The Elephant in the Room - #2 Rod Bearing Failures

#31

Drifting

Join Date: Aug 2009

Location: Bangkok, Thailand, Milpitas, CA & Weeki Wachee, FL

Posts: 2,239

Likes: 0

Received 2 Likes

on

1 Post

Actually your previous comment about an external electric oil pump used as a pre-oiler prior to start up is an idea I have been toying around with for years. This is off subject, but a very good idea for engine longevity, as nearly all wear is generated during startup.

#33

how about running another oil pump on the back of a modified balancing shaft to drive it. that would be cool!. It may seem far fetch, but with some R & D it could be done. it could became a dry sump. you could even leave the OEM pump as a scanning pump , used the new one for pressure only. any thoughts?

Regards,

AL

Regards,

AL

#34

Rennlist Member

Thread Starter

#35

Addict

Rennlist Member

Rennlist

Small Business Partner

Rennlist Member

Rennlist

Small Business Partner

I am working out more details, and testing. Hopefully, we can come up with a final solution to fix the 951/944 oiling system - since we now know what is wrong with it...

I will post more info, as I prepare and confirm our findings.

#36

Rainman

Rennlist Member

Rennlist Member

how about running another oil pump on the back of a modified balancing shaft to drive it. that would be cool!. It may seem far fetch, but with some R & D it could be done. it could became a dry sump. you could even leave the OEM pump as a scanning pump , used the new one for pressure only. any thoughts?

Regards,

AL

Regards,

AL

#37

With two Drivers Championships and two Motorkahana Championships in the bag along with countless lap records & a heap of customer 944 & 944S2 & 951's with class winning & Championship results with no crank/ connecting failures at all

The reason & answer/ Clue is simple ( its in the owners manual that came with the car )

Oil Viscosity & in turn oil film strength , in other words in the owners manual( oil vis page) it states( for road use of say a 944/ 944S / 944S2 / 951 / 968/ 928, from minus ten deg cel to Unlimited high ambient temps use a 20w-50 engine oil ( shaded look at me section )

This is a last century oil viscosity for a last century engine design , nothing wrong with that at all , its just a fact .

Here is my check list:

- Use a large oil cooler and keep oil temps below 260F

- Keep the oil clean and full

- Use the proper oil Viscosity

#39

Addict

Rennlist Member

Rennlist Member

The positive displacement Mocal electric oil pump also does pre-lubrication at 3bar and was bought at Batinc (http://97.74.32.155/files/pump.pdf).

Unfortunately it is noisy and annoying enough, that I typically am running without the pre-lubrication feature.

