View Poll Results: 2-6 Rod Bearing Failures, which 928 engine-trans?

32V 2.727 gearbox (89+)

8

53.33%

32V 2.20 gearbox (85-88)

3

20.00%

16V any gearbox

5

33.33%

Multiple Choice Poll. Voters: 15. You may not vote on this poll

2-6 Rod bearing failure....a study!

#32

Rennlist Member

Its now RD50 part numbered , 15-50 racing oil from Amsoil.

I was a little leary of changing when they announced the change. But, after talking to one of their scientists, he convinced me that the greater zinc content was worth the change.

mk

I was a little leary of changing when they announced the change. But, after talking to one of their scientists, he convinced me that the greater zinc content was worth the change.

mk

#33

Rennlist Member

although scots 4.7 to 5 liter euro conversion was a 4.7 US block that was bored out (not recommended). But, he is on his second racing season, with the 2.75 rear end. It is pretty quick too!

mk

mk

Perhaps your data will be skewed. I posted that I had 16v failure, as I had 16v heads, but there were bolted to '86 shortblocks, so perhaps you would consider these 32v failures as these blocks originally had 32v heads.

For those I might have confused, 85/86 shortblock with 16v Euro S heads/cams/intake was (is?) a common upgrade for 4.5L & 4.7L track cars.

For those I might have confused, 85/86 shortblock with 16v Euro S heads/cams/intake was (is?) a common upgrade for 4.5L & 4.7L track cars.

#34

I have split the girdle on a few of these. And I have seen evidance that the girdle has floated, or slapped alittle, while this is seen on almost every main, it is MOST evident around the main which supplies #2/#6.

Is it possible that some of the failures could be happening because of the block opening up alittle more than normally seen.

Is it possible that some of the failures could be happening because of the block opening up alittle more than normally seen.

#35

Rennlist Member

Really? that is hard to imagine the way it is bolted together with 30 bolts!

Hey, if that is the cause, wouldnt that be soemthing to address. more bolts!

Here is that video that shows the beating we regularly give the 928 at laguna seca.

http://www.youtube.com/swf/l.swf?swf...in-car%20%20ea...

mk

Hey, if that is the cause, wouldnt that be soemthing to address. more bolts!

Here is that video that shows the beating we regularly give the 928 at laguna seca.

http://www.youtube.com/swf/l.swf?swf...in-car%20%20ea...

mk

#36

I think alot of people here greatly underestimate what detonation actually does to this or any other engine. Where else is the force of making 1/8 of 3000hp instead of making 1/8 of 300hp going to go? (It is suggested that detonation causes the cylinder in question to abruptly go from normal pressure to the pressure that would occur in an engine making 10 to 15 times the power).

The "shock" goes into the rod. From the rod it goes into the bearing, and from the bearing, into the crank. The crank is held in the block by that aluminum girdle.

Obviously its not the only issue. But its a big one, as suggest by people who look very closely at these engines. On this forum, and off.

The "shock" goes into the rod. From the rod it goes into the bearing, and from the bearing, into the crank. The crank is held in the block by that aluminum girdle.

Obviously its not the only issue. But its a big one, as suggest by people who look very closely at these engines. On this forum, and off.

#37

Race Car

I think alot of people here greatly underestimate what detonation actually does to this or any other engine. Where else is the force of making 1/8 of 3000hp instead of making 1/8 of 300hp going to go? (It is suggested that detonation causes the cylinder in question to abruptly go from normal pressure to the pressure that would occur in an engine making 10 to 15 times the power).

The "shock" goes into the rod. From the rod it goes into the bearing, and from the bearing, into the crank. The crank is held in the block by that aluminum girdle.

Obviously its not the only issue. But its a big one, as suggest by people who look very closely at these engines. On this forum, and off.

The "shock" goes into the rod. From the rod it goes into the bearing, and from the bearing, into the crank. The crank is held in the block by that aluminum girdle.

Obviously its not the only issue. But its a big one, as suggest by people who look very closely at these engines. On this forum, and off.

Dan

'91 928GT S/C

475hp/460lb.ft

475hp/460lb.ft

#38

As I said, its a more complex issue than just that. Obviously the oil flow is also an issue, but detonation would be much worse on bearings that have oil with entrained air poorly isolating them...

