View Poll Results: 2-6 Rod Bearing Failures, which 928 engine-trans?

32V 2.727 gearbox (89+)

8

53.33%

32V 2.20 gearbox (85-88)

3

20.00%

16V any gearbox

5

33.33%

Multiple Choice Poll. Voters: 15. You may not vote on this poll

2-6 Rod bearing failure....a study!

#61

Colin J wrote:

Entropy engineering wrote:

I care. I wrote that full flow filters can go into bypass under certain conditions. I did not mean that the motor itself had a filter bypass. What I meant is full flow filters have a pressure differential bypass valve built in and there are conditions in which enough pressure differential can exist and oil can bypass the filter, such as cold starts, but also it can open under any condition that generates a pressure drop across the media of more than 8-12 PSI (the usual relief valve spec). Some observations say rapid acceleration and high RPM alone can do this with high flow pumps and high pressure relief valves (like the 8 bar one we have) after the filter, particularly if there is any filter contamination clogging the large pores.

It was mentioned in another thread, that if there is a higher pressure the oil will bypass the filter, this is an incorrect statement. There is absolutely NO provisions in this engine for this. 100% of the oil flow goes through the oil filter at all times. So if your bearing starts to fail, the copper will not be put through to the other bearings and channels requiring a full teardown and cleaning. This is NOT to say that it wouldnt be a good idea though!

Hey if anyone cares, the oil bypass is in the filter. Every filter I've ever seen has a small piece of steel in the bottom that can bend back to let oil bypass or a plate held down with a spring.

#62

Z,

I hadnt really considered running a thinner weight to reduce the pressure. Though I suppose it could work, as it is simply a thinner oil which is getting out of the areas faster. Though I doubt that I could get down to be able to keep it at 75-80 PSI just from a lighter weight. However this idea I do not like for a car without drysump, as it means more of the oil will be in the air at any given time.

Does anyone know off hand what the length, diameter, and spring force is for the factory oil pressure spring? As well, exactly what the maximum pressure is when at full tempature with a new spring?

Alex,

Thanks for the info. Though I doubt I will be able to tell if the oiling upgrades made any difference (cant hurt) unless I throw a bearing. Except I will be running drysump from the get go so I will not be able to really tell any difference because of that.

