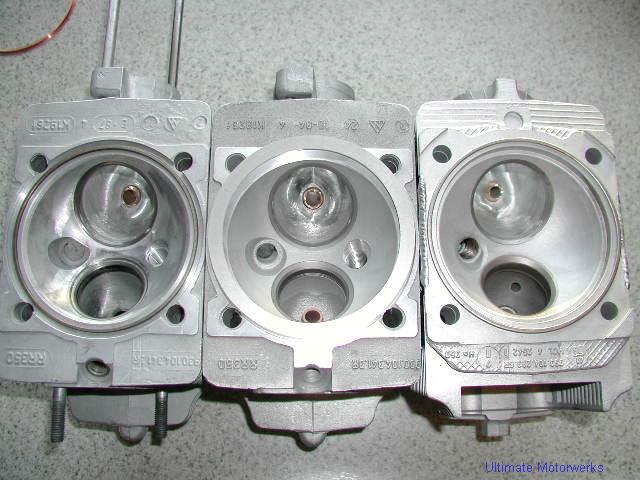

The far left head is a 930 head with the traditional ni-risist or niro ring system cut into the cylinder head. Basically the ring was a high nickel steel ring designed to lock the head and cylinder together. This system worked well to lock the head and to prevent a blow-out/burn through. It does work well but it's weakness is preventing long term solutions for sealing.. The middle head is also a 930 head, but has a C2 style sealing ring machined into the head. There is a pronounced step in this design that does provide a mechanical lock and a added bonus of a gasket type seal.. The right head is a 993TT, it has no provision for a sealing ring or locking gasket in the head, but it does have a metal crush oring that is set in the liner..

The above picture shows that actual sealing rings used in there application. You can see the metal sealing ring used on the TT.

Next is a picture that shows the different cylinder used on the turbo engines.

The top row from left to right show a '94 3.6ltr turbo liner and the sealing ring which is similar to the one used on the TT. The middle cylinder is a stock 993TT with my new copper stepped "L" Evo sealing ring. The right cylinder is a 102mm or 3.8ltr with a factory EVO stepped "L" ring. These rings provide a physical lock, and a flat sealing surface to provide a head gasket effect. This is as good as it gets. Now in 1995 aluminum was used for the gasket, many race shop use the same thing today, however, I used copper because it will withstand higher temperatures, structurally stronger at higher temps, and will provide a better seal between the two surfaces. The better sealing results occur because it is softer and crushes easier. These little jewels are difficult to machine. Copper does not machine easily, it wants to tear. Newer cutting tools have enabled shops today to machine this alloy with greater tolerances vs turning junk parts..

The lower row shows the 930 liner with the C2 style head gasket and the Nirosist rings installed.

This is a close up of the different rings that are installed/used.. One must remember that as we increase the boost pressure and cylinder pressure we do increase heat and the material expand at different rates. Porsche did a awesome job when the designed the piston and allowed it to contain the combustion process inside of the cylinder head dome. For the record, Ollies Machine in LA, does all of my cylinder head twin-plugging. They also invented/perfected the C2 sealing ring concept on turbo engines.. Andial uses Ollies for a majority of there machine work. You can see the 930 head that were twin-plugged by them. I however do my own porting and polishing, I will do all the machine work for the sealing rings, and head surfacing. I failed to mention earlier that that a small groove must be machined into the cylinder heads to accept the leg of the "L". This will allow the gasket to lock the head to the cylinder liner..

The far left head is a 930 head with the traditional ni-risist or niro ring system cut into the cylinder head. Basically the ring was a high nickel steel ring designed to lock the head and cylinder together. This system worked well to lock the head and to prevent a blow-out/burn through. It does work well but it's weakness is preventing long term solutions for sealing.. The middle head is also a 930 head, but has a C2 style sealing ring machined into the head. There is a pronounced step in this design that does provide a mechanical lock and a added bonus of a gasket type seal.. The right head is a 993TT, it has no provision for a sealing ring or locking gasket in the head, but it does have a metal crush oring that is set in the liner..

The above picture shows that actual sealing rings used in there application. You can see the metal sealing ring used on the TT.

Next is a picture that shows the different cylinder used on the turbo engines.

The top row from left to right show a '94 3.6ltr turbo liner and the sealing ring which is similar to the one used on the TT. The middle cylinder is a stock 993TT with my new copper stepped "L" Evo sealing ring. The right cylinder is a 102mm or 3.8ltr with a factory EVO stepped "L" ring. These rings provide a physical lock, and a flat sealing surface to provide a head gasket effect. This is as good as it gets. Now in 1995 aluminum was used for the gasket, many race shop use the same thing today, however, I used copper because it will withstand higher temperatures, structurally stronger at higher temps, and will provide a better seal between the two surfaces. The better sealing results occur because it is softer and crushes easier. These little jewels are difficult to machine. Copper does not machine easily, it wants to tear. Newer cutting tools have enabled shops today to machine this alloy with greater tolerances vs turning junk parts..

