The Elephant in the Room - #2 Rod Bearing Failures

#76

Rennlist Member

Thread Starter

My thinking on this was reduced oil film thickness that did not result in metal to metal contact but resulted in poor pressure distribution over the bearing surface. Poor pressure distribution can result in high localized peak surface pressures that result in surface fatigue. Just a thought.

#77

Not sure a low friction coating (swain or other) protects from fatigue damage? I would have expected metal to metal contact due to lack of or reduced oil film to look somewhat different than this.

Currently running two mocal coolers in series, 13 row and 19 row. Have seen oil temps above 260F when running the straight KISS cooler setup. Engine got very hot during this past year's local club race, which is why I pulled the pan to replace the bearings. But again, this damage is not what I would have expected to see from high oil/engine temps (?).

Currently running two mocal coolers in series, 13 row and 19 row. Have seen oil temps above 260F when running the straight KISS cooler setup. Engine got very hot during this past year's local club race, which is why I pulled the pan to replace the bearings. But again, this damage is not what I would have expected to see from high oil/engine temps (?).

I always thought that Brad Pen 20/50 was a good oil, but then again it might be something else that caused this. There are just to many factors to consider. I which I had access to an experienced engineer that could analyse the 944 engine and come up with a final solution. To limit the risk I will try to use a 10/60 oil with a 50 row oil cooler, and keep boost limited under peak toque. This might not work, but it is worth a try.

#78

Rennlist Member

Why not a straight 50w or 60w race oil? Why go for something with what appears to be a wide range such as a 10w/60? There's no way that it acts as a 10w at cold start but somehow transforms to a 60w when hot. That's marketing.

#79

I agree, but this is also a car that is driven to the track and occasionally on the road, and a straight 60 oil is not an option. I would like a 20 or 25/60 oil, but have not found one for sale in Norway yet. Actually I where considering trying the Miller 10/60 Nano Tech oil.

#80

Drifting

Join Date: Aug 2009

Location: Bangkok, Thailand, Milpitas, CA & Weeki Wachee, FL

Posts: 2,239

Likes: 0

Received 2 Likes

on

1 Post

If it was a 10W-60 synthetic, it is based on a 60 grade base oil, and act like a 10 grade when at 212F/100C. Note: This is opposite of a mineral (dino) oil. However, it will still be less "honey" like at colder temperatures than a true mineral oil.

#81

Drifting

Join Date: Aug 2009

Location: Bangkok, Thailand, Milpitas, CA & Weeki Wachee, FL

Posts: 2,239

Likes: 0

Received 2 Likes

on

1 Post

I agree, but this is also a car that is driven to the track and occasionally on the road, and a straight 60 oil is not an option. I would like a 20 or 25/60 oil, but have not found one for sale in Norway yet. Actually I where considering trying the Miller 10/60 Nano Tech oil.

#82

Rennlist Member

I just don't trust oils that suggest some form of physics miracle. The wider the range of viscosity, the less likely it is to perform what they advertise. Not saying anything bad about Millers by the way. I'm intrigued and tempted by their offerings myself.

#83

Drifting

Join Date: Aug 2009

Location: Bangkok, Thailand, Milpitas, CA & Weeki Wachee, FL

Posts: 2,239

Likes: 0

Received 2 Likes

on

1 Post

Everything I have read about the Miller's is very positive. They have a lot of published test data, which is pretty convincing. However, it is pretty pricey and possibly overkill for most of our engines. On the other hand for race cars like yours Patrick, I think it is called for. Harry is the man to talk to about this though. He has a wealth of information. He also has a masters in engineering from GT, MIT of the south.

Long read on the subject, but has much good information.

http://www.bobistheoilguy.com/forums...Number=2727400

Long read on the subject, but has much good information.

http://www.bobistheoilguy.com/forums...Number=2727400

Last edited by URG8RB8; 04-20-2013 at 03:08 AM. Reason: Added Link

#84

Addict

Rennlist Member

Rennlist Small

Business Sponsor

Rennlist Member

Rennlist Small

Business Sponsor

Looks like its time to run down the ‘oiling problems’ list again!

Here are the problems (some covered already)

1) Heat

2) Aeration

3) Cavitation

4) Dumb *** 90 degree turn

Why?

1) Heat – thins out the oil and eventually breaks the oil down

2) Foam is a lousy lubricant

3) Spinning any pump too fast will cause cavitation and add air into the oil. See #2

4) Pumping a fluid around a 90 degree sharp bend is not a good idea – especially if it is in the crank!

The cause?

1) Even in stock form the 944 turbo really heats up the oil when used hard. Going to a heavier viscosity will only add to the heat – it may help with pressure but it will add heat.

2) Oil level and windage. If you need to see the ‘proof’ on this one then grab an oil pan and pour 5 quarts of water in it. Now simulate hard braking (1G is easily possible on the track) – to simulate 1G of braking tilt the front of the pan down 45 degree. Now that your feet are wet it’s a good time to point out that the crank is about ½” away from the pan near the front. This means that every time you brake hard you are sloshing the oil into a 6000 rpm blender. In addition to this the block and girdle add to the problem since they make all the air from each cylinder travel past the bottom of the girdle and then back up to the neighboring cylinder – right past the oil in the pan and the 6000rpm blender (nice example in previous post).