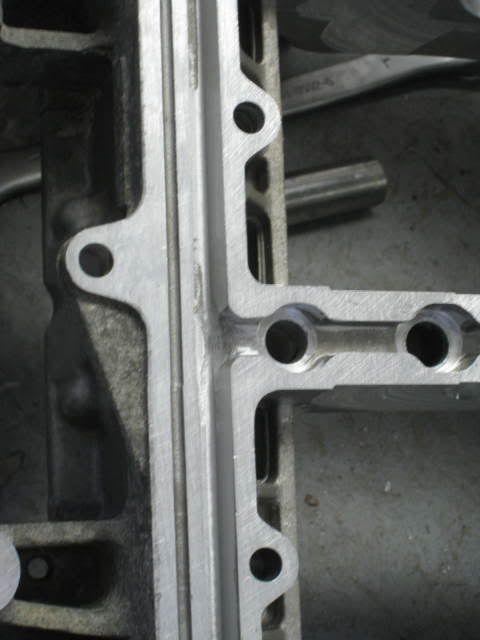

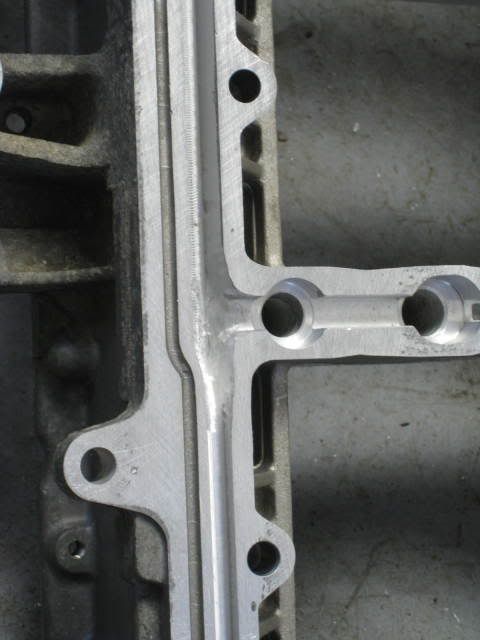

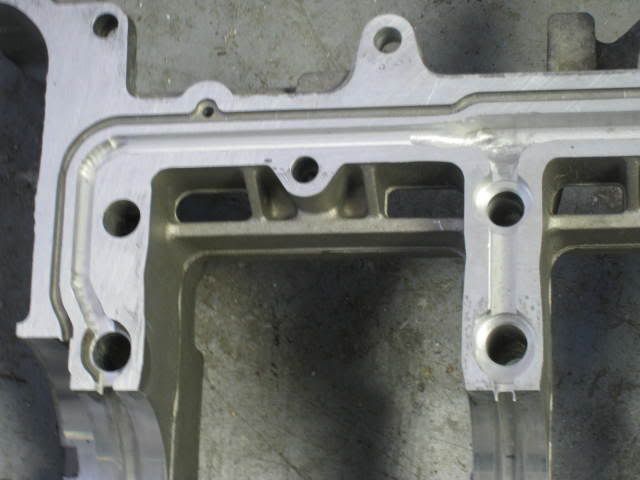

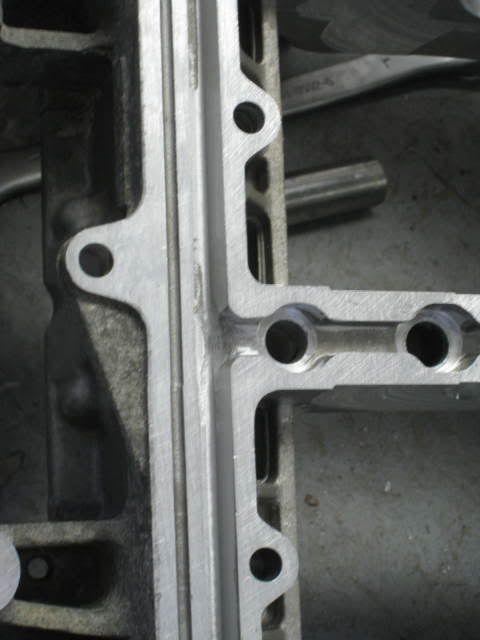

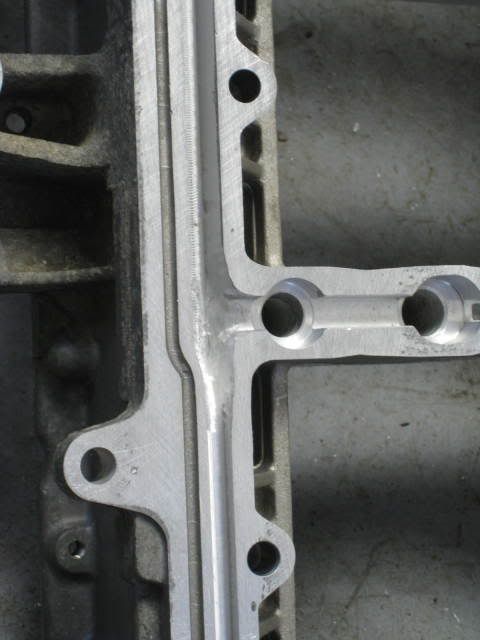

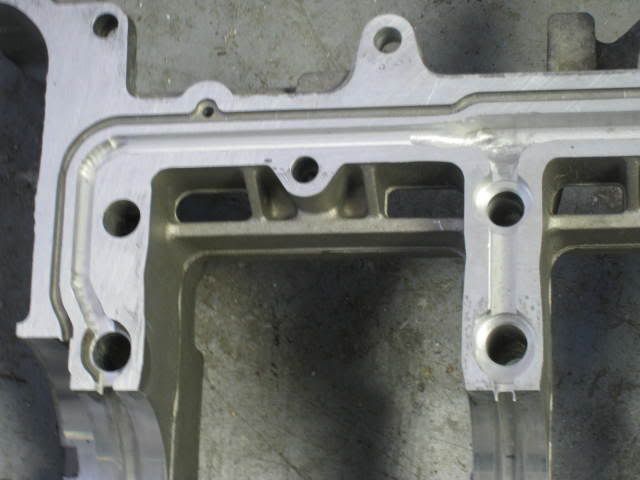

Now I did take some pictures to show the mods I made compaired to stock. Dont mind the girdle pictured as it has been taken from a broken block and modified for welding the pan which I made for my drysump system.

Note the massive step/restrictor to the second main.

As you can see compairing stock to the modifications performed, there is no steps to cause flow disruptions anymore.

I hadnt really considered running a thinner weight to reduce the pressure. Though I suppose it could work, as it is simply a thinner oil which is getting out of the areas faster. Though I doubt that I could get down to be able to keep it at 75-80 PSI just from a lighter weight. However this idea I do not like for a car without drysump, as it means more of the oil will be in the air at any given time.

Does anyone know off hand what the length, diameter, and spring force is for the factory oil pressure spring? As well, exactly what the maximum pressure is when at full tempature with a new spring?

Alex,

Thanks for the info. Though I doubt I will be able to tell if the oiling upgrades made any difference (cant hurt) unless I throw a bearing. Except I will be running drysump from the get go so I will not be able to really tell any difference because of that.

Now I did take some pictures to show the mods I made compaired to stock. Dont mind the girdle pictured as it has been taken from a broken block and modified for welding the pan which I made for my drysump system.

Note the massive step/restrictor to the second main.

As you can see compairing stock to the modifications performed, there is no steps to cause flow disruptions anymore.

#64