#39

Nordschleife Master

I do highly doubt that with this engine. It was an 86 bone stock, brains and all. There is NO other signs of detination in this engine. Rod bearings were perfect. Nothing to the tops, rings perfect. And I met the PO (who was only the second one) who had only ever ran premuim in the engine. And with our weather up here, the chances of any detonation is minimal. Only reason that the car got written off was because of a spin destroying suspension componants.

Plus the torque settings for these bolts is pretty low.

I did however get the girdle back from the machine shop with the oil passages massaged, I will post pics up later.

#40

Rennlist Member

thats what I was thinking. wouldnt your mains and pistons show bearing where there too?'

However, I do have a feeling that detonation could be an issue that maybe Ive avoided by having a rich mixture and mild timing.

One thing that Brian did have is a stock fuel regulator, even though his readings from the dyno showed rich. If he was lean or had some issues, it would show up somewhere you would think. So I wonder what the plugs looked like as well as the combustion chambers.

mk

However, I do have a feeling that detonation could be an issue that maybe Ive avoided by having a rich mixture and mild timing.

One thing that Brian did have is a stock fuel regulator, even though his readings from the dyno showed rich. If he was lean or had some issues, it would show up somewhere you would think. So I wonder what the plugs looked like as well as the combustion chambers.

mk

#41

Nordschleife Master

Brian, I am not sure what route you want your thread to take here. So if you feel that this info I am posting next is not inline with the information that you want, then please PM me and I will move it to a new thread based just on oil control.

I just went to the garage and did a study on the oil passages, routing etc. as I now have my girdle with the modifications done.

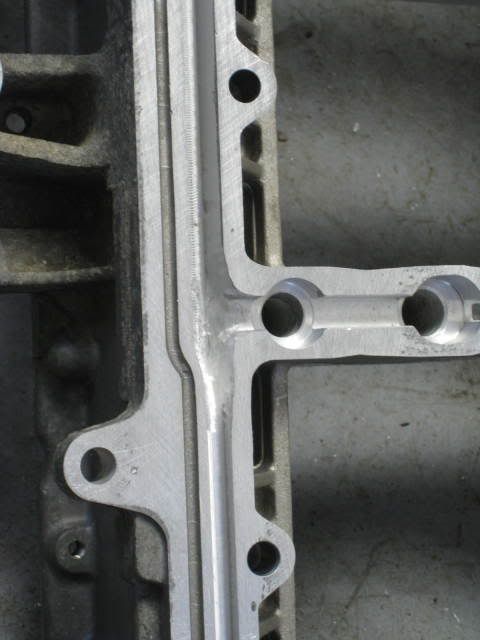

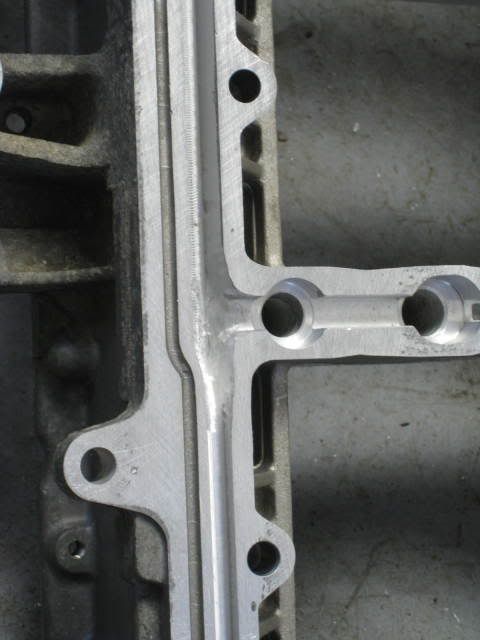

I can tell you this. The wearing that I had noticed earlier on both the block and the girdle is NOT from detenation. I can say this with certainty on the engine I am inspecting/redoing now. All of the lift has happened ONLY on the areas with oil channels. This means that the mains, ONLY the areas with with oil passages in them had lift. So both sides of #3 (center) and only the drivers side for the rest. This said main # 2 and #4 (from FOE) were by far the worst. The two things that these two had in common over the others is the narrowness of oil passages.

Now I have as I said reworked the girdle for better oil flow to all the areas that were IMO not very good.

This should definetly help according to what I am seeing in this engine. However it is not the full solution.