3) Oil pump design. Its not designed for high RPM use. There is no ‘motorsports’ pump…because Porsche used to believe that ‘real’ engines had dry sumps! Cavitation is made worse by heat and aeration.

4) Yes, the crank has drilled 90 degree angles front the mains to the rods. Clearly a dumb *** design. No easy fix!

What to do about it?

1) Add more oil cooling…..and then add some more after that!

2) Keep your oil level correct – too high is just as bad as too low. You will never uncover your pick up so oil ‘starvation’ is not a problem. The only plus to keeping the oil level as high as possible is more oil to cool the system, the down side is more aeration. I recommend ¾ of the way up the two marks on the dip stick. Windage trays are also a good idea, this will help to keep the oil in the pan and cut down a little on windage. The 3.0 blocks are much better at windage control – use one if you can.

3) Dry sump is the best solution for all problems. Not cheap and very hard to put into a street car. A compromise is an external belt driven oil pump, still not a street car solution. Other than that you are stuck with the stock oil pump.

4) Again, no cheap fix. The only fix is a custom made crank. The best way to deal with it is to minimize the aeration.

Worst case scenario is hot, thin, foamy oil. Anything you can do to minimize that is a good thing. Cross drilling is not a solution – getting oil to ‘flow’ better right at the #2 bearing won’t help because all the problems and the flow restriction (90 degree turn) is before the #2 bearing.

BTW – turning the crank down to the Chevy size has some merits – but it has to be done right. The heat treating on the stock crank is very good – it really helps with short term issues.

Here are the problems (some covered already)

1) Heat

2) Aeration

3) Cavitation

4) Dumb *** 90 degree turn

Why?

1) Heat – thins out the oil and eventually breaks the oil down

2) Foam is a lousy lubricant

3) Spinning any pump too fast will cause cavitation and add air into the oil. See #2

4) Pumping a fluid around a 90 degree sharp bend is not a good idea – especially if it is in the crank!

The cause?

1) Even in stock form the 944 turbo really heats up the oil when used hard. Going to a heavier viscosity will only add to the heat – it may help with pressure but it will add heat.

2) Oil level and windage. If you need to see the ‘proof’ on this one then grab an oil pan and pour 5 quarts of water in it. Now simulate hard braking (1G is easily possible on the track) – to simulate 1G of braking tilt the front of the pan down 45 degree. Now that your feet are wet it’s a good time to point out that the crank is about ½” away from the pan near the front. This means that every time you brake hard you are sloshing the oil into a 6000 rpm blender. In addition to this the block and girdle add to the problem since they make all the air from each cylinder travel past the bottom of the girdle and then back up to the neighboring cylinder – right past the oil in the pan and the 6000rpm blender (nice example in previous post).

3) Oil pump design. Its not designed for high RPM use. There is no ‘motorsports’ pump…because Porsche used to believe that ‘real’ engines had dry sumps! Cavitation is made worse by heat and aeration.

4) Yes, the crank has drilled 90 degree angles front the mains to the rods. Clearly a dumb *** design. No easy fix!

What to do about it?

1) Add more oil cooling…..and then add some more after that!

2) Keep your oil level correct – too high is just as bad as too low. You will never uncover your pick up so oil ‘starvation’ is not a problem. The only plus to keeping the oil level as high as possible is more oil to cool the system, the down side is more aeration. I recommend ¾ of the way up the two marks on the dip stick. Windage trays are also a good idea, this will help to keep the oil in the pan and cut down a little on windage. The 3.0 blocks are much better at windage control – use one if you can.

3) Dry sump is the best solution for all problems. Not cheap and very hard to put into a street car. A compromise is an external belt driven oil pump, still not a street car solution. Other than that you are stuck with the stock oil pump.

4) Again, no cheap fix. The only fix is a custom made crank. The best way to deal with it is to minimize the aeration.

Worst case scenario is hot, thin, foamy oil. Anything you can do to minimize that is a good thing. Cross drilling is not a solution – getting oil to ‘flow’ better right at the #2 bearing won’t help because all the problems and the flow restriction (90 degree turn) is before the #2 bearing.

BTW – turning the crank down to the Chevy size has some merits – but it has to be done right. The heat treating on the stock crank is very good – it really helps with short term issues.

#86

Rennlist Member

Thread Starter

#87

Burning Brakes

@Chris. This weekend I went to a motor shop to have my crank balanced. The guy builds opel engines, and kept saying I need to increase bearing clearnaces and also lateral clearances on the big ends. He warned that if the clearances are too tight to allow the oil to properly escape from the rod bearing journal not enough oil will flow and the oil that flows will overheat.