Laust

#40

Rainman

Rennlist Member

Rennlist Member

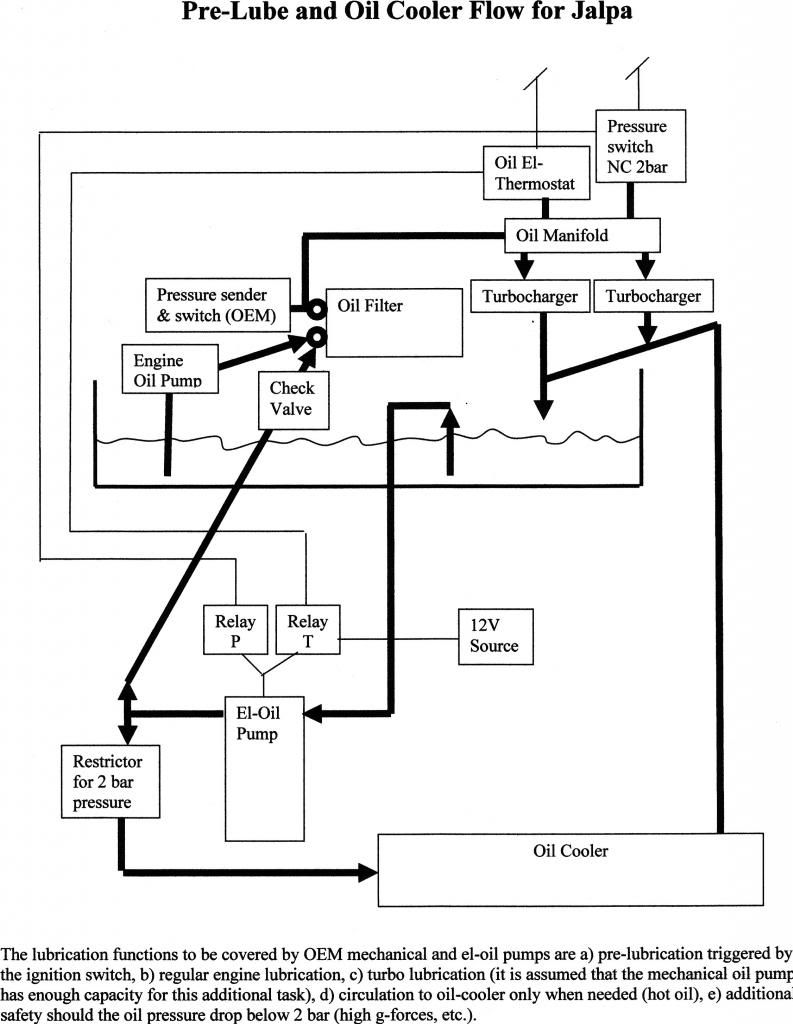

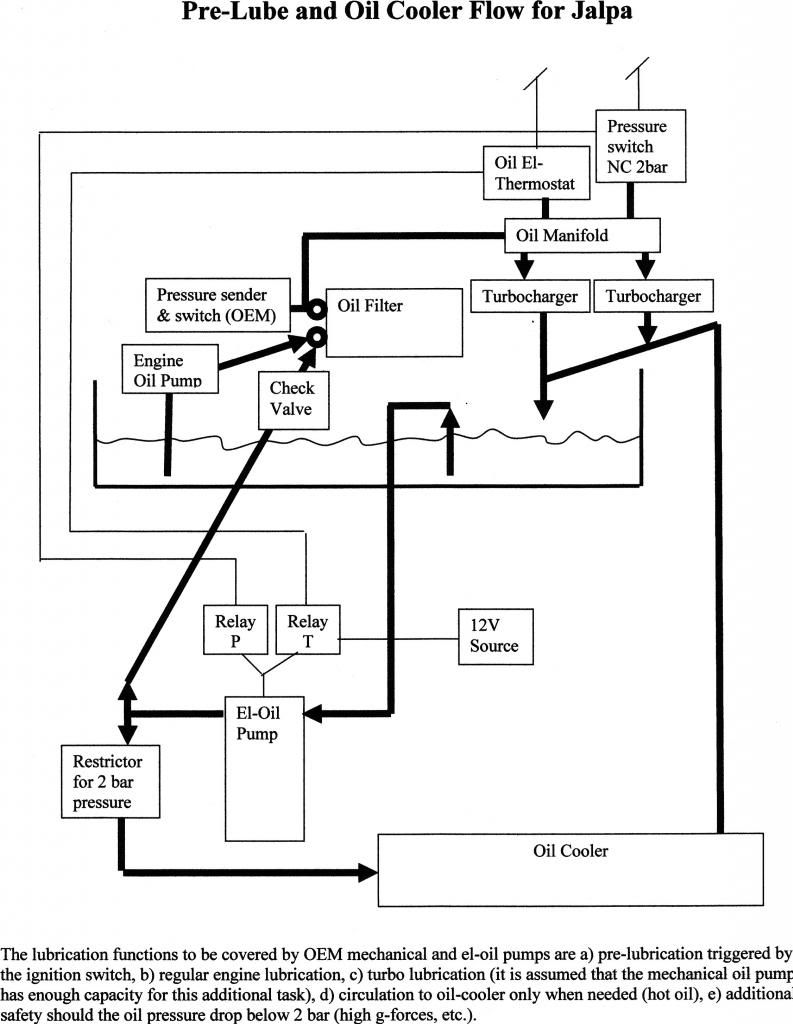

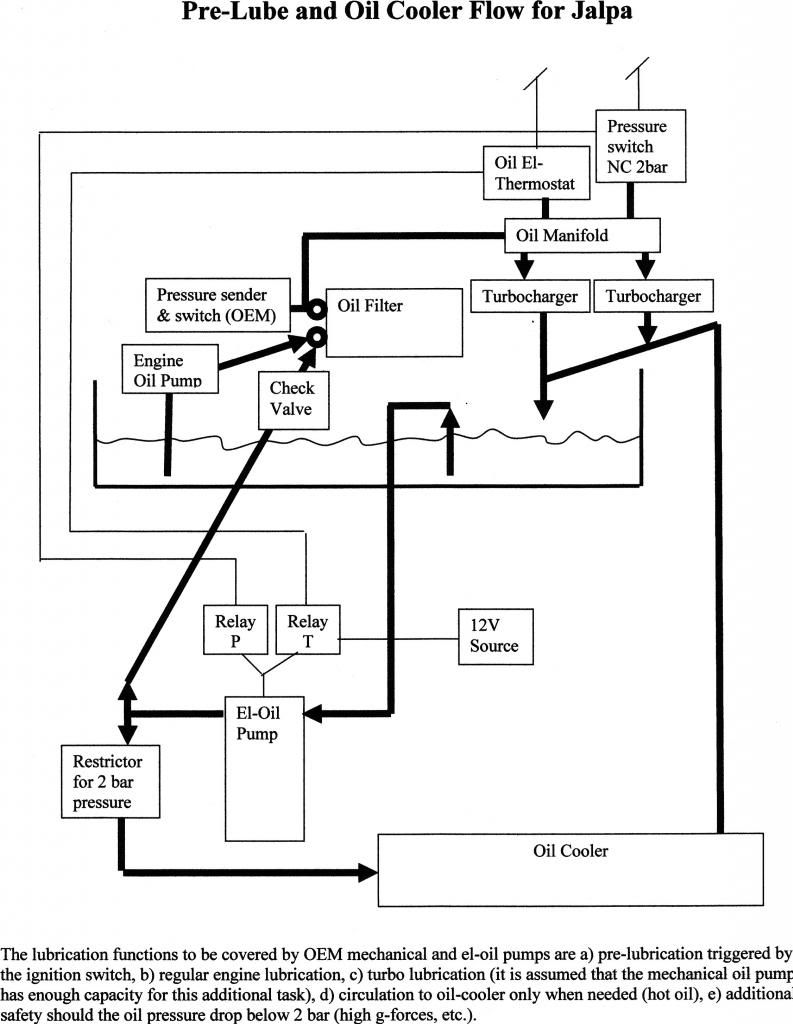

Something like this?

The positive displacement Mocal electric oil pump also does pre-lubrication at 3bar and was bought at Batinc (http://97.74.32.155/files/pump.pdf).

Unfortunately it is noisy and annoying enough, that I typically am running without the pre-lubrication feature.

Laust

The positive displacement Mocal electric oil pump also does pre-lubrication at 3bar and was bought at Batinc (http://97.74.32.155/files/pump.pdf).

Unfortunately it is noisy and annoying enough, that I typically am running without the pre-lubrication feature.

Laust

#41

Drifting

The top of the list for me would be to not run over the stock redline without a dry sump. I see a clear pattern that if you run over the stock redline, the risk of this failure goes up considerably. I personally am going to run my build at a lower max redline of 6400 rpm until I have a complete understanding of this failure.

Lart should have a few in his inventory. A street driven 944 turbo shouldn't ever see enough forces to cause issues as long as you check your stick daily. I used to check my oil level when I was about to start the car. Waiting for your oil light to shine RED in many cases is too late.

This issue is usually a motor that likes oil, and it's not checked with tenacity. Some of these older motors burn oil, and it needs to be filled to the upper mark on the stick fairly often. I used to keep two quarts in the wheel well compartments. Now I have subs there, and I keep it in the seat delete doors under where the stock seats used to live.

A few of the folks that used to be in the business and raced, actually added another .5 quart showing a bit above the top of the stick.

Dry sump is the best option, but this costs a few bucks and not necessary for those just wanting some fun on track days.

George

#42

Drifting

#43

Drifting

Regards,

George

#44

Addict

Rennlist Member

Rennlist Member

Essentially I substituted the OE cam driven pump dedicated for oil cooler duty with an electrical pump and thought it worthwhile adding the longevity and safety features to the installation.

Laust

#45

has anyone try to supply more oil to the #2 rod with a external oil supply line?......... I wounder if a pic of the oiling system for M44 engine is available

Regards,

AL

Regards,

AL