I've built motors for quite a few years, and have been surprised from time to time at the migration of the metal flakes. Just my .02 again but I've seen filters for the 928 depending on if you buy crap or not that range from about 4" tall to probably near 10". The larger ones are obviously going to be less likely to open. Also, in several of the turbo motors I have built (not 928's lol) I have had some pretty solid back to back results with prolong believe it or not. Must of the oil additives are junk that are based on teflon, which basicly turns into this plasticy crap when it gets hot enough. Prolong, from what I understand, is technology developed by German engineers in WWII for their airplanes and was later marked as a product called Bitron. It's simply polarized oil that is supposed to decrease bearing wear. I can vouch that I've seen turbo's and engine bearings last a little bit longer with it. I had this confirmed by a presenter from an oil research facility at a technical training seminar I had to attend for a job. He also said Amsoil was the best oil they tested.

#65

Colin,

Didn't mean to come off prickly, I've run those numbers. Part of it is to look at the angle of repose of the oil in the sump and pan. Mark gave a peak acceleration of 0.49g. At that point in time, the oil is angle 30 degress from horizontal. The pan slope is like 5 degrees.

Entropy,

I thought I recalled that the filter ws spring-loaded internally. Just wasn't sure.

Mark,

What I mant to say is that your engines last beacuse you run on short, slow tracks that are easy to drive.

(How do I make that popcorn guy? )

)

Didn't mean to come off prickly, I've run those numbers. Part of it is to look at the angle of repose of the oil in the sump and pan. Mark gave a peak acceleration of 0.49g. At that point in time, the oil is angle 30 degress from horizontal. The pan slope is like 5 degrees.

Entropy,

I thought I recalled that the filter ws spring-loaded internally. Just wasn't sure.

Mark,

What I mant to say is that your engines last beacuse you run on short, slow tracks that are easy to drive.

(How do I make that popcorn guy?