In both discussions with Greg Gray, and from my own research I have found that anything over 80PSI of oil pressure hurts performance. Now from all the info I have read here, I have yet to go through the manual though, the 928 runs 100+ PSI of oil pressure. I feel that the oil pressure is actually too high and by limiting the pressure to 75-80PSI we would actually be doing ourselves a favor, and by lowering it to that pressure (or maybe a tick lower) we will not induce any damage. According to Greg Gray some of the V8 Supercar series they are limited to 7500RPM and run a max oil pressure of 60PSI.

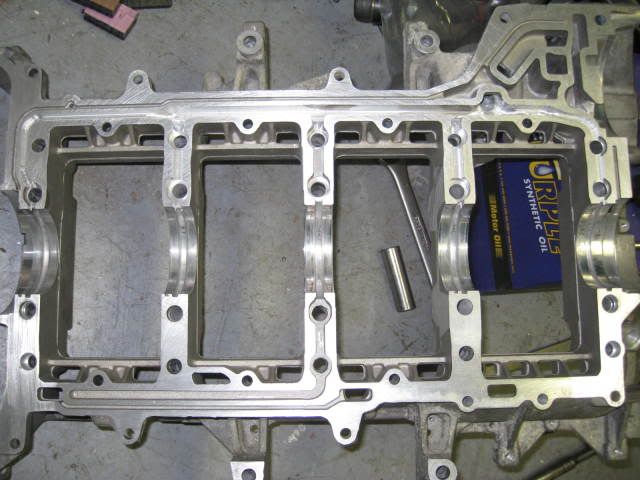

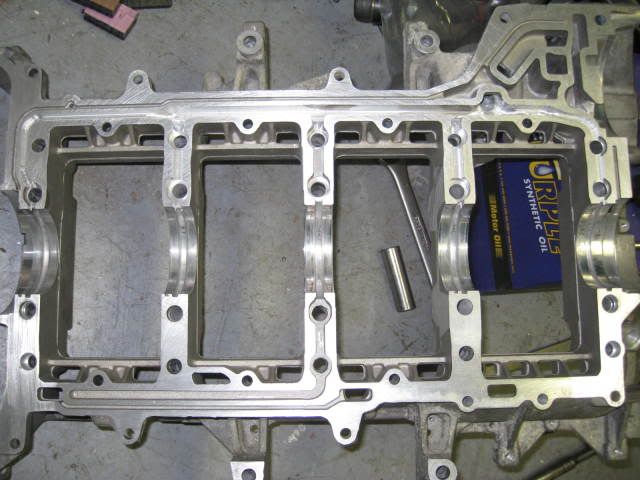

Now for some pictures of my modifications that I have made to the lower girdle oiling passages.

#1 & #2 mains

#2 & #3 mains

#3 & #4 mains

#4 & #5 mains

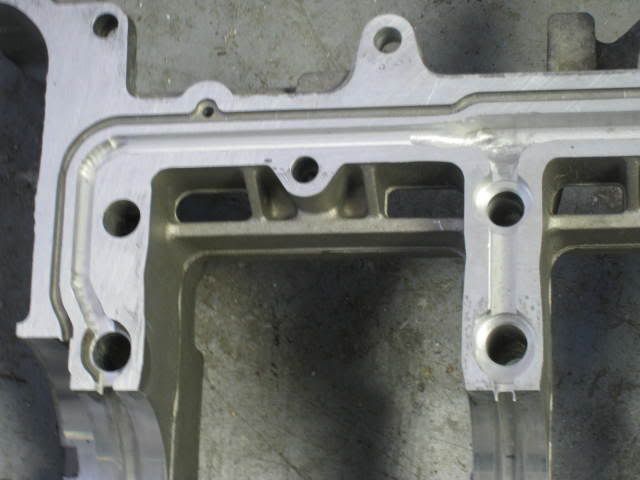

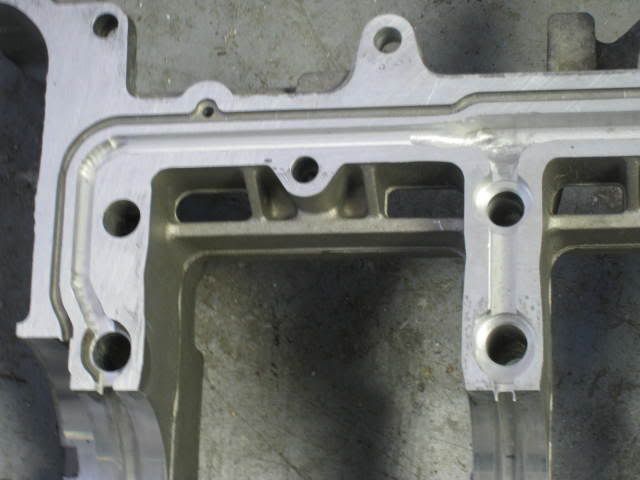

Sharp edges that have been shamfered for #1 & #2

Close up of #2 main shamfering.

