Cam Carrier Torque sequence

#1

I can't find in the factory manual the torque sequence for the cam carrier. Can someone point me in the right direction to find this information. This is for a 4.5 liter 2V engine. Thanks for any information posted.

#4

(from a PM)

I use the same rough pattern as the head for the cam tower for the final tightening. There are more bolts along the bottom so the pattern can't be just like the cylinder head. Work starting from the middle out and alternate top/bottom and left right. The torque is light (20Nm).

Getting the tower all the way down before the final tighten means putting in the bolts and tightening them a little bit at a time. Line up the cam, roughly, before putting the tower on. The cam will force some valves down and that creates resistance in getting the tower on. I start a few bolts and work up to having them all in and go around giving each a turn or two to tighten the tower down. It's slow wok.

I think it's valuable to work it on gradually, using all the bolts, as then the tower isn't distorted. Some engines leak from the tower gaskets and I wonder if it isn't due to putting the tower on unevenly.

I use the same rough pattern as the head for the cam tower for the final tightening. There are more bolts along the bottom so the pattern can't be just like the cylinder head. Work starting from the middle out and alternate top/bottom and left right. The torque is light (20Nm).

Getting the tower all the way down before the final tighten means putting in the bolts and tightening them a little bit at a time. Line up the cam, roughly, before putting the tower on. The cam will force some valves down and that creates resistance in getting the tower on. I start a few bolts and work up to having them all in and go around giving each a turn or two to tighten the tower down. It's slow wok.

I think it's valuable to work it on gradually, using all the bolts, as then the tower isn't distorted. Some engines leak from the tower gaskets and I wonder if it isn't due to putting the tower on unevenly.

#5

Do not use a Scotch Brite pad to remove the old gasket material...only very careful scraping with a razor blade/blades. If someone before you has "attacked" these surfaces with anything that rotates...throw the pieces away and find used ones that have not been ruined....or find a machinist that can resurface the heads and the cam carriers.

Regardless of which gasket you use, do no use any sealant!

Start in the middle, work out in an "X" pattern. 20nm....no more!

Make sure you replace the "figure 8" gaskets under the cast iron lifter sleeves, if the engine is early.

If you are using the stock gaskets with the moly sprayed on the ends, they will fail....almost guaranteed. The center of the gasket will stick and not move. The end section where it is sprayed with moly will not stick and will move around. This will split the gasket....generally right where the oil drilling is located. Plan on doing this job multiple times, if you use these gaskets.

If you use the "old stock" early gaskets that go with the cam carriers with the early removable lifter guides, they will split, regardless of what you do....it's not "if", but "when". The material is too old and too brittle.

I sell a gasket that solved the splitting issues which occur with that absurd moly coated gasket. These gaskets require modification to use on the early cam carriers with removable lifter sleeves.

There's a 944 guy that insists the problems with the stock gasket is from using "old hardware" and that if you use "new hardware" everything will be fine. This doesn't make a whole bunch of sense....it's not like the hardware is "stretching" at 20nm, nor is the hardware "yielded" from the first use. However, it is worth considering. The cam carrier hardware is a bit unique....which might support his theory. Almost all allen headed cap screws are grade 12.9. This hardware is only grade 8.8. (The "lower grade" actually makes it unique!)

Good luck! This job has made more than just a few people question their sanity!

#6

i have to laugh... my job on the 2 valve when i changed the cams (and thus cam towers) was the worst job ive ever done. not because of the bolts or even the assembly afterward... i had a snap on allen extension that was BUTTER! But, the gasket cleaning on the head. heck, even if you had a power tool that rotated, good luck making any use of it (no room) . so, your advice is smart, only a razor blade and getting contorted to climbing, literally in the engine bay to start the scraping process. every time i thought i was done (doing the work in the CT automotive shop) Chris, shop foreman, said.. "nope, not good enough" so i would go back at it. seriously, 8 hours later, i finished and used stock gaskets (GB has better ones) and it never leaked

the worst job EVER!!!!! next time, pull the engine if the gaskets are destroyed and remain on the engine head. however, you might get lucky and have the gasket come off in one piece or be stuck to the cam tower.

have fun!!

the worst job EVER!!!!! next time, pull the engine if the gaskets are destroyed and remain on the engine head. however, you might get lucky and have the gasket come off in one piece or be stuck to the cam tower.

have fun!!