)

)

#67

so...perhaps there is a way to allow the oil pump pickup to move side to side depending on loading..if the oil sloshes to one side....so will the oil pickup?... Possible? impossible?..am I out to lunch not possible??? I haven't looked closely at the oil pump pickup yet?..

#68

Tom,

to make a swivelling oil pickup is a bugger. It has been done in other engines, and has been successful.

However that said you would need to cut out the 4 vertical cast baffles in the pan, which would NOT be an easy task. You would then lower the pickup tube and have a tube which can spin in a circle around the pan. Still not optimum, but would definetly be better.

I do have a few other ideas which I am working on to correct this problem in the engine. But like most things it is not on the front burner.

to make a swivelling oil pickup is a bugger. It has been done in other engines, and has been successful.

However that said you would need to cut out the 4 vertical cast baffles in the pan, which would NOT be an easy task. You would then lower the pickup tube and have a tube which can spin in a circle around the pan. Still not optimum, but would definetly be better.

I do have a few other ideas which I am working on to correct this problem in the engine. But like most things it is not on the front burner.

#69

Joe fan doesnt run a dry sumped engine and has not lost a 2-6 bearing and is pulling a heck of a lot more Gs than you could run in your car. If i see 2.5 bar,its due to bad oil, or i imagine you have other issues.

the "ring" still has accel and decel with turns . Just more of them and some higher speeds!

the "ring" still has accel and decel with turns . Just more of them and some higher speeds!

Z

This is not entirely correct - the reason I went ahead and dry-sumped my car was that I was getting pressure drops of 2.5bar magnitude in BOTH right handers and left handers at the Nurburgring.

Now the car is dry-sumped, the oil pressure stays firmly pegged at the max all the time.

Colin,

The guys in Germany did not find a working solution for their racer - I nearly bought the car in 2007, but was put off by the fact that it had a S2 engine on a GT Cup chasis. Yep, the original Cup engine had thrown a 2/6. I hope your idea works, as I think you are the first one to try it properly.

Alex

This is not entirely correct - the reason I went ahead and dry-sumped my car was that I was getting pressure drops of 2.5bar magnitude in BOTH right handers and left handers at the Nurburgring.

Now the car is dry-sumped, the oil pressure stays firmly pegged at the max all the time.

Colin,

The guys in Germany did not find a working solution for their racer - I nearly bought the car in 2007, but was put off by the fact that it had a S2 engine on a GT Cup chasis. Yep, the original Cup engine had thrown a 2/6. I hope your idea works, as I think you are the first one to try it properly.

Alex

#70

cool!!

I have the same print out from kent Jordan in his 440rwhp Evo running 1:57 vs my 2.01s. Very interesting, especially when you start combining different lap bests and see the differences.

mk

I have the same print out from kent Jordan in his 440rwhp Evo running 1:57 vs my 2.01s. Very interesting, especially when you start combining different lap bests and see the differences.

mk

Here's a better datalog of the lateral accelerations at a place like Thunderhill. Turn 2 gives you sustained >1g lat. acc. for 10 seconds while turning left.

Red line = Pirelli P-Zero Corsa (R-compound tire) 2:07 lap

Black line = Michelin Pilot Sport (street tire) 2:10 lap

Red line = Pirelli P-Zero Corsa (R-compound tire) 2:07 lap

Black line = Michelin Pilot Sport (street tire) 2:10 lap

#71

Really? laguna and sears are easy? Are there any hard turns at RA? the only turn challenging there was the kink. Try coming out to sears and see how you do there, especially around THE entire track!

When Anderson ran WC GT at Sears, his best time was 1:51.3. Scot has run this time with his old junker. Its the only track I know of where Mark took some time to get good at it. Ive run 1:47.9. Anderson came back and ran 1:43-4s and then finally 1:39.9 ( smokin fast, top Speed GT time but on slicks) in the car's current form.