The lower row shows the 930 liner with the C2 style head gasket and the Nirosist rings installed.

This is a close up of the different rings that are installed/used.. One must remember that as we increase the boost pressure and cylinder pressure we do increase heat and the material expand at different rates. Porsche did a awesome job when the designed the piston and allowed it to contain the combustion process inside of the cylinder head dome. For the record, Ollies Machine in LA, does all of my cylinder head twin-plugging. They also invented/perfected the C2 sealing ring concept on turbo engines.. Andial uses Ollies for a majority of there machine work. You can see the 930 head that were twin-plugged by them. I however do my own porting and polishing, I will do all the machine work for the sealing rings, and head surfacing. I failed to mention earlier that that a small groove must be machined into the cylinder heads to accept the leg of the "L". This will allow the gasket to lock the head to the cylinder liner..

Last edited by Kevin; 02-16-2006 at 01:21 AM.

Trending Topics

#8

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

Thread Starter

Thanks, Simon, my rings are solid single piece patterned after the EVO flame rings. PD uses the two ring setup and with the 993TT they provide a third ring as a filler. Different methods for different applications.. I did want to use the copper, as both of us agree, it will seal better.. Another note, these copper rings (EVO flame rings) can be used in the '94 3.6T engine and 993 normally aspirated engine applications in 100mm and 102mm engine builds..

#9

There are many ways to do this. great work. Glad to see good engineering again. I have seen an engine run at "huge" boost, 5.5B, on special fuel, then run very rich at this pressure. The Heads were removed and the Chambers and Piton Tops were jet black with fuel. There were no signs of leaks. Perfect round balck circles. This technology works. Well done. BTW, be very careful of the Crank. The GT3 Cranks do not like continuous high RPM's, like most of the Flat cranks. I have seen several Cranks that broke when run above 8500 and some were run above 9000 RPM. If I remember, the balance requirement change for this higher RPM. I think it was due to the harmonics with no Dampner fitted. Fitting one of these was the cure if I remember. If you need more info, ask Neil, he has plenty of samples in 2 pieces.

#11

I built a big type IV engine many years ago with the 104mm pistons and 10.5:1 compression. Couldn't keep the heads on so welded up the last fin like you did. Made the engine run hotter and still didn't work. Ended up having to modify the heads & case to run a 5th head stud...that fixed the problem.

Like always Kevin...your stuff looks awesome. I'm enjoying the thread.

Like always Kevin...your stuff looks awesome. I'm enjoying the thread.

#13

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

Thread Starter

Left to right- 98mm 930 piston

100mm '94 965 3.6T

100mm 993TT

102mm 3.8ltr 993TT

For those that want to know..

Here are the weights for the pistons..

930 472 grams

965 418 grams

100mm 993TT 427 grams or 15.1 oz

102mm 3.8 456 grams

Wrist Pins weights

930 128 grams

965 134 grams

993TT 120 grams

102mm 120 grams

The ringsets weight are 33 grams for the 965 and 993TT with 38 grams for the larger 102mm 3.8ltr..

Since this project is about a lightweight rotating assy, I have removed 11grams of weight from the stock 993TT pistons with minor grinding/polishing, similar to what is used when you lighten up pistons for balancing. I am planning on tapering the inside ends of the wrist pins to lighten them up a bit..

Last edited by Kevin; 02-16-2006 at 03:37 AM.

#14

Kevin,

Looking forward to continous reading of this thread. This is as juicy as it gets

I somehow feel that this is a few notches above the average DIY

I've got two questions:

1.) You mentioned before that you where looking for Secan cores for intercoolers. Do you have any idea on what intercooler you will run with this application?

2.) Regarding the high rev engine. Do you have an estimate on what the power band would be? I can clearly see a benefit if it would be wider and hopefully with a smooth movement from turbo lag to peak.

Looking forward to continous reading of this thread. This is as juicy as it gets

I somehow feel that this is a few notches above the average DIY

I've got two questions:

1.) You mentioned before that you where looking for Secan cores for intercoolers. Do you have any idea on what intercooler you will run with this application?

2.) Regarding the high rev engine. Do you have an estimate on what the power band would be? I can clearly see a benefit if it would be wider and hopefully with a smooth movement from turbo lag to peak.