"red light" toothed belt

#61

Hey I do have the kepf tool! C'mon im not just gonna trust the guys experience to tighten it by hand ...

Oh and sorry for not putting in my sig that I have 86 motor in my 1985 928...

Oh and sorry for not putting in my sig that I have 86 motor in my 1985 928...

#62

Inventor

Rennlist Member

Rennlist Member

The belt usually rides 2-3mm from the front of the cam gears. Farther back, or forward, indicates a problem with the tensioner arm or pulley (or waterpump).

'86-up cover breather holes were moved forward to allow the front of the cam gears to be seen. (Also, the cam gears are modified with a front slot indicating #1 TDC when aligned with the nub inside the breather.)

Early '85 cannot see the front (or rear) of the gear through the breather holes. Late '85 have '86 covers on the the 5-8 side only.

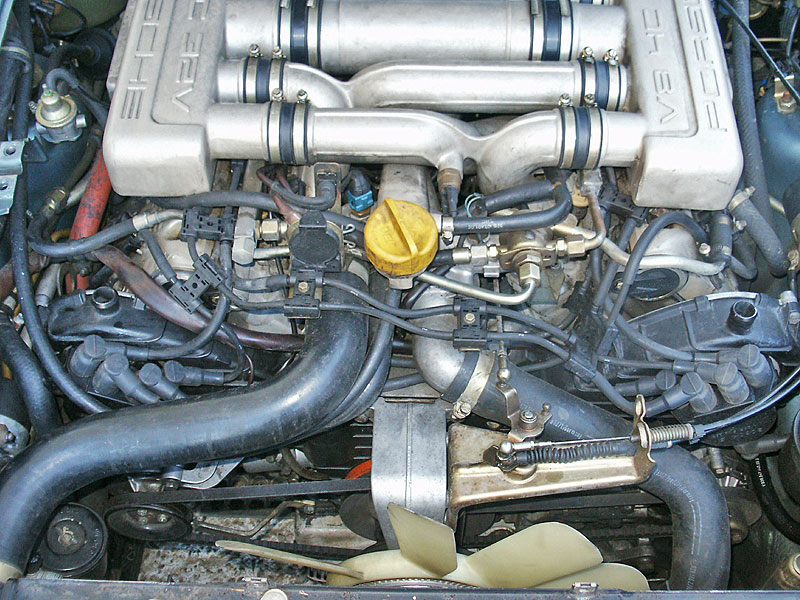

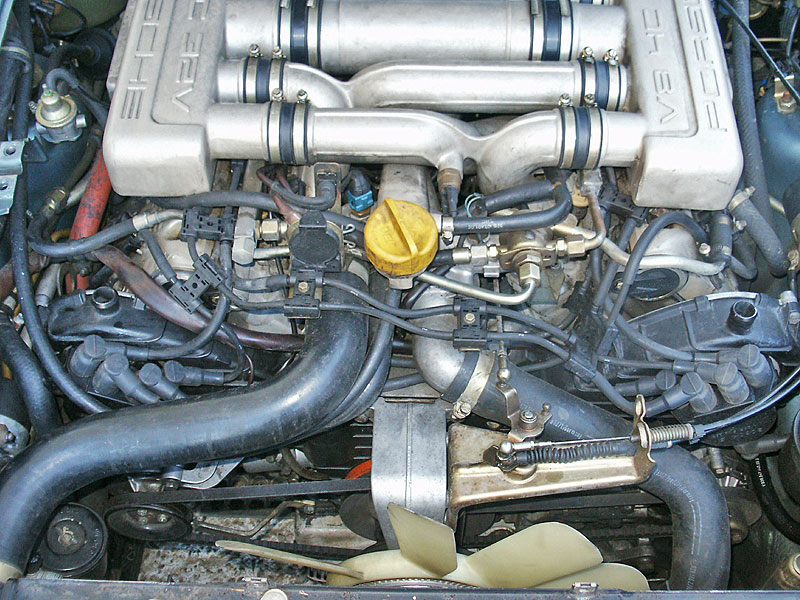

Late '85 engine. Note position (and height) of breather towers.