Point is, folks can loose motors here if g forces and high rpm are the cause.

check out this video if you think Sears is easy . one of my favorite videos. Mark racing with the RSR from Kelly Moss.

http://www.youtube.com/watch?v=2BrZZ...eature=related

But, as I know you are just pulling my leg, the G's loading accel and decel of .46g is only in the lower gears, as you get in the 100mph range, the g's are much more mild, less than half than it would be at 50mph for example.

mk

When Anderson ran WC GT at Sears, his best time was 1:51.3. Scot has run this time with his old junker. Its the only track I know of where Mark took some time to get good at it. Ive run 1:47.9. Anderson came back and ran 1:43-4s and then finally 1:39.9 ( smokin fast, top Speed GT time but on slicks) in the car's current form.

Point is, folks can loose motors here if g forces and high rpm are the cause.

check out this video if you think Sears is easy . one of my favorite videos. Mark racing with the RSR from Kelly Moss.

http://www.youtube.com/watch?v=2BrZZ...eature=related

But, as I know you are just pulling my leg, the G's loading accel and decel of .46g is only in the lower gears, as you get in the 100mph range, the g's are much more mild, less than half than it would be at 50mph for example.

mk

Colin,

Didn't mean to come off prickly, I've run those numbers. Part of it is to look at the angle of repose of the oil in the sump and pan. Mark gave a peak acceleration of 0.49g. At that point in time, the oil is angle 30 degress from horizontal. The pan slope is like 5 degrees.

Entropy,

I thought I recalled that the filter ws spring-loaded internally. Just wasn't sure.

Mark,

What I mant to say is that your engines last beacuse you run on short, slow tracks that are easy to drive.

(How do I make that popcorn guy? )

)

Didn't mean to come off prickly, I've run those numbers. Part of it is to look at the angle of repose of the oil in the sump and pan. Mark gave a peak acceleration of 0.49g. At that point in time, the oil is angle 30 degress from horizontal. The pan slope is like 5 degrees.

Entropy,

I thought I recalled that the filter ws spring-loaded internally. Just wasn't sure.

Mark,

What I mant to say is that your engines last beacuse you run on short, slow tracks that are easy to drive.

(How do I make that popcorn guy?

)

)Last edited by mark kibort; 04-17-2009 at 01:47 AM.

#72

Colin, I like your work and may end up copying it, the one thing about this issue I would have thought is that if you have fixed the oiling restriction in the distribution system, you should get even oil pressure at each of the bearings, as pressure should equalize itself. If someone has already written this I apologize.

Greg

Greg

#73

BTW, I like your oil galley mods. We did some of that, particularly opening up the restriction at the entrance to the main galley that eventually feeds 2/6 and eliminating the step there when rebuilding Dennis's motor.

#74

Z

This is not entirely correct - the reason I went ahead and dry-sumped my car was that I was getting pressure drops of 2.5bar magnitude in BOTH right handers and left handers at the Nurburgring.

Now the car is dry-sumped, the oil pressure stays firmly pegged at the max all the time.

This is not entirely correct - the reason I went ahead and dry-sumped my car was that I was getting pressure drops of 2.5bar magnitude in BOTH right handers and left handers at the Nurburgring.

Now the car is dry-sumped, the oil pressure stays firmly pegged at the max all the time.

I know of an engine in a track car that has had the oil passages modified like Colin has done with his. I have no idea if it really helped or not though. The engine hasn't had a rod bearing failure, but then it's also got an Accusump and sufficient oil cooling to keep the oil temperature stable and where it should be.

Maybe something to think about is that the Accusumps on a couple of track cars that were checked were hot when the cars came off the track at the end of a session. That would indicate that oil had been flowing in and out of them during the track session, and that they'd been doing their intended job. If there's no oil pressure drop problem in the engine, the same oil will just stay in the Accusump, and really won't be hot since it would have just been sitting in there the whole time.

