Suspension and clutch advise

#1

I have a couple of things on my winter project list. I could use a little insight from the guys that know.

I am going to change the clutch. What is the optimal procedure. Engine out or transmission out? Or both? If the engine is coming out then I will look at doing the SAI ports while accessible.

Now that I am doing the clutch, what about a lightweight flywheel? What brand and where do you suggest I get one?

In addition to those upgrades I already have the Bilstein HD shocks and H&R springs and sway bars that will go in at the same time.

Working on a chip. I understand that a 96 C2 is not so easy.

Thanks in advance

Ron

Canada

I am going to change the clutch. What is the optimal procedure. Engine out or transmission out? Or both? If the engine is coming out then I will look at doing the SAI ports while accessible.

Now that I am doing the clutch, what about a lightweight flywheel? What brand and where do you suggest I get one?

In addition to those upgrades I already have the Bilstein HD shocks and H&R springs and sway bars that will go in at the same time.

Working on a chip. I understand that a 96 C2 is not so easy.

Thanks in advance

Ron

Canada

#2

Technical Guru

Rennlist Member

Rennlist Member

Originally Posted by RustyRotors

I am going to change the clutch. What is the optimal procedure. Engine out or transmission out? Or both?

Originally Posted by RustyRotors

what about a lightweight flywheel? What brand and where do you suggest I get one?

Originally Posted by RustyRotors

Working on a chip. I understand that a 96 C2 is not so easy.

#3

Fitting a lightweight clutch to a 993 that uses the standard dual mass is not a good plan. The engine management doesn't know what to do with it, and the car can become quite undrivable.

Peter R.

Peter R.

#4

Originally Posted by Peter R.

Fitting a lightweight clutch to a 993 that uses the standard dual mass is not a good plan. The engine management doesn't know what to do with it, and the car can become quite undrivable.

Peter R.

Peter R.

#5

User experience with using LWF's in 993's varies wildly. I have been doing some research into the subject since I was interested in the conversion myself.

While it is true that some users experience no real problems, things like stalling, overshooting, kangooroo effect etc. have been reported. The major problem with these issues is that there seems to be no guaranteed fix except for a complete ECU swap or reprogramming.

Since there seems to be no sure fire road to success, I thought I'd warn you good folks.

Peter R.

While it is true that some users experience no real problems, things like stalling, overshooting, kangooroo effect etc. have been reported. The major problem with these issues is that there seems to be no guaranteed fix except for a complete ECU swap or reprogramming.

Since there seems to be no sure fire road to success, I thought I'd warn you good folks.

Peter R.

Trending Topics

#8

Rennlist Member

Very occasional stalling, largely if you're not paying attention. Can be tempered by a chip (1995) or judicious adjustment of the ISV. More than worth the trouble for the increased throttle response, acceleration (small change), and much quicker/easier rev matching. IMO!

#9

Drifting

If a couple of 10th's of a second mean so much, by all means install a LWF, but if you're a street based 993 it's essentially a waste of money.

I always say, "learn to drive the car correctly first, then do mods as you skill level increases"

and trust me, it takes a certain amount of skill to take Porsche 911's to the outside of their performance envelope and survive.

ZP44

I always say, "learn to drive the car correctly first, then do mods as you skill level increases"

and trust me, it takes a certain amount of skill to take Porsche 911's to the outside of their performance envelope and survive.

ZP44

#10

Addict

Rennlist Member

Rennlist Member

Join Date: May 2004

Location: Los Angeles

Posts: 2,124

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by ZombiePorsche44

If a couple of 10th's of a second mean so much, by all means install a LWF, but if you're a street based 993 it's essentially a waste of money.

I always say, "learn to drive the car correctly first, then do mods as you skill level increases"

and trust me, it takes a certain amount of skill to take Porsche 911's to the outside of their performance envelope and survive.

ZP44

I always say, "learn to drive the car correctly first, then do mods as you skill level increases"

and trust me, it takes a certain amount of skill to take Porsche 911's to the outside of their performance envelope and survive.

ZP44

#11

Guru

Lifetime Rennlist

Member

Rennlist Small

Business Sponsor

Lifetime Rennlist

Member

Rennlist Small

Business Sponsor

Originally Posted by Peter R.

Fitting a lightweight clutch to a 993 that uses the standard dual mass is not a good plan. The engine management doesn't know what to do with it, and the car can become quite undrivable.

Peter R.

Peter R.

Only the OBD1 993's sometimes struggle with stalling. Driver habits can easily overcome this issue, artificially helping the OBD1 idle circuit recovery.

#12

I will skip the lightweight flywheel.

I do have access to hoist/tools so not an issue there. I have a creaking/squeaking noise coming from the clutch (internal) when depressed. Probably in the release mechanism. If I am going in for that I might as well replace the clutch while I am there. If I don't have to drop the engine to do it I would rather not. I only ask so that I can get a prelim list of parts that I expect I will need. If the engine is not coming out then I will skip all the SAI stuff etc..

