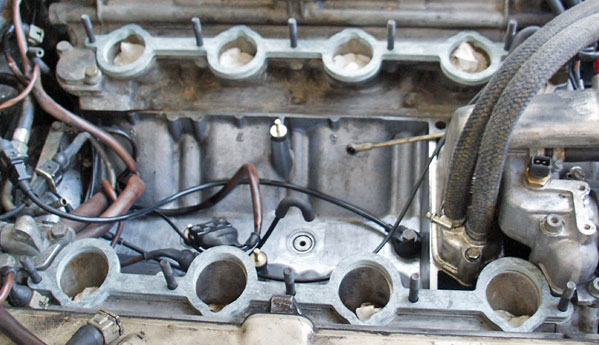

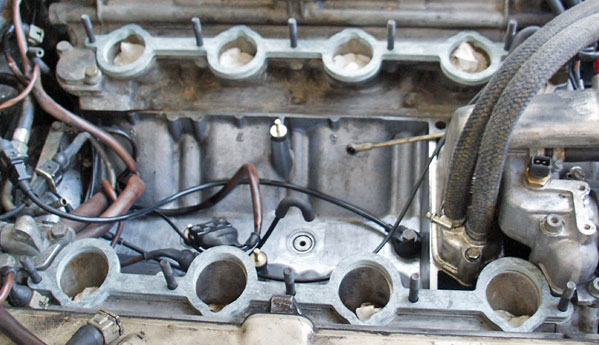

Stock intake - why Todd is only using one spacer

#31

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Thread Starter

Very interesting. Could it be that 2 & 6 are running leaner even in an engine making stock power contributing to the demise of those rod bearings? Sure, there are knock sensors to stop the knock, but repeatedly hitting that limit on the same cylinders over and over again... Maybe one of the reasons Kibort's cars lasted so long is because they ran richer than other racers?

Iíve mentioned this in other threads, might as well add it here. Toddís blow off hose is always bone dry. Even after hours on the dyno under full load (a condition a street car would never see) or repeated runs on the street - no blow by.

Why? No detonation.

Coincidence the GTS motor is ďknownĒ for oil consumption and we also see quite a few posts / threads about GTS motors knocking? Iím not sure, just thinking out loud.

Here we have a factory stroker motor using the same, mis-matched intake as the S4/GT.

Itís very exciting to hear Greg is working on an intake, Brendon has one in the works and Todd has his own design that might progress this winter.

2009 is going to be a very exciting year for the 928 world!!

#32

I need to call him. We were talking about the fact that maybe my design uses too large of a runner. I was using Ross Machine Racing's 2" ID runner and have had help getting the CNC design to merge into the true shape of the port in the space of the wedge shaped design. Smaller, longer runners will help from 1500 to 3500, but above that there is an increasing chance that they will stiffle the volume of air coming in from the SC. I wish I could believe the dyno program - it says shorter - better, up to a certain point, and off boost power is not hurt very much.

#33

The length of the runner swivels on the axis point created by how large the runner is in diameter. I don't think this changes with boost - its simply magnified. I could be wrong.

#34

#35

Race Car

I need to call him. We were talking about the fact that maybe my design uses too large of a runner. I was using Ross Machine Racing's 2" ID runner and have had help getting the CNC design to merge into the true shape of the port in the space of the wedge shaped design. Smaller, longer runners will help from 1500 to 3500, but above that there is an increasing chance that they will stiffle the volume of air coming in from the SC. I wish I could believe the dyno program - it says shorter - better, up to a certain point, and off boost power is not hurt very much.

But seriously, there are three main things you have to think about:

But seriously, there are three main things you have to think about:1) Bends. You want the straightest runners possible. The more bends you have, the more power you lose. If you must have bends, make them as smooth and gradual as possible.

2) Length. You want as equal lengths as is possible, and also as short as possible - the source of sometimes heated debate.

3) Packaging. It has to fit into the space alotted.

All three of these things will be fighting each other. If you have a choice between 1) and 2), 1) wins unless it is trumped by 3). Even though having super short runners is desirable, sometimes it just is not practically possible.

Dan

'91 928GT S/C

475hp/460lb.ft

475hp/460lb.ft

#36

Race Car

Dan

'91 928GT S/C

475hp/460lb.ft

475hp/460lb.ft

#37

The dyno program agrees with me  But seriously, there are three main things you have to think about:

But seriously, there are three main things you have to think about:

1) Bends. You want the straightest runners possible. The more bends you have, the more power you lose. If you must have bends, make them as smooth and gradual as possible.

2) Length. You want as equal lengths as is possible, and also as short as possible - the source of sometimes heated debate.

3) Packaging. It has to fit into the space alotted.

All three of these things will be fighting each other. If you have a choice between 1) and 2), 1) wins unless it is trumped by 3). Even though having super short runners is desirable, sometimes it just is not practically possible.

Dan

'91 928GT S/C 475hp/460lb.ft

475hp/460lb.ft

But seriously, there are three main things you have to think about:

But seriously, there are three main things you have to think about:1) Bends. You want the straightest runners possible. The more bends you have, the more power you lose. If you must have bends, make them as smooth and gradual as possible.

