Removing rusted /broken studs in the turbo

#61

Burning Brakes

To lock the crank I employed a helper, put the car in gear, wedged the discs against the calipers so that they could not rotate, and had the helper stand on the brake pedal. I would guess the proper way of doing it would be to somehow directly prevent the flywheel from rotating, but I couldn't figure out how to do that.

The impact gun didn't work for me - I ended up using a 3 foot long breaker bar instead. Fitting is reverse process, but I did put a little thread lock on the bolt before setting the torque on it - it tightens much easier than it comes off!

Edit: The small o-ring behind the intermediate shaft cover plate was 99970731540. It's a very simple, plain o-ring.

Last edited by Megatron-UK; 04-02-2024 at 05:25 AM. Reason: 99970728541

#62

Thanks, that is very helpful, just dont want to damage the engine in any way when removing the crank bolt, i will give it a shot with the impact if not it will be the bar

Now that I have removed the broken studs from the turbo, took me nearly six hours of drilling and tapping four studs, might try putting some titanium ones in, so that i never have this problem again. I am at the point where I need to remove then engine brace and crank pulley cover.

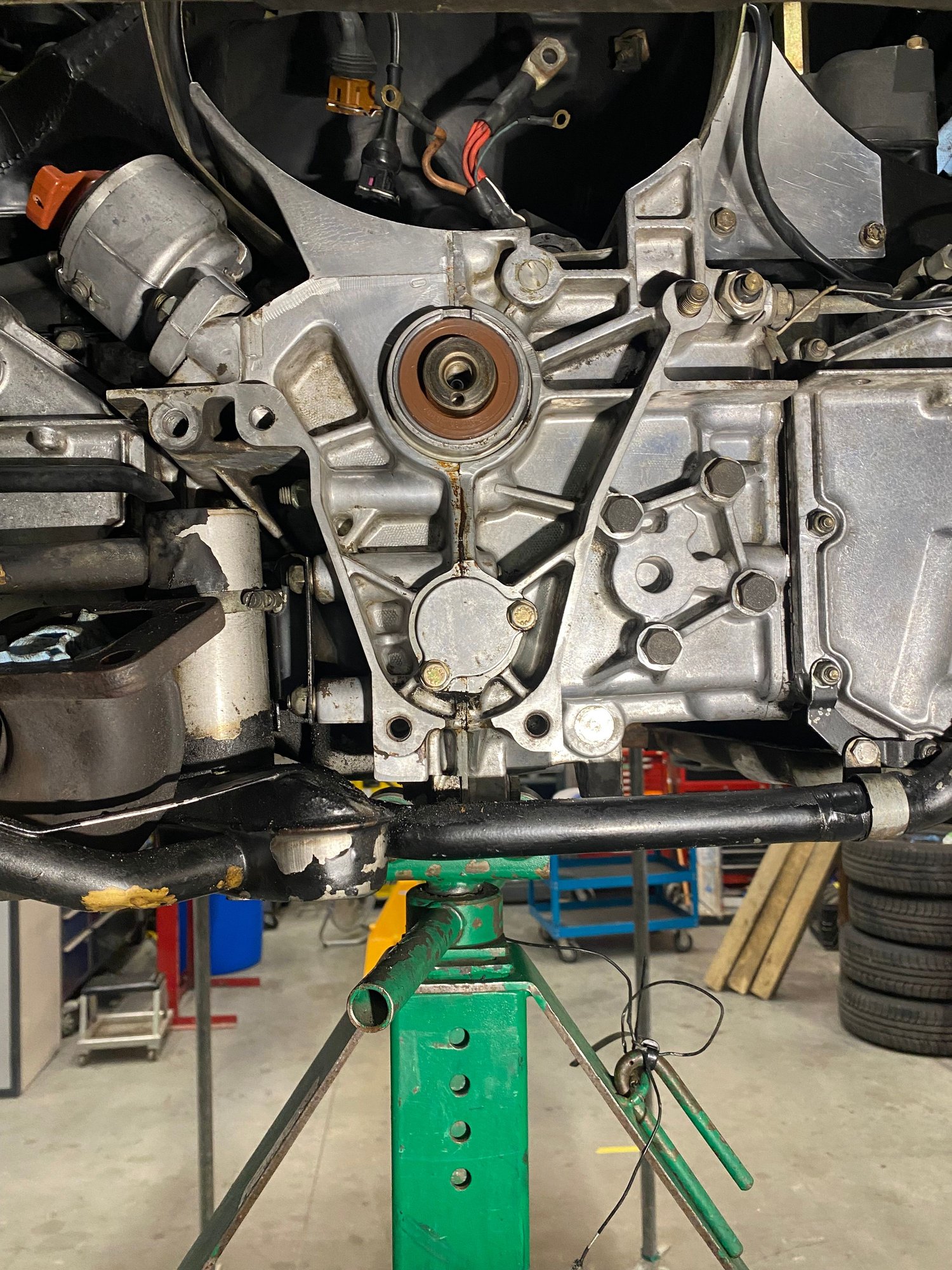

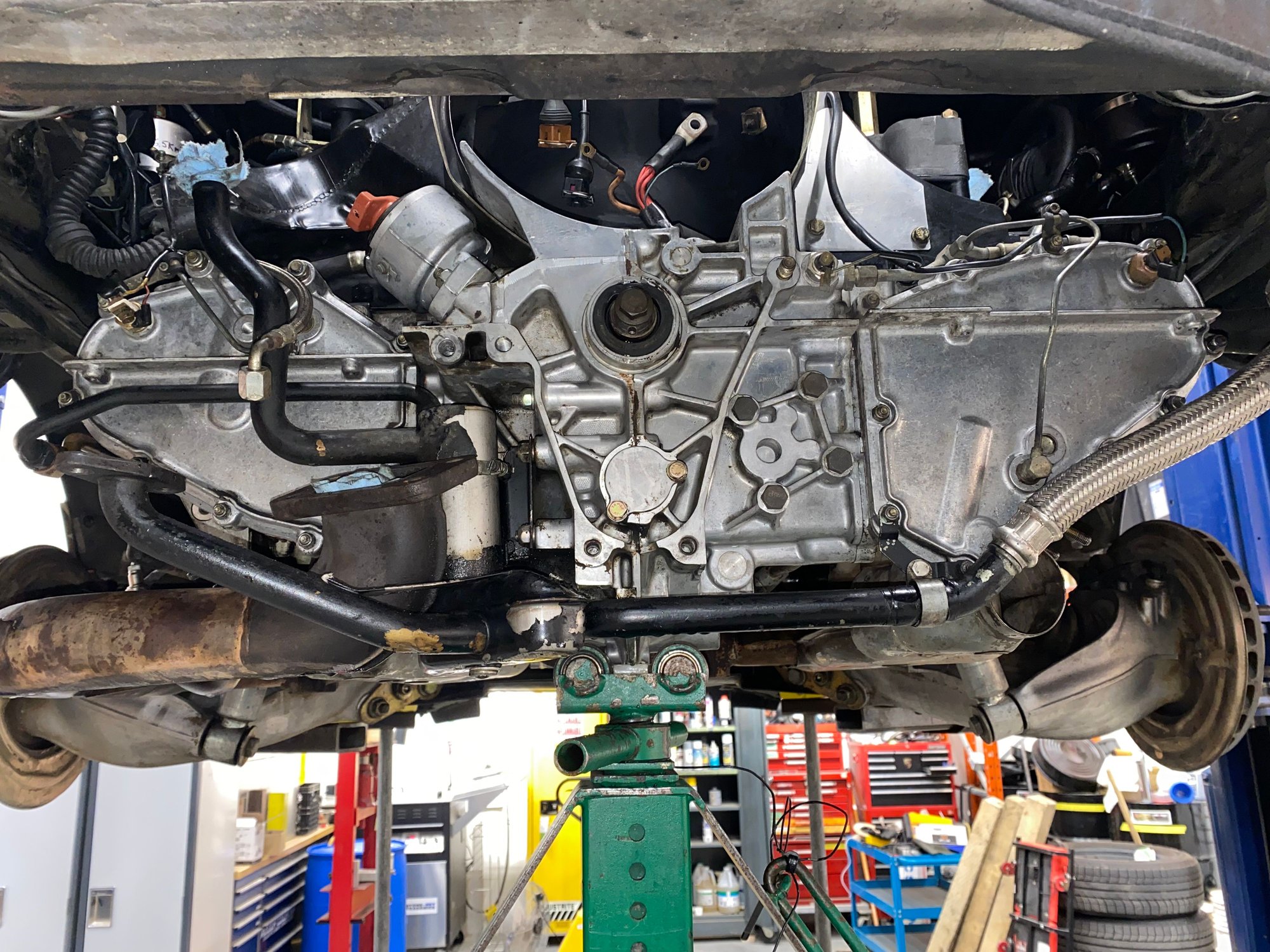

1. Is the crank pulley cover responsible for holding the engine up as i see it is bolted by 4 bolts against the engine brace, Do I have to remove any internal bolts in the crank pulley case

2. Why do i need to drop the engine 6 inches down, it seems once the brace is removed there is good access to the pulley and crank and intermediate shaft seal

