Timing chain cover material ?

#19

Rennlist Member

Are you sure about that? The timing chain case is magnesium and the covers used on the 993 were introduced in 1989 with the 964 but Dupont (they designed the Zytel valve covers for the 993) and Porsche only got together after that? The covers feel like the same material as the case and when they break they look like a (shiny/speckled) metal. You also can't push a red hot pin through the covers...

Exposed magnesium without proper protection will disintegrate in a few years especially in extreme environments. The fans are magnesium and are coated albeit not as well as they should be and as many have learned the hard way will disintegrate if debris hits the edge while spinning and exposes the raw casting to the elements.

What you posted appears to be a factory document although I find it hard to believe that these are magnesium alloy.

#20

Rennlist Member

I think I got the info two years ago from Porsche system at dealer with the name of the actual manufacturer of the covers. I did not guess the bakelite word, must have come from somewhere.

I will look next time there.

Since I am in finance for 24 years now, and work essentially with figures. I think the covers weighted just less than 300 grams each.

I will look next time there.

Since I am in finance for 24 years now, and work essentially with figures. I think the covers weighted just less than 300 grams each.

#21

Technical Guru

Rennlist Member

Rennlist Member

I've just never seen anything from Porsche that specifically says, "these covers are magnesium", only the cases themselves. And short of burning/igniting the covers I wouldn't know how to tell the difference. I've held the cover and the cases in each hand, i've tried pushing a red hot pin into them (to test for plastic) and I've seen them cracked.