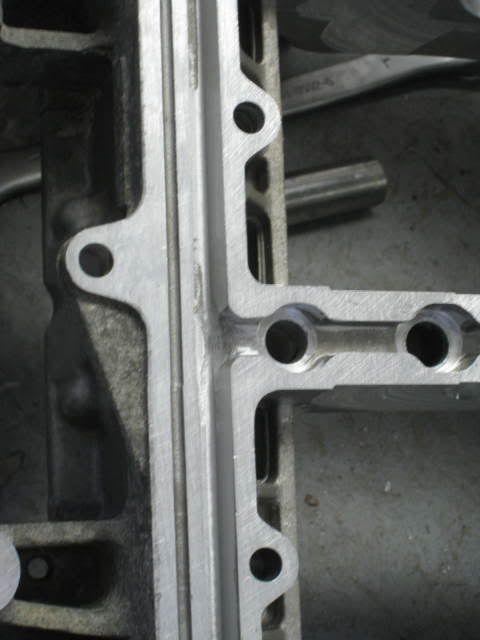

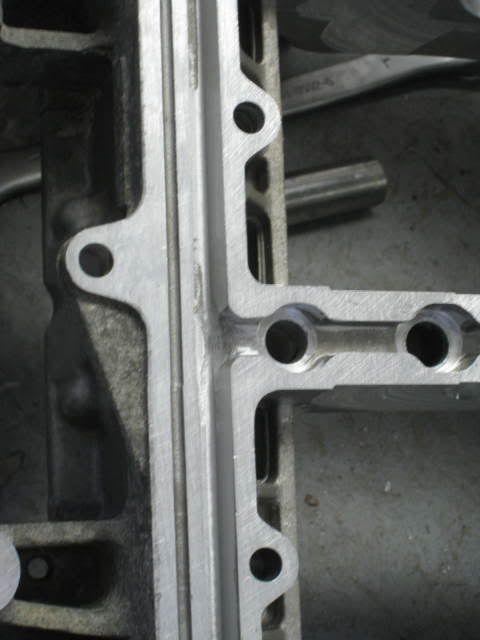

close up of shamfering of #3 main.

The other thing that I wanted to note is that on the engine there is the thermostat control which I have removed for this engine. There is also a pressure bypass that opens around 15 PSI of pressure. This is only to ensure that should the oil cooler restrict flow you will not starve the bearings. Then there is the pressure valve on the engine. This is to the front of the cooler safety. This vents its pressure back to the oil pickup line.

It was mentioned in another thread, that if there is a higher pressure the oil will bypass the filter, this is an incorrect statement. There is absolutely NO provisions in this engine for this. 100% of the oil flow goes through the oil filter at all times. So if your bearing starts to fail, the copper will not be put through to the other bearings and channels requiring a full teardown and cleaning. This is NOT to say that it wouldnt be a good idea though!

I just went to the garage and did a study on the oil passages, routing etc. as I now have my girdle with the modifications done.

I can tell you this. The wearing that I had noticed earlier on both the block and the girdle is NOT from detenation. I can say this with certainty on the engine I am inspecting/redoing now. All of the lift has happened ONLY on the areas with oil channels. This means that the mains, ONLY the areas with with oil passages in them had lift. So both sides of #3 (center) and only the drivers side for the rest. This said main # 2 and #4 (from FOE) were by far the worst. The two things that these two had in common over the others is the narrowness of oil passages.

Now I have as I said reworked the girdle for better oil flow to all the areas that were IMO not very good.

This should definetly help according to what I am seeing in this engine. However it is not the full solution.

