86 Mossgreen Metallic 5 Speed Continues

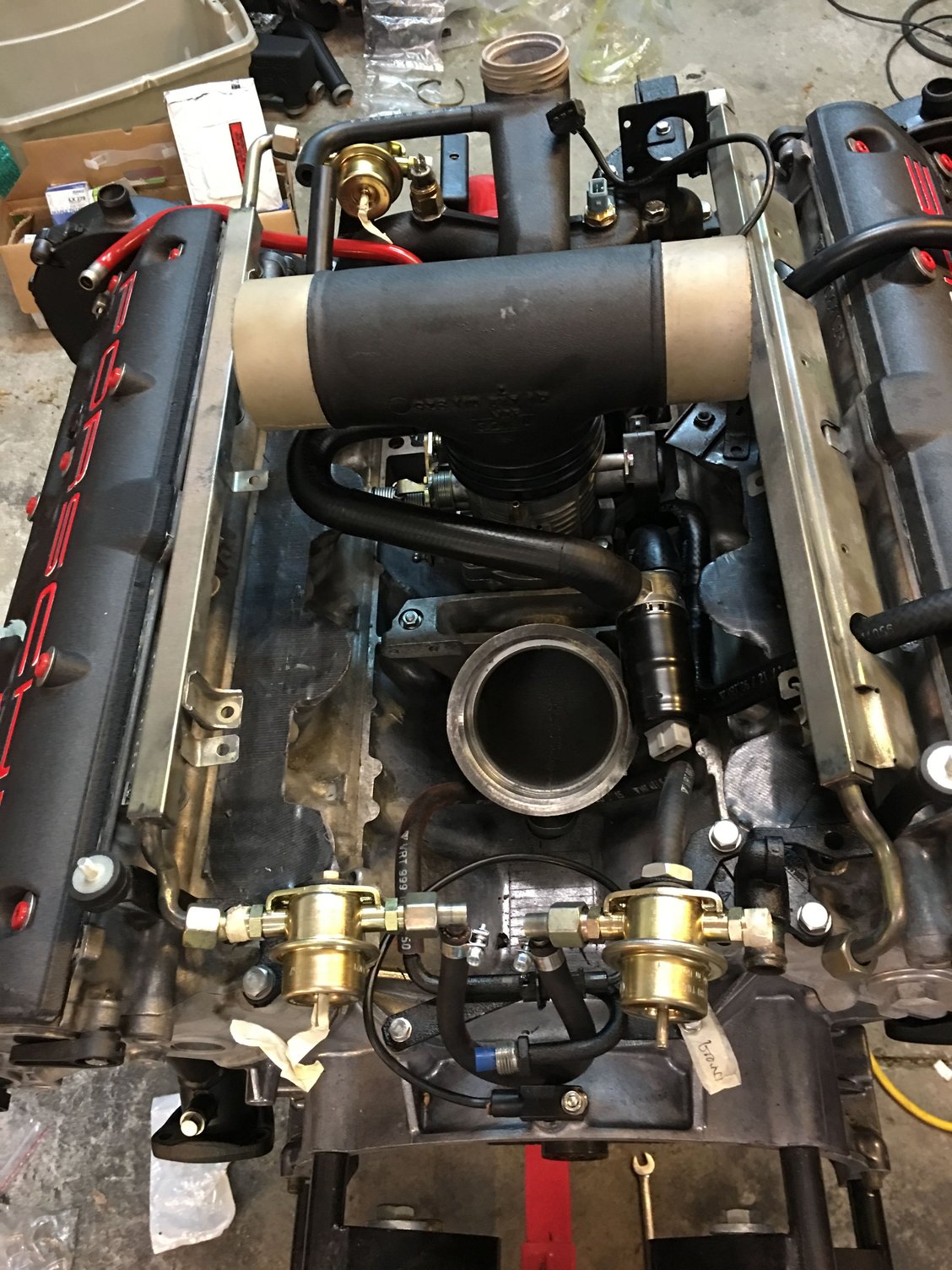

#336

#337

the bolts will be the ground path even though the base of the WB is clean,

the gasket will prevent grounding.