Early '85 cannot see the front (or rear) of the gear through the breather holes. Late '85 have '86 covers on the the 5-8 side only.

Late '85 engine. Note position (and height) of breather towers.

#63

Three Wheelin'

Join Date: Sep 2003

Location: SF Bay Area

Posts: 1,526

Likes: 0

Received 0 Likes

on

0 Posts

According the sig line we're talking about an '85. Plus, being a new owner, I don't think he has the Porsche tool 9201, so those numbers are meaningless to him. The Kempf tool is worth looking at as an alternative.

Pyzik is taking the car to someone else for the check, but he should search here on tensioning the belt and understanding the whole process of tensioning and how many times to turn the crank, if he is to check it himself in the future. The number "5" is going to confuse him if he doesn't do some research. This link is a good start and shows the Kempf tool in action, find "timing belt" within. http://members.rennlist.com/pirtle/svc.html

What is the "wire lug" you refer to?

Pyzik is taking the car to someone else for the check, but he should search here on tensioning the belt and understanding the whole process of tensioning and how many times to turn the crank, if he is to check it himself in the future. The number "5" is going to confuse him if he doesn't do some research. This link is a good start and shows the Kempf tool in action, find "timing belt" within. http://members.rennlist.com/pirtle/svc.html

What is the "wire lug" you refer to?

As far as being confused, doing things by the seat of the pants is no excuse. One is better to do things right the first time. I am sure any german engineer at Porsche would appreciate that. During the first year of VW training school students are not allowed hammers. I am sure such a restriction will cramp most people's styles. 928 International rents the correct tool. Any professional should also have the right tool. The alternator belt tension is set with the same tool. Some Porsche clubs have the tool to be shared too.

There is a electrical lug that goes on the spade conector on the arm. This connector is a common place for a loose connection.

#64

Rennlist Member

So you mean the pin connector wire that plugs into (and through) the TB cover to the tensioner arm. I just didn't know what an electrical "lug" is. I have only ever heard of lugs on wheels.

I don't think the Kempf tool positioned and applied correctly, is unprofessional. And if you don't have the 9201 tension bar checked and calibrated periodically, it can and eventually will give inaccurate readings. I don't know what the factory specs are for checking the 9201, and I don't mean to imply our vendors rent tools that are not calibrated correctly. But that is another PIA that I can totally avoid for $60.00; or for about $450 w/Porkensioner.

PET calls it the "cable" (the wire from the piston to the arm) and "extension cable" (the male pin connector fitted into the cover with wire extension) that runs from the cover to the arm.

There are actually 3 connection points between the piston and the wire harness. Some older models have a flat metal flexible "wand" that connects the piston to the cable extension at the top of the arm. This frequently broke off due to twisting between the piston and the top of the tension arm where a small screw secures it to a spade connector; Porsche replaced the wand with a short braided wire. If you have the flat wand thingy, replace it w/wire, (or get a Pkensioner). Any corrosion or loose connection at any of these 3 points defeats the circuit and results in a trigger of the light.

I don't think the Kempf tool positioned and applied correctly, is unprofessional. And if you don't have the 9201 tension bar checked and calibrated periodically, it can and eventually will give inaccurate readings. I don't know what the factory specs are for checking the 9201, and I don't mean to imply our vendors rent tools that are not calibrated correctly. But that is another PIA that I can totally avoid for $60.00; or for about $450 w/Porkensioner.

PET calls it the "cable" (the wire from the piston to the arm) and "extension cable" (the male pin connector fitted into the cover with wire extension) that runs from the cover to the arm.

There are actually 3 connection points between the piston and the wire harness. Some older models have a flat metal flexible "wand" that connects the piston to the cable extension at the top of the arm. This frequently broke off due to twisting between the piston and the top of the tension arm where a small screw secures it to a spade connector; Porsche replaced the wand with a short braided wire. If you have the flat wand thingy, replace it w/wire, (or get a Pkensioner). Any corrosion or loose connection at any of these 3 points defeats the circuit and results in a trigger of the light.

#65

Pro

#66

I picked up the car an hour ago, the mechanic said he had to add about "half a turn" , but tracking is good and. All teeth are there. Check out the new headlights!

Last edited by Pyzik; 08-03-2014 at 05:57 AM.