2) Length. You want as equal lengths as is possible, and also as short as possible - the source of sometimes heated debate.

3) Packaging. It has to fit into the space alotted.

All three of these things will be fighting each other. If you have a choice between 1) and 2), 1) wins unless it is trumped by 3). Even though having super short runners is desirable, sometimes it just is not practically possible.

Dan

'91 928GT S/C

475hp/460lb.ft

475hp/460lb.ft

#38

Race Car

I will be putting a raised portion in the hood. Not a scoop - just a bubble like what the new M3 had to do to fit the intake under the hood line. I think that its important that we look at those dyno programs as a guide and not fact. Short runners WILL gain power. I guess alot in our case. But the car still has to make good power at 2k rpm, and 3k rpm.

I'm really excited to see what you come up with. With a well-designed hood bulge, this 928 could look really bad ***

Dan

'91 928GT S/C

475hp/460lb.ft

475hp/460lb.ft

#39

Rennlist Member

Wow, all over the board. I'm surprised that Porsche could discount a 13mm spread between the longest and shortest intake track. If you are really short of things to do Rob, any chance of getting the long side measurements as well?

#40

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Perhaps some one could make a bellmouth extention that slip fits into the current opening...a kit that would bring all runners to the same length..looks like it would be 32cm in the numbers above .....then have the side spacer installed.

#41

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Thread Starter

IMO this intake is a prime example that even Porsche cuts corners. Or simply stops development once it's "good enough".

#42

Burning Brakes

Join Date: Sep 2006

Location: Myrtle Beach, South Carolina

Posts: 1,203

Likes: 0

Received 0 Likes

on

0 Posts

Another "issue" with the stock intake is the sharp 90 degree bend intake #5 makes right after the opening. Were as most of the others have a nice, gradual bend sweeping down to the head.

IMO this intake is a prime example that even Porsche cuts corners. Or simply stops development once it's "good enough".

IMO this intake is a prime example that even Porsche cuts corners. Or simply stops development once it's "good enough".

Just asking, my knowledge is limited to the mechanics of air flow in air conditioning system duct work so I may be making a dumb assumption regarding length:bend dynamics in engine intakes....

#43

Inventor

Rennlist Member

Rennlist Member

By way of comparison, S3 intake gasket ports are a 52 x 46 oval (S4 ports are more squarish). The fuel injector hole is 12mm centered on the edge of the oval.

The runners are all 45mm ID (trumpet unknown), and the approximate length is 40cm from head to trumpet for each.

On both S3 and S4, the legs don't line up perfectly with the head; most have 1-2mm of overlap!

thread

The runners are all 45mm ID (trumpet unknown), and the approximate length is 40cm from head to trumpet for each.

On both S3 and S4, the legs don't line up perfectly with the head; most have 1-2mm of overlap!

thread

#44

In case anyone missed those test results, here's where they're discussed:

#45

Advanced

Join Date: Nov 2008

Location: Staffordshire, UK

Posts: 57

Likes: 0

Received 0 Likes

on

0 Posts

That is exactly what Todd is thinking, might not be the only factor but it sure isnít helping.

Iíve mentioned this in other threads, might as well add it here. Toddís blow off hose is always bone dry. Even after hours on the dyno under full load (a condition a street car would never see) or repeated runs on the street - no blow by.

Why? No detonation.

Coincidence the GTS motor is ďknownĒ for oil consumption and we also see quite a few posts / threads about GTS motors knocking? Iím not sure, just thinking out loud.

Here we have a factory stroker motor using the same, mis-matched intake as the S4/GT.

Itís very exciting to hear Greg is working on an intake, Brendon has one in the works and Todd has his own design that might progress this winter.

2009 is going to be a very exciting year for the 928 world!!

Iíve mentioned this in other threads, might as well add it here. Toddís blow off hose is always bone dry. Even after hours on the dyno under full load (a condition a street car would never see) or repeated runs on the street - no blow by.

Why? No detonation.

Coincidence the GTS motor is ďknownĒ for oil consumption and we also see quite a few posts / threads about GTS motors knocking? Iím not sure, just thinking out loud.

Here we have a factory stroker motor using the same, mis-matched intake as the S4/GT.

Itís very exciting to hear Greg is working on an intake, Brendon has one in the works and Todd has his own design that might progress this winter.

2009 is going to be a very exciting year for the 928 world!!

When i first got involved in those cars 300BHP was considered as an unrealistic aim for a road based 2.0 none STi engines, 330BHP on the STi's was doing some serious numbers, they were regularly knocking out #3 big end bearing, the general consensus from the other performance car groups was the alloy flat four was made of chocolate. We went through hundreds of debates about oiling to try and understand why the big ends were dying.

After 10 years of serious tuning advances by the enthusiasts and mappers of these cars, it's now relatively easy to keep a 2.5 litre 550BHP road spec based engine in one piece for large mileage numbers, some of the circuit competition 2.5litre engines are pushing 900BHP. My daily driver 2.0 litre ran 350lbft/bhp in a mild state of tune, the new spec STi's even on stock internals, inlets and turbo's can produce 400BHP all day.