Have you ever experienced or seen any signs of this? I hope you don't mind me asking but what clearances do you recommend for a heavily tracked 300 RWHPish engine? My crank has already been lightly polished, so I guess the heat treatment is lost?

Also, i would like to add the oil return galleys from the head to your list of weak points. They are very very narrow, but worse the oil from the head is dropped directly onto the spinning cranck. This means that no oil what so ever (aprart from the turbo/upper balance shaft return) is allowed to return to the sump without going through "the blender". The 2.5L block is a foam making machine

A kickout on the oil pan on the right hand side could help with this problem. If anyone could just make a new and improved oil pan, deep enough to remove the need for the idioticly thick gasket, and with some proper oil return and windage solutions added. I believe such a product could be a great help and could possibly sell very well to those who want more safety but won't or can't run a dry sump system.

Have you ever experienced or seen any signs of this? I hope you don't mind me asking but what clearances do you recommend for a heavily tracked 300 RWHPish engine? My crank has already been lightly polished, so I guess the heat treatment is lost?

Also, i would like to add the oil return galleys from the head to your list of weak points. They are very very narrow, but worse the oil from the head is dropped directly onto the spinning cranck. This means that no oil what so ever (aprart from the turbo/upper balance shaft return) is allowed to return to the sump without going through "the blender". The 2.5L block is a foam making machine

A kickout on the oil pan on the right hand side could help with this problem. If anyone could just make a new and improved oil pan, deep enough to remove the need for the idioticly thick gasket, and with some proper oil return and windage solutions added. I believe such a product could be a great help and could possibly sell very well to those who want more safety but won't or can't run a dry sump system.

Last edited by bebbetufs; 04-22-2013 at 08:11 AM.

#89

Burning Brakes

From what I've heard they are great for improving the life span of the engine by improving oiling at cold starts, but they can't save the engine on track. They apparently react too slowly. There is a post in this thread by a guy who lost #2 with an accusump installed.

#90

Burning Brakes

Any interest in a new oil pan design?

I've been in contact with a few companies who design oil pans. Several have offered to make an improved aftermarket pan which can take care of some of the most severe windage problems and potentially increase the volume a bit. Please go to this thread if you are interested.

These are the basic specs:

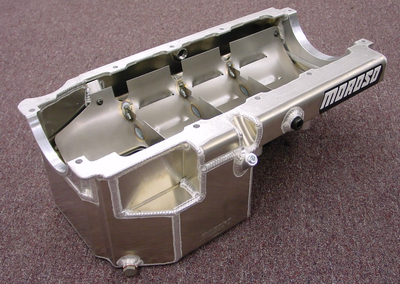

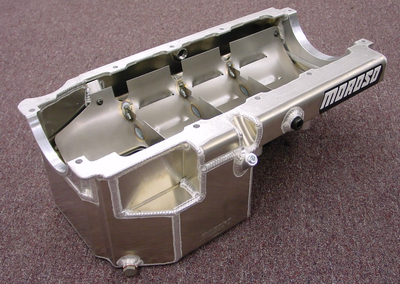

* Most importantly it will have a kick out on the right hand side to allow the oil returning from the head to escape the crank and return to the sump without following the crank around 270 degrees and foaming up. A bit like the kick out on this Moroso pan where the company logo is. This cick-out should work in conjunction with a scraper.

* Built in baflfing system with one-way ports to prevent oil from being sloshed onto the crank when braking, turning and accelereating.

* Integrated crank scrapers like the stock pan, but tighter (possibly teflon blades?).

* Much improved integrated windage tray with proper louvres to cut down on windage. Becuase the tray is installed in the pan it will not be necassary to split the block and ntefere with its integrity and the bearing clearances to install the windage tray. .

* Integrated gasket retainers to stop the gasket from pushing out.

We can also specify other improvements if we want to.

To get this moving we need to can get 10-15 people together in a group buy. Please go to this thread if you are interested.

I've been in contact with a few companies who design oil pans. Several have offered to make an improved aftermarket pan which can take care of some of the most severe windage problems and potentially increase the volume a bit. Please go to this thread if you are interested.

These are the basic specs:

* Most importantly it will have a kick out on the right hand side to allow the oil returning from the head to escape the crank and return to the sump without following the crank around 270 degrees and foaming up. A bit like the kick out on this Moroso pan where the company logo is. This cick-out should work in conjunction with a scraper.

* Built in baflfing system with one-way ports to prevent oil from being sloshed onto the crank when braking, turning and accelereating.

* Integrated crank scrapers like the stock pan, but tighter (possibly teflon blades?).

* Much improved integrated windage tray with proper louvres to cut down on windage. Becuase the tray is installed in the pan it will not be necassary to split the block and ntefere with its integrity and the bearing clearances to install the windage tray. .

* Integrated gasket retainers to stop the gasket from pushing out.

We can also specify other improvements if we want to.

To get this moving we need to can get 10-15 people together in a group buy. Please go to this thread if you are interested.

Last edited by bebbetufs; 04-22-2013 at 05:41 PM.