#67

Three Wheelin'

Join Date: Sep 2003

Location: SF Bay Area

Posts: 1,526

Likes: 0

Received 0 Likes

on

0 Posts

He added a half turn. Oh cool now that is scientific. Good luck. I am continually amazed at how little Porsche mechanics know about the 928. I have never seen any other car so butchered by mechanics as the 928. And that includes one very famous shop that is no longer in business.

#68

Three Wheelin'

Join Date: Sep 2003

Location: SF Bay Area

Posts: 1,526

Likes: 0

Received 0 Likes

on

0 Posts

Steve,

I never once suggested that the Kempf tool is unprofessional. Jay is a great guy and he is missed in contributing to the 928 forum. I contribute here in good faith and resent it when people attempt to twist my words. We all hgave different views and I am sure yours are valid and practical, but please show others respect as well - especially when that knowledge is based on 32 years of 928 ownership and 50 years of mechanic experience.

I never once suggested that the Kempf tool is unprofessional. Jay is a great guy and he is missed in contributing to the 928 forum. I contribute here in good faith and resent it when people attempt to twist my words. We all hgave different views and I am sure yours are valid and practical, but please show others respect as well - especially when that knowledge is based on 32 years of 928 ownership and 50 years of mechanic experience.

#69

Rennlist Member

Dan, I'm sorry, you said

. If one is correct, you seem to be saying that the other is incorrect. My mistake.

As we know Pyzik has the Kempf tool and he can check his unprofessional mechanic (not necessarily my characterization) for himself. What he also needs to know (if he hasn't found it in his reading here and you don't point out), is that it is nearly as bad to set it too tight, which MIGHT be what the mechanic has done, as it is to be too loose. Too tight causes undue wear on the cam gears and can break the gear or the cam snout.

It is possible the mechanic set it correctly with one of the tools (or by coincidence) and didn't tell Pyzik or Pyzik hasn't communicated that here.

Pyzik, the new headlights look great. Happy motoring.

HTML Code:

928 International rents the correct tool.

As we know Pyzik has the Kempf tool and he can check his unprofessional mechanic (not necessarily my characterization) for himself. What he also needs to know (if he hasn't found it in his reading here and you don't point out), is that it is nearly as bad to set it too tight, which MIGHT be what the mechanic has done, as it is to be too loose. Too tight causes undue wear on the cam gears and can break the gear or the cam snout.

It is possible the mechanic set it correctly with one of the tools (or by coincidence) and didn't tell Pyzik or Pyzik hasn't communicated that here.

Pyzik, the new headlights look great. Happy motoring.

#70

He added half turn cuz the belt stretched , not because just to be safe. I told him everything I found out from other posts about making it too tight , water pump damage , he's not a Porsche mechanic but he knows his stuff. Also he's the one that made me get laso pump , he wouldnt take the job if I used rebuild, and made me get me tbelt with the pump and even waiting and store my 928 inside for a week till the belt came .

Last edited by Pyzik; 12-23-2011 at 02:33 PM.

#73

Rennlist Member

The concept of making a finite adjustment by those who ahe regular experience is nothing new. It is a typicla quantum of adjustment applied to new belts after the settling in period. It would be interesting to put one of Jay's tools on a belt that is in need of adjustment after settling in and check the reading put half a turn on the adjuster and see what reading it gives. I wouldn't mind betting it takes it from a lowish [but not silly] reading to one about right.

Regards

Fred

Regards

Fred

#75

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

To me it's a bit odd for a belt to go loose enough to trip the warning at any time. The belts don't (or rather shouldn't) stretch. They do settle in so the tension does drop initially; hence the recommended check at 1500-2000 miles. But if the belt is set correctly initially, somewhere approaching the upper end of the Kempf tool window, it should only drop to a little less than the window mid-point at most - enough so, yes, it would call for snugging to get back to the right setting, but it shouldn't drop enough to trip the warning. So, either the mechanic set the belt on the loose side initially, didn't turn the motor through several revolutions before checking it initially, or didn't do the check exactly at TDC cylinder 1.

About 3/4 of a turn to be precise.

About 3/4 of a turn to be precise.