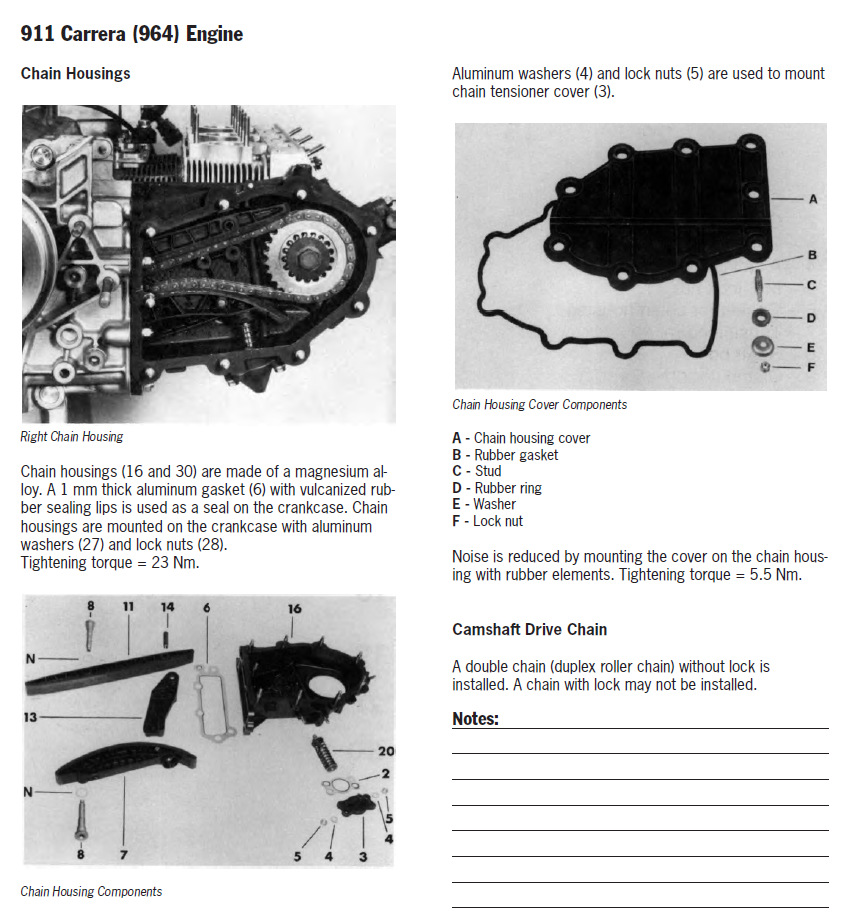

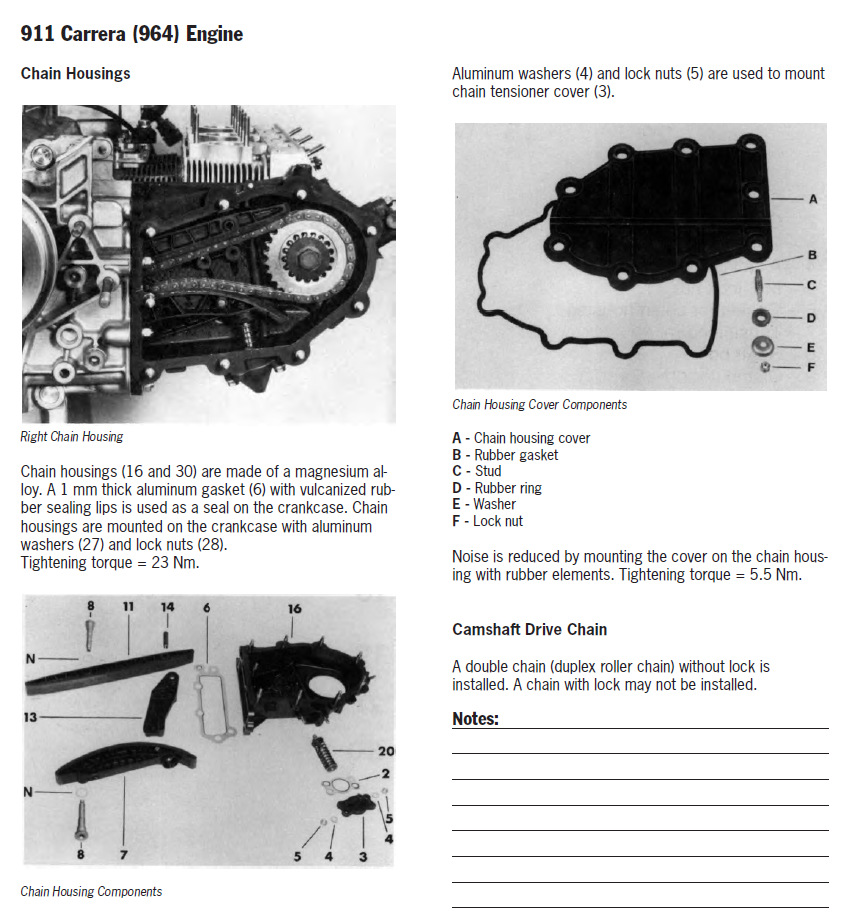

It is a screen-shot from the air cooled 964/993 engine repair manual from Porsche.

#22

Addict

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Would anyone like me to take a file to one and photograph the result? All the ones that I have seen are definitely some form of light aluminium/magnesium alloy, I know plastic when I see it and these are not plastic. The covers and housings are not bare metal, they do have some form of surface treatment, perhaps hard-anodised or similar, and are hence not prone to corrosion.

#23

Rennlist Member

Would anyone like me to take a file to one and photograph the result? All the ones that I have seen are definitely some form of light aluminium/magnesium alloy, I know plastic when I see it and these are not plastic. The covers and housings are not bare metal, they do have some form of surface treatment, perhaps hard-anodised or similar, and are hence not prone to corrosion.

This would make sense because it is both strong and far less susceptible to corrosion. Magnesium has many pros but holding up to the elements is not one of them. Unfortunately I no longer have the certifications otherwise i would post a copy of the certification.

#24

Technical Guru

Rennlist Member

Rennlist Member

I had sent JasonAndreas a response to a PM he sent me earlier apparently the TC covers including the valve covers on the 964 (not 993 which are some form of glass fibered Polyamide) are listed as magnesium in the document he referenced... What I found with the valve covers was they were made of an alloy that I have no record of but were predominantly Aluminum with high levels of Magnesium not unlike an alloy which never caught on called Almag35. I would consider it an aluminum alloy since the majority of the composition consisted of aluminum although many refereed to it as magnesium. I must assume they used the same alloy for both.

#25

Rennlist Member

There is no chemical conversion or anodizing that I am aware of that would not break down after a couple of years that would hold up to the elements as long as these parts have. A simple slip of the wrench or scratch with a screw driver would expose the magnesium and once that occurs just the moisture in the air is enough to start the corrosion process.

I know Porsche used magnesium alloys up through the 70's on the production cars but I believe other than the fans they stopped on most parts. Such parts like the fan shroud for a 914 or the covers and case halves on the earlier 911's but as you know finding surviving parts in good condition is rare. Even the wheels on my friends 935 and rear tranny and support on his 962 are constantly corroding requiring refinishing in environmentally controlled garage.

None of these parts exhibit what I am accustomed to seeing regarding magnesium. Here is a picture of two mag samples of navy grade low corrosion magnesium AZ91ET6 one coated and one not look at what 120 hours of salt fog testing can do and this is to simulate one year at sea. I can only imagine we would be seeing far bigger corrosion issues by now with these parts if they were magnesium. Cross section under 500X magnification

#26

Bringing this back from the dead. My engine is not going to look like poop with crusty old covers and at $250 each new, I am going to ceramic high-temp paint mine. Here is a cover bead blasted next to one that was scrubbed as clean as I could get it.

#27

Seared

Rennlist Member

Rennlist Member

I've refinished my covers, as well as three other sets for Rennlisters. In each case I bead blasted the outside of the covers (only) and washed them in hot soapy water. Once dry, I wiped the surface down with a prep solvent. Then the covers received a few light coats of etch primer followed by three coats of engine paint (in this case, DupliColor 'Cast Coat').

No issues with the finish after a few years of use.

Andreas

#28

That looks great Andreas. Good to know that paint can hold up.

Did you notice the very rough and slightly piited inner gasket mating surface on these covers? Could it contribute to the fact that these things perpetually leak?!

Did you notice the very rough and slightly piited inner gasket mating surface on these covers? Could it contribute to the fact that these things perpetually leak?!

#29

Seared

Rennlist Member

Rennlist Member

Andreas

Last edited by AOW162435; 07-25-2017 at 08:42 AM.

#30

Rennlist Member

Has anyone figured out what coating Porsche used on these and why they used it here but not on other similar parts? Apparently the earlier cars the timing chain covers are magnesium and considering how well they held up over the years the coating did a great job.