I have seen this issue occur on a few cars with powder coated water bridges,

the engine will not get accurate temperature readings and then the computer will adjust the injection system to the wrong parameters,

this can also effect the temperature gauge readings to be erratic.

clean the bolt mating surfaces and use deoxit 100 on the bolt heads and washers and the temp sensor washers

the gasket will prevent grounding.

I have seen this issue occur on a few cars with powder coated water bridges,

the engine will not get accurate temperature readings and then the computer will adjust the injection system to the wrong parameters,

this can also effect the temperature gauge readings to be erratic.

clean the bolt mating surfaces and use deoxit 100 on the bolt heads and washers and the temp sensor washers

#338

the bolts will be the ground path even though the base of the WB is clean,

the gasket will prevent grounding.

I have seen this issue occur on a few cars with powder coated water bridges,

the engine will not get accurate temperature readings and then the computer will adjust the injection system to the wrong parameters,

this can also effect the temperature gauge readings to be erratic.

clean the bolt mating surfaces and use deoxit 100 on the bolt heads and washers and the temp sensor washers

the gasket will prevent grounding.

I have seen this issue occur on a few cars with powder coated water bridges,

the engine will not get accurate temperature readings and then the computer will adjust the injection system to the wrong parameters,

this can also effect the temperature gauge readings to be erratic.

clean the bolt mating surfaces and use deoxit 100 on the bolt heads and washers and the temp sensor washers