I remember model R\C airplanes having a length of flexible tubing with a weight on the end of it as the pickup in their fuel tanks. The weight would just kind of flop around in there, the same way that the fuel did as a result of the G forces that the planes were under as they flew and did various tricks. The engine would get a steady flow of fuel as a result, and there wouldn't be a problem with having the engine die when flying upside down or doing different maneuvers. I wonder how full size acrobatic planes have their fuel and oil pickups setup.

#75

Hello guys, as always I really enjoy reading all your tech posts to do with our great cars. This one especially.

Having not known of, or having never seen a ROD bearing failure (in a 928) I could'nt place a poll. But have been in touch with this oil/bearing discussion for some time.

I really liked the fact that Mark and co. are racing both the 16V and 32V with no problems with the rod bearings. Do they have what I call 'driving with mechanical sympathy', so in touch with there cars that the problem never rears up, but hand the car to another driver and blow the big ends!

Another thing I remember is that I thought that the Porsche 928 cranshaft had it's oil routing in the wrong direction. In other words ported through the crank against centrifigul force?

Although my experience with oil starvation is not with a Porsche 928, it is somewhat similar to the inherit problems of an AMC V8. We setup a video camera in the boot of an AMX, watching an engine oil pressure gauge, and raced around a local flat track to see if the pressure dropped. With an already modified system (wet sump) copied from a Trans Am racer the pressure dropped to zero quite a few times. Rod bearing replacement was a common thing after an event. It was interesting to know that with another driver (slower) the problem just wasnt there.

If anyone is interested, the book 'The Unfair Advantage' has a great read about how they cured the Javelins oil starvation problem with driver Mark Donahue at the wheel. Good stuff even if you are not into AMC's.

Back onto 928's... A quick look at the sump shape and straight away it seems to me that it should be great for deceleration and braking, but terrible if you were accelerating where all the oil runs rearward away from the pickup. You wouldnt go drag racing with a 928 engine in a 928, the oil is at the wrong end.

So to end my burst on the subject I'm kinda thinking that it may be how the engine is used that detirmines it's premature failure. In other words 'trashed the right way'

It's an interesting topic and I'll be watching intently

Cheers,

Glenn

'81 928

'69 AMC Jav

Melbourne Australia

Having not known of, or having never seen a ROD bearing failure (in a 928) I could'nt place a poll. But have been in touch with this oil/bearing discussion for some time.

I really liked the fact that Mark and co. are racing both the 16V and 32V with no problems with the rod bearings. Do they have what I call 'driving with mechanical sympathy', so in touch with there cars that the problem never rears up, but hand the car to another driver and blow the big ends!

Another thing I remember is that I thought that the Porsche 928 cranshaft had it's oil routing in the wrong direction. In other words ported through the crank against centrifigul force?

Although my experience with oil starvation is not with a Porsche 928, it is somewhat similar to the inherit problems of an AMC V8. We setup a video camera in the boot of an AMX, watching an engine oil pressure gauge, and raced around a local flat track to see if the pressure dropped. With an already modified system (wet sump) copied from a Trans Am racer the pressure dropped to zero quite a few times. Rod bearing replacement was a common thing after an event. It was interesting to know that with another driver (slower) the problem just wasnt there.

If anyone is interested, the book 'The Unfair Advantage' has a great read about how they cured the Javelins oil starvation problem with driver Mark Donahue at the wheel. Good stuff even if you are not into AMC's.

Back onto 928's... A quick look at the sump shape and straight away it seems to me that it should be great for deceleration and braking, but terrible if you were accelerating where all the oil runs rearward away from the pickup. You wouldnt go drag racing with a 928 engine in a 928, the oil is at the wrong end.

So to end my burst on the subject I'm kinda thinking that it may be how the engine is used that detirmines it's premature failure. In other words 'trashed the right way'

It's an interesting topic and I'll be watching intently

Cheers,

Glenn

'81 928

'69 AMC Jav

Melbourne Australia