In both discussions with Greg Gray, and from my own research I have found that anything over 80PSI of oil pressure hurts performance. Now from all the info I have read here, I have yet to go through the manual though, the 928 runs 100+ PSI of oil pressure. I feel that the oil pressure is actually too high and by limiting the pressure to 75-80PSI we would actually be doing ourselves a favor, and by lowering it to that pressure (or maybe a tick lower) we will not induce any damage. According to Greg Gray some of the V8 Supercar series they are limited to 7500RPM and run a max oil pressure of 60PSI.

Now for some pictures of my modifications that I have made to the lower girdle oiling passages.

#1 & #2 mains

#2 & #3 mains

#3 & #4 mains

#4 & #5 mains

Sharp edges that have been shamfered for #1 & #2

Close up of #2 main shamfering.

close up of shamfering of #3 main.

The other thing that I wanted to note is that on the engine there is the thermostat control which I have removed for this engine. There is also a pressure bypass that opens around 15 PSI of pressure. This is only to ensure that should the oil cooler restrict flow you will not starve the bearings. Then there is the pressure valve on the engine. This is to the front of the cooler safety. This vents its pressure back to the oil pickup line.

It was mentioned in another thread, that if there is a higher pressure the oil will bypass the filter, this is an incorrect statement. There is absolutely NO provisions in this engine for this. 100% of the oil flow goes through the oil filter at all times. So if your bearing starts to fail, the copper will not be put through to the other bearings and channels requiring a full teardown and cleaning. This is NOT to say that it wouldnt be a good idea though!

#42

Race Director

Thread Starter

Lizard

Girdle improvements are a great idea!

Interesting on the oil pressure....sounds like it would be worthwhile to have a gauge that actually reads above 5bar?

Girdle improvements are a great idea!

Interesting on the oil pressure....sounds like it would be worthwhile to have a gauge that actually reads above 5bar?

#43

Nordschleife Master

Brian, if all we had was 5 bar (72.5PSI) we would probably be fine. But in order to dial it in then yes. We would need a higher PSI guage.

The guage (with own sender) which I put into my car reads in PSI and goes upto 105PSI.

I am thinking it would be a good idea to get a new spring made which would limit to 80PSI.

Anyone else feel like doing the math to figure out what the spring pressure would need to be (keeping it factory length). Cause I sure as heck dont feel like doing all that math!!!!!

Z where are you

As to the girdle improvements which I have made. There was a fellow who had posted up info about the girdle saying that a company which builds track 928s makes modifications and then they havent had an issue. I did my own investigating after that and decided that this was the most that one could really do without weakening anything but increasing the flow as best as is possible to all mains.

The guage (with own sender) which I put into my car reads in PSI and goes upto 105PSI.

I am thinking it would be a good idea to get a new spring made which would limit to 80PSI.

Anyone else feel like doing the math to figure out what the spring pressure would need to be (keeping it factory length). Cause I sure as heck dont feel like doing all that math!!!!!

Z where are you

As to the girdle improvements which I have made. There was a fellow who had posted up info about the girdle saying that a company which builds track 928s makes modifications and then they havent had an issue. I did my own investigating after that and decided that this was the most that one could really do without weakening anything but increasing the flow as best as is possible to all mains.

#44

Drifting

Join Date: Nov 2001

Location: zürich, switzerland

Posts: 2,233

Likes: 0

Received 0 Likes

on

0 Posts

#45

Nordschleife Master

That is interesting, but doesnt it depend on the G loading? does the engine know if you are decelerating from 150-100 vs 120-80mph if the Gs or ave Gs are the same?

<SNIP>

What kind of warm up procedure do you use? Ive recently become more curious about what folks warm-up routine is because Ive been watching guys at the track, start cold engines, rev them up for a while, and then go track'in.

<SNIP>

What kind of warm up procedure do you use? Ive recently become more curious about what folks warm-up routine is because Ive been watching guys at the track, start cold engines, rev them up for a while, and then go track'in.

The oil will foam more during longer acceleration periods. Decelerating actually helps as the oil, foam or no, gets thrown back into the pan. Cornering throws the oil away from the pump, but it's that gulp of foam, or air, that kills the bearings.

I'm also a habitual early downshifter. I'm working on downshifting in the corner rather during braking. (Why are there three pedals when I've only got two feet?) It's fun, but hard on the engine and tranny.

I always warm up the car so the water temp is stabilized at a normal temp before going out. Something like ten minutes of idling when cold and 5 when warm. I don't punch it on the first lap in any case.