What you are about to do has "beaten" more than one 944/928 owner....and many cars have been junked or sold, because people could not get the cam carrier/cam carriers to not leak. A 944 cam carrier almost "jumps" off the engine on a 944. On a 928....they are very time consuming and can be very discouraging. Doing the job once (in the car) is barely tolerable. Doing it a second time will test the limits of almost anyone's patience. Three times requires medication.....intense medication.

Do not use a Scotch Brite pad to remove the old gasket material...only very careful scraping with a razor blade/blades. If someone before you has "attacked" these surfaces with anything that rotates...throw the pieces away and find used ones that have not been ruined....or find a machinist that can resurface the heads and the cam carriers.

Regardless of which gasket you use, do no use any sealant!

Start in the middle, work out in an "X" pattern. 20nm....no more!

Make sure you replace the "figure 8" gaskets under the cast iron lifter sleeves, if the engine is early.

If you are using the stock gaskets with the moly sprayed on the ends, they will fail....almost guaranteed. The center of the gasket will stick and not move. The end section where it is sprayed with moly will not stick and will move around. This will split the gasket....generally right where the oil drilling is located. Plan on doing this job multiple times, if you use these gaskets.

If you use the "old stock" early gaskets that go with the cam carriers with the early removable lifter guides, they will split, regardless of what you do....it's not "if", but "when". The material is too old and too brittle.

I sell a gasket that solved the splitting issues which occur with that absurd moly coated gasket. These gaskets require modification to use on the early cam carriers with removable lifter sleeves.

There's a 944 guy that insists the problems with the stock gasket is from using "old hardware" and that if you use "new hardware" everything will be fine. This doesn't make a whole bunch of sense....it's not like the hardware is "stretching" at 20nm, nor is the hardware "yielded" from the first use. However, it is worth considering. The cam carrier hardware is a bit unique....which might support his theory. Almost all allen headed cap screws are grade 12.9. This hardware is only grade 8.8. (The "lower grade" actually makes it unique!)

Good luck! This job has made more than just a few people question their sanity!

Do not use a Scotch Brite pad to remove the old gasket material...only very careful scraping with a razor blade/blades. If someone before you has "attacked" these surfaces with anything that rotates...throw the pieces away and find used ones that have not been ruined....or find a machinist that can resurface the heads and the cam carriers.

Regardless of which gasket you use, do no use any sealant!

Start in the middle, work out in an "X" pattern. 20nm....no more!

Make sure you replace the "figure 8" gaskets under the cast iron lifter sleeves, if the engine is early.

If you are using the stock gaskets with the moly sprayed on the ends, they will fail....almost guaranteed. The center of the gasket will stick and not move. The end section where it is sprayed with moly will not stick and will move around. This will split the gasket....generally right where the oil drilling is located. Plan on doing this job multiple times, if you use these gaskets.

If you use the "old stock" early gaskets that go with the cam carriers with the early removable lifter guides, they will split, regardless of what you do....it's not "if", but "when". The material is too old and too brittle.

I sell a gasket that solved the splitting issues which occur with that absurd moly coated gasket. These gaskets require modification to use on the early cam carriers with removable lifter sleeves.

There's a 944 guy that insists the problems with the stock gasket is from using "old hardware" and that if you use "new hardware" everything will be fine. This doesn't make a whole bunch of sense....it's not like the hardware is "stretching" at 20nm, nor is the hardware "yielded" from the first use. However, it is worth considering. The cam carrier hardware is a bit unique....which might support his theory. Almost all allen headed cap screws are grade 12.9. This hardware is only grade 8.8. (The "lower grade" actually makes it unique!)

Good luck! This job has made more than just a few people question their sanity!