I am doing suspension so an alignment is happening anyway.

Thanks again.

- Ron

I do have access to hoist/tools so not an issue there. I have a creaking/squeaking noise coming from the clutch (internal) when depressed. Probably in the release mechanism. If I am going in for that I might as well replace the clutch while I am there. If I don't have to drop the engine to do it I would rather not. I only ask so that I can get a prelim list of parts that I expect I will need. If the engine is not coming out then I will skip all the SAI stuff etc..

I am doing suspension so an alignment is happening anyway.

Thanks again.

- Ron

#13

Guru

Lifetime Rennlist

Member

Rennlist Small

Business Sponsor

Lifetime Rennlist

Member

Rennlist Small

Business Sponsor

You may wish to replace the clutch slave cylinder before tearing into the clutch etc. Unless of course your clutch is slipping??

Creaking is common and usually fixed with a new slave cylinder. These can be replaced without removing the engine/trans..

Creaking is common and usually fixed with a new slave cylinder. These can be replaced without removing the engine/trans..

#14

Rennlist Member

I had done exactly what you are doing. Debated the whole flywheel thing. Tons of info using the search. I went with the LWF and don't regret it at all. NO STALLING--not once yet at 5K miles after install. Unless you have a 95' IMHO (and personal experience) you will never experience a stall with a LWF.

While the motor & tranny were out I did a top end rebuild and the SAI ports were plugged big time. I had a code telling me 4, 5 & 6 were plugged, but after seeing the other side, it wouldn't have been long. Here is a picture of the DMF (huge-heavy piece of junk) and the clutch that was worn down to the rivits.

While the motor & tranny were out I did a top end rebuild and the SAI ports were plugged big time. I had a code telling me 4, 5 & 6 were plugged, but after seeing the other side, it wouldn't have been long. Here is a picture of the DMF (huge-heavy piece of junk) and the clutch that was worn down to the rivits.

#15

Technical Guru

Rennlist Member

Rennlist Member

Originally Posted by RustyRotors

I have a creaking/squeaking noise coming from the clutch (internal) when depressed.

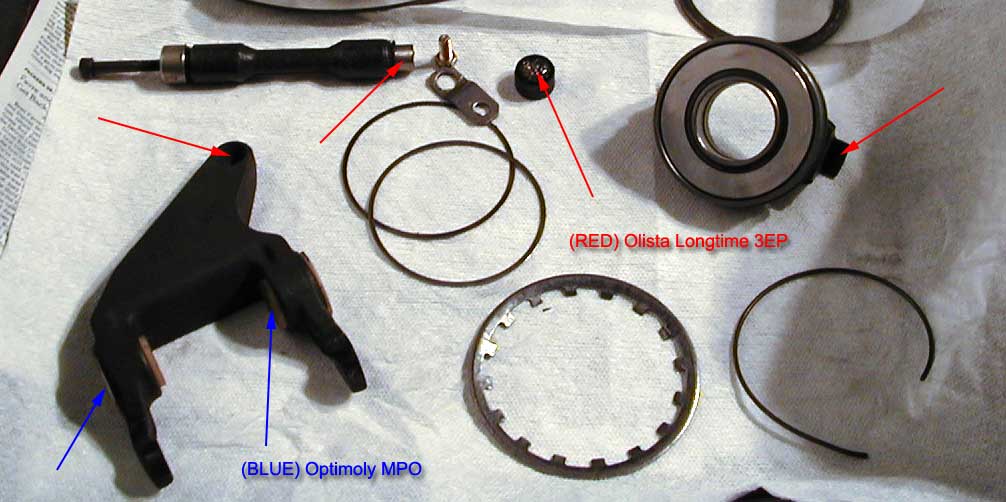

1) The release fork receiving cup for the slave cylinder can run dry causing metal-to-metal contact. The solution is to put Olista Longtime 3EP into the cup.

2) The clutch slave cylinder; you can pop out the metal plunger by unbolting the slave cylinder from the bellhousing and then pushing down on the clutch pedal. Brake fluid will come out with the plunger so be very careful. Take the metal cylinder/plunger and lubricate it with Klüberfluid 9 R 100 and then reinstall the plunger into the slave cylinder. The rubber dust boot is held with a ring (visible in the photo below on the opposite side of the bleeder valve) that you can lock back into place without too much trouble. Usually people just replace the slave cylinder altogether.

3) The guide sleeve that covers the input shaft can be lubed with Olista Longtime 3EP if you have a LWF release bearing or Optimoly MPO if you have a DMF release bearing (with plastic insert). There is no reason you can't use the 3EP with the DMF its just that MPO is more compatible with polyamide. This requires you to separate the engine from the transmission.

Originally Posted by RustyRotors

I am doing suspension so an alignment is happening anyway.

!

!