Simard Crank Brace / I-J Scraper combo

#1

Rennlist Member

Thread Starter

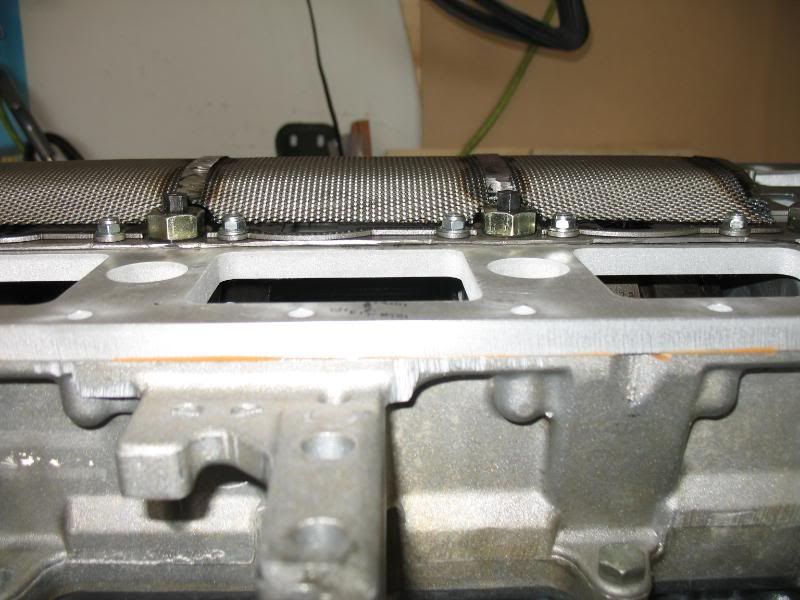

Thanks to Greg Nettles for selling me his I-J crank scraper. It was intended for a 5L, so I'm having to modify it for the stroker. The scraper section wasn't too bad. I'm still working on clearancing the windage tray, and I will have to fab up my own windage screen since the I-J screen interfere's with the Simard Crank Brace/Pan Spacer.

Some of the mounting studs for the I-J scraper system also interfered with the crank brace, but local 928 Owner Al Blose was nice enough to drill and end mill some clearance holes.

Getting close. Once I get these two pieces to work together, I can assemble the short block for real.

Because the scraper system sandwiches inbetween the brace and the crank girdle, but does not go all the way out to the pan rail it forms a gap the same thickness as the scraper at the pan rail. I'm going to have the crank brace machined out to allow the scraper to sit flush inside it to cure this problem.

This pic shows the part of the scraper that contacts the brace, and that I will have to mill out for proper clearance for the brace to accept. And yes for you Simard crank brace fans out there, I am aware that I still need to machine an opening for the dip stick.

Some of the mounting studs for the I-J scraper system also interfered with the crank brace, but local 928 Owner Al Blose was nice enough to drill and end mill some clearance holes.

Getting close. Once I get these two pieces to work together, I can assemble the short block for real.

Because the scraper system sandwiches inbetween the brace and the crank girdle, but does not go all the way out to the pan rail it forms a gap the same thickness as the scraper at the pan rail. I'm going to have the crank brace machined out to allow the scraper to sit flush inside it to cure this problem.

This pic shows the part of the scraper that contacts the brace, and that I will have to mill out for proper clearance for the brace to accept. And yes for you Simard crank brace fans out there, I am aware that I still need to machine an opening for the dip stick.

#4

Rennlist Member

Thread Starter

I'm thinking I'll need 2mm faced off of the interior section of the brace, leaving the outer perimeter that acts as a pan spacer the original thickness.

Doable?

#5

#6

Trending Topics

#8

Rennlist Member

Thread Starter

BC,

Using stock main studs, so I can't run the windage tray on top of the brace. By runing on top like you are doing, the windage tray must sit pretty high off the crank? I guess it doesn't really matter since it's the scrapers job to scrape, just curious if your crank throws actually come through the cut outs in the windage tray.

H,

The purpose of the brace is two-fold, lower the sump like you stated and to provide some additional rigidity to the block.

Using stock main studs, so I can't run the windage tray on top of the brace. By runing on top like you are doing, the windage tray must sit pretty high off the crank? I guess it doesn't really matter since it's the scrapers job to scrape, just curious if your crank throws actually come through the cut outs in the windage tray.