#7

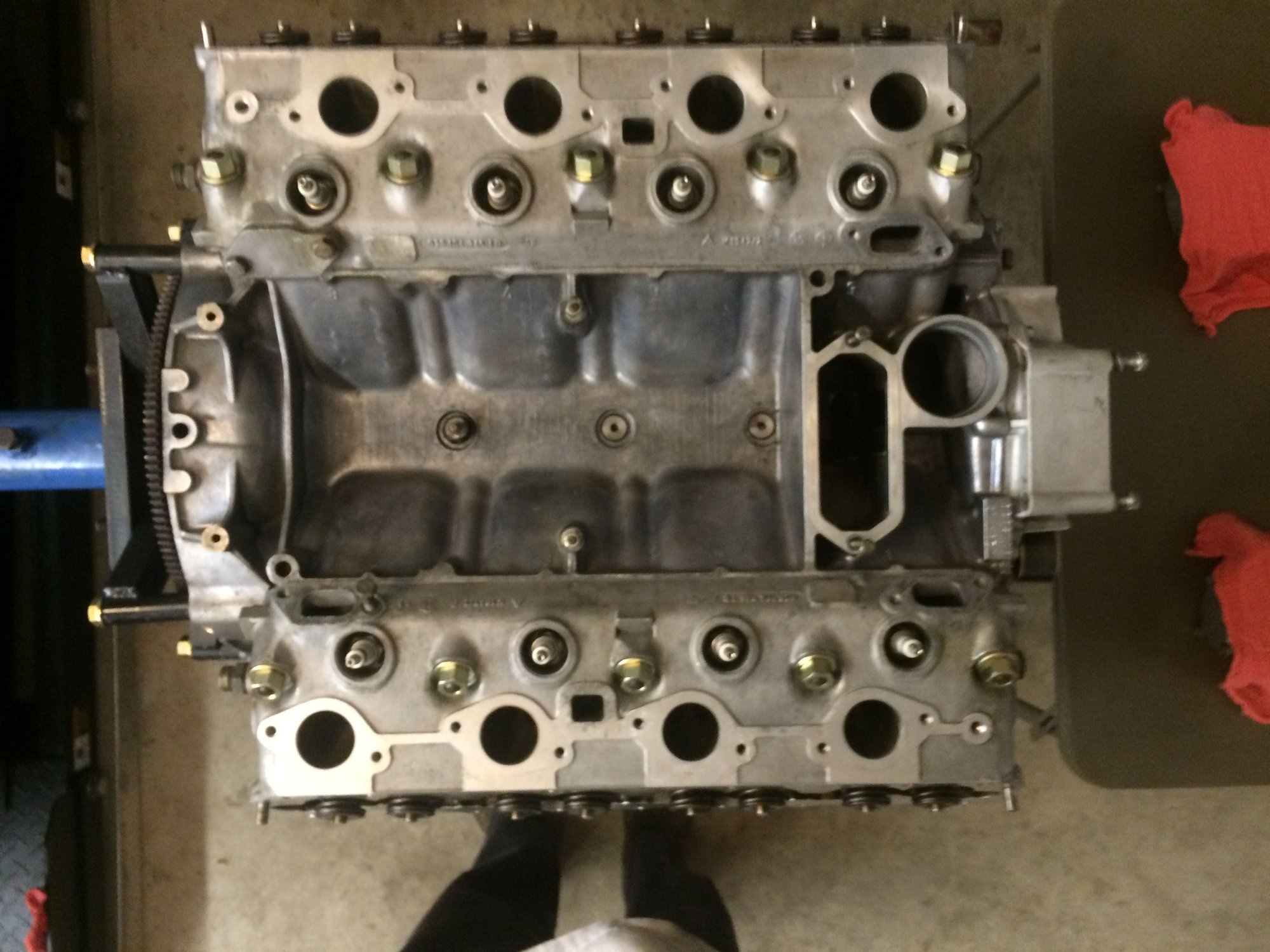

I actually have the engine out on a stand. I'm fixing a bunch of oil leaks that have accumulated over the 35 years. My car is a 1981 USA model. I spent 3 solid days degreasing the bugger and a solid weekend cleaning all the mating surfaces with a razor blade. The engine has never been apart so the surfaces are in nice shape. This car has been in my family for 29 years. I appreciate all the info guys! Wish me luck

Trending Topics

#8

I actually have the engine out on a stand. I'm fixing a bunch of oil leaks that have accumulated over the 35 years. My car is a 1981 USA model. I spent 3 solid days degreasing the bugger and a solid weekend cleaning all the mating surfaces with a razor blade. The engine has never been apart so the surfaces are in nice shape. This car has been in my family for 29 years. I appreciate all the info guys! Wish me luck

#9

I actually have the engine out on a stand. I'm fixing a bunch of oil leaks that have accumulated over the 35 years. My car is a 1981 USA model. I spent 3 solid days degreasing the bugger and a solid weekend cleaning all the mating surfaces with a razor blade. The engine has never been apart so the surfaces are in nice shape. This car has been in my family for 29 years. I appreciate all the info guys! Wish me luck