3. I have had read again, of how you jacked up and supported the engine, I had a closer look at the engine today, are you rubber blocks on the two round raised points on either side of the engine, i believe there is a large drain plug next to it

4, Whilst lifting the engine to put in the axle stands and take the weight off whilst unding the crank cover bolts to brace or dropping it slightly, using the jack, I assume the jack is placed in the centre, is this ok or can it cause any problems to the engine

Now that I have removed the broken studs from the turbo, took me nearly six hours of drilling and tapping four studs, might try putting some titanium ones in, so that i never have this problem again. I am at the point where I need to remove then engine brace and crank pulley cover.

1. Is the crank pulley cover responsible for holding the engine up as i see it is bolted by 4 bolts against the engine brace, Do I have to remove any internal bolts in the crank pulley case

2. Why do i need to drop the engine 6 inches down, it seems once the brace is removed there is good access to the pulley and crank and intermediate shaft seal

3. I have had read again, of how you jacked up and supported the engine, I had a closer look at the engine today, are you rubber blocks on the two round raised points on either side of the engine, i believe there is a large drain plug next to it

4, Whilst lifting the engine to put in the axle stands and take the weight off whilst unding the crank cover bolts to brace or dropping it slightly, using the jack, I assume the jack is placed in the centre, is this ok or can it cause any problems to the engine

Last edited by 911 2; 04-02-2024 at 04:52 PM.

#63

I used Copper anti-seize on this 965 22 years ago. The car was stored outside in Canada. Everything came apart with no issues.