Lots of lessons were learned about why they were killing big ends, some of the main ones were

MAF sensors aging, especially when using oiled Air filters. They don't give up, they slowly deteriorate and over time give the ECU a lower airflow reading than reality, so the engine starts running lean, when you have an already imbalanced engine due to basic design this is enough to make it det on the lean cylinder to the point of failure inducing. It's now normal practice to throw the MAF's away at 65K miles, if you run an oiled filter they can die in a few thousand miles on the MY99/00 version. Some are more robust than others depending on design, the MY99/00 were the worst (a Bosch item shared by the VW group), the earlier ones similar in design to the 928 hot wire MAF item were the safest as they burned the oil off on shutdown, but they still age.

Crankcase emissions into the inlet. When you have an engine that is throwing oil vapour into the inlet, which you will get with forced induction or an engine that breaths a lot into the OEM emissions systems, the effect of that on the combustion process is to increase det because oil vapour in the charge air reduces the effective octane rating of the fuel. It's normal practice to now vent these to external oil catch cans and not feed it into the inlet because of this. If you have an oil burner, run higher octane fuel and look into venting to atmosphere the oil breather system, it helps prevent det.

Tuning for richer average AFR, if you cant individual map the cylinders, always map for the worst case scenario of the leanest cylinder. This means you end up running richer, gaining less fuel economy and potential lower peak power figures, but the engine will not det as much and is therefor less likely to knock the big end out.

The biggest single jump in performance on the stock based cars came when a chap called Steven Done invented an ECU remapping tool called EcuTek, this allowed a reflash of the factory ECU maps. Overnight we went from having to bodge piggyback chips and boost clamps to a properly mappable ECU, without the cost or aggravation of a Motec or other aftermarket ECU. Back then even Prodrive were using piggyback chips to produce their road car upgrades and they were all stuck around the 300BHP mark. Now when you buy a Prodrive tuned Subaru, you are buying an engine that uses EcuTek to remap the OEM ECU. The most we are seeing on a 2.5 litre running on high octane pump fuel (94PON) you can buy on the street with a factory ECU running it all is just under 600BHP.

What you guys now have with the sharktuner is going to help you in a similar way, it's a tool that will help you get the engines better sorted without needing to go to the expense of an aftermarket ECU. If you manage to log each cylinder you should be able to work out what the average AFR will be to make the worst pot safe, then you can start to go forward on chasing higher safe power with the stock ECU. A fully mapable ECU is of course best, but i can see big gains coming even with the stock ECU on a supercharged car in particular.

Turbocharger advances. The turbo's we can now use, even in standard bolt on position are hugely better than what was available a few years ago, we are now seeing figures you wouldn't have dreamt of with bespoke hybrids a few years ago, the hybrids are producing serious BHP/Litre, having larger compressor housings is allowing much higher flows without the heating problems of smaller compressors.

Chargecooling has come on in a big way too, if you don't have good chargecooling you can get a lot of det, once you start to see 40 degrees C charge temps det becomes far more prone. We played about a lot with Water injection for a while, but it worked out better to just get better chargecooling sorted. WI actually loses you power below 42 degrees C charge temp anyway, which is why WRC cars ran with a 38 degrees C switch off and 42 degrees switch on hysterises.

Fuel mixes, you can make big jumps in safety and power making your own fuel brews, mixing in some methanol helps with det but the AFR requirements change. Bio-Ethanol is starting to be played with a bit more now too, the downside is you need twice the fuel flow for the same power, but it's great for det and cylinder cooling plus you can run smaller chargecoolers.

Part of the safe mapping is to drop the ignition advance based on inlet air temperature, the Prodrive road car upgrade maps have a very aggressive strategy in them for this, which is why when they are dynoed they rarely make the official power figures. Thats not a dodgy power plot, thats the mapping doing it's job because chargecooling isnt working on the dyno.

One Achilles heal of the stock Subaru oiling system was the oil pressure relief valve design, it is subjected to unfiltered oil and used a steel plunger in an alloy casing, they had a tendency to stick open occasionally, lowing oil pressure whilst they did that, so the oil pressure relief valve plunger gets swapped out to a better item usually.

Fuel flow and injector feed paths. Depending on model year you can reverse the fuel injector feed path to improve the fuel flow to the leanest cylinder, the latest cars have this issue fixed and flow better out the factory, but that was an area worth working on which was discovered properly by running the AFR gauges on each bank.

If you take a look at the stock Subaru crank you will be gobsmacked how small the big ends are, but oiling for the most part wasn't the problem, it was det hammering the big ends to death. We ran the 2007 Time Attack championship winning 2.3 litre car at about 700BHP on a stock factory crank, that only suffered when it saw some oil surge.

The big ends on the 928 engine are massive compared to a Subaru so as long as you aren't suffering from starvation and arnt hammering the film strength with det they should stand a hell of a lot more, i dont know how stable the main caps are or how strong the crank is so they have to be playing ball too of course.

Oil temperature, everything seems to hold together nicely upto about 125 degrees C, once above that it's far more likely you will have lubrication issues.

Hopefully that gives a bit of input to the debate and you aren't too bored reading it as it's not strickly 928 related.