#340

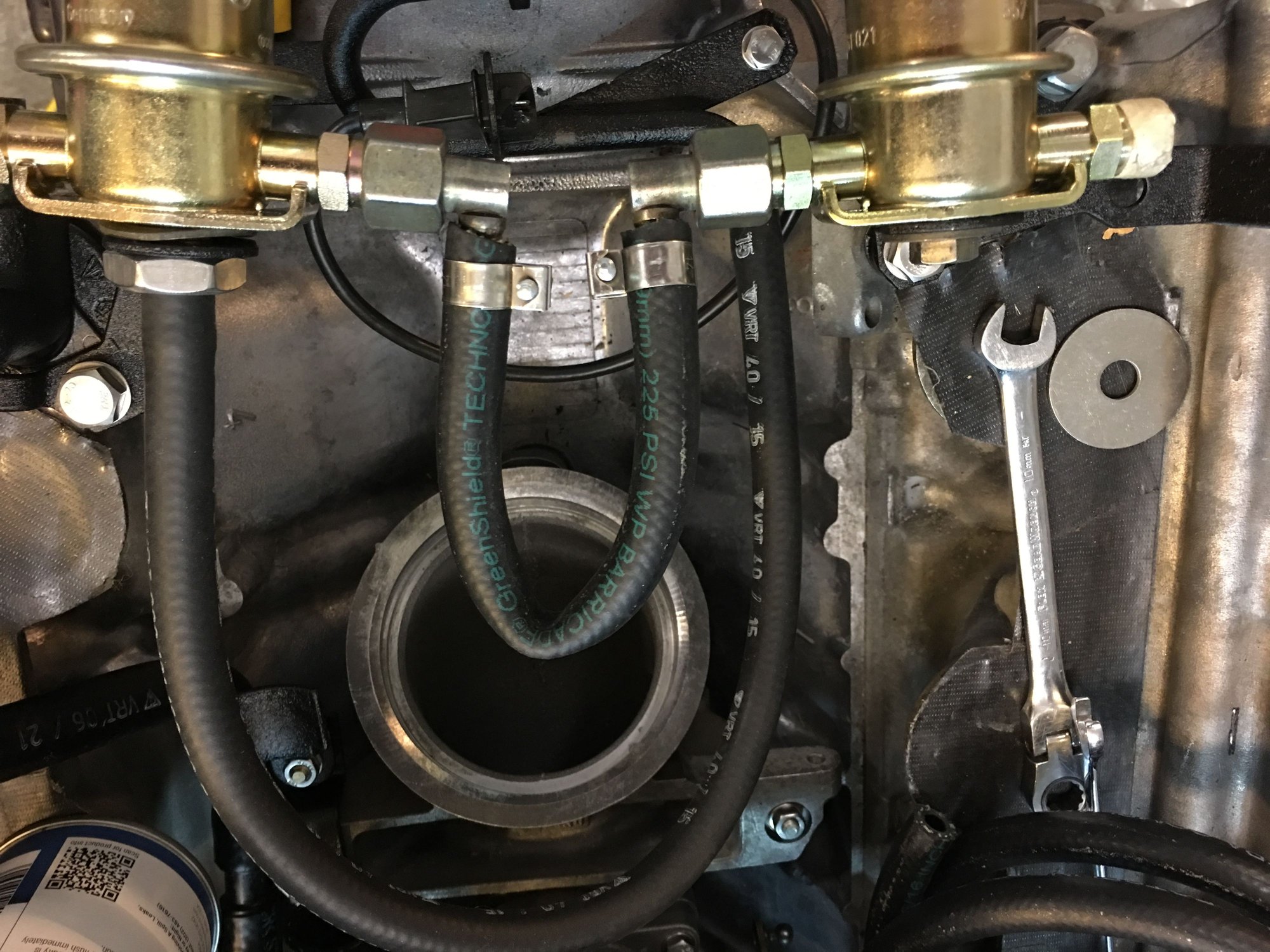

As background, I am running PorKen chips, so I am using an early '87 FPR, which _may_ make a difference.

In any case, I bought new hose and 14 mm clamps from Roger.

I had to cut off the connectors from the end of the old hose, and then I cut the new hose to exactly the same length as the old. This was a mistake. The hose kinked.

I spoke to Roger and he recommended making the hose longer:

"You must make the hose a lot longer and put it behind the engine and below the fuel cooler. The longer the hose the larger the bend radius and no kink."

The next piece was a little over an inch longer, no kink. It may make sense to go even longer.

#343

Looks like you have a '85 type return bracket. (The '86 return hose connection is on the right side, with a shorter hose*.)

If you delete the fuel cooler better to go directly to the return line on the firewall. (I trimmed the line and had a hose supplier rebraze the end for me.)

If you retain the fuel cooler and '85 bracket, there was originally a small bracket fitted on the rear TB housing stud for a (blue) clip to hold the return line.

*Some very early '85 have the FPR on the left side as shown in the WSM. It has been observed that the engine runs oddly with the FPR on the left side. Perhaps because of fuel pressure harmonics.

If you delete the fuel cooler better to go directly to the return line on the firewall. (I trimmed the line and had a hose supplier rebraze the end for me.)

If you retain the fuel cooler and '85 bracket, there was originally a small bracket fitted on the rear TB housing stud for a (blue) clip to hold the return line.

*Some very early '85 have the FPR on the left side as shown in the WSM. It has been observed that the engine runs oddly with the FPR on the left side. Perhaps because of fuel pressure harmonics.

#344

Looks like you have a '85 type return bracket. (The '86 return hose connection is on the right side, with a shorter hose*.)

If you delete the fuel cooler better to go directly to the return line on the firewall. (I trimmed the line and had a hose supplier rebraze the end for me.)

If you retain the fuel cooler and '85 bracket, there was originally a small bracket fitted on the rear TB housing stud for a (blue) clip to hold the return line.

*Some very early '85 have the FPR on the left side as shown in the WSM. It has been observed that the engine runs oddly with the FPR on the left side. Perhaps because of fuel pressure harmonics.

If you delete the fuel cooler better to go directly to the return line on the firewall. (I trimmed the line and had a hose supplier rebraze the end for me.)

If you retain the fuel cooler and '85 bracket, there was originally a small bracket fitted on the rear TB housing stud for a (blue) clip to hold the return line.

*Some very early '85 have the FPR on the left side as shown in the WSM. It has been observed that the engine runs oddly with the FPR on the left side. Perhaps because of fuel pressure harmonics.

Good eye Porken! I also noticed the different return bracket from my existing '86 vs. this earlier '85 motor. I was going to leave it as is, but I will consider re-routing, simplifying this return hose connection to the fuel cooler, as others have said similar in other threads.

The other difference I noted so far is that the bracket for the diagnostic port at the motor front is different, putting that port in a slightly different location.

Last edited by KenRudd; 12-30-2016 at 10:45 AM.

#345

So why the anti-seize at this point? I was just on a roll with the Anti-seize brush and got ahead of myself.