H,

The purpose of the brace is two-fold, lower the sump like you stated and to provide some additional rigidity to the block.

#11

Three Wheelin'

I know Dennis has one of these spacers in his non stroker S4.

#12

Rennlist Member

Thread Starter

Dennis' motor was built with track use in mind, for a street car I don't think you'll need it. Most of the complaints about oil consumption, fried bearings, etc, seem to only come from track use, not typical street use. Constant high revving on the track is going to call for more oil control than stock for sure.

Louie was the first I know of to use a pan spacer. The idea behind the spacer is to get the crank up off the floor of the pan where collected oil can get whipped up by the crank and windage effect at high rpms. On the street, it really shouldn't be too big of a concern (unless you're constantly winding up the motor. ) At the track Louie was experiencing a high degree of aerated oil, and this was one of his many angled attack to solve the problem.

The spacer gets the rotating assembly up off the floor of the pan. The I-J scraper actually does three (maybe more) things: It has a scraper component that captures oil being whipped around the crank, it has a windage tray that provides a physical barrier between the crank and the floor of the pan so that oil off the crank that accumulates on the pan floor on its way to the sump doesn't get picked back up by the crank, and third it has a drip rail component that collects oil draining down from the heads and via isolated channels steers the oil directly to the sump instead of letting it fall to the floor of the pan under the crank like the stock set up. There is also some oil control components regarding the sump itself using hinged baffles and some additional screening to keep oil in the sump portion from spilling back toward the crank under g-loads.

I think that running less oil has been shown to not really address the problems. Even if it leaves less oil to be aerated in the first place, you now have less oil volume overall and run the risk of burning up bearings. Knife edging I believe has a two-fold benefit. The crank spins and displaces less air around it so that there is less windage effect. With less windage I guess any parasitic losses of having the crank churn that big oil cloud would be reduced maybe showing some power gain.

Louie was the first I know of to use a pan spacer. The idea behind the spacer is to get the crank up off the floor of the pan where collected oil can get whipped up by the crank and windage effect at high rpms. On the street, it really shouldn't be too big of a concern (unless you're constantly winding up the motor. ) At the track Louie was experiencing a high degree of aerated oil, and this was one of his many angled attack to solve the problem.

The spacer gets the rotating assembly up off the floor of the pan. The I-J scraper actually does three (maybe more) things: It has a scraper component that captures oil being whipped around the crank, it has a windage tray that provides a physical barrier between the crank and the floor of the pan so that oil off the crank that accumulates on the pan floor on its way to the sump doesn't get picked back up by the crank, and third it has a drip rail component that collects oil draining down from the heads and via isolated channels steers the oil directly to the sump instead of letting it fall to the floor of the pan under the crank like the stock set up. There is also some oil control components regarding the sump itself using hinged baffles and some additional screening to keep oil in the sump portion from spilling back toward the crank under g-loads.

I think that running less oil has been shown to not really address the problems. Even if it leaves less oil to be aerated in the first place, you now have less oil volume overall and run the risk of burning up bearings. Knife edging I believe has a two-fold benefit. The crank spins and displaces less air around it so that there is less windage effect. With less windage I guess any parasitic losses of having the crank churn that big oil cloud would be reduced maybe showing some power gain.

#13

Adam -

Yes, the actual windage screen, which Kevin was nice enough to make for me when he updated the design ( I paid for it - a few months later) - does sit a ways off the crank, but the actual scrapers that are bolted down normally UNDER the Simard Girdle support. The cut outs, I suppose, are not in the proper place now. The throws are still near or in the cutouts though. And the purpose of the screen will still work, as the splashing will be cut down.

The girdle is actually more important to me, since the power level is going to be so high for the stock block construction.

Hopefully when its all working together, it will work in harmony. We'll see.

Yes, the actual windage screen, which Kevin was nice enough to make for me when he updated the design ( I paid for it - a few months later) - does sit a ways off the crank, but the actual scrapers that are bolted down normally UNDER the Simard Girdle support. The cut outs, I suppose, are not in the proper place now. The throws are still near or in the cutouts though. And the purpose of the screen will still work, as the splashing will be cut down.

The girdle is actually more important to me, since the power level is going to be so high for the stock block construction.

Hopefully when its all working together, it will work in harmony. We'll see.

#14

I still want to use minimal sealing material between the brace and the pan so the pan can become more of a structural member.

#15

Three Wheelin'